Master Sourcing Vending Machine Bottles: Essential Guide

Guide to Vending Machine Bottles

- Introduction: Navigating the Global Market for vending machine bottles

- Understanding vending machine bottles Types and Variations

- Key Industrial Applications of vending machine bottles

- Strategic Material Selection Guide for vending machine bottles

- In-depth Look: Manufacturing Processes and Quality Assurance for vending machine bottles

- Comprehensive Cost and Pricing Analysis for vending machine bottles Sourcing

- Spotlight on Potential vending machine bottles Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for vending machine bottles

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the vending machine bottles Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of vending machine bottles

- Strategic Sourcing Conclusion and Outlook for vending machine bottles

Introduction: Navigating the Global Market for vending machine bottles

Navigating the global market for vending machine bottles requires a strategic approach, especially for international B2B buyers from diverse regions such as Africa, South America, the Middle East, and Europe. Vending machine bottles are pivotal in enhancing consumer experience and driving sales, making them an essential component of the automated retail landscape. With the rise of health-conscious consumers and the demand for convenience, the selection of the right bottle can significantly impact business success.

This comprehensive guide delves into various aspects of vending machine bottles, including types (PET, glass, and biodegradable options), materials (sustainability considerations), and manufacturing and quality control processes to ensure safety and durability. Additionally, we will explore key suppliers and their competitive advantages, as well as cost analysis and market trends that influence purchasing decisions.

By providing answers to frequently asked questions, this guide empowers B2B buyers with the knowledge needed for informed sourcing decisions. Buyers will gain insights into the latest innovations and best practices, enabling them to choose products that meet their operational needs while appealing to their target demographics. Understanding these elements not only supports effective procurement strategies but also fosters long-term partnerships with suppliers, essential for thriving in a competitive marketplace.

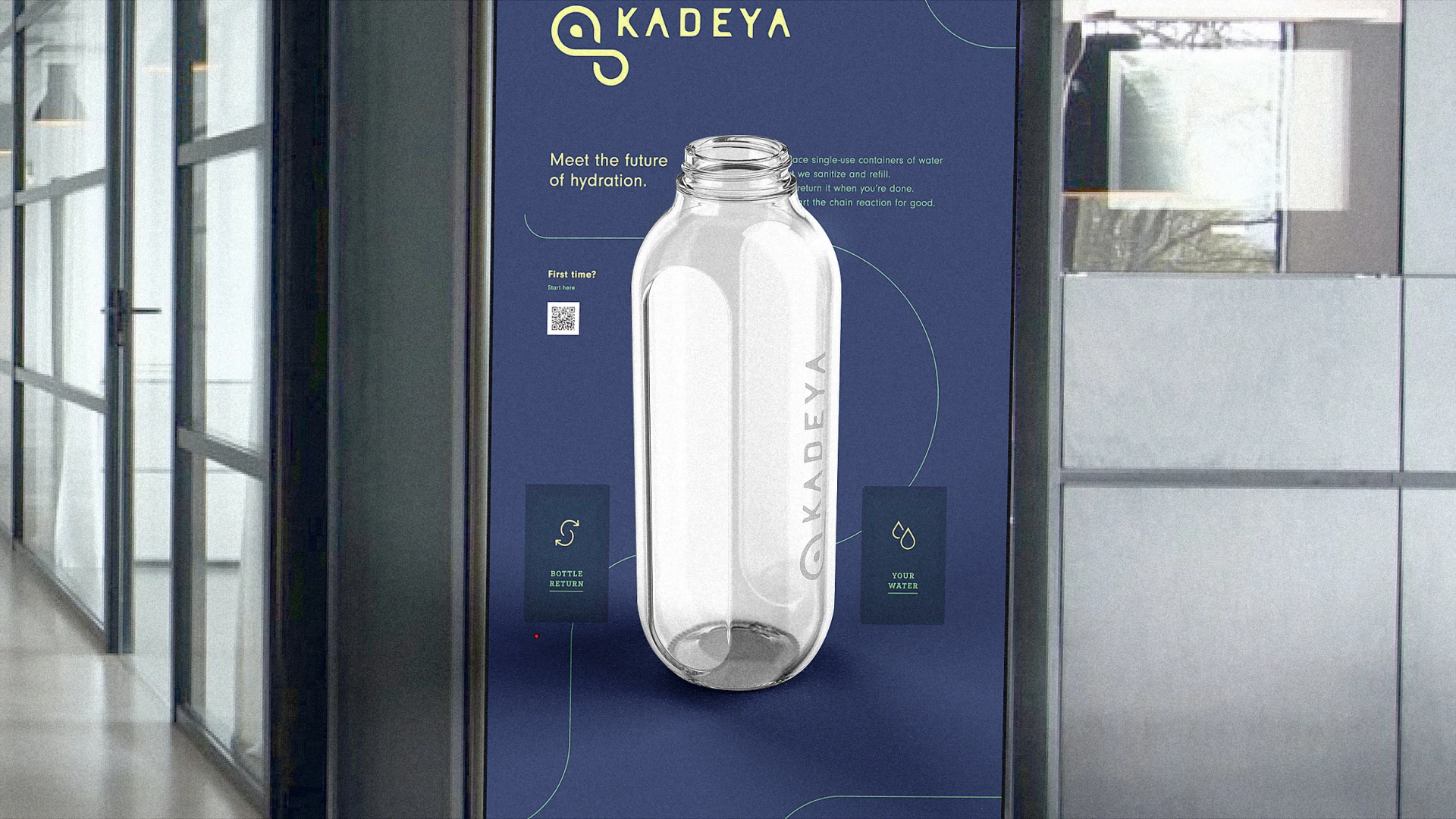

Illustrative Image (Source: Google Search)

Understanding vending machine bottles Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Plastic PET Bottles | Lightweight, recyclable, and versatile shapes | Beverage vending, juices, and waters | Pros: Cost-effective, easy to transport. Cons: Less durable than glass. |

| Glass Bottles | Heavy, premium feel, and excellent barrier properties | High-end beverages, specialty drinks | Pros: Superior taste preservation, recyclable. Cons: Heavier, higher shipping costs. |

| Aluminum Cans | Lightweight, durable, and good thermal conductivity | Soft drinks, energy drinks | Pros: Excellent for cold beverages, recyclable. Cons: Limited shelf life for some products. |

| Tetra Pak Containers | Multi-layered packaging providing long shelf life | Dairy products, juices, and soups | Pros: Extended shelf life, lightweight. Cons: Not as easily recyclable as other options. |

| Custom-Shaped Bottles | Unique designs for branding and marketing | Specialty beverages, promotional items | Pros: Enhances brand visibility, attracts consumers. Cons: Higher production costs, longer lead times. |

Plastic PET Bottles

Plastic PET bottles are a common choice for vending machines due to their lightweight nature and versatility in design. They are ideal for beverages such as water, soft drinks, and juices. B2B buyers should consider their cost-effectiveness and ease of transport, making them suitable for high-volume vending operations. However, it’s important to note that while they are recyclable, they may not offer the same durability as glass alternatives.

Glass Bottles

Glass bottles provide a premium packaging option, often preferred for high-end beverages and specialty drinks. Their excellent barrier properties help preserve taste and quality, making them a popular choice for wine and craft beers. Buyers should weigh the benefits of superior taste preservation against the heavier weight and higher shipping costs associated with glass bottles, especially in regions where transportation logistics can be challenging.

Aluminum Cans

Aluminum cans are favored in the beverage industry for their lightweight and durable characteristics. They are particularly effective for soft drinks and energy drinks, as they provide excellent thermal conductivity, keeping beverages cold. B2B buyers should consider that while aluminum cans are recyclable, the shelf life of the contents can be limited compared to glass, necessitating careful inventory management.

Tetra Pak Containers

Tetra Pak containers are known for their multi-layered packaging, which provides an extended shelf life for products like dairy, juices, and soups. This makes them an attractive option for B2B buyers looking for long-lasting solutions. However, the trade-off includes challenges with recycling, as the materials used can be more complex than traditional options. Buyers should evaluate their market needs regarding product longevity versus environmental impact.

Custom-Shaped Bottles

Custom-shaped bottles allow brands to stand out in a crowded market, enhancing visibility and consumer attraction. They are particularly useful for specialty beverages and promotional items. B2B buyers should consider the potential for increased sales through unique branding but should also be aware of the higher production costs and longer lead times associated with custom designs.

Related Video: Pros And Cons Of Starting A Vending Machine Business

Key Industrial Applications of vending machine bottles

| Industry/Sector | Specific Application of Vending Machine Bottles | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food & Beverage | Beverage dispensing in public spaces | Increased accessibility and convenience for consumers | Compliance with food safety standards, durability |

| Healthcare | Medical supplies dispensing | Streamlined access to essential supplies for patients | Sterilization requirements, material safety |

| Education | Snack and beverage provision in schools | Promotes healthy eating habits among students | Nutritional compliance, variety of offerings |

| Hospitality | Guest services in hotels and resorts | Enhances guest experience and satisfaction | Custom branding options, refill frequency |

| Retail | Quick service for on-the-go consumers | Boosts impulse purchases and customer satisfaction | Payment system integration, ease of use |

Food & Beverage

Vending machine bottles are extensively used in the food and beverage industry, particularly for beverage dispensing in public spaces such as parks, airports, and shopping malls. These bottles provide a convenient and hygienic way for consumers to access drinks on-the-go. For international buyers, ensuring compliance with local food safety standards is crucial, along with selecting durable materials that can withstand various environmental conditions.

Healthcare

In healthcare settings, vending machine bottles play a vital role in dispensing medical supplies, such as sanitizers, gloves, and masks. This application enhances the accessibility of essential supplies for patients and healthcare workers alike, especially in emergency situations. Buyers in this sector must prioritize sourcing bottles that meet strict sterilization requirements and material safety standards to ensure patient safety.

Education

Schools and universities utilize vending machine bottles to provide snacks and beverages to students. This application not only caters to the dietary needs of students but also promotes healthy eating habits by offering nutritious options. B2B buyers in the education sector should consider nutritional compliance and a variety of offerings to appeal to diverse student preferences, while also ensuring that the vending machines are user-friendly.

Hospitality

In the hospitality industry, vending machine bottles are used to enhance guest services in hotels and resorts. By providing easy access to drinks and snacks, these bottles improve the overall guest experience and satisfaction. Buyers in this sector should explore custom branding options to align with their hotel’s identity, as well as consider the frequency of refills to meet high customer demand.

Retail

Vending machine bottles serve as a quick service solution for on-the-go consumers in retail environments. By offering a variety of beverages and snacks, they boost impulse purchases and enhance customer satisfaction. For B2B buyers, key considerations include integrating payment systems for seamless transactions and ensuring the ease of use of the vending machines to cater to a diverse clientele, including tourists and locals alike.

Related Video: Case Packing Machine for Bottles using Cobot | Clearpack

Strategic Material Selection Guide for vending machine bottles

When selecting materials for vending machine bottles, international B2B buyers must consider several factors, including the material’s properties, cost, manufacturing complexity, and compliance with regional standards. Below is an analysis of four common materials used in the production of vending machine bottles, focusing on their key properties, advantages, disadvantages, and specific considerations for buyers in Africa, South America, the Middle East, and Europe.

1. Polyethylene Terephthalate (PET)

Key Properties:

PET is a lightweight, strong, and clear plastic that can withstand temperatures up to 60°C (140°F). It has excellent barrier properties against oxygen and carbon dioxide, making it suitable for carbonated beverages.

Pros & Cons:

– Advantages: PET is highly durable, resistant to impact, and can be recycled. It is also cost-effective, making it a popular choice for high-volume production.

– Disadvantages: While PET has good chemical resistance, it can be affected by certain solvents and is less suitable for high-temperature applications beyond its limit.

Impact on Application:

PET is ideal for soft drinks, juices, and bottled water due to its clarity and barrier properties. However, it may not be suitable for hot beverages.

Specific Considerations:

Buyers must ensure compliance with food safety standards such as FDA regulations in the U.S. and EFSA in Europe. Additionally, buyers should consider the recycling infrastructure in their region, as PET is widely recycled but may not be in all markets.

2. Polypropylene (PP)

Key Properties:

Polypropylene is a thermoplastic polymer known for its high melting point (up to 100°C or 212°F) and chemical resistance. It is also lightweight and has good impact resistance.

Pros & Cons:

– Advantages: PP is more resistant to heat and chemicals compared to PET, making it suitable for a wider range of beverages, including hot drinks. It is also cost-effective and has a lower environmental impact due to its recyclability.

– Disadvantages: PP can be less transparent than PET, which may be a drawback for products where visibility is important.

Impact on Application:

PP is suitable for dairy products, sauces, and hot beverages, offering versatility in the types of products that can be dispensed.

Specific Considerations:

International buyers should check for compliance with regional standards such as ASTM and ISO. In markets like Europe, buyers may also need to consider the implications of the EU Plastics Strategy on their sourcing.

3. Glass

Key Properties:

Glass is a non-reactive material with excellent barrier properties against gases and moisture. It can withstand high temperatures and is fully recyclable.

Pros & Cons:

– Advantages: Glass is chemically inert, making it ideal for beverages that may react with plastics. It provides a premium feel and is often perceived as more environmentally friendly due to its recyclability.

– Disadvantages: Glass is heavier and more fragile than plastic, leading to higher transportation costs and the risk of breakage.

Impact on Application:

Glass is often used for premium beverages, such as craft beers and juices, where the quality of packaging is paramount.

Specific Considerations:

Buyers must consider the weight and fragility of glass when shipping, especially in regions with less developed infrastructure. Compliance with safety standards is also crucial, particularly in markets with strict regulations regarding food and beverage packaging.

4. Aluminum

Key Properties:

Aluminum is lightweight, durable, and has excellent barrier properties against light, oxygen, and moisture. It can withstand high pressures, making it suitable for carbonated beverages.

Pros & Cons:

– Advantages: Aluminum cans are highly recyclable and can be produced with a lower carbon footprint compared to plastic. They are also resistant to corrosion and can be coated for additional protection.

– Disadvantages: The initial cost of aluminum can be higher than that of plastics, and the manufacturing process can be more complex.

Impact on Application:

Aluminum is commonly used for soft drinks, energy drinks, and alcoholic beverages, providing a lightweight and durable option for vending machines.

Specific Considerations:

Buyers should be aware of the recycling systems in their respective countries, as aluminum recycling rates are high in many regions. Compliance with standards such as ASTM and local health regulations is also essential.

Summary Table

| Material | Typical Use Case for vending machine bottles | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyethylene Terephthalate (PET) | Soft drinks, juices, bottled water | Lightweight, strong, recyclable | Limited temperature resistance | Low |

| Polypropylene (PP) | Dairy products, sauces, hot beverages | High heat and chemical resistance | Less transparency | Low |

| Glass | Premium beverages (craft beers, juices) | Chemically inert, recyclable | Heavier and fragile | High |

| Aluminum | Soft drinks, energy drinks, alcoholic beverages | Lightweight, excellent barrier properties | Higher initial cost, complex manufacturing | Medium |

This guide provides a comprehensive overview for international B2B buyers looking to select the most appropriate materials for vending machine bottles, ensuring they make informed decisions that align with their operational and market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for vending machine bottles

Manufacturing Processes for Vending Machine Bottles

The production of vending machine bottles involves several key stages that ensure both functionality and quality. Understanding these processes is crucial for B2B buyers, especially when sourcing from international suppliers.

1. Material Preparation

The first step in manufacturing vending machine bottles is selecting the appropriate materials. Typically, bottles are made from polyethylene terephthalate (PET), known for its lightweight, durability, and recyclability.

- Material Selection: Buyers should ensure that suppliers use food-grade materials that comply with international safety standards.

- Quality Control: Conduct inspections on raw materials before they enter the production process. This can include checking for certifications and conducting tests for contaminants.

2. Forming

Once materials are prepared, the next phase involves forming the bottles. This is generally achieved through various techniques:

- Injection Molding: Used for creating preforms, which are then heated and stretched to form bottles. This method allows for precision in shape and thickness.

- Blow Molding: Preforms are heated and expanded using air pressure into the desired bottle shape. This is common for producing large quantities efficiently.

Key Techniques:

– Thermoforming can also be used for specific designs where a sheet of plastic is heated and formed into a bottle shape.

– Buyers should ensure that the forming process maintains dimensional accuracy and consistency across production batches.

3. Assembly

After the forming process, assembly involves attaching any necessary components, such as caps and labels.

- Cap and Label Application: Automated systems are often used to ensure speed and accuracy.

- Quality Checks: Assembled products should undergo checks to verify that caps fit correctly and labels are applied without defects.

4. Finishing

The finishing stage enhances the aesthetic and functional qualities of the bottles. This can include:

- Surface Treatment: Applying coatings or treatments to enhance clarity, scratch resistance, or UV protection.

- Printing: High-quality printing techniques are employed for branding and information.

Buyer’s Insight: Buyers should verify that the finishing processes do not compromise the bottle’s integrity or safety.

Quality Assurance in Vending Machine Bottle Manufacturing

Quality assurance is critical in ensuring that the produced bottles meet both safety and performance standards. Buyers should be familiar with international standards and specific industry requirements.

International Standards

- ISO 9001: This standard focuses on quality management systems and is crucial for suppliers looking to ensure consistency in their manufacturing processes.

- CE Marking: Particularly relevant for European buyers, indicating compliance with health, safety, and environmental protection standards.

- API Standards: For bottles that may be used in pharmaceutical vending machines, compliance with API standards is essential.

Quality Control Checkpoints

Effective quality control throughout the manufacturing process is vital. Here are the main checkpoints:

- Incoming Quality Control (IQC): Inspect raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Conduct checks during the manufacturing process to catch defects early. This can include monitoring temperature and pressure during molding.

- Final Quality Control (FQC): After assembly and finishing, a comprehensive inspection should be performed to ensure the final product meets all specifications.

Common Testing Methods

- Mechanical Testing: Assessing tensile strength, impact resistance, and other physical properties.

- Chemical Testing: Ensuring that materials are free from harmful substances and meet food safety standards.

- Visual Inspections: Checking for aesthetic defects such as scratches, discoloration, or label misalignment.

Verifying Supplier Quality Control

International B2B buyers should implement strategies to verify the quality control processes of their suppliers:

- Audits: Conduct on-site audits of manufacturing facilities to assess compliance with quality standards and practices.

- Reports: Request detailed quality assurance reports that outline the testing methods used and the results of inspections.

- Third-Party Inspections: Engage third-party inspection agencies to provide an unbiased assessment of the manufacturer’s quality control processes.

QC and Certification Nuances for International Buyers

When sourcing vending machine bottles from suppliers in Africa, South America, the Middle East, and Europe, buyers must be aware of regional regulations and certifications:

- Regional Compliance: Different regions may have specific regulations regarding materials and safety. For example, the European Union has stringent regulations on food contact materials.

- Documentation: Ensure that suppliers provide relevant documentation, including certificates of compliance, test results, and material safety data sheets (MSDS).

- Cultural Considerations: Understanding local manufacturing practices and quality expectations can enhance communication and help prevent misunderstandings.

Conclusion

For B2B buyers, particularly those operating in diverse international markets, understanding the manufacturing processes and quality assurance measures for vending machine bottles is essential. By focusing on material quality, utilizing effective manufacturing techniques, and implementing rigorous quality control measures, buyers can ensure they source reliable, safe, and high-quality products that meet their business needs.

Related Video: Manufacturing process of a glass bottle || Machines and Industry

Comprehensive Cost and Pricing Analysis for vending machine bottles Sourcing

When sourcing vending machine bottles, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers. This section delves into the cost components, price influencers, and provides actionable tips tailored for buyers from Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The primary materials for vending machine bottles include plastics (like PET, PVC) and occasionally glass or aluminum. The choice of material significantly affects the overall cost. For example, while PET is lightweight and cost-effective, glass offers a premium feel but at a higher price.

-

Labor: Labor costs vary widely by region. In emerging markets, labor is generally cheaper, which can lower the manufacturing costs significantly. However, skilled labor may command higher wages, particularly in regions with a focus on quality and safety standards.

-

Manufacturing Overhead: This includes utilities, facility costs, and indirect labor. Overhead can be minimized through efficient production processes and technology investments, which are crucial for maintaining competitive pricing.

-

Tooling: Initial costs for molds and tooling are significant in bottle production. Custom designs require specialized tooling, which can inflate upfront costs. For bulk orders, these costs can be amortized over the production run, reducing the per-unit cost.

-

Quality Control (QC): Investing in robust QC processes ensures that the bottles meet the required standards and certifications, which is essential for compliance in various markets. While this adds to the cost, it helps prevent costly recalls or reputational damage.

-

Logistics: Transportation costs are influenced by the distance from the supplier to the buyer, shipping methods, and the chosen Incoterms. Buyers should evaluate the total logistics cost, including customs duties and tariffs, which can vary significantly by region.

-

Margin: Suppliers typically add a profit margin to their costs. Understanding the typical margins in the industry can help buyers gauge whether they are receiving competitive pricing.

Price Influencers

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs due to economies of scale. Negotiating the MOQ can yield better pricing, especially for long-term contracts.

-

Specifications/Customization: Custom designs or specifications can increase costs. Standard designs may be more cost-effective, so buyers should assess their needs carefully.

-

Materials: The choice of materials directly impacts pricing. Eco-friendly materials may come at a premium, but they can appeal to sustainability-conscious consumers.

-

Quality/Certifications: Bottles that meet specific safety and quality standards may incur higher costs. Certifications can influence marketability, especially in regulated markets.

-

Supplier Factors: The supplier’s reputation, production capacity, and reliability play critical roles in pricing. Established suppliers may charge higher prices but offer better quality assurance.

-

Incoterms: The agreed-upon Incoterms can affect the overall cost structure. Buyers should clarify who bears the costs and risks at various stages of transport.

Buyer Tips

-

Negotiation: Always negotiate terms and prices. Building a relationship with suppliers can lead to better pricing and terms in the long run.

-

Cost-Efficiency: Look beyond just the purchase price; consider the Total Cost of Ownership (TCO), which includes maintenance, logistics, and potential waste costs.

-

Pricing Nuances: Be aware of regional pricing variations. For example, prices may differ significantly between Europe and Africa due to local demand and supply conditions.

-

Market Research: Conduct thorough market research to understand typical pricing and cost structures. This knowledge can empower buyers during negotiations.

-

Diversification of Suppliers: Engaging multiple suppliers can provide leverage in negotiations and ensure a backup in case of supply chain disruptions.

Disclaimer

Prices for vending machine bottles can vary widely based on numerous factors, including market conditions, supplier negotiations, and order specifications. It is advisable for buyers to conduct their own due diligence and obtain multiple quotes to ensure competitive pricing.

Spotlight on Potential vending machine bottles Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘vending machine bottles’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for vending machine bottles

Key Technical Properties of Vending Machine Bottles

Understanding the essential technical properties of vending machine bottles is crucial for international B2B buyers seeking quality and compliance with industry standards. Here are several critical specifications:

-

Material Grade

– Vending machine bottles are commonly made from materials such as PET (Polyethylene Terephthalate), HDPE (High-Density Polyethylene), or glass. The material grade affects the bottle’s strength, flexibility, and recyclability. For instance, PET is lightweight and shatter-resistant, making it ideal for high-traffic environments.

– Importance: Choosing the right material ensures durability during transportation and enhances customer satisfaction with product quality. -

Volume Capacity

– This specification refers to the amount of liquid the bottle can hold, typically measured in milliliters (mL) or liters (L). Common sizes range from 300 mL to 1.5 L for vending machine applications.

– Importance: Understanding volume capacity helps businesses align their offerings with consumer demand and maximize vending machine space efficiency. -

Neck Finish

– The neck finish includes the dimensions and threading of the bottle’s neck, which determines compatibility with caps and dispensing mechanisms. Standard neck finishes include 28mm and 38mm diameters.

– Importance: Proper neck specifications facilitate easy sealing and ensure that products remain fresh, thereby reducing waste and enhancing customer experience. -

Tolerance Levels

– Tolerance levels indicate the acceptable variations in bottle dimensions. These specifications are critical for ensuring that bottles fit correctly in vending machines and are compatible with filling and capping equipment.

– Importance: High tolerance levels minimize production errors, ensuring consistent product quality and reducing operational costs. -

Weight

– The weight of the bottle impacts shipping costs and environmental sustainability. Lighter bottles reduce transportation expenses and carbon footprints.

– Importance: Buyers should consider lightweight options to improve logistics efficiency and reduce overall product costs. -

Recyclability

– This property indicates whether the bottle can be recycled, and if so, the recycling process involved. For example, PET bottles are widely accepted in recycling programs.

– Importance: As sustainability becomes increasingly important, offering recyclable products can enhance brand reputation and meet regulatory requirements in various regions.

Common Trade Terminology

Navigating the B2B landscape requires familiarity with specific trade terms. Here are some key terms relevant to vending machine bottles:

-

OEM (Original Equipment Manufacturer)

– Refers to companies that produce products for other brands to sell under their own name. In the context of vending machine bottles, an OEM can create custom bottles based on client specifications.

– Importance: Engaging with OEMs allows businesses to leverage specialized manufacturing capabilities and tailor products to market needs. -

MOQ (Minimum Order Quantity)

– The minimum number of units a supplier is willing to sell. This quantity can vary significantly based on the manufacturer and the product type.

– Importance: Understanding MOQ helps buyers gauge initial investment and inventory management, especially for new product launches. -

RFQ (Request for Quotation)

– A document sent to suppliers requesting pricing for specific products or services. An RFQ typically includes details such as specifications, quantities, and delivery timelines.

– Importance: Utilizing RFQs enables buyers to compare pricing and terms from different suppliers, ensuring better purchasing decisions. -

Incoterms (International Commercial Terms)

– A set of internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Common terms include FOB (Free on Board) and CIF (Cost, Insurance, and Freight).

– Importance: Familiarity with Incoterms is vital for understanding shipping responsibilities, costs, and risk management in cross-border transactions. -

Lead Time

– The time it takes from placing an order until the product is delivered. Lead times can vary based on production schedules, shipping methods, and supplier capabilities.

– Importance: Knowing lead times helps buyers plan inventory and sales strategies effectively, minimizing stockouts or excess inventory.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions that enhance their operational efficiency and market competitiveness.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the vending machine bottles Sector

Market Overview & Key Trends

The vending machine bottles sector is witnessing significant growth driven by increasing urbanization and the rising demand for convenient, on-the-go beverage solutions. In emerging markets across Africa and South America, the adoption of vending machines is accelerating due to a burgeoning middle class and changing consumer lifestyles. In Europe and the Middle East, sustainability and health consciousness are becoming critical purchasing factors, leading to a surge in demand for eco-friendly and health-oriented beverage options.

B2B tech advancements are reshaping the vending machine landscape. Smart vending machines equipped with IoT technology allow for real-time inventory management, enhancing operational efficiency. These machines can track consumer preferences and behaviors, enabling suppliers to optimize their offerings. Additionally, cashless payment systems are becoming standard, catering to a tech-savvy consumer base that favors contactless transactions.

International buyers should also be aware of regional market dynamics. In Europe, stringent regulations around packaging waste and recycling are influencing sourcing decisions, pushing suppliers to adopt sustainable practices. In contrast, markets in Africa and South America may face challenges related to infrastructure and supply chain efficiency, necessitating localized sourcing strategies.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer a mere buzzword but a crucial component of business strategy in the vending machine bottles sector. The environmental impact of plastic waste is a pressing concern, prompting many companies to seek alternatives. B2B buyers are increasingly prioritizing suppliers that can provide bottles made from recycled materials or biodegradable options.

Ethical sourcing practices are also gaining traction, with businesses expected to ensure their supply chains are transparent and responsible. Certifications such as ISO 14001 for environmental management and FSC certification for sustainable sourcing of materials are becoming essential for suppliers aiming to attract international buyers. These certifications not only enhance brand reputation but also meet the growing consumer demand for ethical and sustainable products.

Investing in sustainable practices can lead to long-term cost savings through reduced waste and increased operational efficiency. Buyers should evaluate potential suppliers based on their commitment to sustainability and ethical sourcing, as these factors will likely influence purchasing decisions in the coming years.

Brief Evolution/History

The vending machine industry has evolved significantly since its inception in the early 20th century. Initially focused on simple snack and beverage dispensing, the sector has transformed with technological advancements and changing consumer preferences. The introduction of cashless payment systems and IoT capabilities has revolutionized operations, allowing for smarter inventory management and enhanced consumer engagement.

As environmental concerns have become more prevalent, the sector is now increasingly focused on sustainability, prompting manufacturers to innovate with eco-friendly materials and practices. This evolution reflects a broader shift in consumer values and market demands, making it imperative for B2B buyers to align with suppliers who prioritize sustainability and innovation in their offerings.

In conclusion, understanding these market dynamics, sourcing trends, and sustainability considerations is essential for international B2B buyers in the vending machine bottles sector to make informed purchasing decisions that align with current and future market demands.

Related Video: Is global trade transforming? | Counting the Cost

Frequently Asked Questions (FAQs) for B2B Buyers of vending machine bottles

-

What factors should I consider when vetting suppliers for vending machine bottles?

When vetting suppliers, prioritize their experience in the industry, production capacity, and compliance with international quality standards. Request references and case studies from previous clients, particularly those in your region. It’s also beneficial to conduct site visits or virtual tours to assess their manufacturing processes. Ensure they have robust quality assurance protocols in place and can provide certifications such as ISO or relevant safety standards. -

Can I customize vending machine bottles to fit my brand?

Yes, many suppliers offer customization options, including logo printing, color variations, and size adjustments. Discuss your specific branding needs with potential suppliers early in the negotiation process. Be clear about your design requirements and ask for samples to ensure the final product meets your expectations. Keep in mind that customization may affect the minimum order quantity (MOQ) and lead time. -

What are typical minimum order quantities (MOQs) and lead times for vending machine bottles?

MOQs can vary significantly depending on the supplier and the level of customization. Generally, you might expect MOQs to range from 1,000 to 10,000 units. Lead times also depend on factors such as order complexity, supplier location, and shipping arrangements. It’s advisable to discuss these details upfront to align your purchasing schedule with the supplier’s capabilities. -

What payment methods are commonly accepted by suppliers?

Most suppliers accept various payment methods, including bank transfers, letters of credit, and online payment platforms. For international transactions, ensure that the payment method you choose offers adequate security and protection. Discuss payment terms upfront to avoid misunderstandings, and consider using escrow services for large orders to safeguard your investment. -

How do I ensure quality assurance and compliance with international standards?

To ensure quality, request copies of relevant certifications and conduct thorough inspections during production. Some suppliers may offer third-party inspection services that can verify product quality before shipping. Familiarize yourself with the quality standards applicable in your region and communicate these requirements clearly to the supplier to avoid compliance issues. -

What logistics considerations should I keep in mind when sourcing vending machine bottles?

Logistics can significantly impact your supply chain efficiency. Discuss shipping options, costs, and delivery timelines with your supplier. Consider the benefits of using freight forwarders who specialize in international shipping to manage customs clearance and documentation. Additionally, factor in storage and distribution logistics upon arrival in your country to ensure smooth operations. -

What steps can I take to resolve disputes with my supplier?

To minimize disputes, establish clear terms of agreement regarding delivery, payment, and quality expectations in your contract. If disputes arise, attempt to resolve them amicably through direct communication first. If necessary, refer to the terms of your contract regarding dispute resolution methods, such as mediation or arbitration. Keep records of all communications and agreements to support your case if formal action is required. -

How can I protect my intellectual property (IP) when working with international suppliers?

Protecting your IP is crucial when engaging with suppliers. Start by signing a non-disclosure agreement (NDA) before sharing sensitive information. Additionally, consider registering your trademarks and designs in the countries where you operate. Engage legal counsel familiar with international trade laws to draft contracts that include IP protection clauses, specifying ownership rights and usage limitations for your designs and branding.

Strategic Sourcing Conclusion and Outlook for vending machine bottles

In the evolving landscape of vending machine bottles, strategic sourcing emerges as a critical driver for success. B2B buyers from Africa, South America, the Middle East, and Europe must prioritize partnerships with suppliers who not only understand local market dynamics but also emphasize sustainability and innovation in their offerings. Key takeaways include the necessity for due diligence in supplier selection, considering factors such as quality, cost-effectiveness, and supply chain reliability.

Illustrative Image (Source: Google Search)

Investing in eco-friendly materials and customized solutions can enhance brand image and cater to the growing consumer demand for sustainable products. Moreover, leveraging technology to streamline procurement processes can lead to more efficient operations and better pricing strategies.

As we look to the future, the demand for vending machine bottles is set to increase, driven by changing consumer behaviors and a rise in on-the-go consumption. International buyers should act now—evaluate their sourcing strategies, engage with innovative suppliers, and explore new markets. Seize the opportunity to lead in this sector by committing to sustainable practices and strategic partnerships that can propel your business forward in a competitive landscape.