Master Sourcing Token Vending Machines: Your Complete B2B

Guide to Token Vending Machine

- Introduction: Navigating the Global Market for token vending machine

- Understanding token vending machine Types and Variations

- Key Industrial Applications of token vending machine

- Strategic Material Selection Guide for token vending machine

- In-depth Look: Manufacturing Processes and Quality Assurance for token vending machine

- Comprehensive Cost and Pricing Analysis for token vending machine Sourcing

- Spotlight on Potential token vending machine Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for token vending machine

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the token vending machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of token vending machine

- Strategic Sourcing Conclusion and Outlook for token vending machine

Introduction: Navigating the Global Market for token vending machine

In today’s rapidly evolving marketplace, the demand for token vending machines is on the rise, driven by their versatility and efficiency across various sectors. These machines serve as pivotal tools for businesses seeking to streamline transactions, enhance customer engagement, and facilitate cashless payments. Whether in entertainment venues, transportation hubs, or retail environments, token vending machines offer a seamless experience that appeals to modern consumers.

This comprehensive guide delves into the intricate world of token vending machines, providing international B2B buyers with essential insights to make informed sourcing decisions. We will explore various types of machines, from basic models to advanced, integrated solutions, as well as the materials used in their construction, ensuring durability and security.

Additionally, we will cover critical aspects such as manufacturing processes and quality control standards, helping buyers identify reliable suppliers. Understanding the cost factors involved is crucial, as it allows for strategic budgeting and investment planning. Moreover, the guide will present a thorough analysis of the global market trends, particularly focusing on regions like Africa, South America, the Middle East, and Europe, including key players in Poland and Italy.

With a dedicated FAQ section addressing common queries, this guide empowers B2B buyers to navigate the complexities of sourcing token vending machines effectively, ensuring they choose the right solutions for their business needs.

Understanding token vending machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Coin-Operated | Accepts coins or tokens; mechanical mechanism | Amusement parks, laundromats | Pros: Simple, low maintenance. Cons: Limited payment options, prone to jams. |

| Cashless Token Vending | Accepts credit/debit cards and mobile payments | Public transport, gaming centers | Pros: Convenient, reduces cash handling. Cons: Higher initial cost, requires internet connectivity. |

| Customizable Token Machines | Modular design; can dispense various tokens/types | Events, attractions, retail | Pros: Flexible, tailored to specific needs. Cons: More complex setup, potential for higher costs. |

| Smart Token Vending Machines | Integrated software for data analytics and remote monitoring | Smart cities, entertainment venues | Pros: Real-time data, improved inventory management. Cons: Higher maintenance, requires tech support. |

| Mobile Token Vending Kiosks | Portable, can be set up in various locations | Festivals, outdoor events | Pros: Flexible placement, easy to transport. Cons: Limited capacity, may require frequent refilling. |

Traditional Coin-Operated Machines

Traditional coin-operated token vending machines are mechanical devices that accept coins or tokens, making them ideal for locations like amusement parks and laundromats. Their simplicity and low maintenance requirements are appealing for businesses with budget constraints. However, they offer limited payment options, which may deter customers who prefer cashless transactions, and they are prone to mechanical jams, leading to potential downtime.

Cashless Token Vending

Cashless token vending machines allow customers to make purchases using credit/debit cards or mobile payment solutions. This modern approach is particularly beneficial in public transport systems and gaming centers, where convenience is key. While they reduce the need for cash handling and can enhance customer satisfaction, the higher initial investment and dependency on stable internet connectivity can be drawbacks for some businesses.

Customizable Token Machines

Customizable token vending machines feature modular designs that can dispense various types of tokens based on specific business needs. This adaptability makes them suitable for events, attractions, and retail environments where unique offerings are essential. Although they provide flexibility and can cater to diverse customer preferences, the complexity of setup and potentially higher costs should be carefully evaluated by buyers.

Smart Token Vending Machines

Smart token vending machines integrate advanced technology, enabling data analytics and remote monitoring capabilities. These machines are ideal for smart city initiatives and entertainment venues where real-time data can enhance operational efficiency. Despite their advantages, such as improved inventory management, buyers should consider the higher maintenance requirements and the need for technical support, which can add to operational costs.

Mobile Token Vending Kiosks

Mobile token vending kiosks are portable machines that can be easily set up at various locations, making them perfect for festivals and outdoor events. Their flexibility in placement allows businesses to adapt to changing customer flows effectively. However, they typically have limited capacity and may require frequent refilling, which could pose logistical challenges for operators.

Related Video: Machine Learning in 2024 – Beginner’s Course

Key Industrial Applications of token vending machine

| Industry/Sector | Specific Application of Token Vending Machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Transportation | Public Transport Fare Collection | Streamlined payment process, reduced queue times | Integration with existing ticketing systems, currency compatibility |

| Entertainment | Arcade and Amusement Facilities | Increased revenue through cashless transactions | Durability for high usage, user-friendly interface |

| Manufacturing | Employee Access Control | Enhanced security and efficient workforce management | Customization options, compatibility with access control systems |

| Retail | Loyalty Program Rewards Redemption | Improved customer engagement and retention | Software integration with CRM systems, data analytics capabilities |

| Education | Campus Facility Access | Controlled access to facilities, enhanced safety | Scalability to accommodate varying campus sizes, support for multiple token types |

Transportation: Public Transport Fare Collection

Token vending machines are increasingly utilized in public transport systems across Africa, South America, the Middle East, and Europe. By enabling passengers to purchase tokens for fares, these machines significantly reduce the time spent in queues, enhancing overall passenger experience. For international buyers, it is essential to consider the machine’s compatibility with local currencies and existing ticketing systems to ensure seamless integration.

Entertainment: Arcade and Amusement Facilities

In entertainment venues such as arcades, token vending machines facilitate cashless transactions, allowing patrons to easily purchase gaming tokens. This not only increases revenue but also enhances customer satisfaction by minimizing the hassle of carrying cash. Buyers should focus on the machine’s durability and user-friendly interface, as high foot traffic can lead to wear and tear.

Manufacturing: Employee Access Control

In manufacturing settings, token vending machines serve a dual purpose: providing employees with access to secure areas and monitoring attendance. These machines can issue access tokens that limit entry to authorized personnel, thereby improving security. Buyers in this sector need to assess customization options to fit their specific access control systems and ensure compatibility with existing infrastructure.

Retail: Loyalty Program Rewards Redemption

Retail businesses employ token vending machines to streamline the redemption of loyalty rewards. Customers can exchange points for tokens that can be used for purchases, fostering a sense of engagement and loyalty. When sourcing these machines, retailers should evaluate software integration capabilities with their existing CRM systems to maximize data analytics and customer insights.

Education: Campus Facility Access

Educational institutions leverage token vending machines to manage access to various facilities, from libraries to laboratories. These machines allow students to obtain access tokens, ensuring that only authorized individuals can enter sensitive areas. For international buyers, scalability is a critical consideration, as institutions may need to accommodate fluctuating student populations and various token types.

Related Video: How to Start a Vending Machine Business, Cost, Tips, How Much You Make

Strategic Material Selection Guide for token vending machine

When selecting materials for token vending machines, international B2B buyers must consider various factors, including durability, cost, and compliance with regional standards. Here, we analyze four common materials used in the construction of token vending machines: stainless steel, aluminum, plastic, and carbon steel. Each material has distinct properties and implications for performance, cost, and suitability for specific applications.

Stainless Steel

Key Properties: Stainless steel is renowned for its excellent corrosion resistance, high strength, and ability to withstand extreme temperatures. It typically has a temperature rating of up to 800°C and can handle pressures exceeding 1000 psi, depending on the grade.

Pros & Cons: The durability of stainless steel makes it ideal for outdoor installations and environments prone to moisture. However, it is more expensive than other materials, which can impact overall project costs. Manufacturing complexity can also be higher due to the need for specialized tools and techniques.

Impact on Application: Stainless steel is compatible with a wide range of media, including water, air, and various chemicals. Its resistance to corrosion ensures longevity, making it suitable for high-traffic areas.

Considerations for International Buyers: Buyers in regions like Europe may prefer stainless steel due to its compliance with EU standards for food safety and hygiene. In contrast, buyers in Africa and South America should consider local corrosion resistance needs based on environmental conditions.

Aluminum

Key Properties: Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity. It typically operates effectively at temperatures up to 150°C and can handle moderate pressures.

Pros & Cons: The primary advantage of aluminum is its low weight, which simplifies installation and reduces shipping costs. However, it is less durable than stainless steel and can be prone to dents and scratches. Additionally, aluminum may not be suitable for high-pressure applications.

Impact on Application: Aluminum is ideal for applications where weight is a critical factor, such as portable vending machines. However, its lower strength may limit its use in high-traffic or high-impact environments.

Considerations for International Buyers: Buyers from the Middle East should consider the potential for thermal expansion in hot climates. Compliance with local standards for aluminum alloys is also crucial, particularly in Europe, where specific grades may be mandated.

Plastic

Key Properties: Various plastics, such as polycarbonate and ABS, offer excellent impact resistance, lightweight properties, and good chemical resistance. They typically operate effectively at temperatures up to 80°C.

Pros & Cons: Plastics are cost-effective and can be molded into complex shapes, allowing for innovative designs. However, they may not withstand high temperatures or pressures, making them unsuitable for all applications. Their durability can also vary significantly based on the type of plastic used.

Impact on Application: Plastic is suitable for internal components of vending machines, such as coin hoppers and display panels. However, exposure to UV light can lead to degradation over time, limiting outdoor use.

Considerations for International Buyers: Compliance with safety and environmental regulations is essential, especially in Europe, where certain plastics may be restricted. Buyers in Africa and South America should assess local availability and cost of specific plastic types.

Carbon Steel

Key Properties: Carbon steel is known for its high strength and toughness, with a temperature rating typically up to 400°C. However, it lacks inherent corrosion resistance.

Pros & Cons: The primary advantage of carbon steel is its low cost and high strength, making it suitable for structural components. On the downside, it is susceptible to rust and corrosion, necessitating protective coatings.

Impact on Application: Carbon steel is often used for the frame and structural supports of vending machines. However, its susceptibility to corrosion limits its use in humid or wet environments without adequate protection.

Considerations for International Buyers: Buyers in Europe may need to ensure compliance with standards such as EN 10025 for structural steel. In contrast, buyers in the Middle East should consider the effects of high humidity on carbon steel applications.

Summary Table

| Material | Typical Use Case for token vending machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | External casing and high-wear components | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Aluminum | Portable vending machines and internal components | Lightweight and cost-effective | Less durable, prone to dents | Medium |

| Plastic | Internal components like hoppers and display panels | Cost-effective and moldable | Limited temperature and pressure range | Low |

| Carbon Steel | Structural components and frames | High strength and low cost | Susceptible to corrosion | Low |

This material selection guide provides actionable insights for international B2B buyers, enabling informed decisions that align with their operational needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for token vending machine

Manufacturing Processes for Token Vending Machines

Understanding the manufacturing processes of token vending machines is essential for B2B buyers looking to ensure quality and efficiency in their supply chains. The production of these machines typically involves several key stages, each employing specific techniques to guarantee functionality and durability.

Main Stages of Manufacturing

-

Material Preparation

– Material Selection: The primary materials used in token vending machines include metals (steel, aluminum), plastics, and electronic components. The choice of materials impacts durability, weight, and cost.

– Cutting and Shaping: Metals are cut using laser cutting or water jet cutting techniques, while plastics may be molded or extruded. Precision in this stage is critical to ensure parts fit together correctly during assembly. -

Forming

– Stamping and Bending: Metal sheets are often stamped to create necessary shapes and then bent into position. This process requires specialized machinery to achieve the desired specifications.

– Injection Molding: For plastic components, injection molding is a prevalent method. This technique allows for complex shapes and high-volume production with consistent quality. -

Assembly

– Sub-Assembly: Components are often pre-assembled into sub-assemblies (e.g., coin mechanisms, electronic boards) before final assembly. This modular approach enhances efficiency and simplifies troubleshooting.

– Final Assembly: The final assembly involves integrating all components, including mechanical parts, electronics, and the outer casing. Automated assembly lines are commonly used to speed up this process while maintaining accuracy.

- Finishing

– Surface Treatment: This includes painting, powder coating, or galvanizing to enhance aesthetics and protect against corrosion. The choice of finishing technique can affect the machine’s lifespan and maintenance needs.

– Quality Checks: Final inspections are conducted to ensure that all parts meet the required specifications before the machines are packaged and shipped.

Quality Assurance in Manufacturing

Quality assurance (QA) is a critical component in the manufacturing of token vending machines. It ensures that the final product meets both international standards and customer expectations.

International Standards

- ISO 9001: This standard outlines the criteria for a quality management system (QMS). Manufacturers aiming for ISO 9001 certification demonstrate their ability to consistently provide products that meet customer and regulatory requirements.

- CE Marking: For products sold in the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards. This is particularly relevant for buyers in Europe, including countries like Poland and Italy.

- API Standards: The American Petroleum Institute (API) standards may apply if the vending machines are designed for use in gas stations or similar environments, ensuring compatibility and safety.

Key Quality Control Checkpoints

-

Incoming Quality Control (IQC)

– Inspect raw materials and components upon arrival to ensure they meet specified standards before production begins. -

In-Process Quality Control (IPQC)

– Conduct inspections during the manufacturing process. This involves monitoring critical dimensions and functionality at various stages to catch defects early. -

Final Quality Control (FQC)

– Perform comprehensive testing and inspections on completed machines. This includes functionality tests, safety checks, and visual inspections for aesthetic quality.

Common Testing Methods

- Functional Testing: Ensures that all electronic components (e.g., coin acceptors, display screens) operate correctly.

- Durability Testing: Involves subjecting machines to stress tests to evaluate their performance under various conditions, simulating real-world usage.

- Environmental Testing: Checks the machine’s performance under different environmental conditions, such as humidity and temperature extremes.

Verifying Supplier Quality Control

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying supplier quality control is crucial to avoid potential issues.

- Audits: Conduct regular audits of suppliers to assess their manufacturing processes, quality management systems, and compliance with international standards. This can be scheduled annually or bi-annually.

- Quality Reports: Request detailed quality assurance reports from suppliers, outlining their QC processes, test results, and any corrective actions taken for non-conformities.

- Third-Party Inspections: Engage independent third-party inspection services to perform quality assessments before shipment. This adds an extra layer of assurance that the products meet required specifications.

Quality Control Nuances for International Buyers

International B2B buyers should be aware of specific nuances regarding quality control that may impact their purchasing decisions:

- Regulatory Compliance: Different regions have varying regulations regarding safety and quality. Buyers should ensure that their suppliers are compliant with local laws in their target markets.

- Cultural Differences: Understanding the cultural context of suppliers can enhance communication and expectations regarding quality. It’s essential to build strong relationships to facilitate smoother transactions.

- Supply Chain Transparency: Opt for suppliers that provide transparency in their supply chain processes. This includes traceability of materials and components, which can help in addressing quality issues more effectively.

By focusing on these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing token vending machines, ensuring that they meet both quality standards and market demands.

Related Video: The Most Sophisticated Manufacturing Process In The World Inside The Fab | Intel

Comprehensive Cost and Pricing Analysis for token vending machine Sourcing

Cost Structure for Token Vending Machines

When sourcing token vending machines, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include:

-

Materials: The raw materials needed for the production of vending machines, which can include metal, plastic, electronic components, and coin mechanisms. The choice of materials significantly affects the durability and overall quality of the machine.

-

Labor: This encompasses the wages paid to workers involved in the manufacturing process. Labor costs can vary significantly based on geographic location, skill level, and local labor laws.

-

Manufacturing Overhead: This includes indirect costs such as utilities, equipment maintenance, and factory rent. Efficient manufacturing processes can help minimize overhead costs.

-

Tooling: This refers to the costs associated with the tools and machinery required for production. Initial tooling can be a significant upfront expense, especially for custom machines.

-

Quality Control (QC): Ensuring that the machines meet quality standards involves additional costs related to testing and inspection processes.

-

Logistics: Costs incurred in the transportation of the machines from the manufacturer to the buyer. This includes shipping, handling, and any customs duties that may apply.

-

Margin: The profit margin that suppliers add to their costs. This can vary widely depending on the supplier’s business model and market positioning.

Price Influencers in Token Vending Machines

Several factors influence the pricing of token vending machines, which B2B buyers should consider:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to discounts. Understanding the supplier’s MOQ can help in negotiating better prices.

-

Specifications/Customization: Custom features or specifications can increase costs. Buyers should assess whether customizations are necessary or if standard options meet their needs.

-

Materials: The choice of materials can affect both the initial purchase price and the long-term durability of the machine. High-quality materials may lead to higher upfront costs but lower maintenance expenses over time.

-

Quality and Certifications: Machines that meet international quality standards or certifications may command higher prices. Buyers should consider the value of these certifications in relation to their operational needs.

-

Supplier Factors: Supplier reputation, reliability, and service capabilities can impact pricing. Established suppliers may charge more due to their proven track record and support services.

-

Incoterms: The terms of shipping and delivery can influence costs. Understanding Incoterms helps buyers clarify who is responsible for various aspects of shipping, which can affect total costs.

Buyer Tips for Cost-Efficiency

To maximize value when sourcing token vending machines, consider the following strategies:

-

Negotiate Effectively: Leverage volume commitments and long-term partnerships to negotiate better pricing and terms. Building a strong relationship with suppliers can also lead to future discounts.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider maintenance, repair, and operational costs over the machine’s lifespan to assess true value.

-

Understand Pricing Nuances: Different regions may have varying pricing structures due to local economic conditions, tariffs, and supply chain dynamics. Buyers from Africa, South America, the Middle East, and Europe (e.g., Poland, Italy) should account for these factors in their pricing evaluations.

-

Stay Informed on Market Trends: Regularly monitor industry trends and market shifts to anticipate changes in pricing. This can help buyers make timely purchasing decisions.

-

Request Detailed Quotes: Ensure that quotes from suppliers itemize costs clearly. This transparency will aid in comparing offers and understanding the breakdown of expenses.

Disclaimer

Prices indicated in this analysis are subject to change based on market conditions, supplier negotiations, and other external factors. Always consult with suppliers for the most accurate and current pricing information.

Spotlight on Potential token vending machine Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘token vending machine’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for token vending machine

When evaluating token vending machines for international procurement, understanding essential technical properties and trade terminology is critical for informed decision-making. This guide aims to clarify these aspects for B2B buyers, particularly in Africa, South America, the Middle East, and Europe.

Key Technical Properties

-

Material Grade

The material grade of a vending machine impacts its durability and maintenance requirements. Common materials include stainless steel and high-grade plastics, which resist corrosion and wear. For B2B buyers, selecting the right material ensures longevity and reduces replacement costs, especially in high-traffic environments. -

Tolerance Levels

Tolerance refers to the allowable deviation in manufacturing dimensions. For token vending machines, maintaining strict tolerances is essential for ensuring proper function and reliability. Poor tolerances can lead to mechanical failures or increased downtime, affecting customer satisfaction. Buyers should inquire about tolerance specifications to ensure compatibility with their operational standards. -

Power Supply Specifications

Understanding the power requirements, including voltage and frequency, is crucial, particularly for international transactions. Different regions have varying electrical standards; thus, machines must be compatible with local power supply conditions. This knowledge helps prevent operational issues and ensures compliance with local regulations. -

Capacity

The capacity of a vending machine—how many tokens it can hold and dispense—directly affects its operational efficiency. Buyers should evaluate their expected usage rates to select a machine that meets their demand without frequent refills. A higher capacity can also mean lower operational costs over time. -

User Interface

The usability of the vending machine’s interface is vital for customer satisfaction. Features such as touch screens, multilingual options, and user-friendly navigation can enhance the user experience. B2B buyers should consider the target demographic when evaluating these features to ensure accessibility and ease of use. -

Security Features

Security is a paramount concern for vending machine operators. Features such as anti-theft mechanisms, secure payment processing, and surveillance capabilities can protect investments. Understanding these properties helps buyers mitigate risks associated with theft and fraud.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts and equipment that may be marketed by another manufacturer. In the context of token vending machines, working with reputable OEMs ensures quality and compatibility of components, which is crucial for reliable operation. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, understanding MOQ is essential for budgeting and inventory planning. Negotiating lower MOQs can be beneficial, especially for small businesses or startups. -

RFQ (Request for Quotation)

An RFQ is a document that an organization sends to suppliers to request pricing and other details about a product. In the vending machine industry, an RFQ helps buyers compare offers and make informed purchasing decisions. A well-structured RFQ can streamline the procurement process. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. Understanding these terms, such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight), is crucial for B2B buyers to clarify shipping costs, risks, and delivery obligations. -

Lead Time

Lead time is the period between the initiation of an order and its completion. For token vending machines, lead time affects inventory management and cash flow. Buyers should factor in lead times to ensure they meet market demands without overstocking or running out of products. -

Warranty

A warranty is a guarantee provided by the manufacturer regarding the condition of the vending machine and its parts. Understanding warranty terms is essential for B2B buyers, as it impacts potential repair costs and the longevity of the investment.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make more informed decisions, ensuring that their procurement processes are efficient, cost-effective, and aligned with their operational needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the token vending machine Sector

Market Overview & Key Trends

The token vending machine sector is undergoing significant transformation driven by several global factors. The rise of cashless transactions and the increasing adoption of digital payment systems are reshaping the landscape. In regions like Africa and South America, mobile payment technologies are gaining traction, prompting manufacturers to integrate advanced payment solutions into vending machines. This shift not only enhances user convenience but also opens new revenue streams for businesses.

Emerging technologies such as IoT (Internet of Things) are also playing a crucial role. Smart vending machines equipped with sensors can monitor inventory levels and collect consumer data, enabling businesses to optimize operations and tailor offerings to customer preferences. This trend is particularly relevant for international buyers, as it allows for data-driven decision-making that can improve profitability.

Moreover, sustainability is becoming a key consideration in the purchasing decisions of B2B buyers. As environmental regulations tighten globally, manufacturers are expected to adopt eco-friendly practices and materials. This includes the use of recyclable materials in machine production and energy-efficient designs that reduce operational costs. For buyers in Europe, particularly in markets like Poland and Italy, aligning with suppliers who prioritize sustainability can enhance brand reputation and meet consumer demand for greener options.

Sustainability & Ethical Sourcing in B2B

Sustainability and ethical sourcing are increasingly critical in the token vending machine sector. The environmental impact of manufacturing processes and materials used in these machines cannot be overlooked. For instance, the production of traditional vending machines often involves significant energy consumption and waste generation. Consequently, B2B buyers are encouraged to seek suppliers who utilize renewable energy sources and implement waste reduction strategies in their manufacturing processes.

Moreover, the importance of ethical supply chains is paramount. Buyers should prioritize partnerships with manufacturers who adhere to fair labor practices and have transparent sourcing policies. Certifications such as ISO 14001 for environmental management and Fair Trade certification can serve as indicators of a supplier’s commitment to sustainability and ethical practices.

In terms of materials, opting for machines made from recycled or sustainably sourced components is a practical step towards reducing the carbon footprint. Additionally, integrating biodegradable or eco-friendly materials into the machine’s design can enhance its appeal to environmentally conscious consumers, particularly in European markets where such attributes are increasingly valued.

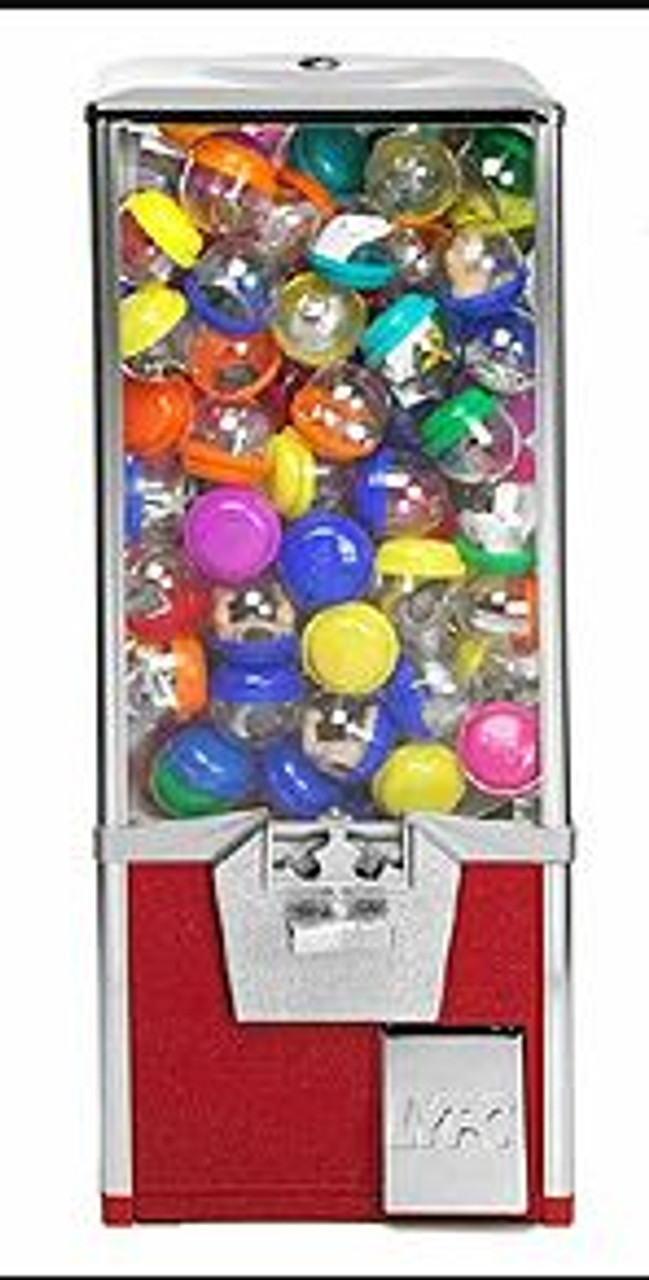

Illustrative Image (Source: Google Search)

Brief Evolution/History

The evolution of token vending machines can be traced back to their inception in the late 19th century, primarily serving the amusement and entertainment sectors. Initially, these machines dispensed tokens for games or rides, but as technology advanced, their applications expanded significantly. By the mid-20th century, vending machines began to incorporate a wider range of products, from snacks to tickets.

The integration of electronic payment systems in the late 20th century marked a pivotal shift, allowing for cashless transactions and enhancing user convenience. Today, with the advent of IoT and smart technologies, the industry is witnessing a new wave of innovation. Modern token vending machines are not only functional but also equipped with features that enhance user interaction and operational efficiency, making them a vital component of the evolving retail landscape. This historical context underscores the importance of staying abreast of technological advancements and market dynamics for B2B buyers navigating this sector.

Related Video: International Trade 101 | Economics Explained

Frequently Asked Questions (FAQs) for B2B Buyers of token vending machine

-

What key factors should I consider when vetting suppliers of token vending machines?

When vetting suppliers, prioritize their industry experience, reputation, and customer reviews. Check for certifications relevant to your region, such as ISO or CE marks, which indicate compliance with international standards. It’s also crucial to assess their financial stability and after-sales support services. Engaging in direct communication can provide insights into their responsiveness and willingness to customize products to meet your specific needs. -

Can token vending machines be customized for specific markets or branding?

Yes, many suppliers offer customization options for token vending machines, including branding, color schemes, and functionality tailored to local market needs. Before placing an order, discuss your requirements with the supplier to ensure they can accommodate your requests. Customization may involve additional costs and longer lead times, so factor this into your project timeline and budget. -

What are the typical minimum order quantities (MOQs) and lead times for token vending machines?

Minimum order quantities can vary significantly between suppliers, often ranging from 10 to 50 units for bulk purchases. Lead times also differ based on customization and supplier location, typically ranging from 4 to 12 weeks. It’s advisable to confirm these details during initial discussions and consider ordering samples to evaluate product quality before committing to larger orders. -

What payment methods are commonly accepted when sourcing token vending machines internationally?

Most suppliers accept various payment methods, including bank transfers, letters of credit, and PayPal. For international transactions, ensure you understand the currency exchange rates and any additional fees that may apply. Negotiate favorable payment terms, such as a deposit upfront and the balance upon delivery, to mitigate financial risks. -

How can I ensure quality assurance and certifications for token vending machines?

Request detailed information about the quality assurance processes implemented by the supplier. Ask for copies of relevant certifications and testing reports that demonstrate compliance with international standards. Consider conducting factory visits or third-party inspections to verify product quality before shipment, especially for bulk orders. -

What logistics considerations should I keep in mind when importing token vending machines?

When importing, consider shipping methods (air vs. sea), customs regulations, and potential tariffs that may apply to your country. Engage a reliable freight forwarder who can assist with logistics and documentation. Ensure your supplier provides the necessary export documentation, such as commercial invoices and packing lists, to facilitate a smooth customs clearance process. -

How can disputes with suppliers be effectively managed?

Clear communication is key in managing disputes. Establish a written contract that outlines terms, including delivery timelines, product specifications, and payment terms. In case of disputes, try resolving them amicably through negotiation. If necessary, consider mediation or arbitration as alternatives to litigation, which can be costly and time-consuming. -

What are the best practices for post-purchase support and maintenance of token vending machines?

Ensure your supplier provides comprehensive post-purchase support, including installation, training, and maintenance services. Establish a clear communication channel for reporting issues or requesting assistance. Regular maintenance checks are essential to ensure optimal performance and longevity of the machines, so consider scheduling these in advance to avoid operational disruptions.

Illustrative Image (Source: Google Search)

Strategic Sourcing Conclusion and Outlook for token vending machine

The strategic sourcing of token vending machines presents a valuable opportunity for international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. By understanding the unique market dynamics and consumer preferences within these regions, buyers can make informed decisions that enhance operational efficiency and customer satisfaction.

Key Takeaways:

- Market Awareness: Recognizing regional differences in demand can lead to more tailored offerings and improved sales outcomes.

- Supplier Relationships: Building strong partnerships with reputable manufacturers ensures access to quality products and support, which is crucial for long-term success.

- Technological Integration: Embracing innovations such as cashless payment systems and remote management features can significantly enhance user experience and operational control.

As we look to the future, the token vending machine market is poised for growth, driven by increasing urbanization and technological advancements. B2B buyers are encouraged to leverage strategic sourcing not just as a procurement function, but as a catalyst for competitive advantage. Engage with suppliers early, explore customization options, and remain adaptable to market changes to maximize value. The time to invest in this burgeoning market is now—seize the opportunity to position your business for success.