Master Sourcing Vending Machine Lock Picks for Enhanced

Guide to Vending Machine Lock Pick

- Introduction: Navigating the Global Market for vending machine lock pick

- Understanding vending machine lock pick Types and Variations

- Key Industrial Applications of vending machine lock pick

- Strategic Material Selection Guide for vending machine lock pick

- In-depth Look: Manufacturing Processes and Quality Assurance for vending machine lock pick

- Comprehensive Cost and Pricing Analysis for vending machine lock pick Sourcing

- Spotlight on Potential vending machine lock pick Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for vending machine lock pick

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the vending machine lock pick Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of vending machine lock pick

- Strategic Sourcing Conclusion and Outlook for vending machine lock pick

Introduction: Navigating the Global Market for vending machine lock pick

Navigating the global market for vending machine lock picks is essential for international B2B buyers aiming to enhance their operational security and efficiency. As the demand for vending machines continues to rise across diverse regions—especially in Africa, South America, the Middle East, and Europe—the importance of reliable locking mechanisms cannot be overstated. These lock picks are not merely tools; they are pivotal in ensuring access control, theft prevention, and operational continuity.

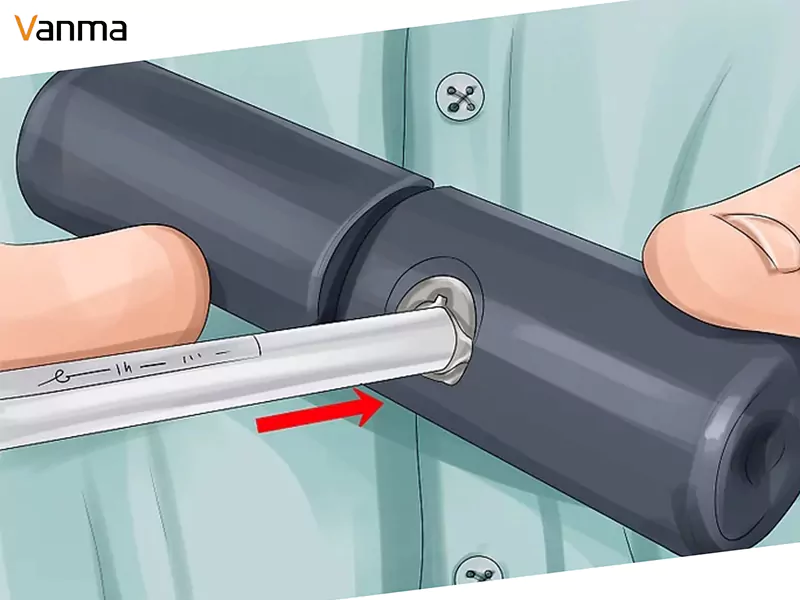

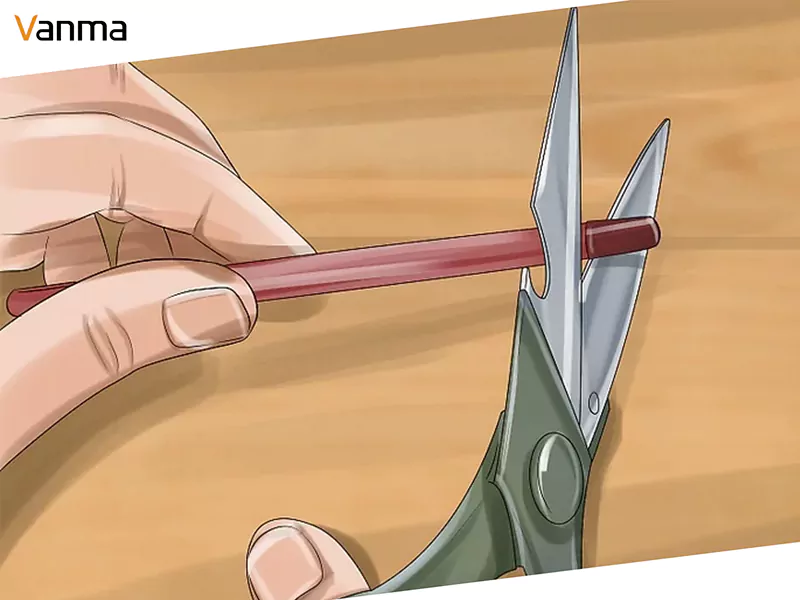

Illustrative Image (Source: Google Search)

This comprehensive guide delves into the multifaceted world of vending machine lock picks, offering insights into various types and materials available in the market. By exploring aspects such as manufacturing quality control, supplier evaluations, and cost considerations, buyers can make informed decisions that align with their business needs. Additionally, the guide addresses the current market landscape, equipping purchasers with the knowledge to navigate potential challenges and opportunities effectively.

For B2B buyers, particularly those operating in regions like Poland and South Africa, understanding the intricacies of vending machine lock picks can empower better sourcing strategies. This guide is designed to foster informed decision-making, enabling you to select the most suitable products that meet security standards while also being cost-effective. With FAQs addressing common concerns, buyers will find the information necessary to optimize their procurement processes, ensuring that their investments yield maximum security and value.

Understanding vending machine lock pick Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Lock Pick | Basic design for most vending machines | General vending machine services | Pros: Cost-effective, widely available. Cons: Limited functionality with advanced locks. |

| Electronic Lock Pick | Uses electronic signals to unlock | High-security vending operations | Pros: Enhanced security, remote access. Cons: Requires power source, potential for technical issues. |

| Combination Lock Pick | Multi-digit combination for security | High-value product dispensing | Pros: Increased security, customizable codes. Cons: Complexity may deter quick access. |

| Bypass Tool | Specialized for bypassing specific locks | Emergency access situations | Pros: Quick access in emergencies. Cons: Risk of damage to locking mechanism. |

| RFID Lock Pick | Utilizes RFID technology for unlocking | Modern vending solutions | Pros: Seamless access, integration with smart systems. Cons: Requires compatible locks, higher cost. |

Standard Lock Pick

The standard lock pick is designed for conventional vending machines, featuring a simple mechanism that allows for ease of use. These tools are generally suitable for businesses that operate a variety of vending machines without advanced locking systems. When purchasing, buyers should consider the availability of these picks in local markets and their compatibility with existing machines. The affordability and straightforward design make them a popular choice, but they may not be effective against more sophisticated locking mechanisms.

Electronic Lock Pick

Electronic lock picks represent a modern solution for securing vending machines, utilizing electronic signals to unlock. These picks are particularly beneficial for businesses that require higher security, such as those dispensing high-value items. Buyers must ensure that their vending machines are compatible with electronic locking systems, and they should also consider the need for a reliable power source. While these tools enhance security and allow for remote access, they may also introduce potential technical issues that require maintenance.

Combination Lock Pick

Combination lock picks are designed for vending machines that use multi-digit codes for access. This type of pick is ideal for businesses that prioritize security and wish to customize access codes. When considering a purchase, B2B buyers should evaluate the complexity of the combination mechanism, as a more intricate design may complicate access for users. The increased security is a significant advantage, but the complexity can also deter quick access, especially in high-traffic situations.

Bypass Tool

Bypass tools are specialized devices that enable users to quickly bypass specific locking mechanisms in emergencies. These tools are invaluable for businesses that may need immediate access to their machines, such as during maintenance or in the event of a malfunction. Buyers should weigh the benefits of quick access against the potential risk of damaging the locking mechanism. While they serve a critical function in urgent scenarios, the use of bypass tools may require additional training for staff to avoid unintended damage.

RFID Lock Pick

RFID (Radio-Frequency Identification) lock picks leverage advanced technology to unlock vending machines equipped with RFID systems. This type of pick is suitable for modern vending solutions that integrate with smart systems, offering seamless access for authorized users. B2B buyers should ensure that their vending machines are compatible with RFID technology before investing. Although RFID picks provide significant convenience and security, they typically come at a higher cost and require machines that support RFID functionality.

Related Video: How to pick a vending machine lock

Key Industrial Applications of vending machine lock pick

| Industry/Sector | Specific Application of vending machine lock pick | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Accessing locked vending machines for service | Reduces downtime, ensures customer satisfaction | Quality assurance, compatibility with various lock types |

| Transportation | Emergency access to vending machines in transit | Quick resolution of access issues, maintains service | Durability in various environments, ease of use |

| Healthcare | Access to vending machines in hospitals | Ensures availability of essential supplies | Compliance with health regulations, reliability under pressure |

| Hospitality | Maintenance of vending machines in hotels | Enhances guest experience through uninterrupted service | Security features, training for staff on usage |

| Education | Access to vending machines on campuses | Facilitates smooth operation of student services | Training for staff, compatibility with various vending machines |

Key Applications of Vending Machine Lock Picks

Retail: In the retail sector, vending machine lock picks are crucial for accessing machines that are frequently stocked or serviced. Retailers face challenges when machines malfunction or are jammed, leading to lost sales and dissatisfied customers. By providing quick access to locked machines, businesses can minimize downtime and ensure that products are readily available. International buyers should consider the compatibility of lock picks with different types of vending machines and prioritize suppliers that offer robust quality assurance.

Transportation: In the transportation industry, vending machines are often located in transit stations, airports, and on vehicles. Lock picks are essential for emergency access to these machines, allowing staff to quickly resolve issues that may disrupt service. This capability is vital for maintaining customer satisfaction and operational efficiency. Buyers in this sector should seek durable lock picks that can withstand various environmental conditions and are easy to operate under pressure.

Healthcare: Hospitals and healthcare facilities rely on vending machines to provide essential supplies and snacks to staff and visitors. Accessing these machines swiftly is critical, especially during emergencies. A vending machine lock pick allows healthcare staff to gain immediate access without damaging the machines. Compliance with health regulations and ensuring reliability under various conditions are key considerations for international buyers in this sector.

Hospitality: In the hospitality industry, vending machines enhance guest experience by providing easy access to snacks and beverages. Maintenance staff often need to access these machines for stocking or repairs. A lock pick facilitates this process, ensuring that guests have uninterrupted access to services. Buyers should consider sourcing lock picks with added security features to prevent unauthorized access, as well as options that include staff training on effective use.

Education: Educational institutions often have vending machines on campuses to serve students. Ensuring that these machines are operational is essential for providing convenient access to food and drinks. Lock picks enable staff to quickly resolve access issues, thus maintaining smooth operations. International buyers should prioritize suppliers that offer training for staff on using these tools effectively, as well as ensuring compatibility with various vending machine models.

Related Video: Huk tubular lock pick set, how to unlock a vending machine tubular lock with a huk pick set

Strategic Material Selection Guide for vending machine lock pick

When selecting materials for vending machine lock picks, it is crucial to consider properties that ensure performance, durability, and compliance with regional standards. Below, we analyze four common materials used in the production of vending machine lock picks, highlighting their key properties, advantages, disadvantages, and considerations for international buyers.

1. Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high strength, and durability. It can withstand a wide range of temperatures and pressures, making it suitable for various environments.

Pros & Cons:

The primary advantage of stainless steel is its resistance to rust and corrosion, which extends the lifespan of lock picks. However, it is more expensive than other materials like carbon steel. Manufacturing complexity is moderate, as it requires specialized tooling and processes.

Impact on Application:

Stainless steel lock picks are particularly effective in humid or corrosive environments, such as coastal areas or regions with high rainfall. They maintain performance over time, reducing the need for frequent replacements.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM A240 for stainless steel grades. In regions like Europe, certifications may be required to meet safety and quality regulations.

2. Carbon Steel

Key Properties:

Carbon steel is characterized by its high tensile strength and hardness. It is less resistant to corrosion compared to stainless steel but can be treated for enhanced durability.

Pros & Cons:

The main advantage of carbon steel is its cost-effectiveness, making it a popular choice for budget-conscious buyers. However, its susceptibility to rust without proper treatment is a significant drawback. Manufacturing processes are relatively straightforward, leading to lower production costs.

Impact on Application:

Carbon steel lock picks are suitable for general use in dry environments but may fail in humid conditions without protective coatings. They are often used in less demanding applications where cost is a primary concern.

Considerations for International Buyers:

Buyers should be aware of the need for protective coatings to prevent corrosion. Compliance with standards such as ASTM A36 may be necessary, depending on the application and region.

3. Brass

Key Properties:

Brass is a copper-zinc alloy known for its excellent machinability and corrosion resistance. It has good thermal and electrical conductivity, which can be beneficial in specific applications.

Pros & Cons:

Brass lock picks are durable and resistant to corrosion, making them suitable for various environments. However, they are softer than steel, which can lead to wear over time. The cost is moderate, but the manufacturing process can be more complex due to the need for precision machining.

Impact on Application:

Brass is often used in applications where aesthetics matter, as it has a pleasing appearance. It is effective in environments that are not excessively humid or corrosive.

Considerations for International Buyers:

Buyers should consider compliance with relevant standards, such as ASTM B36 for brass products. In regions with strict regulations, such as Europe, ensuring the alloy meets specific quality certifications is essential.

4. Aluminum

Key Properties:

Aluminum is lightweight and has good corrosion resistance. It is less strong than steel but can be alloyed for improved performance.

Pros & Cons:

The primary advantage of aluminum is its lightweight nature, making it easy to handle and transport. However, it is generally less durable than steel and may not withstand heavy use. The cost is typically low, and manufacturing is straightforward.

Impact on Application:

Aluminum lock picks are suitable for light-duty applications where weight is a concern. They are effective in environments where corrosion resistance is needed but are not ideal for heavy-duty use.

Considerations for International Buyers:

Buyers should ensure compliance with standards such as ASTM B221 for aluminum products. In regions like South America and Africa, understanding local regulations regarding material usage is crucial.

Summary Table

| Material | Typical Use Case for vending machine lock pick | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | High-humidity environments | Excellent corrosion resistance | Higher cost compared to carbon steel | High |

| Carbon Steel | General use in dry environments | Cost-effective | Susceptible to rust without treatment | Low |

| Brass | Aesthetic applications | Good machinability and corrosion resistance | Softer than steel, prone to wear | Medium |

| Aluminum | Light-duty applications | Lightweight and easy to handle | Less durable than steel | Low |

This guide provides a comprehensive overview of material options for vending machine lock picks, enabling international buyers to make informed decisions based on performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for vending machine lock pick

Manufacturing Processes for Vending Machine Lock Picks

The production of vending machine lock picks involves several critical stages, each designed to ensure high-quality output that meets international standards. The typical manufacturing process includes:

1. Material Preparation

The first step in the manufacturing process is the selection and preparation of raw materials. Common materials used in lock pick production include high-carbon steel, stainless steel, and various alloys. These materials are chosen for their durability and resistance to wear and corrosion.

- Material Testing: Before processing, materials undergo rigorous testing for hardness, tensile strength, and corrosion resistance. This ensures that only high-quality materials are used in the manufacturing process.

2. Forming

The forming stage involves shaping the prepared materials into the desired lock pick configurations. This can be achieved through various techniques:

-

Stamping: A high-speed stamping process is often used to create precise shapes and sizes. This method is efficient for mass production and ensures uniformity across products.

-

CNC Machining: Computer Numerical Control (CNC) machining allows for intricate designs and tighter tolerances. This method is particularly useful for creating specialized lock picks that require specific dimensions.

3. Assembly

Once the individual components are formed, they are assembled into the final product. This stage may involve:

-

Manual Assembly: Skilled workers assemble components by hand to ensure quality control and precision, especially in complex designs.

-

Automated Assembly: In larger production runs, automated systems may be used to streamline the assembly process, improving efficiency and reducing labor costs.

4. Finishing

The finishing stage enhances the lock picks’ aesthetic and functional qualities. Techniques include:

-

Polishing: This process removes any rough edges and improves surface smoothness, which is crucial for the lock pick’s performance.

-

Coating: Applying protective coatings, such as nickel plating or powder coating, enhances corrosion resistance and longevity.

Quality Assurance (QA) Standards

Quality assurance is vital in ensuring that vending machine lock picks meet international safety and performance standards. B2B buyers should be familiar with relevant standards and quality checkpoints.

International Standards

-

ISO 9001: This standard outlines requirements for a quality management system (QMS) and is crucial for manufacturers aiming to ensure consistent quality in their products.

-

CE Marking: For products sold in Europe, CE marking signifies compliance with health, safety, and environmental protection standards.

-

API Standards: The American Petroleum Institute (API) standards may also be relevant, especially if lock picks are used in specialized environments.

Quality Control Checkpoints

Quality control is integrated at various stages of the manufacturing process:

-

Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified requirements.

-

In-Process Quality Control (IPQC): Ongoing inspections are conducted during production to monitor processes and ensure they adhere to standards.

-

Final Quality Control (FQC): The final products undergo rigorous testing to ensure they meet specifications before shipping.

Common Testing Methods

Manufacturers typically employ several testing methods to verify the quality of lock picks:

-

Functional Testing: Ensures the lock picks operate as intended. This may involve testing the picks against various lock mechanisms.

-

Durability Testing: Products are subjected to stress tests to assess their resistance to wear and tear.

-

Corrosion Testing: Samples are exposed to corrosive environments to evaluate the effectiveness of protective coatings.

Verifying Supplier Quality Control

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential. Here are some actionable strategies:

-

Supplier Audits: Conduct regular audits of suppliers to evaluate their manufacturing processes and quality control systems. This can be done in-person or through third-party auditing firms.

-

Quality Reports: Request detailed quality reports from suppliers, including information on material testing, quality control procedures, and compliance with international standards.

-

Third-Party Inspections: Engage third-party inspection services to perform independent checks on products before shipment. This helps ensure that the products meet specified quality criteria.

-

Certifications Review: Verify the authenticity of quality certifications such as ISO and CE. Ensure that the supplier’s certificates are current and relevant to the products being purchased.

Navigating QC Nuances for International Buyers

Different regions may have unique requirements and expectations regarding quality control:

-

Africa: Buyers should be aware of local regulations and standards, which may differ significantly from international norms. Establishing clear communication with suppliers regarding these standards is crucial.

-

South America: Many countries in this region have specific import regulations that may affect product quality. Understanding these regulations can help buyers avoid complications.

-

Middle East: Buyers should consider cultural differences in business practices, which may influence quality assurance processes. Building strong relationships with suppliers can facilitate better quality outcomes.

-

Europe (e.g., Poland): European buyers often prioritize compliance with stringent EU regulations. Suppliers should be prepared to demonstrate adherence to these standards to gain trust.

Conclusion

Understanding the manufacturing processes and quality assurance standards for vending machine lock picks is essential for B2B buyers. By focusing on material quality, production techniques, and rigorous testing, buyers can ensure they source reliable products. Additionally, verifying supplier quality control through audits and third-party inspections will further enhance the purchasing process, ensuring that the products meet the necessary international standards.

Related Video: How to open vending machine and change lock part 1

Comprehensive Cost and Pricing Analysis for vending machine lock pick Sourcing

Cost Structure of Vending Machine Lock Picks

When sourcing vending machine lock picks, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The type of materials used (e.g., stainless steel, brass) significantly influences the cost. Higher-quality materials typically lead to better durability and longer life, which can justify a higher upfront cost.

-

Labor: Labor costs vary widely depending on the manufacturing location. For example, labor costs in South Africa might differ significantly from those in Europe or South America, impacting the overall pricing.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and administrative expenses. Manufacturers in regions with higher operational costs will reflect these in their pricing.

-

Tooling: The cost of tools and molds used in production can be substantial, particularly for customized or specialized lock picks. This is a one-time cost that can be amortized over a larger production volume.

-

Quality Control (QC): Ensuring the product meets quality standards is crucial. QC processes can add to the cost but are essential for maintaining product integrity, especially in regulated markets.

-

Logistics: Transportation costs can vary depending on the distance, mode of transport, and shipping terms. Incoterms play a significant role in determining who bears these costs, affecting the final price.

-

Margin: Suppliers will include their profit margin in the final pricing. Understanding the typical margins in your supplier’s region can provide insight into negotiating better deals.

Price Influencers

Several factors influence the pricing of vending machine lock picks:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often reduce per-unit costs. Negotiating favorable terms based on anticipated purchase volumes can lead to significant savings.

-

Specifications/Customization: Custom designs or specifications can drive up costs. Clearly defining your requirements from the outset can prevent unexpected expenses.

-

Materials: The choice of materials can affect both price and performance. Opting for premium materials may increase initial costs but can lead to lower long-term maintenance expenses.

-

Quality/Certifications: Products that meet specific quality standards or certifications often command higher prices. Buyers should consider whether these certifications are necessary for their market.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their proven track record.

-

Incoterms: Understanding shipping terms can significantly impact overall costs. Different Incoterms determine the responsibilities of buyers and sellers, affecting shipping expenses and risk.

Buyer Tips for Negotiation and Cost-Efficiency

-

Negotiate Terms: Always negotiate pricing and payment terms. Establishing a long-term relationship with suppliers can yield better prices and service.

-

Evaluate Total Cost of Ownership (TCO): Consider the entire lifecycle costs, including maintenance and replacement, rather than just upfront costs. A higher initial investment in quality may lead to lower TCO.

-

Understand Pricing Nuances: Be aware of regional pricing variations. For example, prices in Poland might differ due to local demand and economic conditions compared to South Africa or Brazil.

-

Request Detailed Quotes: Ensure that quotes breakdown all cost components. This transparency will help in identifying areas for negotiation.

-

Consider Local Suppliers: Sourcing from local suppliers can reduce logistics costs and lead times. It can also simplify communication and support.

-

Stay Informed: Keep abreast of market trends and pricing shifts. This knowledge can empower you during negotiations and help you anticipate future costs.

Disclaimer on Indicative Prices

Prices for vending machine lock picks can vary significantly based on the factors discussed. It is essential for buyers to obtain multiple quotes and consider all variables before making purchasing decisions.

Spotlight on Potential vending machine lock pick Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘vending machine lock pick’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for vending machine lock pick

Key Technical Properties of Vending Machine Lock Picks

When sourcing vending machine lock picks, international B2B buyers should consider several critical technical properties that ensure the reliability and security of the products. Here are the essential specifications to evaluate:

-

Material Grade

The material used in lock picks significantly influences their durability and effectiveness. High-carbon steel or stainless steel is commonly preferred due to their strength and resistance to wear. Selecting lock picks made from these materials ensures longevity, which is crucial for businesses that rely on vending machines for consistent revenue. -

Tolerance

Tolerance refers to the allowable deviation in dimensions during manufacturing. For lock picks, tighter tolerances mean a better fit and increased efficiency in operation. A tolerance of ±0.01 mm is often ideal, as it minimizes the risk of malfunction and enhances user experience. -

Finish Quality

The finish of a lock pick can affect its performance and resistance to corrosion. Options such as chrome plating or powder coating can provide additional protection against environmental factors. A high-quality finish not only extends the product life but also contributes to the aesthetic appeal, which may be important for branding. -

Ergonomic Design

An ergonomic design ensures ease of use and comfort for the operator. Features like contoured handles or textured grips can improve handling, which is particularly beneficial during prolonged use. Ensuring that the lock picks are user-friendly can lead to increased efficiency in service operations. -

Compatibility

Different vending machines may require specific types of lock picks. Buyers should ensure that the selected picks are compatible with the lock systems of the machines they intend to service. This compatibility ensures that the tools will function correctly without damaging the locks. -

Security Features

Advanced lock picks may incorporate security features such as anti-pick pins or specialized tumblers. These innovations can provide added protection against unauthorized access, making them essential for businesses that prioritize security.

Common Trade Terms in the Vending Machine Lock Pick Industry

Understanding industry terminology is crucial for effective communication and negotiation in B2B transactions. Here are some key terms commonly used in the vending machine lock pick market:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. For buyers, partnering with OEMs can lead to customized solutions that meet specific needs, ensuring the lock picks are tailored to their vending machines. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is vital for budgeting and inventory management, as purchasing below this threshold may lead to higher per-unit costs or inability to complete an order. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request quotes from suppliers for specific products. This process allows buyers to compare prices and terms, making it easier to find the best deal for vending machine lock picks.

Illustrative Image (Source: Google Search)

-

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding these terms is essential for international transactions to avoid misunderstandings and ensure smooth logistics. -

Lead Time

Lead time refers to the duration between placing an order and receiving the product. This metric is crucial for planning purposes, especially for businesses that rely on timely access to lock picks to maintain their vending machine operations. -

Warranty

A warranty is a guarantee provided by the manufacturer regarding the condition of the product and its lifespan. Buyers should always inquire about warranty terms, as this can affect long-term costs and product support.

By understanding these essential properties and terms, international B2B buyers can make informed decisions that enhance the security and efficiency of their vending operations.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the vending machine lock pick Sector

Market Overview & Key Trends

The vending machine lock pick sector is experiencing notable growth, driven by several global factors. As urbanization increases, the demand for vending machines, particularly in retail and public spaces, is on the rise. This trend is further fueled by the growing preference for contactless payment options and automated retail solutions, making the security of these machines paramount. International B2B buyers, especially from Africa, South America, the Middle East, and Europe, must stay attuned to the latest technological advancements in lock mechanisms, including smart locks that offer enhanced security features.

Emerging trends in B2B sourcing include the integration of IoT technology within lock systems, allowing for remote monitoring and management. Buyers are increasingly looking for suppliers who can provide innovative solutions that enhance security while offering convenience. Additionally, the rise of e-commerce has led to increased competition among suppliers, prompting them to adopt agile sourcing strategies and improve their supply chain efficiencies. Buyers should also consider regional variations in demand, as markets like Poland and South Africa may have specific preferences influenced by local regulations and consumer behavior.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical consideration in the vending machine lock pick sector. The environmental impact of manufacturing processes and materials used in lock systems is under scrutiny. International B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to ethical sourcing and environmental responsibility. This includes using recycled materials and minimizing waste during production.

Buyers should look for suppliers that hold relevant certifications such as ISO 14001, which indicates a commitment to effective environmental management systems. Additionally, the use of “green” materials, such as bio-based plastics and recyclable metals, can significantly reduce the carbon footprint associated with vending machine locks. By aligning with suppliers that prioritize sustainability, buyers not only enhance their brand reputation but also cater to a growing market segment that values eco-friendly practices.

Brief Evolution/History

The evolution of vending machine locks can be traced back to the early 20th century, when the first mechanical locks were introduced. Over the decades, advancements in technology have transformed these locks from simple mechanical systems to complex electronic and smart locks. Today, the incorporation of IoT capabilities allows for remote access and monitoring, reflecting the broader trends in automation and connectivity across industries. This historical context is essential for B2B buyers, as understanding past developments helps inform future purchasing decisions and investment in innovative security solutions.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of vending machine lock pick

-

What should I consider when vetting suppliers for vending machine lock picks?

When vetting suppliers, prioritize their experience in manufacturing vending machine lock picks, checking for a solid track record and customer reviews. Request references and verify their business licenses. Evaluate their production capabilities, quality control processes, and compliance with international standards, such as ISO certifications. Additionally, assess their responsiveness and willingness to accommodate your specific needs. -

Can I customize the vending machine lock picks to fit my specific machines?

Yes, many suppliers offer customization options. You should communicate your requirements clearly, including dimensions, materials, and specific functionalities. Discuss the minimum order quantities (MOQs) for customized products, as these may differ from standard offerings. Ensure the supplier provides prototypes or samples for approval before full-scale production. -

What are the typical minimum order quantities (MOQs) and lead times for vending machine lock picks?

MOQs vary significantly by supplier and customization level, ranging from 100 to 1,000 units. Standard lead times can be between 4 to 12 weeks, depending on production schedules and your location. To avoid delays, it’s advisable to place orders well in advance, especially if you anticipate high demand or seasonal spikes. -

What payment terms should I expect when sourcing from international suppliers?

Payment terms can vary widely, but common practices include 30% upfront payment with the balance due before shipment. Some suppliers may offer net payment terms based on your creditworthiness. Ensure you discuss and agree on payment methods, such as wire transfers or letters of credit, and confirm any additional fees that may apply for international transactions. -

How do I ensure quality assurance and certifications for vending machine lock picks?

Request detailed information about the supplier’s quality assurance processes, including testing methods and certifications. Look for compliance with international standards, such as CE or UL certifications, which indicate safety and reliability. Additionally, consider third-party inspections before shipment to verify product quality, especially for large orders. -

What logistics options are available for shipping vending machine lock picks internationally?

Logistics options generally include air freight, sea freight, and courier services. Air freight is faster but more expensive, while sea freight is cost-effective for larger shipments. Discuss with your supplier about their preferred logistics partners and any possible customs clearance assistance they can provide, ensuring you understand all shipping costs and delivery timelines. -

How can I resolve disputes with suppliers regarding vending machine lock picks?

To resolve disputes effectively, maintain clear and open communication with your supplier. Start by documenting all agreements and correspondence to provide a reference point. If issues arise, discuss them directly with your supplier to seek a resolution. If necessary, consider mediation or arbitration as per the terms outlined in your contract to avoid lengthy legal proceedings. -

What are the common challenges faced when sourcing vending machine lock picks internationally?

Common challenges include language barriers, varying quality standards, and differences in legal regulations. Additionally, logistical issues like delays in shipping and customs clearance can complicate the process. To mitigate these challenges, work with suppliers experienced in international trade and consider hiring a local agent or consultant familiar with the target market’s regulations and practices.

Strategic Sourcing Conclusion and Outlook for vending machine lock pick

In the evolving landscape of vending machine security, strategic sourcing emerges as a vital tool for international B2B buyers, particularly in Africa, South America, the Middle East, and Europe. By carefully selecting vendors and products, businesses can enhance their operational efficiency and minimize risks associated with theft or unauthorized access. Key takeaways include understanding the importance of quality materials, evaluating vendor reliability, and considering the total cost of ownership rather than just the initial purchase price.

Investing in high-quality vending machine lock picks not only ensures durability but also fosters long-term partnerships with suppliers who can provide ongoing support and innovation. As markets continue to grow and diversify, the demand for secure and efficient vending solutions will rise.

Looking ahead, international B2B buyers are encouraged to leverage strategic sourcing to stay competitive. By actively engaging with suppliers and industry experts, businesses can adapt to market changes and capitalize on emerging opportunities. Take the next step in securing your vending operations—explore new partnerships and invest in advanced locking solutions that will safeguard your assets and enhance customer trust.