Master the Market: Ice Vending Machines for Sale That Boost

Guide to Ice Vending Machines For Sale

- Introduction: Navigating the Global Market for ice vending machines for sale

- Understanding ice vending machines for sale Types and Variations

- Key Industrial Applications of ice vending machines for sale

- Strategic Material Selection Guide for ice vending machines for sale

- In-depth Look: Manufacturing Processes and Quality Assurance for ice vending machines for sale

- Comprehensive Cost and Pricing Analysis for ice vending machines for sale Sourcing

- Spotlight on Potential ice vending machines for sale Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for ice vending machines for sale

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the ice vending machines for sale Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of ice vending machines for sale

- Strategic Sourcing Conclusion and Outlook for ice vending machines for sale

Introduction: Navigating the Global Market for ice vending machines for sale

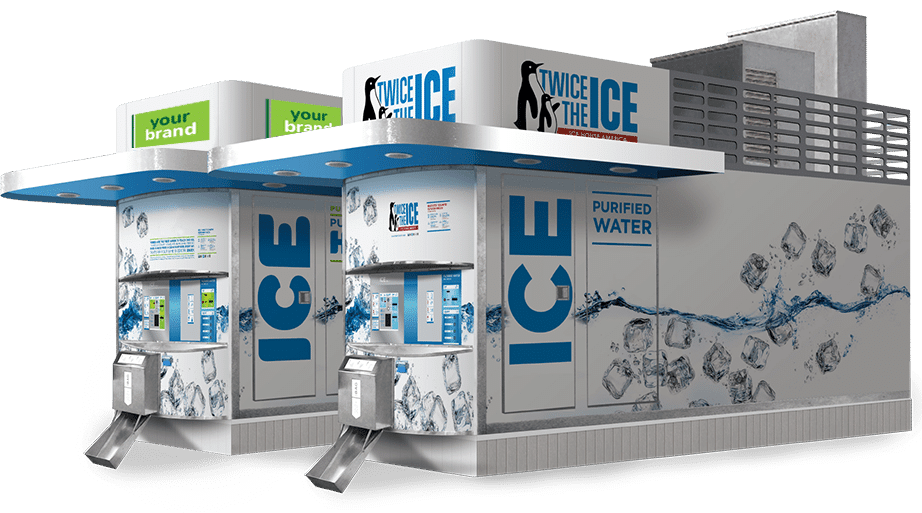

In today’s competitive landscape, ice vending machines are rapidly becoming essential assets for businesses across various sectors, including hospitality, retail, and event management. These machines not only provide convenience and efficiency but also meet the growing demand for quick and accessible ice solutions in regions where traditional ice supply methods may fall short. For international B2B buyers from Africa, South America, the Middle East, and Europe, understanding the nuances of the ice vending machine market can unlock significant opportunities for growth and profitability.

This comprehensive guide delves into the diverse types of ice vending machines available, evaluating their materials, manufacturing processes, and quality control measures. It also highlights key suppliers and market dynamics, providing insights into pricing structures and cost considerations that are critical for budget-conscious procurement decisions.

By equipping buyers with detailed knowledge on market trends, features, and operational efficiencies, this guide empowers informed sourcing decisions. It addresses frequently asked questions to demystify the purchasing process, enabling businesses to identify the best machines that align with their operational needs and regional demands.

Navigating the global market for ice vending machines can be complex, but with the right information at hand, B2B buyers can strategically position themselves to capitalize on this growing trend, ensuring they remain competitive in their respective markets.

Understanding ice vending machines for sale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standalone Ice Vending | Fully automated, self-contained units | Convenience stores, gas stations | Pros: Easy to install; Cons: Limited ice production capacity. |

| Bulk Ice Vending | High-capacity machines for large quantities of ice | Events, large venues, festivals | Pros: Cost-effective for bulk purchases; Cons: Requires more space. |

| Mobile Ice Vending | Portable units for on-the-go sales | Food trucks, outdoor events | Pros: Flexible location; Cons: Limited storage capacity. |

| Solar-Powered Ice Vending | Eco-friendly machines utilizing solar energy | Remote areas, eco-conscious businesses | Pros: Reduces energy costs; Cons: Higher initial investment. |

| Ice and Beverage Combo | Machines that dispense both ice and drinks | Restaurants, catering services | Pros: Versatile; Cons: More complex maintenance needs. |

Standalone Ice Vending

Standalone ice vending machines are fully automated and designed to operate independently. They are ideal for locations such as convenience stores and gas stations, where customers can purchase ice directly without staff assistance. When considering these machines, buyers should evaluate their ease of installation and the potential for generating passive income. However, the production capacity may be limited, which could affect sales during peak demand periods.

Bulk Ice Vending

Bulk ice vending machines are designed for high-capacity ice production, making them suitable for events, large venues, and festivals. These machines can dispense large quantities of ice quickly, catering to the needs of businesses that require bulk purchases. Buyers should consider the cost-effectiveness of these machines, especially for high-volume sales. However, they do require more space and a higher upfront investment, which could be a barrier for smaller operations.

Mobile Ice Vending

Mobile ice vending machines offer flexibility and portability, allowing businesses to sell ice at various locations, such as food truck events or outdoor festivals. These machines are designed to be easily transportable, making them a great option for entrepreneurs looking to capitalize on transient markets. While they provide the advantage of location versatility, buyers must be aware of the limited storage capacity, which may necessitate frequent refills.

Solar-Powered Ice Vending

Solar-powered ice vending machines are an eco-friendly option that utilizes renewable energy, making them suitable for remote areas or businesses focused on sustainability. These machines can significantly reduce energy costs over time, appealing to environmentally conscious buyers. However, the initial investment is typically higher than traditional models, which may deter some businesses from making the switch.

Ice and Beverage Combo

Ice and beverage combo machines provide a dual function by dispensing both ice and drinks, making them particularly beneficial for restaurants and catering services. This versatility can attract a wider customer base and increase sales opportunities. However, the complexity of maintenance and potential for higher operational costs should be carefully considered by buyers before making a purchase decision.

Related Video: Kooler Ice Vending Machines – IM600XL vs. IM1000

Key Industrial Applications of ice vending machines for sale

| Industry/Sector | Specific Application of ice vending machines for sale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Retail and Convenience Stores | Increased sales through on-demand ice availability | Energy efficiency, machine capacity, and maintenance support |

| Hospitality | Hotels and Resorts | Enhanced guest experience with easy access to ice | Customization options, service agreements, and reliability |

| Construction | Job Sites and Temporary Camps | Quick and easy ice supply for hydration and safety | Portability, durability, and ease of operation |

| Events and Catering | Festivals and Outdoor Events | Immediate ice supply to meet fluctuating demand | Scalability, ease of transport, and service support |

| Medical and Health | Hospitals and Clinics | Essential for patient care and medical procedures | Compliance with health regulations, safety features, and reliability |

Food and Beverage

In the food and beverage sector, ice vending machines are increasingly utilized in retail and convenience stores to provide quick, on-demand ice for customers. This application addresses the problem of limited ice availability, especially during peak seasons. For international buyers, particularly in regions with warm climates like Africa and South America, sourcing machines that are energy-efficient and have a high capacity is essential. Additionally, maintenance support is crucial to ensure uninterrupted service, maximizing sales opportunities.

Hospitality

Within the hospitality industry, hotels and resorts leverage ice vending machines to enhance guest experiences by offering convenient access to ice. This application solves the challenge of providing guests with easy access to ice without burdening staff with additional tasks. Buyers in Europe and the Middle East should consider customization options that align with their brand image, as well as service agreements that ensure reliability and quick response times for maintenance issues.

Construction

Ice vending machines find practical applications on construction job sites and temporary camps, where they provide a necessary supply of ice for hydration and safety. These machines help mitigate the risks associated with heat exposure for workers. For buyers in regions like Africa and South America, the key considerations include portability and durability, ensuring that the machines can withstand harsh conditions and are easy to transport between sites.

Events and Catering

In the events and catering sector, ice vending machines are crucial for providing immediate ice supply during festivals and outdoor events. This application addresses the fluctuating demand for ice, especially during large gatherings. Buyers need to focus on scalability and ease of transport when selecting machines, as events often require quick setup and breakdown. Additionally, having robust service support is essential to handle any unexpected issues that may arise during high-demand periods.

Medical and Health

In medical and health settings, ice vending machines serve a critical role in hospitals and clinics by supplying ice for patient care and various medical procedures. This application is vital for maintaining patient comfort and for specific treatments that require ice. International buyers must ensure that the machines comply with health regulations and possess safety features to protect patients and staff. Reliability is another key consideration, as any downtime can directly impact patient care.

Strategic Material Selection Guide for ice vending machines for sale

When selecting materials for ice vending machines, international B2B buyers must consider various factors that impact performance, durability, and compliance with regional standards. Below is an analysis of common materials used in the construction of ice vending machines, focusing on their properties, advantages, disadvantages, and specific considerations for buyers in Africa, South America, the Middle East, and Europe.

Stainless Steel

Key Properties: Stainless steel is known for its excellent corrosion resistance and high strength-to-weight ratio. It can withstand extreme temperatures and pressures, making it ideal for environments where ice is produced and stored.

Pros & Cons: The primary advantage of stainless steel is its durability and resistance to rust, which is crucial in humid climates. However, it is generally more expensive than other materials, which can impact the overall cost of the vending machine. Manufacturing complexity is moderate, as stainless steel requires specialized equipment for cutting and welding.

Impact on Application: Stainless steel is compatible with water and ice, ensuring that there is no leaching of harmful substances. Its hygienic properties are also beneficial in food-related applications, which is essential for compliance with health regulations.

Considerations for International Buyers: Buyers should ensure that the stainless steel used meets international standards such as ASTM A240 or DIN 1.4301. In regions like Africa and South America, where corrosion can be a significant issue, selecting high-grade stainless steel can mitigate long-term maintenance costs.

Aluminum

Key Properties: Aluminum is lightweight and has good corrosion resistance, particularly when anodized. It can handle moderate temperatures and pressures, making it suitable for many components of ice vending machines.

Pros & Cons: The main advantage of aluminum is its low weight, which can reduce shipping costs and ease installation. However, it is less durable than stainless steel and can be susceptible to denting and scratching. The manufacturing process is generally simpler, which can lower production costs.

Impact on Application: Aluminum is compatible with ice and water, but its lower strength may limit its use in high-stress areas of the vending machine. It is essential to ensure that any aluminum components are properly treated to prevent corrosion.

Considerations for International Buyers: Buyers should be aware of local standards for aluminum, such as JIS H 4040 in Japan or EN 573 in Europe. In regions with high humidity, like parts of the Middle East, ensuring proper anodization can enhance longevity.

Polycarbonate

Key Properties: Polycarbonate is a high-impact plastic that offers good clarity and thermal resistance. It can withstand low temperatures, making it suitable for ice-related applications.

Pros & Cons: The key advantage of polycarbonate is its lightweight nature and high impact resistance, which can reduce breakage during transport and use. However, it is less durable in terms of long-term exposure to UV light and may yellow over time. Manufacturing complexity is low, allowing for cost-effective production.

Impact on Application: Polycarbonate is suitable for components that require transparency, such as windows or display panels. However, it should not be used in areas exposed to high heat or direct sunlight without UV protection.

Considerations for International Buyers: Buyers should check for compliance with safety standards, particularly in regions like Europe, where strict regulations govern the use of plastics in food-related applications. Understanding local recycling regulations for polycarbonate is also essential.

Galvanized Steel

Key Properties: Galvanized steel is carbon steel that has been coated with zinc to prevent corrosion. It offers moderate strength and can withstand various environmental conditions.

Pros & Cons: The primary advantage of galvanized steel is its cost-effectiveness and good corrosion resistance compared to untreated steel. However, it is not as durable as stainless steel and can suffer from rust over time if the coating is damaged. Manufacturing processes are relatively straightforward.

Impact on Application: Galvanized steel is suitable for structural components but may not be ideal for areas in direct contact with ice or water without additional protection.

Considerations for International Buyers: Buyers should ensure that the galvanizing process meets standards such as ASTM A123. In humid regions, like parts of Africa and South America, additional coatings may be necessary to extend the lifespan of galvanized components.

Summary Table

| Material | Typical Use Case for ice vending machines for sale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural components, ice storage bins | Excellent corrosion resistance | Higher cost compared to alternatives | High |

| Aluminum | Lightweight frames, non-structural parts | Low weight, ease of installation | Less durable, susceptible to dents | Medium |

| Polycarbonate | Windows, display panels | High impact resistance, clarity | UV degradation over time | Medium |

| Galvanized Steel | Structural supports, non-contact components | Cost-effective, moderate corrosion resistance | Not as durable as stainless steel | Low |

This guide provides a comprehensive overview of material options for ice vending machines, ensuring that international B2B buyers can make informed decisions that align with their operational needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for ice vending machines for sale

The manufacturing of ice vending machines involves several crucial stages that ensure the final product meets both functional and quality standards. For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding these processes is essential for making informed purchasing decisions.

Manufacturing Processes

Material Preparation

The first stage in the manufacturing process is material preparation. This involves selecting high-quality materials that can withstand the rigors of outdoor use, such as stainless steel, which is both durable and resistant to corrosion. Other components may include refrigeration units, electrical wiring, and control systems. Suppliers must ensure that all materials meet relevant international and regional standards to guarantee safety and performance.

Forming

Once the materials are prepared, they undergo forming processes. This can include cutting, bending, and welding of metal components to create the machine’s structure. Advanced techniques like laser cutting and CNC machining are often employed to achieve precision and consistency. For B2B buyers, it is beneficial to inquire about the technologies used in forming, as these can significantly impact the durability and efficiency of the vending machines.

Assembly

The assembly phase is where individual components are put together to form the complete machine. This typically involves both manual labor and automated processes to ensure accuracy. Key components such as the ice-making unit, storage bin, dispensing mechanism, and payment systems are integrated during this stage. It is vital for buyers to understand the assembly techniques used, as they can affect both the performance and reliability of the machine.

Finishing

The finishing process includes painting, coating, and other treatments to enhance the machine’s aesthetic appeal and protect it from environmental factors. Powder coating is a common technique used for its durability and resistance to chipping and fading. Buyers should look for suppliers that offer customization options in finishing, allowing them to align the machines with their branding or operational requirements.

Quality Assurance

Ensuring quality is critical in the manufacturing of ice vending machines. Buyers should be aware of the international standards and industry-specific certifications that suppliers must adhere to.

International Standards

A widely recognized standard is ISO 9001, which focuses on quality management systems. This certification indicates that the manufacturer has established processes for continuous improvement and customer satisfaction. Additionally, compliance with safety standards such as CE (Conformité Européenne) for European markets and API (American Petroleum Institute) standards can be critical, particularly for buyers in Europe and the Middle East.

Quality Control Checkpoints

Quality control (QC) is typically divided into several checkpoints:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials and components upon arrival to ensure they meet specifications.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to monitor the production process and identify any defects early.

-

Final Quality Control (FQC): Once the assembly is complete, final inspections are carried out to ensure that the machine operates correctly and meets all quality standards.

B2B buyers should inquire about the specific QC processes employed by suppliers to ensure that they consistently produce high-quality machines.

Common Testing Methods

Various testing methods are used to validate the performance and safety of ice vending machines, including:

-

Functional Testing: Ensuring the machine operates as intended, including ice production and dispensing mechanisms.

-

Safety Testing: Assessing electrical safety, thermal performance, and structural integrity.

-

Durability Testing: Simulating long-term use to evaluate how the machine withstands wear and tear.

Verifying Supplier Quality Control

For B2B buyers, verifying a supplier’s quality control measures is crucial. Here are some actionable steps:

-

Conduct Audits: Request to perform on-site audits of the manufacturing facility. This allows buyers to assess the production environment and quality control processes directly.

-

Review Quality Reports: Ask suppliers for detailed quality reports that outline their QC processes, testing results, and any certifications obtained.

-

Engage Third-Party Inspectors: Consider hiring independent inspectors who specialize in manufacturing quality assurance. They can provide unbiased evaluations of the supplier’s capabilities.

Quality Control and Certification Nuances

International B2B buyers, especially from diverse regions such as Africa, South America, the Middle East, and Europe, must navigate various certification requirements. Understanding these nuances can aid in smoother transactions:

-

Regional Compliance: Different regions may have specific compliance requirements. For instance, CE marking is essential for machines sold in Europe, while UL certification may be necessary for the U.S. market.

-

Documentation: Ensure that suppliers provide all necessary documentation, including certificates of conformity and test reports, to facilitate customs clearance and compliance checks in your region.

-

Cultural Considerations: When dealing with suppliers from different regions, be aware of cultural differences that may influence business practices, including negotiation styles and communication preferences.

Conclusion

Understanding the manufacturing processes and quality assurance measures for ice vending machines is vital for international B2B buyers. By focusing on material preparation, forming, assembly, and finishing, along with rigorous quality control practices, buyers can ensure they select reliable suppliers. Furthermore, navigating international standards and verifying supplier quality through audits and reports will enhance procurement success.

Related Video: Most Satisfying Factory Production Processes And Heavy-Duty Factory Machines!

Comprehensive Cost and Pricing Analysis for ice vending machines for sale Sourcing

The cost structure for ice vending machines is multifaceted, involving various components that contribute to the overall price. Understanding these elements is crucial for B2B buyers aiming to make informed purchasing decisions.

Cost Components

-

Materials: The primary materials used in ice vending machines include stainless steel, refrigeration components, and electronic systems. The choice of materials significantly impacts the durability and efficiency of the machines. High-quality materials may increase upfront costs but can lead to lower maintenance expenses over time.

-

Labor: Labor costs encompass wages for skilled workers involved in the manufacturing process. Regions with higher labor costs may influence the final price. Buyers should consider sourcing from areas with competitive labor rates without compromising quality.

-

Manufacturing Overhead: This includes all indirect costs related to production, such as utilities, rent, and administrative expenses. Efficient manufacturing processes can reduce overhead, enabling suppliers to offer more competitive pricing.

-

Tooling: Tooling costs are associated with the machinery and equipment used in the manufacturing process. Custom designs may require specialized tooling, which can raise costs. Buyers should evaluate whether standard models meet their needs to avoid unnecessary expenses.

-

Quality Control (QC): Quality assurance processes are essential to ensure that machines meet safety and performance standards. While rigorous QC may add to costs, it is a vital investment that can prevent future operational issues.

-

Logistics: Shipping and handling fees can vary significantly based on the destination, transportation method, and the size of the order. Buyers should factor in these logistics costs when calculating the total expenditure.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding industry standards for margins can assist buyers in negotiating fair prices.

Price Influencers

Several factors can influence the pricing of ice vending machines:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often attract discounts due to economies of scale. Buyers should assess their demand to negotiate favorable terms.

-

Specifications/Customization: Custom features or specifications can lead to increased costs. Buyers should determine if standard models suffice or if customization is essential.

-

Materials and Quality Certifications: Machines built with premium materials and certified for safety and performance may command higher prices. Buyers should prioritize quality to minimize long-term operational costs.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may offer warranties and better support, justifying a higher price.

-

Incoterms: The chosen Incoterms (International Commercial Terms) dictate the responsibilities of buyers and sellers regarding shipping and risk. Understanding these terms is crucial for calculating total costs accurately.

Buyer Tips

-

Negotiation: Engaging in negotiations with suppliers can lead to better pricing. Buyers should be prepared to discuss their volume needs and any unique requirements to leverage favorable terms.

-

Cost-Efficiency: Evaluate the total cost of ownership rather than just the initial purchase price. Consider long-term operational costs, including energy consumption and maintenance.

-

Pricing Nuances for International Buyers: When sourcing from different regions, be aware of currency fluctuations, import duties, and taxes that could affect the final price. Buyers from Africa, South America, the Middle East, and Europe should conduct thorough market research to understand these nuances.

-

Disclaimer for Indicative Prices: It’s essential to recognize that pricing can vary widely based on the factors outlined above. Buyers should request detailed quotes to understand the specific costs associated with their requirements.

By comprehensively analyzing these components and influencers, international B2B buyers can make strategic sourcing decisions that align with their business goals and operational needs.

Spotlight on Potential ice vending machines for sale Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘ice vending machines for sale’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for ice vending machines for sale

Key Technical Properties of Ice Vending Machines

Understanding the essential technical properties of ice vending machines is crucial for making informed purchasing decisions. Here are some critical specifications that every B2B buyer should consider:

-

Material Grade

Ice vending machines are typically constructed from stainless steel or other corrosion-resistant materials. The material grade affects durability, maintenance, and hygiene standards. Higher-grade materials, such as 304 or 316 stainless steel, offer better resistance to rust and are easier to clean, which is vital for food safety compliance. -

Production Capacity

This specification refers to the volume of ice the machine can produce within a given time frame, often measured in pounds or kilograms per hour. For businesses with high demand, selecting a machine with a higher production capacity is essential to ensure that supply meets customer needs, particularly in busy locations or peak seasons. -

Energy Efficiency Rating

Energy consumption is a significant operational cost for ice vending machines. Look for units that have energy efficiency certifications, such as ENERGY STAR. A higher efficiency rating not only reduces utility costs but also aligns with sustainability goals, which can be appealing to environmentally conscious consumers and partners. -

Storage Capacity

Storage capacity indicates how much ice the machine can hold at any given time, usually measured in cubic feet. A larger storage capacity allows for greater inventory management flexibility, ensuring that businesses can meet customer demand without frequent replenishment. -

Operating Temperature Range

This specification describes the ambient temperature range in which the ice vending machine can effectively operate. Machines designed for warmer climates, such as those in Africa or South America, should have a wider operating temperature range to ensure reliability in hot conditions. -

Control System

Modern ice vending machines often feature digital control systems that allow for precise monitoring of ice production and inventory levels. These systems can enhance operational efficiency and provide data for better decision-making, which is essential for businesses looking to optimize their processes.

Common Trade Terminology

Familiarity with industry jargon can streamline communication and negotiations. Here are some essential terms relevant to the ice vending machine market:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products that may be marketed by another company. When sourcing ice vending machines, understanding whether the supplier is an OEM can impact quality assurance and warranty considerations. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is critical for budgeting and inventory management, particularly for businesses that are just starting or looking to test new markets. -

RFQ (Request for Quotation)

An RFQ is a formal request sent to suppliers to obtain pricing for specific products or services. Issuing an RFQ can help B2B buyers compare prices and terms from multiple vendors, ensuring they secure the best deal for ice vending machines. -

Incoterms (International Commercial Terms)

These are predefined commercial terms published by the International Chamber of Commerce, outlining the responsibilities of buyers and sellers in international trade. Familiarity with Incoterms helps clarify shipping costs, delivery timelines, and risk management, which is crucial when importing ice vending machines from different regions.

Illustrative Image (Source: Google Search)

-

Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. Understanding lead times is essential for planning and ensuring that your business can meet customer demands without interruption. -

Warranty

A warranty is a guarantee provided by the manufacturer regarding the condition of the product, often covering repairs or replacements for a specified period. Knowing the warranty terms can protect your investment and reduce long-term costs associated with maintenance or failures.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when purchasing ice vending machines, ensuring they select the best equipment for their business needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the ice vending machines for sale Sector

Market Overview & Key Trends

The ice vending machine sector is experiencing significant growth, driven by increasing demand for convenient, on-the-go ice solutions across various markets. Factors such as the rise of outdoor activities, food delivery services, and the expansion of hospitality businesses are propelling this demand globally. For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, understanding local market dynamics is crucial.

Emerging technologies are reshaping sourcing trends. IoT-enabled ice vending machines that allow remote monitoring and management are gaining traction, offering operational efficiency and enhanced customer engagement. Buyers should look for machines equipped with mobile payment options and contactless interfaces, as these features cater to the modern consumer’s preferences. Additionally, the trend towards modular and customizable vending solutions is becoming prevalent, allowing businesses to adapt their offerings to specific customer needs and local market conditions.

Moreover, sustainability is becoming an integral consideration in the purchasing process. As consumers become more environmentally conscious, B2B buyers should prioritize suppliers that emphasize eco-friendly practices, such as energy-efficient machines and sustainable sourcing of materials. Understanding these dynamics and trends will empower buyers to make informed purchasing decisions that align with both market demands and sustainability goals.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer an optional consideration but a critical factor for B2B buyers in the ice vending machine sector. The environmental impact of manufacturing and operating these machines can be substantial, encompassing energy consumption, water usage, and waste generation. Therefore, buyers must assess the lifecycle of the machines they intend to purchase, focusing on energy efficiency ratings and water conservation features.

Ethical sourcing is equally important. Buyers should seek suppliers who demonstrate a commitment to sustainable practices, such as using recyclable materials and engaging in fair labor practices. Certifications like ISO 14001 for environmental management or Energy Star ratings can serve as indicators of a supplier’s commitment to sustainability. By prioritizing suppliers with strong ethical standards and sustainable practices, businesses can not only reduce their environmental footprint but also enhance their brand reputation and meet the growing consumer demand for responsible products.

Brief Evolution/History

The evolution of ice vending machines has been marked by technological advancements and changing consumer behavior. Initially, these machines were simple structures that dispensed bulk ice. However, as convenience and efficiency became paramount, manufacturers began to incorporate sophisticated technologies such as automated ice production and advanced refrigeration systems.

In recent years, the trend has shifted towards more user-friendly and eco-friendly designs, reflecting a broader societal push for sustainability and convenience. This evolution has opened new avenues for B2B buyers, who now have access to machines that not only meet operational needs but also align with modern ethical standards and consumer expectations. Understanding this history can help buyers appreciate the current landscape and anticipate future innovations in the sector.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of ice vending machines for sale

-

What criteria should I use to vet suppliers of ice vending machines?

When vetting suppliers, prioritize their experience in the industry, reputation, and customer reviews. Request references from previous buyers and assess their response times and communication clarity. Examine their production capabilities, certifications, and compliance with international standards. Additionally, consider their ability to provide after-sales support and spare parts, which can be crucial for maintenance and operational efficiency. -

Can ice vending machines be customized for my specific needs?

Yes, many manufacturers offer customization options for ice vending machines. You can tailor features such as size, ice production capacity, payment systems, and branding elements to align with your business model. Discuss your specific requirements during initial conversations with suppliers. It’s advisable to request prototypes or detailed specifications to ensure that the final product meets your expectations. -

What are the typical minimum order quantities (MOQ) and lead times for ice vending machines?

MOQs can vary significantly based on the supplier’s production capabilities and the complexity of the machines. Generally, MOQs range from 5 to 50 units. Lead times can also differ, typically ranging from 4 to 12 weeks after order confirmation, depending on customization and availability of materials. Always confirm these details upfront and consider the impact on your business timeline. -

What payment options are available for purchasing ice vending machines internationally?

Payment options may include wire transfers, letters of credit, or online payment platforms. It’s essential to discuss terms upfront to ensure clarity and security. Many suppliers may request a deposit upon order confirmation, with the balance due before shipping. Evaluate the payment terms for flexibility and protection against potential disputes, especially in international transactions.

Illustrative Image (Source: Google Search)

-

What quality assurance measures should I look for in ice vending machines?

Look for suppliers who can provide quality assurance certifications such as ISO 9001 or CE marking, indicating adherence to international quality standards. Request detailed information about their manufacturing process, testing protocols, and warranty policies. It’s also advisable to conduct a factory visit if possible, or request third-party inspection reports to verify quality before shipment. -

How are logistics and shipping managed for ice vending machines?

Logistics for ice vending machines can be complex due to their size and weight. Coordinate with suppliers to understand their shipping methods, and whether they handle logistics or if you need to arrange for freight forwarders. Discuss incoterms (e.g., FOB, CIF) to clarify responsibilities for shipping costs and risks. Ensure that the supplier provides proper documentation for customs clearance to avoid delays. -

What steps should I take in case of a dispute with a supplier?

In the event of a dispute, first attempt to resolve the issue through direct communication with the supplier. Document all correspondence and agreements. If necessary, refer to the terms outlined in your contract regarding dispute resolution procedures. Consider involving a third-party mediator or legal advisor if the issue remains unresolved, and always keep a record of all transactions for reference. -

Are there specific certifications or regulations I need to be aware of when importing ice vending machines?

Yes, it’s crucial to understand the import regulations and certification requirements specific to your country. Research local health and safety standards, electrical certifications, and environmental regulations that may apply to ice vending machines. Engaging with a customs broker can help navigate these regulations and ensure compliance, minimizing the risk of delays or fines during importation.

Strategic Sourcing Conclusion and Outlook for ice vending machines for sale

In navigating the complex landscape of ice vending machines, international B2B buyers must prioritize strategic sourcing to ensure optimal procurement. Key takeaways include the importance of evaluating suppliers based on reliability, technological innovation, and compliance with local regulations. Buyers should also consider the total cost of ownership, which encompasses not only initial purchase price but also maintenance, energy efficiency, and potential return on investment.

Furthermore, understanding regional market dynamics is crucial. For buyers in Africa, South America, the Middle East, and Europe, leveraging local partnerships can enhance supply chain efficiency and reduce lead times. Engaging with manufacturers that offer comprehensive support and customization options will also facilitate smoother operations and customer satisfaction.

As the demand for convenient and sustainable ice solutions continues to rise, staying ahead of industry trends will be vital. Now is the time for international B2B buyers to capitalize on emerging opportunities within their markets. By investing in strategic sourcing, you position your business not only to meet current demands but also to thrive in the evolving landscape of ice vending solutions. Embrace these insights and take proactive steps to secure your competitive advantage.