Master the Art of Sourcing Pet Vending Machines for B2B

Guide to Pet Vending Machine

- Introduction: Navigating the Global Market for pet vending machine

- Understanding pet vending machine Types and Variations

- Key Industrial Applications of pet vending machine

- Strategic Material Selection Guide for pet vending machine

- In-depth Look: Manufacturing Processes and Quality Assurance for pet vending machine

- Comprehensive Cost and Pricing Analysis for pet vending machine Sourcing

- Spotlight on Potential pet vending machine Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for pet vending machine

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the pet vending machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of pet vending machine

- Strategic Sourcing Conclusion and Outlook for pet vending machine

Introduction: Navigating the Global Market for pet vending machine

As the pet industry continues to flourish globally, the emergence of pet vending machines marks a significant innovation in pet care and retail. These automated kiosks offer a convenient solution for pet owners to access essential supplies, from food and toys to grooming products, directly in their neighborhoods. For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding the landscape of pet vending machines is crucial for making informed sourcing decisions.

This comprehensive guide delves into the various types of pet vending machines, examining their features and functionalities to help buyers choose the right model for their market. It also covers the materials used in manufacturing, ensuring durability and safety for pets. Buyers will gain insights into manufacturing practices and quality control standards, which are vital for ensuring product reliability and compliance with local regulations.

Additionally, this guide provides an overview of suppliers in the pet vending machine market, offering a comparison of costs and market trends. With a dedicated FAQ section, we aim to address common queries and challenges faced by buyers in this niche. By equipping stakeholders with essential knowledge, this guide empowers them to navigate the global market confidently, fostering successful partnerships and enhancing customer satisfaction in the burgeoning pet care sector.

Understanding pet vending machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Automated Pet Food Dispenser | Dispenses various types of pet food in measured portions | Pet stores, veterinary clinics | Pros: Easy inventory management; Cons: Limited to food only. |

| Pet Toy Vending Machine | Offers a variety of toys and accessories for pets | Retail environments, pet expos | Pros: Attracts impulse buyers; Cons: Requires frequent restocking. |

| Pet Health Supply Kiosk | Provides health-related products (medications, supplements) | Pharmacies, veterinary practices | Pros: Addresses urgent needs; Cons: Regulatory compliance needed. |

| Self-Service Pet Wash Station | Includes washing facilities with automated payment options | Grooming salons, pet parks | Pros: Offers convenience for pet owners; Cons: High initial setup costs. |

| Pet Adoption Kiosk | Connects potential adopters with local shelters and available pets | Community centers, shopping malls | Pros: Promotes animal welfare; Cons: Requires partnerships with shelters. |

Automated Pet Food Dispenser

This type of vending machine is designed to dispense various kinds of pet food in controlled portions. Ideal for pet stores and veterinary clinics, it allows businesses to manage inventory efficiently while offering convenience to customers. Buyers should consider the machine’s capacity, the variety of food it can dispense, and how it integrates with inventory management systems.

Pet Toy Vending Machine

Pet toy vending machines provide a selection of toys and accessories that appeal to pet owners and can be strategically placed in high-traffic retail environments or at pet expos. These machines capitalize on impulse buying behavior, making them an attractive option for retailers. Key considerations for B2B buyers include the variety of products offered and the frequency of required restocking.

Pet Health Supply Kiosk

These kiosks are tailored to dispense health-related products such as medications and dietary supplements for pets. They are suitable for pharmacies and veterinary practices where pet owners may need quick access to essential health items. Buyers must ensure compliance with local regulations regarding the sale of pet medications and consider the need for educational materials to assist customers.

Self-Service Pet Wash Station

Self-service pet wash stations provide an automated way for pet owners to wash their pets without the hassle of home clean-up. Commonly found in grooming salons and pet parks, these stations cater to busy pet owners looking for convenience. B2B buyers should evaluate initial setup costs, ongoing maintenance, and the potential for additional services such as grooming or pet care products.

Pet Adoption Kiosk

Pet adoption kiosks serve as a bridge between potential pet adopters and local animal shelters. Placed in community centers or shopping malls, they promote animal welfare while providing an avenue for shelters to connect with the public. For B2B buyers, understanding the partnership dynamics with shelters and the technology required for real-time updates on available pets is crucial.

Related Video: Machine Learning in 2024 – Beginner’s Course

Key Industrial Applications of pet vending machine

| Industry/Sector | Specific Application of Pet Vending Machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Automated pet food and accessory sales | Increased foot traffic, 24/7 sales capability | Machine size, product variety, payment systems, maintenance support |

| Veterinary Clinics | On-site pet care products | Convenience for pet owners, additional revenue stream | Product safety, regulatory compliance, stock management |

| Pet Services | Pet grooming and care supplies | Enhanced service offerings, customer loyalty | Product range, machine customization, service contracts |

| Events & Festivals | Temporary pet product vending | Unique visitor engagement, additional revenue | Portability, ease of setup, product selection |

| Hotels & Resorts | Pet amenities vending | Improved guest experience, niche market appeal | Product variety, branding options, machine aesthetics |

Retail

In retail environments, pet vending machines serve as automated points of sale for pet food and accessories. These machines can operate 24/7, allowing businesses to increase sales without the need for additional staffing. For international B2B buyers, particularly from regions like Africa and South America, the selection of products must cater to local pet ownership trends and preferences. Additionally, payment systems should accommodate local currencies and electronic payment methods to enhance consumer convenience.

Veterinary Clinics

Veterinary clinics can utilize pet vending machines to provide on-site pet care products such as medications, food, and grooming supplies. This convenience allows pet owners to purchase essential items immediately after consultations, thus increasing the clinic’s revenue streams. Buyers in the Middle East and Europe should consider regulatory compliance regarding product safety and labeling, as well as stock management systems to ensure a steady supply of popular items.

Pet Services

Businesses that offer pet grooming and care services can enhance their offerings by installing vending machines stocked with grooming supplies and pet care products. This not only provides convenience for customers but also fosters loyalty as clients can easily purchase necessary items on-site. For buyers in Europe, customization options for branding and service contracts for maintenance are critical factors to consider when sourcing these machines.

Events & Festivals

Pet vending machines can be strategically placed at events and festivals, offering pet-related products to attendees. This application allows for unique visitor engagement and can generate additional revenue streams. B2B buyers from regions like Brazil and Africa should prioritize the portability of these machines, ensuring they are easy to set up and dismantle while also providing a diverse product selection to meet varying consumer needs.

Hotels & Resorts

In hotels and resorts, pet vending machines can provide amenities for guests traveling with pets, such as snacks, toys, and hygiene products. This enhances the guest experience and caters to the growing market of pet-friendly accommodations. Buyers in the Middle East should focus on sourcing machines that offer a variety of products, aesthetic appeal, and branding options to align with the hotel’s image and guest expectations.

Related Video: DIY Vending Machine – Arduino based Mechatronics Project

Strategic Material Selection Guide for pet vending machine

When selecting materials for pet vending machines, it is crucial to consider various factors such as durability, cost, and compatibility with the intended application. Below, we analyze four common materials used in the construction of pet vending machines, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe.

1. Stainless Steel (e.g., 304/316)

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand a wide range of temperatures. Grade 316 offers superior resistance to saltwater and acidic environments, making it ideal for coastal areas or humid climates.

Pros & Cons:

Stainless steel is highly durable and can withstand heavy usage, making it suitable for high-traffic locations. However, it tends to be more expensive than other materials, and its manufacturing process can be complex due to the need for specialized equipment.

Impact on Application:

This material is compatible with food-grade applications, ensuring safety for pet food and treats. Its resistance to corrosion also means lower maintenance costs over time.

Considerations for International Buyers:

Buyers should ensure compliance with local health and safety standards regarding food contact materials. In regions like Europe, adherence to EU regulations is critical, while buyers in the Middle East may need to consider local certifications.

2. High-Density Polyethylene (HDPE)

Key Properties:

HDPE is a lightweight, durable plastic that offers excellent impact resistance and is resistant to many chemicals. It operates well in a temperature range of -40°F to 120°F (-40°C to 49°C).

Pros & Cons:

The primary advantage of HDPE is its cost-effectiveness and ease of manufacturing, which allows for intricate designs. However, it may not be as durable as metal options and can be susceptible to UV degradation if not treated.

Impact on Application:

HDPE is suitable for non-food contact applications, but it can be used for components that require chemical resistance. Its lightweight nature makes it easier to transport and install.

Considerations for International Buyers:

Buyers should verify that the HDPE used complies with local regulations regarding plastics, particularly in food applications. In regions like Africa and South America, where recycling practices may vary, sourcing from suppliers with sustainable practices can enhance brand reputation.

3. Aluminum

Key Properties:

Aluminum is lightweight and has good corrosion resistance, especially when anodized. It has a high strength-to-weight ratio and performs well under a variety of temperatures.

Pros & Cons:

Aluminum is relatively inexpensive and easy to machine, making it a popular choice for many applications. However, it is less durable than stainless steel and can be prone to scratching and denting.

Impact on Application:

Aluminum is suitable for structural components of vending machines but may require a protective coating for food contact areas to prevent leaching.

Considerations for International Buyers:

Compliance with local standards for aluminum in food applications is crucial. Buyers in Europe should check for compliance with EU regulations, while those in the Middle East may need to consider local health codes.

4. Glass Reinforced Plastic (GRP)

Key Properties:

GRP combines glass fibers with resin, resulting in a strong, lightweight material that is resistant to corrosion and UV light. It can withstand a wide range of temperatures and is often used in outdoor applications.

Pros & Cons:

GRP is highly customizable and can be molded into complex shapes, making it suitable for unique designs. However, it can be more expensive than standard plastics and may require specialized manufacturing processes.

Impact on Application:

GRP is ideal for external panels of vending machines, providing both aesthetic appeal and protection against the elements. It is also compatible with food-grade applications when properly formulated.

Considerations for International Buyers:

Buyers should ensure that GRP materials meet local food safety regulations. In regions like South America, where environmental conditions can vary, selecting UV-stabilized GRP can enhance longevity.

Summary Table

| Material | Typical Use Case for pet vending machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel (e.g., 304/316) | Structural components, food contact areas | Excellent durability and corrosion resistance | Higher cost, complex manufacturing | High |

| High-Density Polyethylene (HDPE) | Non-food contact components | Cost-effective, easy to manufacture | Less durable, susceptible to UV degradation | Low |

| Aluminum | Structural components | Lightweight, good corrosion resistance | Less durable than stainless steel | Medium |

| Glass Reinforced Plastic (GRP) | External panels | Customizable, strong, UV resistant | Higher cost, specialized manufacturing | Medium |

This guide provides a comprehensive overview of material options for pet vending machines, enabling international B2B buyers to make informed decisions that align with their operational needs and regional regulations.

In-depth Look: Manufacturing Processes and Quality Assurance for pet vending machine

Manufacturing Processes for Pet Vending Machines

The manufacturing of pet vending machines is a multi-stage process involving careful planning, precision engineering, and adherence to quality standards. Understanding these processes is crucial for B2B buyers looking to source reliable and durable equipment.

Main Stages of Manufacturing

-

Material Preparation

– Selection of Materials: The first step is selecting high-quality materials that can withstand various environmental conditions. Common materials include stainless steel for the frame, high-density polyethylene for the casing, and durable electronic components.

– Pre-Processing: Materials undergo cutting, shaping, and surface treatment to prepare them for forming. This stage may involve processes like laser cutting or CNC machining to ensure precision. -

Forming

– Molding and Fabrication: Techniques such as injection molding for plastic components and metal stamping for structural parts are employed. These methods allow for mass production while maintaining consistency.

– Welding and Assembly: Components are welded together or assembled using fasteners. Automated welding techniques may be used for stronger joints, particularly in high-stress areas. -

Assembly

– Integration of Components: Once the structural frame is complete, internal components like vending mechanisms, electronic controls, and payment systems are integrated. This stage is critical as it determines the machine’s functionality.

– Testing During Assembly: As components are added, preliminary tests ensure each part functions correctly. This includes checking electrical connections and mechanical movements. -

Finishing

– Surface Treatment: The exterior surfaces undergo finishing processes such as powder coating or painting. This not only enhances aesthetics but also provides protection against weather and wear.

– Final Assembly and Quality Control: After finishing, the machine is fully assembled, and final quality checks are performed to ensure all systems are operational.

Key Techniques in Manufacturing

- Lean Manufacturing: Many manufacturers adopt lean principles to minimize waste and optimize efficiency. This approach can lead to cost savings, which can be passed on to buyers.

- Automation: Utilizing robotic arms and automated systems for assembly can improve precision and reduce labor costs. Automation also allows for faster production cycles.

- Modular Design: Designing machines in modular components facilitates easier repairs and upgrades, adding long-term value for buyers.

Quality Assurance in Manufacturing

Quality assurance is vital in ensuring that pet vending machines meet both international and industry-specific standards. Buyers should be familiar with these standards to assess supplier credibility effectively.

Relevant International Standards

- ISO 9001: This standard sets out the criteria for a quality management system. It is applicable to any organization and emphasizes consistent quality and customer satisfaction.

- CE Marking: Required for products sold in the European Economic Area (EEA), CE marking indicates conformity with health, safety, and environmental protection standards.

- API Standards: Although primarily associated with the petroleum industry, API standards can apply to specific mechanical components of vending machines, ensuring they meet rigorous performance criteria.

Quality Control Checkpoints

- Incoming Quality Control (IQC): This involves inspecting raw materials and components as they arrive at the manufacturing facility. Buyers should verify that suppliers maintain strict IQC protocols to prevent defects.

- In-Process Quality Control (IPQC): During the manufacturing process, regular checks are performed to ensure components are fabricated correctly. This can include dimensional checks and functionality tests.

- Final Quality Control (FQC): After assembly, the final product undergoes thorough testing. This stage often includes functionality tests, safety checks, and compliance verifications against applicable standards.

Common Testing Methods

- Functional Testing: Ensures that all mechanical and electronic systems operate as intended.

- Stress Testing: Evaluates how the machine performs under extreme conditions, such as high usage or adverse environmental conditions.

- Electrical Testing: Checks wiring, connectivity, and safety features to prevent electrical failures.

Verifying Supplier Quality Control

For B2B buyers, especially those operating in diverse markets like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential:

- Supplier Audits: Conducting audits of potential suppliers can provide insights into their manufacturing practices and quality control measures. This should include a review of their certifications and processes.

- Quality Reports: Requesting detailed quality reports from suppliers can help buyers assess the reliability of products. Reports should outline defect rates, testing methods, and compliance with international standards.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the manufacturing processes and product quality. This is particularly valuable for buyers unfamiliar with local suppliers.

Quality Control and Certification Nuances for International Buyers

When sourcing from international suppliers, buyers must consider the nuances of quality control and certification:

- Cultural Differences: Different regions may have varying approaches to quality management. Understanding these differences can aid in effectively communicating quality expectations.

- Regulatory Compliance: Buyers should ensure that products meet the specific regulatory requirements of their target markets. This includes understanding import regulations and certifications required for different regions.

- Language Barriers: Clear communication is crucial. Buyers should ensure that all documentation, including quality reports and certification details, is available in a language they understand.

By grasping the manufacturing processes and quality assurance measures associated with pet vending machines, B2B buyers can make informed decisions that align with their business needs and market demands. Investing time in understanding these aspects will ultimately enhance supplier relationships and product reliability.

Related Video: PET Plastic Bottle Manufacturing Process Step-by-Step Introduction

Comprehensive Cost and Pricing Analysis for pet vending machine Sourcing

In sourcing pet vending machines, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. This section outlines the key cost components, price influencers, and actionable tips for buyers to ensure efficient procurement.

Cost Components

-

Materials: The primary materials for pet vending machines include metal, plastics, and electronic components. The quality and source of these materials significantly affect the overall cost. Buyers should consider sourcing locally to reduce costs or opting for higher-quality materials that may incur a higher initial expense but offer durability and reliability.

-

Labor: Labor costs vary greatly by region. In countries with lower labor costs, such as certain South American or African nations, production can be more economical. However, the skill level of the workforce can influence the final product’s quality, which is vital for maintaining brand reputation.

-

Manufacturing Overhead: This encompasses costs related to facilities, utilities, and administrative expenses associated with production. Understanding these overheads can help buyers assess the pricing strategies of different suppliers.

-

Tooling: Initial tooling costs can be substantial, especially for custom designs. Buyers should inquire about these costs during negotiations, particularly if large volumes are ordered, as they may be amortized over a larger batch, lowering the unit price.

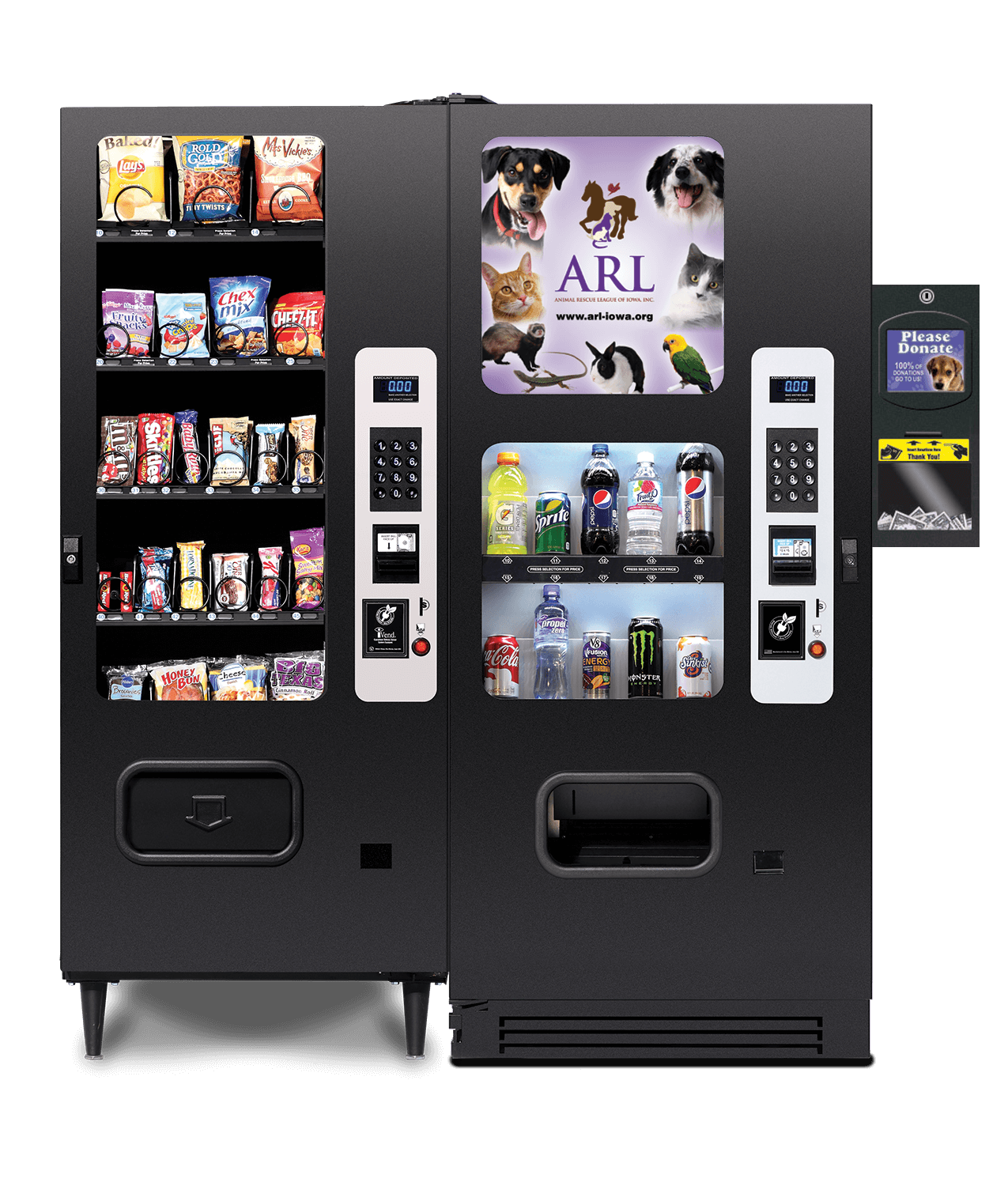

Illustrative Image (Source: Google Search)

-

Quality Control (QC): Quality assurance processes are essential, particularly for products used in public settings. Implementing robust QC measures can add to costs but are crucial for avoiding defects and ensuring customer satisfaction.

-

Logistics: Shipping and handling costs can vary significantly based on distance, mode of transportation, and local customs regulations. Understanding Incoterms is crucial to determining which party bears these costs.

-

Margin: The profit margin that suppliers build into their pricing can vary widely. Buyers should aim for transparency in pricing to understand the margin applied and negotiate accordingly.

Price Influencers

-

Volume/MOQ: Minimum Order Quantities (MOQs) can significantly affect pricing. Higher volumes typically lead to lower per-unit costs. Buyers should assess their market demand to leverage bulk discounts.

-

Specifications/Customization: Custom features can increase costs. Buyers should define their needs clearly to avoid unnecessary expenses while ensuring that the machine meets market demands.

-

Materials Quality/Certifications: High-quality materials and compliance with international safety standards can raise costs but are often necessary for market entry in regions with strict regulations.

-

Supplier Factors: The reliability, reputation, and financial stability of suppliers can influence pricing. Conducting due diligence on suppliers helps in making informed decisions.

Buyer Tips

-

Negotiation: Effective negotiation strategies can lead to better pricing and terms. Buyers should be prepared with data on market prices and competitor offerings.

-

Cost-Efficiency: Focus on the Total Cost of Ownership (TCO) rather than just the initial purchase price. Consider maintenance, operational costs, and potential downtime when evaluating options.

-

Pricing Nuances for International Buyers: International buyers must be aware of currency fluctuations, trade tariffs, and local market conditions that can affect pricing. Engaging with local experts or consultants can provide valuable insights into these factors.

-

Disclaimer for Indicative Prices: Prices for pet vending machines can vary widely based on numerous factors, including location, supplier, and specific machine configurations. It is advisable for buyers to request quotes from multiple suppliers to ensure competitive pricing and terms.

By comprehensively understanding these cost components and price influencers, international B2B buyers can make informed decisions when sourcing pet vending machines, optimizing both quality and cost-effectiveness in their procurement strategies.

Spotlight on Potential pet vending machine Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘pet vending machine’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for pet vending machine

Key Technical Properties of Pet Vending Machines

When considering the procurement of pet vending machines, understanding their technical specifications is crucial for ensuring quality, reliability, and suitability for specific market needs. Here are some essential technical properties to consider:

Illustrative Image (Source: Google Search)

-

Material Grade

– Definition: This refers to the quality of materials used in the construction of the vending machine, including metals, plastics, and glass.

– B2B Importance: High-grade materials enhance durability, reduce maintenance costs, and ensure safety, especially for food and pet-related products. Buyers should verify compliance with local regulations regarding food safety and animal welfare. -

Dimensions and Capacity

– Definition: The size of the vending machine and its storage capacity for pet products.

– B2B Importance: Understanding the dimensions helps in planning the installation space and determining how many products can be stocked. This impacts inventory management and customer satisfaction, especially in high-traffic areas. -

Power Requirements

– Definition: The electrical specifications needed to operate the machine, including voltage and energy consumption.

– B2B Importance: Proper power requirements ensure compatibility with local electrical systems, avoiding costly installation issues. Low energy consumption models are preferable for long-term operational cost savings. -

User Interface and Technology

– Definition: The technology integrated into the machine, such as touch screens, payment systems (cash, card, mobile payment), and inventory monitoring.

– B2B Importance: An intuitive user interface enhances customer experience and can lead to increased sales. Advanced technology can also reduce theft and improve stock management through real-time monitoring. -

Environmental Resistance

– Definition: The machine’s ability to withstand various environmental conditions, such as temperature fluctuations, humidity, and vandalism.

– B2B Importance: Machines that can endure harsh outdoor conditions will have a longer lifespan and require less frequent maintenance, making them more cost-effective for businesses in diverse climates. -

Safety Features

– Definition: Safety mechanisms such as emergency shut-off switches, secure locking systems, and child safety features.

– B2B Importance: Ensuring safety not only protects consumers but also shields businesses from liability issues. It’s essential for compliance with health and safety regulations.

Common Trade Terminology in the Pet Vending Machine Industry

Familiarity with industry jargon can facilitate smoother negotiations and transactions. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships can help buyers source quality components and negotiate better terms with manufacturers. -

MOQ (Minimum Order Quantity)

– Definition: The smallest number of units that a supplier is willing to sell.

– Importance: Knowing the MOQ is critical for budgeting and inventory planning. Smaller businesses may need to negotiate lower MOQs to manage cash flow effectively. -

RFQ (Request for Quotation)

– Definition: A document issued by a buyer requesting price and other terms from suppliers.

– Importance: Submitting an RFQ allows buyers to compare pricing and terms across multiple suppliers, ensuring they secure the best deal. -

Incoterms (International Commercial Terms)

– Definition: A series of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers.

– Importance: Familiarity with Incoterms is vital for international trade, as they dictate who bears the costs and risks associated with shipping, delivery, and customs clearance. -

Lead Time

– Definition: The amount of time it takes from placing an order to receiving the goods.

– Importance: Understanding lead times helps businesses manage their supply chain and inventory levels, preventing stockouts or overstock situations. -

Warranty and Service Agreements

– Definition: Contracts that outline the terms of product warranties and the services provided by the manufacturer or supplier.

– Importance: Clear warranty terms protect buyers against defects and ensure support for maintenance, crucial for long-term operational success.

Understanding these technical properties and trade terminologies can significantly enhance decision-making processes for international B2B buyers in the pet vending machine market, ultimately leading to more informed and strategic purchasing decisions.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the pet vending machine Sector

Market Overview & Key Trends

The pet vending machine sector is witnessing a robust transformation driven by several global factors. Increasing pet ownership across regions, particularly in Africa, South America, the Middle East, and Europe, is a significant driver. The rise in disposable incomes and changing lifestyles have led consumers to seek convenience and quality in pet care products. Consequently, B2B buyers are increasingly interested in sourcing innovative vending solutions that cater to this growing demand.

Emerging technologies such as IoT (Internet of Things) and AI (Artificial Intelligence) are reshaping the vending machine landscape. Smart vending machines equipped with sensors and data analytics can monitor inventory levels, streamline supply chain logistics, and enhance user experiences through personalized recommendations. These advancements enable businesses to optimize their operations and better meet consumer needs.

International buyers should also pay attention to regional trends. For instance, in Saudi Arabia, the increasing trend of pet ownership is matched by a demand for high-quality, nutritious pet food, while Brazil’s market is leaning towards eco-friendly products. Buyers must adapt their sourcing strategies to reflect local preferences and regulations, ensuring compliance and maximizing market penetration.

Sustainability & Ethical Sourcing in B2B

As sustainability becomes a central concern for consumers and businesses alike, the pet vending machine sector must prioritize ethical sourcing and environmentally friendly practices. The environmental impact of manufacturing and disposing of vending machines is significant; therefore, companies should invest in sustainable materials and processes. This includes using recyclable materials for machine construction and biodegradable packaging for pet products.

Ethical supply chains are not merely a compliance requirement but also a competitive advantage. B2B buyers are increasingly looking for suppliers who can demonstrate a commitment to sustainability through certifications such as ISO 14001 or LEED. These certifications signal to consumers that a brand values environmental responsibility, which can enhance brand loyalty and market appeal.

Moreover, incorporating local sourcing practices can reduce carbon footprints and support local economies. Businesses should consider partnerships with local suppliers of pet products to foster community relations and further their sustainability goals.

Brief Evolution/History

The concept of vending machines has evolved significantly since their inception in the early 20th century. Initially focused on simple snacks and drinks, the introduction of specialized vending machines for pet products began in the late 1990s. As pet ownership surged, these machines adapted to offer a wider range of products, including food, toys, and grooming supplies.

In recent years, the integration of technology has further revolutionized the sector, allowing for enhanced user experiences and operational efficiencies. Today, pet vending machines are not just automated retail points; they represent a fusion of convenience, technology, and sustainability, positioning themselves as essential components in the evolving landscape of pet care.

For B2B buyers, understanding this evolution is critical for identifying innovative solutions that meet both current market demands and future trends.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of pet vending machine

-

What should I consider when vetting suppliers for pet vending machines?

When vetting suppliers, prioritize those with a proven track record in the pet vending machine industry. Check their business credentials, customer reviews, and certifications. Request references from previous clients, and ensure they have experience in your target market. Look for suppliers who provide transparency regarding their production processes, quality control measures, and after-sales support. Consider visiting their facilities if possible, as this can provide valuable insights into their operational capabilities and standards. -

Can I customize the pet vending machines to suit my market needs?

Yes, many suppliers offer customization options to cater to specific market demands. You can request modifications in design, size, product offerings, and branding. Discuss your preferences regarding features such as payment systems, touchscreen interfaces, and product selections tailored to local pet ownership trends. Ensure that any customizations are feasible within your budget and timeline, and confirm with the supplier how these changes will impact the overall lead time and costs. -

What are the typical minimum order quantities (MOQs) and lead times for pet vending machines?

MOQs can vary widely depending on the supplier and the level of customization required. Generally, expect MOQs to range from 10 to 50 units. Lead times also vary, typically spanning from 4 to 12 weeks after order confirmation. It’s crucial to discuss these details upfront with potential suppliers, as they can significantly impact your inventory planning and cash flow. Always account for potential delays in logistics and customs clearance, especially when importing from overseas. -

What payment terms are commonly accepted by suppliers?

Payment terms can differ significantly among suppliers. Many accept a combination of upfront payments and payment upon delivery or installation. Standard practices include a 30% deposit upon order confirmation and the remaining balance before shipment. Negotiate terms that align with your financial capabilities, and ensure you have a clear understanding of any additional costs, such as shipping or customs duties. Consider using secure payment methods or escrow services to mitigate risks associated with international transactions. -

How can I ensure the quality of the pet vending machines I purchase?

To ensure quality, request samples before finalizing your order. Verify that the machines meet international safety and quality standards, such as CE or ISO certifications. Ask suppliers for their quality assurance processes, including any third-party inspections they may conduct. Establish a clear agreement on quality expectations and potential remedies if the products do not meet these standards. Regular communication during production can also help address any concerns early. -

What certifications should I look for in pet vending machines?

Key certifications to look for include CE marking for compliance with European health, safety, and environmental protection standards, and ISO certification for quality management systems. Depending on your region, you may also need to verify compliance with local regulations regarding electronic devices. Ensure that the supplier can provide documentation for all relevant certifications, which can be crucial for customs clearance and market entry. -

What logistics considerations should I keep in mind when importing pet vending machines?

When importing, consider shipping methods, costs, and delivery timelines. Choose a reliable logistics partner experienced in handling bulky or sensitive equipment. Be aware of customs regulations in your country, including tariffs and import duties, and ensure all paperwork is prepared in advance to avoid delays. Additionally, establish a clear delivery schedule with your supplier to coordinate logistics effectively and minimize storage costs upon arrival. -

How should I handle disputes with suppliers?

Dispute resolution should be addressed in your contract with the supplier. Include clauses that outline procedures for handling disagreements, such as mediation or arbitration. Maintain clear and professional communication to resolve issues amicably, and document all correspondence. If the dispute cannot be resolved, refer to the agreed-upon dispute resolution method in your contract. Building a good relationship with your supplier can often help prevent disputes from escalating.

Strategic Sourcing Conclusion and Outlook for pet vending machine

As the pet vending machine market continues to evolve, strategic sourcing emerges as a pivotal strategy for international B2B buyers. By understanding regional preferences and leveraging local partnerships, businesses can enhance their supply chain efficiency and product offerings. Investing in reliable suppliers who prioritize quality and innovation will not only meet the growing demand for pet products but also ensure sustainability and compliance with local regulations.

Key takeaways include the importance of market research to identify consumer trends, the need for robust supplier relationships, and the potential for technology integration to streamline operations. Buyers should also consider the benefits of diversifying their product range to cater to different markets, especially in regions like Africa and South America, where pet ownership is on the rise.

Looking ahead, the pet vending machine sector presents a wealth of opportunities. International B2B buyers are encouraged to take proactive steps in sourcing strategies that align with their business goals. By doing so, they can not only capitalize on emerging trends but also position themselves as leaders in a competitive marketplace. The future is bright for those who invest wisely in this innovative sector.