Master Sourcing Vending Machine Toys Bulk for Maximum

Guide to Vending Machine Toys Bulk

- Introduction: Navigating the Global Market for vending machine toys bulk

- Understanding vending machine toys bulk Types and Variations

- Key Industrial Applications of vending machine toys bulk

- Strategic Material Selection Guide for vending machine toys bulk

- In-depth Look: Manufacturing Processes and Quality Assurance for vending machine toys bulk

- Comprehensive Cost and Pricing Analysis for vending machine toys bulk Sourcing

- Spotlight on Potential vending machine toys bulk Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for vending machine toys bulk

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the vending machine toys bulk Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of vending machine toys bulk

- Strategic Sourcing Conclusion and Outlook for vending machine toys bulk

Introduction: Navigating the Global Market for vending machine toys bulk

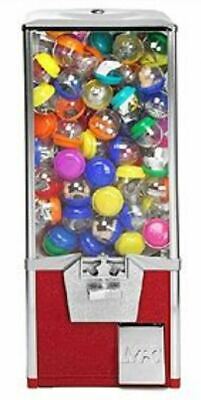

In today’s global economy, vending machine toys represent a vibrant and lucrative niche within the retail sector. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the dynamics of sourcing these products in bulk is essential. Vending machine toys not only captivate consumers of all ages but also serve as effective marketing tools that can enhance brand visibility and customer engagement.

This comprehensive guide delves into the critical aspects of the vending machine toys market, offering insights on various types of toys, materials used, and the manufacturing processes involved. Buyers will find detailed information on quality control measures and the importance of sourcing from reputable suppliers to ensure product safety and compliance with international standards. Furthermore, the guide provides an overview of pricing structures, market trends, and potential profit margins, helping businesses make informed purchasing decisions.

By addressing frequently asked questions and common challenges faced in the industry, this guide empowers B2B buyers to navigate the complexities of the global market confidently. Whether you’re a retailer looking to enhance your product offerings or a distributor aiming to expand your inventory, understanding the vending machine toy market is pivotal for success. Equip yourself with the knowledge to capitalize on this growing segment and drive your business forward.

Understanding vending machine toys bulk Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Capsule Toys | Small, collectible figures often in plastic capsules | Arcades, family entertainment centers | Pros: Affordable, high demand; Cons: Limited lifespan, may require frequent restocking. |

| Plush Toys | Soft, stuffed animals available in various sizes | Toy stores, amusement parks | Pros: High perceived value, appealing to younger audiences; Cons: Higher upfront cost, takes up more space. |

| Educational Toys | Toys designed to promote learning and skill development | Schools, daycare centers | Pros: Supports educational initiatives, encourages repeat purchases; Cons: Requires careful selection to match educational goals. |

| Novelty Items | Unique and quirky toys that stand out in the market | Festivals, events, promotional giveaways | Pros: Attracts attention, can create brand loyalty; Cons: May not have broad appeal, inventory turnover can be unpredictable. |

| Themed Merchandise | Toys based on popular franchises or themes | Retail stores, themed attractions | Pros: Taps into existing fan bases, high resale potential; Cons: Licensing fees can be expensive, market trends can change rapidly. |

Capsule Toys

Capsule toys are small, often collectible figures encased in plastic capsules, typically dispensed by vending machines. Their compact size and low price point make them highly appealing to children and collectors alike. B2B buyers should consider the demand for specific themes or characters, as trends can significantly influence sales. Regular restocking is essential due to their high turnover rate, making efficient supply chain management crucial.

Plush Toys

Plush toys are soft, cuddly items available in various sizes and styles, making them a popular choice for vending machines in family-friendly environments. Their high perceived value and emotional appeal can lead to increased sales. However, buyers should be aware of the higher upfront costs and the space required for display. It’s essential to curate a selection that resonates with the target audience, particularly in locations like amusement parks or toy stores.

Educational Toys

Educational toys are designed to enhance learning and skill development, making them suitable for venues such as schools and daycare centers. These toys can promote cognitive skills and are often favored by parents looking for constructive play options for their children. B2B buyers should focus on selecting toys that align with educational goals and market demands. While they can encourage repeat purchases, careful curation is necessary to ensure relevance and effectiveness.

Novelty Items

Novelty items are quirky and unique toys that tend to attract attention in vending machines, especially during events and festivals. These products can create brand loyalty and engage customers through their distinctiveness. However, B2B buyers should consider the potential for limited appeal and unpredictable inventory turnover. Effective marketing strategies can help to boost visibility and sales in this category.

Themed Merchandise

Themed merchandise consists of toys based on popular franchises, characters, or themes, making them ideal for retail stores and themed attractions. This type of toy can leverage existing fan bases and often has a high resale potential. Buyers should be cautious of licensing fees that can increase costs and the need to stay updated on market trends, as consumer interests can shift rapidly. Successful purchasing in this category requires a keen understanding of current trends and audience preferences.

Related Video: What are Transformer Models and how do they work?

Key Industrial Applications of vending machine toys bulk

| Industry/Sector | Specific Application of vending machine toys bulk | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Enhancing customer engagement in stores | Increases foot traffic and impulse purchases | Product variety, seasonal relevance, supplier reliability |

| Education | Reward systems in schools | Motivates students and encourages participation | Safety standards, educational value, compliance with regulations |

| Entertainment & Leisure | Attractions in amusement parks | Provides a fun experience, encourages repeat visits | Licensing agreements, product novelty, durability |

| Hospitality | Guest rewards in hotels | Enhances guest experience and loyalty | Custom branding options, quality assurance, supply chain efficiency |

| Events & Promotions | Giveaways at trade shows and exhibitions | Drives engagement, enhances brand visibility | Customization options, lead time, supplier flexibility |

Retail

In the retail sector, vending machine toys can significantly enhance customer engagement. By placing these machines strategically in stores, businesses can attract foot traffic and stimulate impulse purchases. These toys often appeal to children and collectors, creating a fun shopping atmosphere. International buyers should consider product variety and seasonal relevance to align with local market trends, ensuring that the toys resonate with their target audience.

Education

Vending machine toys are increasingly being used in educational settings as part of reward systems. Schools utilize these toys to motivate students and encourage participation in various activities, such as reading programs or sports events. Buyers in this sector must prioritize safety standards and educational value when sourcing these toys, as well as compliance with local regulations to ensure a safe environment for children.

Entertainment & Leisure

In amusement parks, vending machine toys serve as attractions that enhance the visitor experience. These toys can range from themed merchandise to collectible items tied to park characters or events. The presence of these machines not only provides entertainment but also encourages repeat visits. Buyers should focus on licensing agreements to ensure authenticity, along with product novelty and durability to withstand outdoor conditions.

Hospitality

Hotels and resorts can leverage vending machine toys as guest rewards, enhancing the overall experience and fostering loyalty. These toys can be used as part of promotional packages or loyalty programs, appealing to families traveling with children. When sourcing, businesses should look for custom branding options to align with their brand identity, ensuring quality assurance and supply chain efficiency to maintain a consistent guest experience.

Events & Promotions

At trade shows and exhibitions, vending machine toys can be effective giveaways that drive engagement and enhance brand visibility. By offering unique and appealing toys, businesses can attract potential customers and create memorable interactions. Key considerations for international buyers include customization options to reflect brand messaging, lead time for production, and supplier flexibility to accommodate varying event schedules.

Related Video: I Built the ULTIMATE LEGO VENDING Machine!!

Strategic Material Selection Guide for vending machine toys bulk

When selecting materials for vending machine toys, international B2B buyers must consider various factors that affect performance, safety, and compliance with regional standards. The following analysis covers four common materials used in vending machine toys, detailing their properties, advantages, disadvantages, and specific considerations for buyers in Africa, South America, the Middle East, and Europe.

1. Plastic (Polypropylene and Polyethylene)

Key Properties:

Plastics like polypropylene (PP) and polyethylene (PE) are lightweight, resistant to moisture, and have good impact strength. They can withstand a wide range of temperatures, making them suitable for various environments.

Pros & Cons:

Plastics are cost-effective and easy to mold, allowing for intricate designs. However, they may not be as durable as other materials and can degrade under UV exposure if not treated. Additionally, they can be less environmentally friendly, raising concerns among eco-conscious consumers.

Impact on Application:

Plastics are compatible with most media used in vending machines. However, specific grades should be selected based on the intended use, particularly for toys that may come into contact with food or beverages.

Considerations for Buyers:

Buyers should ensure that the plastics used comply with international safety standards, such as ASTM F963 for toy safety. Different regions may have varying regulations regarding the use of certain plastics, particularly concerning phthalates and BPA.

2. Metal (Zinc Alloy)

Key Properties:

Zinc alloys offer excellent strength and durability, with good corrosion resistance when properly coated. They can withstand high pressures, making them suitable for toys requiring robust construction.

Pros & Cons:

The primary advantage of zinc alloys is their durability and aesthetic appeal, as they can be plated for a shiny finish. However, they are heavier and more expensive than plastics, which may increase shipping costs. Manufacturing complexity is also higher due to the need for casting and finishing processes.

Impact on Application:

Zinc alloys are suitable for toys that require a metallic finish or added weight. They are generally safe for children but should be inspected for sharp edges or small parts that could pose choking hazards.

Considerations for Buyers:

International buyers should verify that zinc alloys meet local safety standards, such as EN 71 in Europe, which regulates toy safety. Understanding the alloy composition is essential to ensure compliance with regulations regarding heavy metals.

3. Rubber (Thermoplastic Rubber)

Key Properties:

Thermoplastic rubber (TPR) combines the properties of rubber and plastic, offering flexibility, resilience, and a soft touch. It can withstand a range of temperatures and is resistant to wear and tear.

Pros & Cons:

TPR is ideal for toys that require a soft feel and flexibility, making them safer for younger children. However, it can be more expensive than traditional plastics and may have limited color retention over time.

Impact on Application:

This material is suitable for toys that are designed to be squeezed or manipulated. It is also compatible with various media, but buyers should ensure that the TPR used is non-toxic and compliant with safety standards.

Considerations for Buyers:

Buyers must check for certifications like ASTM D4236, which indicates non-toxicity. Additionally, TPR should meet specific regional standards for toys, especially in markets with stringent safety regulations.

4. Wood (Bamboo and Plywood)

Key Properties:

Wood materials, particularly bamboo and plywood, are strong, biodegradable, and provide a natural aesthetic. They can withstand moderate pressure and have good thermal stability.

Pros & Cons:

Wood is environmentally friendly and offers a unique tactile experience. However, it can be susceptible to moisture and pests, requiring proper treatment. Additionally, manufacturing wooden toys can be more labor-intensive and costly.

Impact on Application:

Wooden toys are often favored for their durability and safety. They are suitable for applications where a natural look is preferred but may not be ideal for environments with high humidity.

Considerations for Buyers:

International buyers should ensure that wood products comply with regulations regarding sustainable sourcing and treatment for pest resistance. Certifications like FSC (Forest Stewardship Council) can enhance marketability in eco-conscious regions.

Summary Table

| Material | Typical Use Case for vending machine toys bulk | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic (Polypropylene/PE) | General toys, small figurines | Cost-effective, lightweight | Less durable, UV degradation | Low |

| Metal (Zinc Alloy) | Collectible items, keychains | Durable, aesthetic appeal | Heavier, higher manufacturing cost | Med |

| Rubber (Thermoplastic Rubber) | Soft toys, stress balls | Flexible, safe for children | More expensive, limited color retention | Med |

| Wood (Bamboo/Plywood) | Eco-friendly toys, educational items | Biodegradable, unique aesthetic | Susceptible to moisture, costly | High |

This strategic material selection guide provides a comprehensive overview for international B2B buyers, ensuring informed decisions that align with product performance, safety standards, and market preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for vending machine toys bulk

The manufacturing processes and quality assurance protocols for vending machine toys are critical components for B2B buyers, particularly in international markets such as Africa, South America, the Middle East, and Europe. This section outlines the typical stages of manufacturing, key techniques employed, and the relevant quality control measures that ensure the final products meet both safety and quality standards.

Manufacturing Process Overview

The production of vending machine toys typically involves several key stages, each crucial for ensuring the durability, safety, and appeal of the final product.

1. Material Preparation

The first step in the manufacturing process is the preparation of raw materials. Common materials include plastics, rubber, and sometimes metal.

- Material Selection: It is essential to choose non-toxic, child-safe materials, especially for toys aimed at younger audiences.

- Supplier Verification: Buyers should ensure that suppliers provide Material Safety Data Sheets (MSDS) that outline the properties and safety of these materials.

2. Forming

Once materials are prepared, the next stage involves forming the toys into their desired shapes.

- Injection Molding: This is the most common technique used, where molten plastic is injected into molds to create the toy shapes.

- Blow Molding: Used for hollow toys, this technique involves inflating a heated plastic tube into a mold.

- Rotational Molding: This is used for larger toys, where powdered plastic is heated in a mold that rotates, evenly distributing the material.

3. Assembly

After forming, the toys may require assembly, particularly if they consist of multiple parts.

- Automated Assembly Lines: These are often employed for efficiency, especially for high-volume orders.

- Manual Assembly: For more intricate designs, skilled labor may be necessary to ensure precision and quality.

4. Finishing

The final stage involves finishing touches to enhance the toy’s appeal and safety.

- Surface Treatment: This may include painting, applying decals, or adding textures.

- Quality Checks: This stage often includes visual inspections to ensure that the toys meet aesthetic standards.

Quality Assurance Protocols

Quality assurance is vital in the manufacturing of vending machine toys, particularly to comply with international standards and consumer safety regulations.

Relevant International Standards

International standards play a critical role in ensuring the safety and quality of toys. Key standards include:

- ISO 9001: This standard focuses on quality management systems and ensures that manufacturers maintain consistent quality.

- EN 71: This European standard specifically addresses safety requirements for toys, covering aspects like mechanical safety, flammability, and chemical properties.

- CE Marking: Products sold in Europe must have CE marking, indicating compliance with relevant safety directives.

Quality Control Checkpoints

Quality control (QC) involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during production ensures that any defects are caught early.

- Final Quality Control (FQC): This final inspection checks the finished products against quality standards before packaging.

Common Testing Methods

Several testing methods are employed to ensure that toys meet safety and quality standards:

- Mechanical Testing: Assessing the toy’s durability and strength, especially for parts that may break off.

- Chemical Testing: Ensuring that materials are free from harmful substances, such as heavy metals or phthalates.

- Flammability Testing: Evaluating how the toy behaves when exposed to flames.

Verification of Supplier Quality Control

For B2B buyers, particularly those operating in diverse international markets, verifying a supplier’s quality control processes is crucial.

- Supplier Audits: Conducting regular audits of suppliers can help ensure that they adhere to required standards and practices. Buyers should establish clear audit criteria based on international standards.

- Quality Reports: Requesting detailed quality reports and certificates from suppliers provides insights into their quality assurance processes and any testing performed.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the products before shipment, ensuring compliance with safety standards.

Navigating Quality Control Nuances

International buyers should be aware of specific nuances in quality control that may vary by region:

- Regional Regulations: Different countries may have varying regulations regarding toy safety. For example, the U.S. Consumer Product Safety Commission (CPSC) has stringent regulations that differ from those in Europe.

- Cultural Considerations: In markets like Africa and South America, local preferences and safety concerns may affect the types of toys produced and the materials used.

- Documentation and Certification: Buyers should ensure that all necessary documentation, such as compliance certificates and test reports, accompany shipments to avoid customs issues.

By understanding the manufacturing processes and quality assurance measures relevant to vending machine toys, international B2B buyers can make informed purchasing decisions, ensuring they source safe and high-quality products for their markets.

Related Video: Production’s process in Miniland – How we make our toys?

Comprehensive Cost and Pricing Analysis for vending machine toys bulk Sourcing

When sourcing vending machine toys in bulk, understanding the comprehensive cost structure and pricing dynamics is essential for international buyers. This analysis will help you navigate the complexities of sourcing, ensuring you make informed decisions that enhance profitability and efficiency.

Cost Components

-

Materials: The primary cost driver in vending machine toys is the raw materials used in production. Common materials include plastics, rubber, and occasionally electronics for more complex toys. Fluctuations in material prices can significantly impact overall costs, so it’s prudent to source from suppliers who can provide stable pricing or long-term contracts.

-

Labor: Labor costs vary greatly depending on the manufacturing location. Countries in Asia may offer lower labor costs compared to those in Europe or North America. When negotiating, consider the skill level required for production; higher-skilled labor might lead to higher quality toys but at increased costs.

-

Manufacturing Overhead: This includes utilities, maintenance, and other indirect costs associated with production. Understanding a supplier’s overhead can provide insights into their pricing structure and help identify potential areas for negotiation.

-

Tooling: If custom molds or tooling are required for specific toy designs, these costs must be factored into the overall pricing. Tooling can be a significant upfront investment but may reduce per-unit costs in the long run through economies of scale.

-

Quality Control (QC): Ensuring product quality is critical, especially for toys. Implementing a robust QC process may incur additional costs but can prevent costly recalls and damage to your brand reputation.

-

Logistics: Freight and shipping costs can vary significantly based on the origin of the toys and your delivery location. Consider the total shipping time and cost, including tariffs and customs duties, which can affect your pricing structure.

-

Margin: Finally, suppliers will add a profit margin to their costs. Understanding the typical margins in the industry can help you evaluate whether a supplier’s pricing is competitive.

Price Influencers

Several factors can influence the pricing of vending machine toys:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes often lead to lower per-unit costs. Suppliers may offer discounts for bulk purchases, making it beneficial to consolidate orders whenever possible.

-

Specifications/Customization: Custom designs or unique features can increase costs. Clearly define your specifications to avoid unexpected charges.

-

Materials: The choice of materials impacts not only cost but also the perceived value of the toys. Eco-friendly or high-quality materials may command higher prices.

-

Quality/Certifications: Products with certifications (e.g., CE, ASTM) may be priced higher due to the assurance of safety and compliance, which is particularly important for toys.

-

Supplier Factors: The supplier’s reputation, reliability, and production capacity can all influence pricing. Conduct thorough due diligence to assess potential partners.

-

Incoterms: Understanding shipping terms (e.g., FOB, CIF) is crucial as they determine responsibility for shipping costs and risks, which can affect total landed costs.

Buyer Tips

-

Negotiation: Engage suppliers in negotiation to secure better pricing. Highlight potential long-term partnerships to motivate suppliers to offer favorable terms.

-

Cost-Efficiency: Consider the total cost of ownership rather than just initial pricing. Assess all associated costs, including logistics and quality assurance, to get a clearer picture of your expenditure.

-

Pricing Nuances: Be aware of regional pricing strategies. In markets like Africa and South America, local suppliers may offer competitive rates but may lack the quality assurance seen in established suppliers from Europe or Asia.

-

Disclaimer for Indicative Prices: Always remember that prices can fluctuate based on market conditions, currency exchange rates, and geopolitical factors. Request updated quotes frequently to ensure you are operating with the most current pricing.

By understanding these components and influencers, international B2B buyers can better navigate the complexities of sourcing vending machine toys in bulk, ultimately leading to smarter purchasing decisions and improved profitability.

Spotlight on Potential vending machine toys bulk Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘vending machine toys bulk’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for vending machine toys bulk

Vending machine toys are a popular commodity in the B2B market, particularly for businesses looking to enhance customer engagement. Understanding the essential technical properties and industry terminology is crucial for international buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe. This knowledge can facilitate informed purchasing decisions and effective negotiations.

Key Technical Properties

-

Material Grade

– The quality of materials used in vending machine toys is paramount. Common materials include plastic (such as ABS and PVC) and rubber. Higher-grade materials ensure durability and safety, which is vital for compliance with international safety standards. Buyers should prioritize suppliers who provide certifications confirming material quality. -

Size and Tolerance

– The dimensions of the toys must adhere to specific tolerances to ensure they fit properly in vending machines. Typical tolerances might range from ±0.5mm to ±1mm. Understanding these specifications helps in selecting toys that not only fit the machine but also appeal to the target demographic, enhancing customer satisfaction. -

Safety Standards

– Compliance with safety regulations (e.g., EN71 in Europe, ASTM F963 in the USA) is critical. These standards govern the safety of toys, including the absence of harmful chemicals and small parts that pose choking hazards. Buyers should request safety test reports to ensure that the toys meet the necessary regulations for their respective markets. -

Packaging Specifications

– Proper packaging is essential for protection during shipping and to attract consumers. Specifications might include dimensions, weight, and materials used for packaging. Efficient packaging can also influence shipping costs and shelf appeal, making it a significant consideration for B2B buyers. -

Color and Design Customization

– Customization options for colors and designs can significantly impact marketability. Buyers should inquire about the supplier’s capabilities for producing customized designs that align with their brand identity or marketing strategies.

Common Trade Terms

- OEM (Original Equipment Manufacturer)

– This term refers to companies that manufacture products based on the specifications provided by another company, typically a brand owner. For buyers, partnering with an OEM can result in tailored products that meet specific market needs.

Illustrative Image (Source: Google Search)

-

MOQ (Minimum Order Quantity)

– MOQ indicates the smallest quantity of product that a supplier is willing to sell. Understanding MOQ is essential for buyers to plan their inventory effectively and ensure that they meet the supplier’s requirements for cost-effectiveness. -

RFQ (Request for Quotation)

– An RFQ is a document that buyers send to suppliers to solicit price quotes for specific products. This process helps businesses compare prices and terms from multiple suppliers, facilitating better negotiation outcomes. -

Incoterms

– Incoterms (International Commercial Terms) are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms helps buyers understand their obligations and manage risk in international transactions. -

Lead Time

– This term refers to the amount of time it takes from placing an order to receiving the goods. Understanding lead times is crucial for inventory management and planning, particularly for seasonal businesses or promotions.

By being well-versed in these technical properties and trade terminologies, international B2B buyers can navigate the vending machine toy market more effectively, ensuring they make informed decisions that align with their business objectives.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the vending machine toys bulk Sector

Market Overview & Key Trends

The global market for vending machine toys is currently experiencing a dynamic shift, driven by several factors that influence B2B purchasing decisions. Firstly, the rise of e-commerce and digital platforms has transformed sourcing strategies, enabling international buyers from regions such as Africa, South America, the Middle East, and Europe to access a broader range of products and suppliers. This digital transition allows for real-time price comparisons, supplier evaluations, and streamlined logistics, making it easier for businesses to identify the best deals.

Emerging trends include the growing demand for customizable toys that cater to local preferences and cultural nuances. Buyers are increasingly looking for products that resonate with their target demographics, thus requiring suppliers to offer a diverse range of options. Additionally, technology integration, such as data analytics and AI, is becoming pivotal in inventory management and consumer behavior analysis, helping businesses optimize stock levels and enhance customer satisfaction.

Market dynamics are also influenced by changing consumer preferences towards sustainability and ethical sourcing. International buyers are now prioritizing suppliers who demonstrate a commitment to social responsibility, which is reshaping procurement strategies across the globe. Companies that adapt to these trends and invest in sustainable practices will likely gain a competitive edge in the market.

Sustainability & Ethical Sourcing in B2B

Sustainability has emerged as a critical concern in the vending machine toys sector, with significant implications for international B2B buyers. The environmental impact of toy production—often involving plastic and non-biodegradable materials—has prompted a shift towards greener alternatives. Buyers are increasingly seeking suppliers who use eco-friendly materials, such as recycled plastics and organic textiles, to align with their corporate social responsibility goals.

Ethical sourcing is equally important, as businesses strive to ensure that their supply chains are free from labor exploitation and environmental degradation. Certifications such as Fair Trade, ISO 14001 (Environmental Management), and the Global Organic Textile Standard (GOTS) are becoming essential benchmarks for evaluating suppliers. By partnering with certified manufacturers, companies can enhance their brand reputation and meet the growing consumer demand for ethically produced goods.

Moreover, implementing sustainable practices can lead to cost savings in the long run. For instance, investing in energy-efficient production processes not only reduces carbon footprints but can also lower operational costs, making it a financially sound choice for B2B buyers.

Brief Evolution/History

The vending machine toys industry has evolved significantly over the past few decades. Originally characterized by simple, inexpensive trinkets, the sector has transformed into a competitive marketplace driven by innovation and consumer engagement. The introduction of capsule vending machines in the late 20th century marked a pivotal moment, allowing for a diverse array of toys that appealed to children and collectors alike.

As the market matured, the focus shifted towards quality and variety, with manufacturers beginning to incorporate popular culture trends into their offerings. This evolution has been fueled by technological advancements, enabling the production of high-quality, collectible items that resonate with consumers. Today, the industry is not only about selling toys but also about creating experiences that foster brand loyalty and consumer engagement, setting the stage for further growth and innovation in the years to come.

Related Video: What global trade deals are really about (hint: it’s not trade) | Haley Edwards | TEDxMidAtlantic

Frequently Asked Questions (FAQs) for B2B Buyers of vending machine toys bulk

-

What should I consider when vetting suppliers for vending machine toys?

When vetting suppliers, prioritize their experience in the industry, customer reviews, and certifications. Check if they specialize in vending machine toys and request samples to evaluate quality. It’s also beneficial to verify their compliance with international safety standards, especially if you are sourcing from regions with different regulations. Establish clear communication to assess their responsiveness and reliability in handling inquiries and orders. -

Can I customize the toys for my vending machines?

Yes, many suppliers offer customization options for vending machine toys. You can discuss specific designs, colors, and branding to align with your business needs. Ensure you clarify the minimum order quantity (MOQ) for custom items, as it may differ from standard products. Engaging in early discussions about customization can help you align expectations and timelines effectively. -

What are typical minimum order quantities (MOQ) and lead times?

MOQs for vending machine toys can vary widely depending on the supplier and the type of toys. Generally, expect an MOQ of 500 to 1,000 units for standard toys. Lead times also depend on customization; standard products may take 2-4 weeks, while customized orders could take 6-12 weeks. Always confirm these details upfront to avoid delays in your supply chain.

Illustrative Image (Source: Google Search)

-

What payment methods are commonly accepted in international transactions?

Most suppliers accept various payment methods, including bank transfers, PayPal, and letters of credit. It’s essential to discuss payment terms before finalizing your order. Consider using escrow services for large transactions to ensure security. Additionally, clarify if there are any upfront deposits required and the schedule for subsequent payments to maintain cash flow. -

How can I ensure quality assurance and certifications for the toys?

Request detailed information about the quality assurance processes your suppliers follow. Ask for relevant certifications such as EN71 (for Europe), ASTM (for the U.S.), or other local safety regulations applicable to your region. Some suppliers might provide inspection reports or third-party testing results to assure you of compliance. Regular audits of suppliers can also help maintain quality standards. -

What logistics considerations should I be aware of when importing toys?

When importing vending machine toys, consider shipping options, customs regulations, and duties. Discuss with your supplier whether they handle logistics or if you need to arrange shipping separately. Familiarize yourself with incoterms to understand who is responsible for costs and risks at each stage of the shipping process. Plan for potential delays at customs by ensuring all documentation is correctly prepared. -

How can I handle disputes with suppliers effectively?

To manage disputes, establish clear terms in your contract regarding quality, delivery timelines, and payment. Maintain open lines of communication with your supplier to resolve issues quickly. If a dispute arises, document all interactions and agreements. Consider mediation or arbitration if direct negotiations fail, and ensure that any legal recourse aligns with international trade laws applicable to your transaction.

- What are the common trends in vending machine toys that I should be aware of?

Stay informed about current trends, such as eco-friendly toys or licensed merchandise, which can attract more customers. Monitor market preferences in your target regions, as they may differ significantly. Attending trade shows and industry events can provide insights into new products and innovations. Engaging with online communities or forums can also help you gauge consumer interests and competitor strategies.

Strategic Sourcing Conclusion and Outlook for vending machine toys bulk

As the vending machine toys market continues to evolve, international B2B buyers must prioritize strategic sourcing to ensure competitiveness and sustainability. Key takeaways from this guide emphasize the importance of understanding local market preferences, leveraging supplier relationships, and optimizing inventory management. By focusing on these aspects, businesses can enhance their product offerings and meet the diverse needs of consumers across different regions.

Strategic sourcing not only improves cost-efficiency but also fosters innovation through collaboration with suppliers. This is particularly crucial for buyers in Africa, South America, the Middle East, and Europe, where cultural nuances and consumer behaviors can significantly influence purchasing decisions.

Looking ahead, international buyers should remain agile and responsive to market changes. Engaging in continuous research and development, as well as exploring emerging trends like eco-friendly products, will be vital for long-term success.

Call to Action: Embrace strategic sourcing practices today to position your business for growth in the vending machine toys sector. By aligning with the right partners and remaining attuned to market dynamics, you can unlock new opportunities and enhance your competitive edge in the global marketplace.