Master the Market for Vending Machine Movers: Essential

Guide to Vending Machine Movers

- Introduction: Navigating the Global Market for vending machine movers

- Understanding vending machine movers Types and Variations

- Key Industrial Applications of vending machine movers

- Strategic Material Selection Guide for vending machine movers

- In-depth Look: Manufacturing Processes and Quality Assurance for vending machine movers

- Comprehensive Cost and Pricing Analysis for vending machine movers Sourcing

- Spotlight on Potential vending machine movers Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for vending machine movers

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the vending machine movers Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of vending machine movers

- Strategic Sourcing Conclusion and Outlook for vending machine movers

Introduction: Navigating the Global Market for vending machine movers

In today’s fast-paced business environment, the demand for efficient and reliable vending machine movers is surging across various global markets. As businesses expand their operations, the need to relocate or install vending machines swiftly and securely becomes paramount. Vending machine movers not only facilitate this process but also ensure that machines are transported without damage, maximizing uptime and profitability. For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding the intricacies of this market is essential for making informed procurement decisions.

This guide aims to provide a comprehensive overview of vending machine movers, covering essential aspects including types of movers, materials used in their construction, manufacturing and quality control standards, and a variety of suppliers. Additionally, we will delve into cost considerations and market trends, ensuring that you have a holistic understanding of the factors influencing your purchasing decisions.

By equipping yourself with actionable insights and expert knowledge, you can navigate the complexities of sourcing vending machine movers tailored to your specific needs. Whether you’re based in Colombia or Poland, this guide will empower you to make strategic choices that enhance operational efficiency and drive business growth. As you embark on your journey in the global market, let this resource be your essential companion in making informed, impactful sourcing decisions.

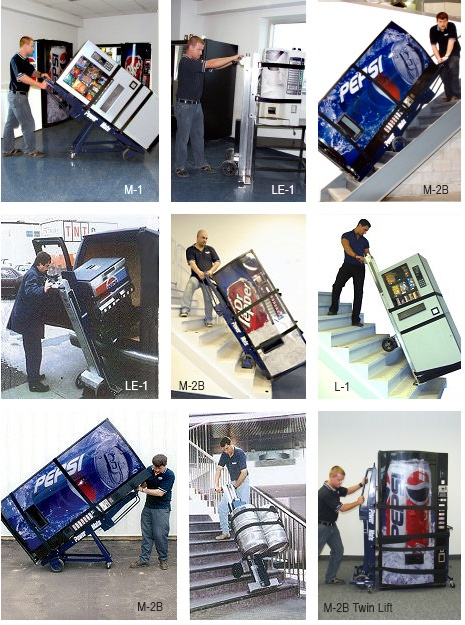

Understanding vending machine movers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Manual Vending Machine Movers | Hand-operated, typically lightweight and portable | Small businesses, events | Cost-effective but requires physical effort and may be slow. |

| Electric Vending Machine Movers | Motorized for easy transportation, suitable for heavy machines | Large retail setups, warehouses | Efficient and reduces labor costs, but higher initial investment. |

| Semi-Automatic Vending Machine Movers | Combines manual effort with mechanical assistance | Mid-sized retailers, trade shows | Balances cost and efficiency, but may require maintenance. |

| Heavy-Duty Vending Machine Movers | Designed for heavy and bulky vending machines | Manufacturing, large venues | Highly durable and efficient but can be cumbersome to operate. |

| Custom Vending Machine Movers | Tailored designs for specific machine types or environments | Niche markets, specialized applications | Perfect fit for unique needs, but may have longer lead times. |

Manual Vending Machine Movers

Manual vending machine movers are hand-operated devices designed for transporting vending machines without the need for electrical power. They are typically lightweight and portable, making them ideal for small businesses or temporary setups, such as events or fairs. Key purchasing considerations include the weight capacity and ease of use, as these movers require physical effort from the operator. While they are cost-effective, buyers should be aware that they may not be suitable for heavy or large vending machines.

Electric Vending Machine Movers

Electric vending machine movers are motorized units that facilitate the movement of heavy vending machines with minimal physical effort. They are particularly beneficial for large retail setups and warehouses where efficiency is paramount. B2B buyers should consider the power source, weight capacity, and the potential reduction in labor costs when evaluating these movers. Although the initial investment may be higher than manual options, the time saved during transportation can lead to increased productivity.

Semi-Automatic Vending Machine Movers

Semi-automatic vending machine movers offer a blend of manual operation and mechanical assistance, making them suitable for mid-sized retailers and trade shows. These movers typically have a powered lift mechanism while still requiring some manual effort for maneuvering. Key considerations for buyers include the balance between cost and efficiency, as well as maintenance requirements. While they provide improved functionality over purely manual options, it is essential to ensure that the mover can handle the specific weight and size of the vending machines in use.

Heavy-Duty Vending Machine Movers

Heavy-duty vending machine movers are specifically designed to transport large and bulky vending machines, making them ideal for manufacturing facilities and large venues. They are built with robust materials and often feature advanced mechanisms for stability and ease of movement. For B2B buyers, it is crucial to assess the mover’s weight capacity and operational ease, as these units can be cumbersome. Although they offer high durability and efficiency, the trade-off may be in their complexity and the need for trained personnel to operate them safely.

Custom Vending Machine Movers

Custom vending machine movers are tailored solutions designed to meet the unique needs of specific machine types or environments. They are particularly beneficial for niche markets or specialized applications where standard movers may not suffice. When considering these options, buyers should evaluate the lead time for custom manufacturing and the potential for higher costs compared to off-the-shelf solutions. While they ensure a perfect fit for unique requirements, planning and communication with manufacturers are essential to align expectations and specifications.

Related Video: Machine Learning in 2024 – Beginner’s Course

Key Industrial Applications of vending machine movers

| Industry/Sector | Specific Application of Vending Machine Movers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Installation and relocation of vending machines | Increased sales through strategic placement | Weight capacity, maneuverability, and ease of use |

| Education | Moving vending machines in schools and campuses | Improved accessibility and student satisfaction | Compliance with safety regulations, durability |

| Hospitality | Efficient setup of vending machines in hotels | Enhanced guest experience and convenience | Aesthetic design, energy efficiency, and service support |

| Healthcare | Transporting vending machines in hospitals | Quick access to essential products for staff | Sanitation standards, reliability, and ease of cleaning |

| Corporate Offices | Relocating vending machines within office spaces | Increased employee satisfaction and productivity | Customization options, payment systems compatibility |

Retail

In the retail sector, vending machine movers play a crucial role in the installation and relocation of vending machines to maximize sales opportunities. Businesses often need to reposition machines based on consumer traffic patterns or promotional strategies. Vending machine movers facilitate this process by enabling quick and efficient movement without damaging the machines or surrounding areas. For international buyers, considerations like weight capacity and maneuverability are essential, especially in densely populated urban environments.

Education

In educational institutions, vending machine movers are used to relocate machines within schools and campuses to enhance accessibility for students. By strategically placing vending machines in high-traffic areas, schools can improve student satisfaction and increase sales. Buyers in this sector must consider compliance with safety regulations and the durability of the moving equipment, as machines may be moved frequently and need to withstand a variety of environments.

Hospitality

In the hospitality industry, vending machine movers assist in the efficient setup and relocation of machines in hotels and resorts. These machines provide guests with convenient access to snacks and beverages, significantly enhancing their overall experience. For B2B buyers, factors such as aesthetic design and energy efficiency are paramount, as these machines must blend seamlessly into the hotel environment while also being cost-effective to operate.

Healthcare

Vending machine movers are essential in healthcare settings, where they facilitate the transport of vending machines stocked with essential products for staff and visitors. Quick access to snacks and beverages can improve staff morale and efficiency, particularly in high-demand areas like hospitals. Buyers must prioritize sanitation standards and reliability, as machines need to be cleaned frequently and must operate without interruption to meet the needs of healthcare professionals.

Corporate Offices

In corporate office environments, vending machine movers are utilized to relocate machines to enhance employee satisfaction and productivity. By strategically placing machines in break rooms or near meeting areas, companies can ensure that employees have easy access to refreshments. Buyers in this sector should consider customization options and compatibility with various payment systems to cater to diverse employee preferences and enhance user experience.

Related Video: DIY Vending Machine – Arduino based Mechatronics Project

Strategic Material Selection Guide for vending machine movers

When selecting materials for vending machine movers, it’s crucial to consider the specific properties, advantages, and limitations of each material type. This section analyzes four common materials used in the construction of vending machine movers, focusing on their performance characteristics, suitability for various applications, and considerations for international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe.

Aluminum

Key Properties:

Aluminum is lightweight and has a good strength-to-weight ratio. It exhibits excellent corrosion resistance, making it suitable for environments with high humidity or exposure to moisture.

Pros & Cons:

The primary advantage of aluminum is its lightweight nature, which facilitates easier handling and transportation of vending machines. However, it can be more expensive than steel and may not provide the same level of structural strength under heavy loads. Additionally, manufacturing complexity can increase due to the need for specialized welding techniques.

Impact on Application:

Aluminum is compatible with various media, including food products, but care must be taken to avoid reactions with acidic substances. Its lightweight nature allows for faster installation and relocation of vending machines.

Considerations for International Buyers:

When sourcing aluminum components, ensure compliance with standards such as ASTM B221 (for extruded aluminum) or EN 573 (European standard). Buyers should also consider the availability of aluminum alloys that meet local regulations in their respective regions.

Carbon Steel

Key Properties:

Carbon steel is known for its high tensile strength and durability. It can withstand significant pressure and is often treated for corrosion resistance.

Pros & Cons:

Carbon steel is cost-effective and readily available, making it a popular choice for vending machine movers. However, it is susceptible to rust if not properly coated or maintained, which can lead to structural failures over time. Manufacturing processes are generally straightforward, but heavy components can increase shipping costs.

Impact on Application:

This material is suitable for heavy-duty applications where strength is paramount. It is compatible with various media, but caution should be exercised to prevent corrosion in wet environments.

Considerations for International Buyers:

Buyers should ensure that the carbon steel used complies with relevant standards such as ASTM A36 or EN 10025. Additionally, understanding local corrosion resistance requirements is essential, particularly in humid regions like parts of Africa and South America.

Stainless Steel

Key Properties:

Stainless steel offers excellent corrosion resistance, high strength, and durability. It can withstand extreme temperatures and pressures, making it ideal for various environments.

Pros & Cons:

The primary advantage of stainless steel is its longevity and minimal maintenance requirements due to its resistance to corrosion. However, it is more expensive than carbon steel and aluminum, which may impact budget considerations. The complexity of manufacturing and welding can also increase costs.

Impact on Application:

Stainless steel is highly versatile and can be used in environments where hygiene is critical, such as in food vending machines. It is compatible with a wide range of media, including beverages and snacks.

Considerations for International Buyers:

Ensure compliance with standards such as ASTM A240 (for stainless steel sheets) or EN 10088. Buyers should also be aware of the specific grades of stainless steel that are suitable for their applications, especially in regions with varying environmental conditions.

Polypropylene

Key Properties:

Polypropylene is a thermoplastic polymer known for its chemical resistance, lightweight nature, and flexibility. It can withstand moderate temperatures and is resistant to many solvents.

Pros & Cons:

The key advantage of polypropylene is its low cost and ease of manufacturing, making it suitable for components that do not require high strength. However, it is not as durable as metals and can degrade under UV exposure, limiting its outdoor applications.

Impact on Application:

Polypropylene is suitable for internal components of vending machines, such as trays or dividers, where exposure to harsh conditions is minimal. It is compatible with various food products, making it a viable option for food vending machines.

Considerations for International Buyers:

Buyers should ensure that polypropylene materials meet relevant standards such as ASTM D638 (for tensile properties) and consider local regulations regarding food safety and material compatibility.

Summary Table

| Material | Typical Use Case for vending machine movers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight frames for easy mobility | Excellent corrosion resistance | More expensive than steel | High |

| Carbon Steel | Heavy-duty structural components | Cost-effective and strong | Susceptible to rust without protection | Low |

| Stainless Steel | Components in food vending machines | High durability and minimal maintenance | Higher cost and manufacturing complexity | High |

| Polypropylene | Internal trays and dividers | Low cost and easy to manufacture | Not suitable for high-stress applications | Low |

This guide provides a comprehensive overview of material options for vending machine movers, helping international B2B buyers make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for vending machine movers

Manufacturing Processes for Vending Machine Movers

The manufacturing of vending machine movers involves a series of systematic processes that ensure the final product is robust, reliable, and capable of meeting the demands of various environments. Understanding these processes is crucial for international B2B buyers seeking quality and efficiency in their supply chains.

Main Stages of Manufacturing

- Material Preparation

– Selection of Materials: The first step involves selecting high-quality materials such as steel, aluminum, and plastic composites. The choice of materials impacts the durability and weight capacity of the vending machine movers.

– Cutting and Shaping: Raw materials are cut into required dimensions using advanced cutting tools. Techniques such as laser cutting and water jet cutting ensure precision and reduce waste.

Illustrative Image (Source: Google Search)

-

Forming

– Bending and Forming Techniques: After cutting, materials undergo bending processes. Techniques like CNC (Computer Numerical Control) bending allow for complex shapes necessary for the structural integrity of the movers.

– Welding and Joining: Components are welded or joined using methods such as MIG (Metal Inert Gas) or TIG (Tungsten Inert Gas) welding. This stage is critical to ensuring that the frame is sturdy and can withstand heavy loads. -

Assembly

– Component Assembly: This stage involves assembling the various parts, including wheels, motors, and frames. Automated assembly lines may be employed to enhance efficiency and reduce human error.

– Integration of Technology: Modern vending machine movers often incorporate electronic components for enhanced functionality, such as GPS tracking and automated lift systems. -

Finishing

– Surface Treatment: To enhance durability and aesthetics, finishing processes such as powder coating or anodizing are applied. These treatments protect against corrosion and wear, especially in diverse climates.

– Final Inspection: Before the product is packaged, a thorough inspection is conducted to ensure all components meet design specifications.

Quality Assurance in Manufacturing

Quality assurance (QA) is an integral part of the manufacturing process for vending machine movers. It ensures that products not only meet company standards but also comply with international regulations.

Relevant International Standards

- ISO 9001: This is a widely recognized quality management standard that emphasizes consistent quality and customer satisfaction. Manufacturers adhering to ISO 9001 demonstrate a commitment to continuous improvement and process optimization.

- CE Marking: In Europe, CE marking indicates compliance with health, safety, and environmental protection standards. This is crucial for B2B buyers in Europe, as it ensures that the products are safe and reliable.

- API Standards: For specific industries, such as those involving heavy machinery, adherence to American Petroleum Institute (API) standards can be relevant, ensuring that the equipment meets rigorous safety and performance criteria.

Quality Control Checkpoints

-

Incoming Quality Control (IQC)

– At this checkpoint, raw materials and components are inspected upon arrival. This ensures that only high-quality materials are used in production, reducing defects later in the process. -

In-Process Quality Control (IPQC)

– During manufacturing, regular checks are performed to monitor the production process. This includes verifying that machinery is functioning correctly and that assembly procedures are followed accurately. -

Final Quality Control (FQC)

– Before products are shipped, a final inspection is conducted. This includes testing functionality, weight capacity, and safety features to ensure the product meets all specifications.

Common Testing Methods

- Load Testing: This is essential for vending machine movers to ensure they can handle the weight of the machines they will transport.

- Durability Testing: Products undergo stress tests to simulate real-world use and ensure longevity.

- Safety Testing: Compliance with safety standards is verified through various tests, including electrical safety and operational safety assessments.

Verifying Supplier Quality Control

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial for minimizing risks.

-

Supplier Audits

– Conducting regular audits of potential suppliers can help verify their compliance with international standards. Audits assess their manufacturing processes, quality control measures, and adherence to standards like ISO 9001. -

Quality Reports

– Requesting detailed quality reports can provide insight into a supplier’s QA processes. These reports should include data on defect rates, corrective actions taken, and performance against standards. -

Third-Party Inspections

– Engaging third-party inspection agencies can provide an unbiased assessment of a supplier’s quality control practices. These agencies can conduct inspections at various stages of production and provide comprehensive reports.

Quality Control and Certification Nuances

International buyers need to be aware of specific nuances regarding quality control and certification when sourcing vending machine movers:

- Regional Regulations: Different regions may have varying regulations regarding manufacturing and safety standards. Buyers should familiarize themselves with local laws, especially when importing products.

- Cultural Considerations: Understanding cultural differences in business practices can aid in establishing effective communication with suppliers regarding quality expectations.

- Documentation: Ensure that all certifications and quality assurance documents are available and verifiable. This helps in mitigating risks associated with non-compliance and enhances trust in supplier relationships.

By understanding the manufacturing processes and quality assurance measures in place for vending machine movers, international B2B buyers can make informed decisions that align with their operational needs and standards.

Related Video: SMART Quality Control for Manufacturing

Comprehensive Cost and Pricing Analysis for vending machine movers Sourcing

Understanding the Cost Structure of Vending Machine Movers

When sourcing vending machine movers, it’s essential to grasp the comprehensive cost structure that influences pricing. The primary components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the supplier’s margin.

-

Materials: The choice of materials significantly impacts cost. High-quality metals or specialized plastics that resist wear can increase initial expenses but lead to longer-lasting products.

-

Labor: Labor costs vary by region and can be influenced by local wage laws. In regions like Africa and South America, labor might be more affordable, yet the skill level can vary.

-

Manufacturing Overhead: This includes utilities, rent, and equipment maintenance costs. Factories in Europe may have higher overhead due to stricter regulations, impacting pricing.

-

Tooling: The cost of custom tooling for specific machine designs can be a significant upfront investment. Buyers should evaluate whether standard models can meet their needs to avoid unnecessary tooling costs.

-

Quality Control: Implementing rigorous QC processes adds to manufacturing costs but is crucial for ensuring product reliability, especially for international buyers concerned about standards.

-

Logistics: Transportation and import duties can vary widely. Choosing the right Incoterms can greatly affect total shipping costs and responsibilities between buyer and seller.

-

Margin: Lastly, the supplier’s margin will vary based on their business model and market position. Understanding the typical margins in your target market can aid in negotiations.

Influencers on Pricing

Several factors can influence the final price of vending machine movers:

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically attract discounts. Understanding the supplier’s pricing tiers based on volume can lead to significant savings.

-

Specifications/Customization: Custom features may increase costs. Buyers should assess whether the added features justify the price increase or if standard options suffice.

-

Quality/Certifications: Products certified for safety or quality assurance may command higher prices. Buyers should evaluate the necessity of these certifications based on their market requirements.

-

Supplier Factors: The supplier’s reputation, experience, and reliability can influence pricing. Established suppliers may charge a premium for their proven track record.

-

Incoterms: The choice of Incoterms affects shipping costs and risk allocation. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is crucial for cost management.

Buyer Tips for Cost-Efficiency

-

Negotiate Wisely: Leverage volume purchasing and long-term partnerships to negotiate better terms. Highlighting competitive offers from other suppliers can also strengthen your position.

-

Evaluate Total Cost of Ownership (TCO): Don’t focus solely on the initial purchase price. Consider the long-term maintenance, operational costs, and potential downtime costs associated with lower-quality machines.

-

Understand Pricing Nuances: Be aware of regional pricing variations. For instance, suppliers in South America may offer lower prices due to lower labor costs, but this could come at the expense of quality.

-

Stay Informed on Market Trends: Keep abreast of changes in material costs or labor rates in the regions of interest. This knowledge will empower you to make informed purchasing decisions.

-

Conduct Supplier Audits: If possible, visit suppliers to assess their operations firsthand. This can provide insights into their production capabilities, quality standards, and overall reliability.

Disclaimer on Indicative Prices

Pricing for vending machine movers can fluctuate based on market conditions, material costs, and other variables. It is advisable for buyers to obtain multiple quotes and conduct thorough due diligence to ensure they are making informed purchasing decisions tailored to their specific needs and market conditions.

Spotlight on Potential vending machine movers Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for vending machine movers.)*

Essential Technical Properties and Trade Terminology for vending machine movers

Key Technical Properties for Vending Machine Movers

When considering vending machine movers, understanding the essential technical properties is crucial for ensuring efficiency, safety, and compliance with industry standards. Below are several key specifications that B2B buyers should prioritize:

-

Load Capacity

The load capacity indicates the maximum weight a vending machine mover can safely transport. This specification is critical as it directly impacts the mover’s effectiveness in handling various vending machine models. For international buyers, confirming the load capacity can prevent costly damages and ensure compliance with local regulations regarding transportation safety. -

Material Grade

The construction material of a vending machine mover affects its durability and performance. Common materials include steel and aluminum, each offering different strengths and weight considerations. Buyers should assess the material grade to ensure it meets their operational needs, particularly in regions where environmental factors may influence performance, such as humidity or extreme temperatures. -

Tolerance Levels

Tolerance refers to the allowable deviation in dimensions of the mover components. High tolerance levels ensure precision in operation, particularly when maneuvering in tight spaces. For B2B buyers, understanding these tolerances is vital for ensuring compatibility with different vending machine models and minimizing operational hiccups. -

Wheel Specifications

The size and type of wheels (e.g., rubber, polyurethane) significantly influence the mover’s maneuverability and ease of transport. Larger wheels can navigate uneven surfaces more effectively, which is often a consideration in various regions where vending machines are placed in diverse environments. Buyers should evaluate wheel specifications based on the terrain and locations where they plan to deploy the machines. -

Ergonomic Design

Ergonomics focuses on creating equipment that maximizes efficiency while minimizing strain on operators. Features such as adjustable handles, lightweight frames, and easy-to-use controls can significantly enhance the user experience. For international buyers, investing in ergonomically designed movers can lead to reduced injury rates and increased productivity among staff.

Common Trade Terminology

Navigating the trade landscape requires familiarity with specific jargon that can impact negotiations and procurement processes. Here are several essential terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. Understanding OEM relationships is vital for buyers looking to source reliable and compatible components for vending machines. Identifying OEMs can also help in negotiating better pricing and terms. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is crucial for budget-conscious buyers, as it affects purchasing decisions and inventory management. Buyers should negotiate MOQs that align with their operational needs to avoid excess inventory costs. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers requesting pricing and terms for specific products or services. Crafting a well-defined RFQ can lead to more accurate quotations and better negotiation outcomes. For international buyers, clear communication in RFQs is essential to avoid misunderstandings due to language barriers or regional differences. -

Incoterms (International Commercial Terms)

Incoterms are a set of pre-defined commercial terms published by the International Chamber of Commerce (ICC) that are widely used in international shipping and freight. They define the responsibilities of buyers and sellers in transactions, impacting shipping costs and risk management. Familiarity with Incoterms can help buyers mitigate risks associated with cross-border transactions. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the goods. Understanding lead times is essential for effective supply chain management and planning. Buyers should account for potential delays, especially when importing from international suppliers, to ensure timely deployment of vending machines. -

Warranty Period

The warranty period specifies the duration for which the manufacturer guarantees the product against defects. A comprehensive warranty can provide peace of mind and protect against unforeseen expenses. Buyers should always inquire about warranty terms to ensure they are making a sound investment.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing vending machine movers, ultimately enhancing their operational efficiency and market competitiveness.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the vending machine movers Sector

Market Overview & Key Trends

The vending machine movers sector is witnessing significant transformation driven by technological advancements and changing consumer behaviors. Key global drivers include the rise of e-commerce, increased urbanization, and a growing emphasis on convenience. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding local market dynamics is crucial. In Colombia, for example, a growing middle class is driving demand for vending services, while in Poland, the emphasis is on high-tech, user-friendly machines that enhance customer experience.

Emerging trends include the integration of IoT (Internet of Things) technologies, enabling real-time inventory management and remote monitoring of machines. This technology not only optimizes operational efficiency but also improves customer satisfaction by ensuring popular products are always available. Additionally, the rise of cashless payment systems, including mobile wallets and contactless cards, is reshaping how transactions are conducted, making machines more accessible to tech-savvy consumers.

Moreover, as sustainability gains prominence, B2B buyers are increasingly seeking suppliers that prioritize eco-friendly practices. This shift is evident in the growing interest in energy-efficient machines and recyclable materials, which not only appeal to environmentally conscious consumers but also align with regulatory trends across Europe and other regions.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a focal point for businesses in the vending machine movers sector. The environmental impact of traditional vending machines—often associated with high energy consumption and waste generation—has prompted a shift towards more sustainable practices. B2B buyers must consider suppliers that utilize energy-efficient technology, such as LED lighting and low-energy compressors, which significantly reduce operational costs and carbon footprints.

Moreover, ethical sourcing is increasingly essential. Buyers should prioritize suppliers who maintain transparent supply chains, ensuring that materials are sourced responsibly and ethically. Certifications such as ISO 14001 for environmental management and Fair Trade practices can serve as indicators of a supplier’s commitment to sustainability and ethical standards. Utilizing recycled materials in machine production not only helps minimize waste but can also enhance brand reputation among environmentally conscious consumers.

In regions like Africa and South America, where the demand for sustainable practices is rising, aligning with suppliers who prioritize these values can open doors to new markets and customer segments. By investing in sustainable and ethical supply chains, B2B buyers can contribute to a more sustainable future while also meeting the growing demand from consumers for responsible business practices.

Brief Evolution/History

The vending machine industry has evolved significantly since its inception in the early 20th century. Initially simple machines offering basic snacks and drinks, today’s vending machines are equipped with advanced technology, offering diverse products ranging from fresh food to electronics. This evolution has been driven by technological innovations, such as cashless payment systems and IoT connectivity, which have enhanced consumer interaction and operational efficiency.

In recent years, the focus on sustainability has further shaped the industry’s trajectory. As global awareness of environmental issues has increased, manufacturers have adapted by introducing energy-efficient machines and sustainable materials. This historical context underscores the importance of aligning with suppliers who not only understand the technological advancements but also prioritize sustainability and ethical sourcing, making them invaluable partners for B2B buyers in today’s dynamic market landscape.

Related Video: Is global trade transforming? | Counting the Cost

Frequently Asked Questions (FAQs) for B2B Buyers of vending machine movers

-

What should I consider when vetting suppliers for vending machine movers?

When vetting suppliers, prioritize their industry experience, reputation, and customer testimonials. Request references and check their track record in delivering quality products. Additionally, assess their production capabilities and technology used in manufacturing. Ensure that they comply with international standards and regulations relevant to your region. A thorough background check can help mitigate risks associated with supplier reliability and product quality. -

Can vending machine movers be customized to fit specific needs?

Yes, many suppliers offer customization options to meet the specific requirements of your business. This may include size adjustments, branding, or additional features tailored to your market. When discussing customization, provide detailed specifications and expected outcomes to ensure the final product aligns with your operational needs. Confirm any additional costs and lead times associated with custom orders during negotiations. -

What are the typical minimum order quantities (MOQ) and lead times for vending machine movers?

Minimum order quantities can vary significantly by supplier, often ranging from 10 to 100 units. For international buyers, larger orders may be more cost-effective, but it’s essential to balance inventory needs with cash flow. Lead times typically range from 4 to 12 weeks, depending on the complexity of the order and the supplier’s location. Always clarify these details upfront to avoid delays in your supply chain. -

What payment terms should I expect when sourcing vending machine movers internationally?

Payment terms can vary widely among suppliers, but common practices include a deposit upfront (usually 30% to 50%) and the balance upon delivery or prior to shipment. Consider using letters of credit for larger transactions to mitigate risk. Additionally, inquire about payment methods accepted, such as wire transfers or online payment platforms, and ensure they align with your financial processes and international transaction capabilities. -

How can I ensure quality assurance and certification compliance?

To ensure quality assurance, request certifications from suppliers that verify compliance with international standards, such as ISO 9001 or CE marking. It’s beneficial to establish a quality control process, including inspections at various production stages. Consider conducting third-party audits or requesting samples before placing large orders. This proactive approach can help ensure that the products meet your quality expectations and regulatory requirements. -

What logistics considerations should I keep in mind for international shipping?

Logistics play a crucial role in the procurement of vending machine movers. Consider the shipping methods available (air, sea, or land) based on cost and urgency. Verify the supplier’s experience with international shipping and customs clearance processes. Additionally, discuss who will bear the cost of shipping and insurance, and ensure that all logistics details are documented in the contract to avoid misunderstandings. -

What steps should I take in case of a dispute with a supplier?

In the event of a dispute, first, review the contract terms to understand your rights and obligations. Initiate a dialogue with the supplier to resolve the issue amicably. If that fails, consider mediation or arbitration as alternative dispute resolution methods before escalating to legal action. Document all communications and maintain records of transactions, as this information will be vital in any dispute resolution process. -

Are there specific regulations I need to be aware of when importing vending machine movers?

Yes, each region has distinct regulations regarding the importation of goods. For example, in Europe, CE marking may be required to demonstrate compliance with safety standards. In Africa and South America, customs duties and tariffs vary, impacting total costs. Research local regulations, including safety standards and environmental compliance, and consult with a customs broker to navigate the complexities of international trade and ensure smooth importation.

Illustrative Image (Source: Google Search)

Strategic Sourcing Conclusion and Outlook for vending machine movers

In conclusion, the strategic sourcing of vending machine movers presents a significant opportunity for international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. By prioritizing partnerships with reputable movers, businesses can ensure not only the safe transportation of their assets but also the continuity of service and customer satisfaction. Key takeaways include the importance of evaluating potential movers based on their experience, technology integration, and capacity to handle diverse vending machine types.

Moreover, fostering relationships with local suppliers can yield cost savings and reduce lead times, which is critical in competitive markets like Colombia and Poland. Engaging with vendors who understand regional logistics challenges can help mitigate risks associated with transit delays or equipment damage.

As you look toward the future, consider leveraging technology and data analytics to refine your sourcing strategies. This proactive approach will not only enhance operational efficiency but also position your business for sustained growth. Embrace the evolving landscape of vending machine logistics to stay ahead in the marketplace. Start exploring partnerships that align with your strategic goals today, and unlock the full potential of your vending operations.