Master Sourcing Tap Card Vending Machines for Enhanced B2B

Guide to Tap Card Vending Machine

- Introduction: Navigating the Global Market for tap card vending machine

- Understanding tap card vending machine Types and Variations

- Key Industrial Applications of tap card vending machine

- Strategic Material Selection Guide for tap card vending machine

- In-depth Look: Manufacturing Processes and Quality Assurance for tap card vending machine

- Comprehensive Cost and Pricing Analysis for tap card vending machine Sourcing

- Spotlight on Potential tap card vending machine Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for tap card vending machine

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the tap card vending machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of tap card vending machine

- Strategic Sourcing Conclusion and Outlook for tap card vending machine

Introduction: Navigating the Global Market for tap card vending machine

In today’s rapidly evolving marketplace, the tap card vending machine stands as a pivotal technology for businesses seeking to enhance operational efficiency and customer engagement. These machines are not just tools for dispensing products; they represent a growing trend towards contactless transactions, which have become essential in a post-pandemic world. For international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe, understanding the nuances of this technology is crucial for making informed sourcing decisions.

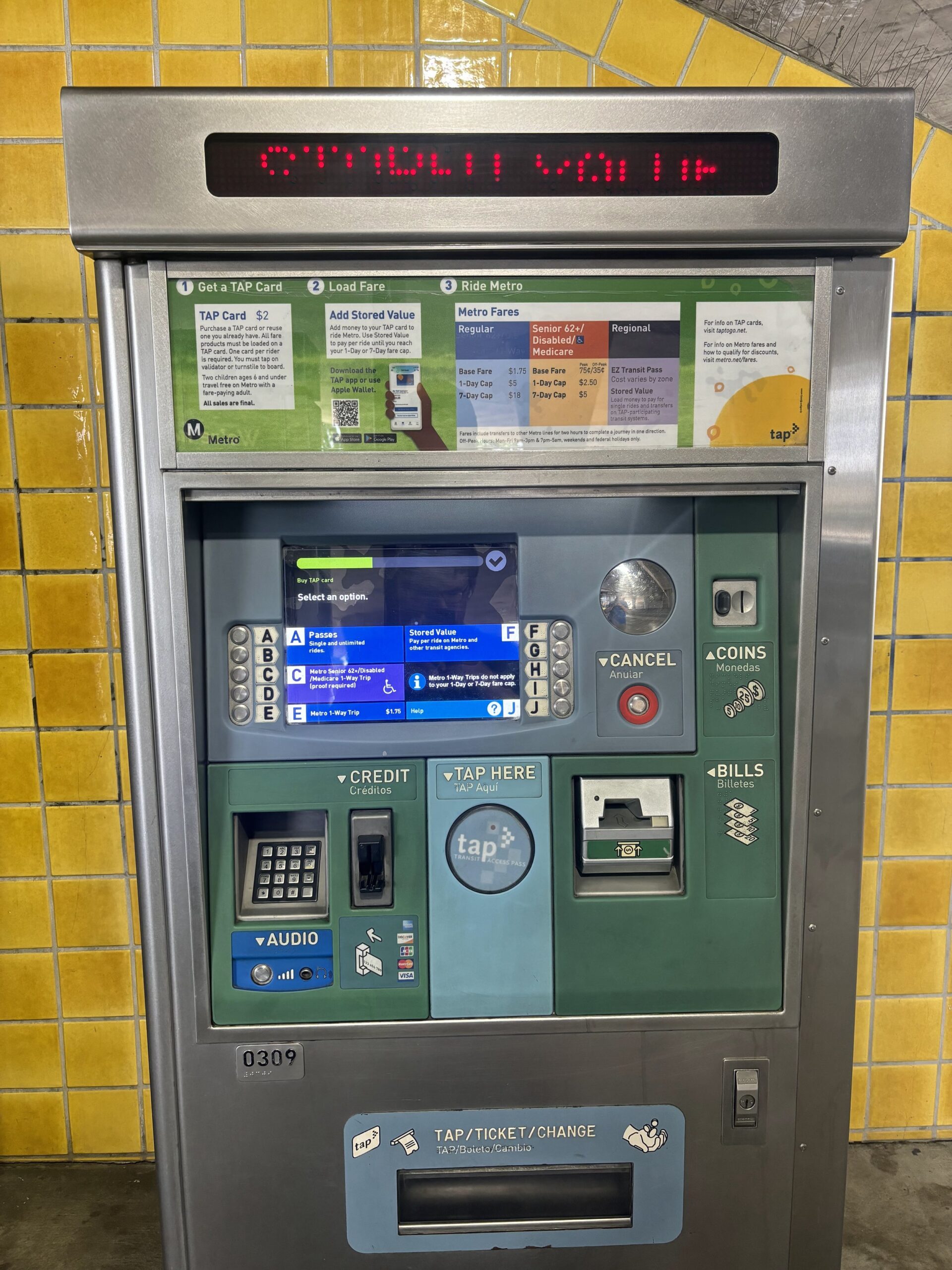

Illustrative Image (Source: Google Search)

This comprehensive guide delves into the various types of tap card vending machines available, their materials, and the manufacturing processes that ensure quality and reliability. Buyers will gain insights into the landscape of suppliers, enabling them to identify reputable partners that align with their business needs. Additionally, we will explore cost considerations and market trends that influence pricing, ensuring that buyers can negotiate effectively.

With a focus on practical applications, the guide will address frequently asked questions, equipping buyers with the knowledge needed to navigate challenges and seize opportunities in the global market. By leveraging this information, B2B buyers can make strategic decisions that enhance their operations, improve customer satisfaction, and ultimately drive growth in their respective markets.

Understanding tap card vending machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Tap Card Vending Machine | Accepts various card types, user-friendly interface | Public transport, event venues | Pros: Easy to use, widely accepted; Cons: Limited customization options. |

| Mobile Tap Card Vending Machine | Compact, often battery-operated, connects to mobile apps | Festivals, remote locations | Pros: Portable, flexible payment options; Cons: May require frequent charging. |

| Integrated Tap Card Kiosks | Combines vending with information display | Shopping malls, airports | Pros: Dual functionality, enhances user engagement; Cons: Higher initial investment. |

| Contactless Payment Vending Machine | Supports NFC and RFID technologies | Retail, convenience stores | Pros: Fast transactions, reduces cash handling; Cons: May require infrastructure upgrades. |

| Customizable Tap Card Solutions | Tailored to specific business needs, branding options | Corporate events, branded promotions | Pros: Unique branding, meets specific requirements; Cons: Longer lead times for delivery. |

Standard Tap Card Vending Machine

Standard tap card vending machines are designed for high-volume environments like public transport systems and event venues. They typically accept a variety of card types and feature a user-friendly interface, making them accessible to a broad audience. When considering these machines, B2B buyers should evaluate the machine’s compatibility with existing card systems and the potential for integration with ticketing or loyalty programs. While they are easy to use, customization options may be limited, which could be a drawback for businesses seeking a unique branding opportunity.

Mobile Tap Card Vending Machine

Mobile tap card vending machines offer portability and flexibility, making them ideal for temporary setups at festivals or remote locations. These machines often operate on battery power and can connect to mobile applications for a seamless user experience. B2B buyers should consider the frequency of use and the need for charging infrastructure, as these machines may require more maintenance than stationary options. Their compact design and adaptability to various payment methods are significant advantages, though they may not be suitable for high-volume sales.

Integrated Tap Card Kiosks

Integrated tap card kiosks combine vending capabilities with information displays, providing an interactive experience for users. Commonly found in shopping malls and airports, these kiosks can serve dual purposes, enhancing customer engagement while facilitating transactions. B2B buyers should assess the initial investment costs against the potential for increased foot traffic and customer interaction. While they offer advanced functionality, the complexity of the technology could lead to higher maintenance costs.

Contactless Payment Vending Machine

Contactless payment vending machines leverage NFC and RFID technologies to enable fast transactions, catering to the growing demand for cashless payment solutions. These machines are particularly effective in retail and convenience store environments, where speed and efficiency are paramount. Buyers should consider the infrastructure needed to support these machines, as they may require upgrades to existing systems. While they enhance transaction speed and reduce cash handling, the initial setup costs could be a concern for budget-conscious businesses.

Customizable Tap Card Solutions

Customizable tap card solutions are tailored to meet specific business needs, offering branding opportunities and unique functionalities. These machines are suitable for corporate events and promotional activities, allowing businesses to create a memorable customer experience. B2B buyers should weigh the benefits of customization against the longer lead times for delivery and potential higher costs. While these solutions can effectively enhance brand visibility, the complexity of customization may require additional planning and coordination.

Related Video: DIY Card Vending Machine – Easy Cardboard Craft

Key Industrial Applications of tap card vending machine

| Industry/Sector | Specific Application of tap card vending machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Transportation | Ticketing solutions for public transport systems | Streamlined fare collection, reduced queue times | Compatibility with local payment systems, ease of integration |

| Retail | Contactless payment for merchandise | Enhanced customer experience, faster transaction times | Durability, user-friendly interface, and support for multiple currencies |

| Events and Venues | Access control for events and exhibitions | Improved security, efficient attendee management | Integration with event management software, scalability for large crowds |

| Hospitality | Room key management in hotels | Increased guest satisfaction, operational efficiency | Customization options, remote management capabilities |

| Education | Campus access control and services | Enhanced safety, streamlined student services | Compatibility with student ID systems, data privacy compliance |

Transportation

In the transportation sector, tap card vending machines are utilized for ticketing solutions in public transport systems. They facilitate contactless fare collection, allowing passengers to quickly tap their cards for entry, which significantly reduces queue times. For international buyers, it’s crucial to consider compatibility with local payment systems and the ease of integration with existing transport infrastructure.

Retail

In retail, tap card vending machines serve as contactless payment solutions for merchandise. This technology enhances the customer experience by enabling faster transaction times and reducing the need for cash handling. B2B buyers should focus on the durability of the machines, a user-friendly interface, and support for multiple currencies to cater to diverse customer bases, especially in regions with varying payment preferences.

Events and Venues

For events and venues, tap card vending machines are essential for access control, improving security and attendee management. They allow event organizers to efficiently manage entry points and track attendance, which is vital for safety and logistical planning. Buyers in this sector should consider the integration capabilities with event management software and the scalability of the machines to accommodate large crowds.

Hospitality

In the hospitality industry, tap card vending machines are used for room key management in hotels. They streamline the check-in process, allowing guests to access their rooms with a simple tap, thus enhancing guest satisfaction and operational efficiency. Buyers should look for customization options that align with their branding and remote management capabilities to facilitate operations across multiple locations.

Education

In educational institutions, tap card vending machines are employed for campus access control and various student services. This technology enhances safety by restricting access to authorized individuals and streamlining services such as library access and cafeteria payments. International B2B buyers need to ensure compatibility with existing student ID systems and compliance with data privacy regulations to protect student information.

Related Video: How to use an OMNY card vending machine

Strategic Material Selection Guide for tap card vending machine

When selecting materials for tap card vending machines, international B2B buyers must consider various factors that affect performance, durability, and compliance with regional standards. Here, we analyze four common materials used in the construction of these machines: stainless steel, aluminum, polycarbonate, and ABS plastic. Each material has distinct properties, advantages, and limitations that can influence the overall functionality and marketability of the vending machines.

Stainless Steel

Key Properties: Stainless steel is known for its excellent corrosion resistance, high tensile strength, and ability to withstand extreme temperatures. It typically has a temperature rating of up to 800°C and is resistant to many chemicals, making it suitable for outdoor installations.

Pros & Cons: The primary advantage of stainless steel is its durability and longevity, which can significantly reduce maintenance costs. However, it is more expensive than other materials, which may impact the overall cost of the vending machine. Additionally, the manufacturing complexity can be higher due to the need for specialized welding and finishing processes.

Impact on Application: Stainless steel is highly compatible with various media, including water and other liquids, making it ideal for vending machines that dispense beverages or require cleaning.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local corrosion resistance standards. In Europe, adherence to ASTM and DIN standards is crucial, particularly for outdoor applications.

Aluminum

Key Properties: Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity. It can withstand moderate temperatures, typically up to 300°C, and is often anodized for enhanced surface protection.

Pros & Cons: The lightweight nature of aluminum allows for easier transportation and installation, which can reduce logistics costs. However, it is less durable than stainless steel and may be prone to dents and scratches. This can affect the aesthetic appeal over time.

Impact on Application: Aluminum is suitable for indoor vending machines or those located in low-impact environments. Its compatibility with various media is generally good, but it may not be ideal for high-humidity or corrosive environments.

Considerations for International Buyers: Buyers should be aware of the specific anodizing standards in their region to ensure longevity. Compliance with JIS standards may be necessary for buyers in Asia, while European buyers should consider EN standards.

Polycarbonate

Key Properties: Polycarbonate is a thermoplastic known for its high impact resistance and optical clarity. It can withstand temperatures up to 120°C and is lightweight, making it an attractive option for certain components of vending machines.

Pros & Cons: The main advantage of polycarbonate is its excellent impact resistance, which reduces the risk of breakage in high-traffic areas. However, it is less durable than metals and can be susceptible to scratching and UV degradation over time.

Impact on Application: Polycarbonate is often used for protective covers and displays in vending machines, providing visibility while protecting internal components. Its chemical resistance is good, but it may not be suitable for exposure to certain solvents.

Considerations for International Buyers: Buyers should ensure that polycarbonate materials meet relevant safety standards, particularly in Europe where EN standards apply. In regions like the Middle East, UV resistance may be a critical factor due to high sunlight exposure.

ABS Plastic

Key Properties: ABS (Acrylonitrile Butadiene Styrene) is a thermoplastic known for its toughness and impact resistance. It operates effectively at temperatures up to 80°C and is often used in applications requiring a balance of strength and flexibility.

Pros & Cons: ABS is cost-effective and easy to mold, which simplifies manufacturing processes. However, it is less resistant to heat and chemicals compared to other materials, which can limit its application in harsher environments.

Impact on Application: ABS is suitable for internal components and housing of vending machines. Its compatibility with various media is generally acceptable, but it may not be ideal for machines dispensing hot liquids.

Considerations for International Buyers: Compliance with safety and environmental standards is essential, particularly in Europe where REACH regulations may apply. Buyers in Africa and South America should also consider local regulations regarding plastic use.

Summary Table

| Material | Typical Use Case for tap card vending machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Outdoor vending machines, high-traffic areas | Exceptional durability and corrosion resistance | Higher cost, complex manufacturing | High |

| Aluminum | Indoor vending machines | Lightweight and easy to transport | Less durable, prone to dents | Medium |

| Polycarbonate | Protective covers, displays | High impact resistance | Susceptible to scratching, UV degradation | Medium |

| ABS Plastic | Internal components, housing | Cost-effective and easy to mold | Less heat and chemical resistance | Low |

This strategic material selection guide provides B2B buyers with essential insights into the properties, advantages, and limitations of materials used in tap card vending machines. Understanding these factors can help buyers make informed decisions that align with their operational needs and market requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for tap card vending machine

The manufacturing of tap card vending machines involves a series of well-defined stages, each crucial for ensuring the final product meets the required standards for functionality, durability, and user experience. For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, understanding these processes can help in making informed purchasing decisions.

Manufacturing Process

1. Material Preparation

The initial phase involves sourcing high-quality materials, including metals, plastics, and electronic components. Common materials used in the manufacturing of tap card vending machines include:

- Metal Alloys: Used for structural components to ensure durability and resistance to wear and tear.

- Plastics: Typically utilized for exterior casings and internal fixtures, chosen for their lightweight and corrosion-resistant properties.

- Electronic Components: Such as card readers, microcontrollers, and payment processing modules, are sourced from reliable suppliers to guarantee performance.

2. Forming

Once materials are prepared, they undergo various forming processes:

- Sheet Metal Fabrication: Metal sheets are cut, bent, and shaped using techniques like laser cutting and CNC machining to create the machine’s chassis.

- Injection Molding: This method is often used for producing plastic parts, ensuring precision and consistency in shape and size.

- PCB Assembly: The electronic circuit boards are assembled, including soldering components onto the boards and integrating them with other electronic systems.

3. Assembly

In the assembly phase, all components are brought together:

- Mechanical Assembly: The chassis is assembled with the internal mechanisms, including card dispensers, coin mechanisms, and payment interfaces.

- Electrical Integration: Wiring and connecting electronic components, ensuring that all systems communicate effectively and are properly powered.

- Software Installation: The machine’s operating system and software applications are installed, programmed, and tested for functionality.

4. Finishing

The final stage of manufacturing involves aesthetic and functional enhancements:

- Surface Treatment: This may include painting, powder coating, or applying protective coatings to enhance durability and appearance.

- Quality Checks: Each unit undergoes a series of inspections to verify that it meets design specifications and functional requirements before it is packaged and shipped.

Quality Assurance

Quality assurance is vital for ensuring that tap card vending machines operate reliably and meet international standards.

Relevant International Standards

B2B buyers should be aware of the following quality standards:

- ISO 9001: This standard outlines the requirements for a quality management system, ensuring that manufacturers consistently provide products that meet customer and regulatory requirements.

- CE Marking: Indicates that the product complies with EU safety, health, and environmental protection standards, which is essential for machines sold in European markets.

- API Standards: For specific components, especially those related to electronic payment processing, adhering to API standards ensures compatibility and security.

Quality Control Checkpoints

Quality control (QC) is integrated at several points in the manufacturing process:

- Incoming Quality Control (IQC): Materials and components are inspected upon arrival to ensure they meet predefined specifications.

- In-Process Quality Control (IPQC): Checks conducted during the manufacturing process to monitor the production and identify any deviations from the standards.

- Final Quality Control (FQC): A comprehensive evaluation of the finished product, ensuring it meets all functional and aesthetic criteria before shipping.

Common Testing Methods

Testing methods play a crucial role in the QC process:

- Functional Testing: Each machine is tested to ensure that all features work as intended, including card reading, payment processing, and dispensing mechanisms.

- Environmental Testing: Machines may be subjected to temperature and humidity tests to ensure they can withstand various environmental conditions.

- Safety Testing: Compliance with safety standards to prevent electrical failures or hazards during operation.

Verifying Supplier Quality Control

B2B buyers must be diligent in verifying the quality control measures of their suppliers. Here are some actionable steps:

- Supplier Audits: Conducting regular audits of suppliers can help assess their adherence to quality standards and manufacturing practices.

- Quality Reports: Requesting detailed quality reports, including metrics on defect rates and compliance with standards, provides insight into the supplier’s performance.

- Third-Party Inspections: Engaging third-party inspection services can provide unbiased evaluations of the manufacturing processes and final products, ensuring they meet required specifications.

QC and Certification Nuances for International Buyers

When dealing with suppliers from different regions, it is crucial to understand the nuances of quality certifications:

- Local Standards Compliance: Different regions may have specific standards; for instance, CE marking is essential for Europe, while UL certification may be necessary for North America. Buyers should ensure that the manufacturer complies with the relevant certifications for their target market.

- Cultural and Regional Differences: Understanding the manufacturing culture in regions like Africa or South America may require additional due diligence, as practices may vary significantly from those in Europe or North America.

- Supply Chain Transparency: Buyers should seek suppliers who provide transparency in their supply chain processes, ensuring that all materials and components are sourced ethically and sustainably.

By gaining insights into the manufacturing processes and quality assurance mechanisms for tap card vending machines, B2B buyers can make informed decisions that align with their operational needs and market standards.

Related Video: Lean Manufacturing – Lean Factory Tour – FastCap

Comprehensive Cost and Pricing Analysis for tap card vending machine Sourcing

To effectively source tap card vending machines, international B2B buyers must understand the comprehensive cost structure and pricing dynamics involved in this market. The cost components and price influencers play a significant role in determining the overall expenditure and negotiation strategies.

Cost Components

- Materials: The primary materials used in the manufacturing of tap card vending machines include metals, plastics, electronic components, and touchscreens. The choice of materials significantly impacts the durability, functionality, and ultimately the cost of the machine. For instance, higher-grade materials may increase initial costs but can reduce long-term maintenance expenses.

Illustrative Image (Source: Google Search)

-

Labor: Labor costs vary by region and can be influenced by local wage standards. In countries with higher labor costs, like those in Europe, the manufacturing expenses will be more pronounced compared to regions in Africa or South America, where labor may be less expensive.

-

Manufacturing Overhead: This includes expenses related to the factory’s operations, such as utilities, rent, and management salaries. Understanding the overhead can help buyers assess the price competitiveness of different suppliers.

-

Tooling: Customization of vending machines often requires specific tooling, which can be a significant upfront cost. Buyers should consider how tooling costs will affect the overall pricing, especially for bespoke machines.

-

Quality Control (QC): Quality assurance processes are critical, especially for electronic devices. The costs associated with QC can vary widely among suppliers. Buyers should inquire about the QC measures in place and their costs, as they directly affect the machine’s reliability and lifespan.

-

Logistics: Shipping and handling costs can add significantly to the total cost, particularly for international orders. Factors such as distance, shipping method, and customs duties must be considered.

-

Margin: Suppliers typically apply a margin over their costs, which can vary based on market competition and demand. Understanding typical margins in the industry can help buyers negotiate better deals.

Price Influencers

-

Volume/MOQ (Minimum Order Quantity): Bulk purchases often lead to discounts. Buyers should evaluate their needs and consider negotiating prices based on order quantities.

-

Specifications/Customization: Customized machines can incur additional costs. Buyers should assess the necessity of custom features versus off-the-shelf models to maximize cost efficiency.

-

Materials: The choice of materials can affect both the cost and the quality of the vending machine. Discussing material options with suppliers can lead to potential savings.

-

Quality/Certifications: Machines that meet international standards or have specific certifications (like CE or ISO) may command higher prices but can offer better reliability and lower total costs in the long run.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more but can provide better quality and service.

-

Incoterms: Understanding the agreed terms of shipping (such as FOB, CIF, etc.) is critical, as it affects who bears the costs and risks during transit.

Buyer Tips

-

Negotiation: Be prepared to negotiate on price, especially when ordering in bulk. Leveraging multiple quotes can provide leverage during discussions.

-

Cost-Efficiency: Assess the total cost of ownership rather than just the purchase price. This includes maintenance, operational costs, and potential downtime costs.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, tariffs, and local taxation that may impact the final cost. Engaging with local experts can provide insights into hidden costs.

-

Supplier Relationships: Building long-term relationships with suppliers can lead to better pricing and terms over time.

-

Research and Due Diligence: Conduct thorough research on potential suppliers, including their manufacturing capabilities, quality control processes, and customer reviews.

In conclusion, understanding the intricate details of cost components and pricing influencers is vital for international B2B buyers in the tap card vending machine market. By applying these insights, buyers can make informed decisions that enhance their sourcing strategies.

Disclaimer: Prices and costs are indicative and may vary based on market conditions and specific buyer requirements. Always consult with suppliers for accurate and up-to-date pricing information.

Spotlight on Potential tap card vending machine Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘tap card vending machine’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for tap card vending machine

Key Technical Properties of Tap Card Vending Machines

When evaluating tap card vending machines, B2B buyers should focus on several critical technical specifications that influence performance, durability, and overall value. Here are key properties to consider:

-

Material Grade

– Definition: The quality and type of materials used in the construction of the vending machine, typically metals like stainless steel or aluminum, and durable plastics.

– Importance: High-grade materials enhance durability, resistance to corrosion, and overall lifespan, which is essential for machines exposed to various environmental conditions, particularly in outdoor settings. -

Power Supply Specifications

– Definition: Voltage and current requirements necessary for the operation of the vending machine, often specified in volts (V) and amps (A).

– Importance: Understanding power requirements ensures compatibility with local electrical standards, reducing the risk of operational failures or the need for additional electrical infrastructure. -

User Interface Technology

– Definition: The type of interface used for customer interactions, such as touchscreen displays or physical buttons, often coupled with card readers.

– Importance: A user-friendly interface improves customer experience, leading to higher sales. Businesses should assess whether the technology aligns with their target market’s preferences. -

Capacity and Size

– Definition: The dimensions of the machine and the volume of products it can hold, often measured in liters or number of items.

– Importance: Capacity influences the machine’s operational efficiency and suitability for various locations. Buyers must consider space constraints and demand forecasts when selecting the size. -

Connectivity Options

– Definition: Availability of network connections such as Wi-Fi, Ethernet, or cellular data for remote management and monitoring.

– Importance: Connectivity allows for real-time inventory tracking, sales data analysis, and remote troubleshooting, which can significantly reduce operational downtime. -

Security Features

– Definition: Mechanisms implemented to protect the machine against theft and vandalism, including reinforced locks, alarms, and surveillance integration.

– Importance: Investing in robust security features minimizes loss and maintenance costs, making the machine more appealing to operators.

Common Trade Terminology in the Vending Machine Industry

Familiarity with industry jargon is crucial for effective communication and negotiation in the B2B landscape. Here are essential terms to understand:

- OEM (Original Equipment Manufacturer)

- Definition: A company that produces parts and equipment that may be marketed by another manufacturer.

-

Relevance: Knowing whether a vending machine is produced by an OEM can affect warranty considerations and the availability of replacement parts.

-

MOQ (Minimum Order Quantity)

- Definition: The smallest quantity of a product that a supplier is willing to sell.

-

Relevance: Understanding MOQ is vital for budgeting and planning inventory, especially for businesses looking to minimize upfront costs.

-

RFQ (Request for Quotation)

- Definition: A document sent to suppliers to solicit price quotes for specific products or services.

-

Relevance: Submitting RFQs can help businesses compare prices and terms from multiple vendors, facilitating better purchasing decisions.

-

Incoterms (International Commercial Terms)

- Definition: A set of predefined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international transactions.

-

Relevance: Familiarity with Incoterms can help buyers understand shipping responsibilities, costs, and risks, ensuring smoother cross-border transactions.

-

Lead Time

- Definition: The time taken from placing an order to the delivery of the product.

-

Relevance: Knowing the lead time is essential for planning inventory and ensuring that products are available when needed, particularly in high-demand situations.

-

Warranty Period

- Definition: The duration for which a product is guaranteed against defects or malfunctions.

- Relevance: A longer warranty period often indicates higher quality and can provide peace of mind for businesses investing in expensive vending machines.

Understanding these technical properties and trade terms will empower international B2B buyers to make informed decisions when sourcing tap card vending machines, enhancing operational efficiency and profitability.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the tap card vending machine Sector

Market Overview & Key Trends

The tap card vending machine sector is witnessing substantial growth globally, driven by the increasing demand for contactless payment solutions and the need for convenient, automated retail experiences. Key markets in Africa, South America, the Middle East, and Europe are adapting to these trends, with international B2B buyers seeking innovative vending solutions that integrate advanced technology.

Global Drivers:

1. Shift Towards Contactless Payments: The rise in contactless transactions, particularly post-pandemic, has accelerated the adoption of tap card vending machines. This trend is crucial for buyers looking to enhance customer convenience and improve transaction speeds.

2. Urbanization and Smart Cities: As urban areas expand, the demand for automated solutions in public spaces grows. Vending machines equipped with tap card technology are becoming essential in transport hubs, malls, and educational institutions.

3. Technological Advancements: The integration of IoT (Internet of Things) in vending solutions provides real-time data analytics, enabling better inventory management and operational efficiency. Buyers should consider suppliers offering robust software support alongside hardware.

Emerging B2B Tech/Sourcing Trends:

– Customization and Personalization: B2B buyers are increasingly looking for customizable machines that can cater to specific market needs, such as unique product offerings or branding requirements.

– Sustainable Solutions: There is a growing emphasis on sustainability, with buyers preferring machines made from eco-friendly materials and those that utilize energy-efficient technologies.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a cornerstone for B2B buyers in the tap card vending machine market. The environmental impact of manufacturing and operating vending machines is under scrutiny, urging companies to adopt greener practices.

Importance of Ethical Supply Chains:

– Environmental Responsibility: Buyers are now demanding that suppliers demonstrate reduced carbon footprints and responsible sourcing of materials. This includes using recycled materials and minimizing waste throughout the manufacturing process.

– Transparency: An ethical supply chain fosters trust. Buyers should look for suppliers who can provide clear documentation regarding their sourcing practices and the environmental impact of their operations.

Green Certifications and Materials:

– Consider vendors that offer products with certifications like ISO 14001 (Environmental Management) or those compliant with RoHS (Restriction of Hazardous Substances). Such certifications not only ensure adherence to environmental standards but also enhance brand reputation.

– Utilize machines made from biodegradable or recyclable materials. This is particularly relevant in regions like Europe, where regulatory frameworks are increasingly stringent regarding waste management.

Brief Evolution/History

The evolution of tap card vending machines can be traced back to the early 2000s when traditional vending machines began to incorporate electronic payment systems. Initially designed for convenience, these machines have transformed significantly, integrating advanced technologies such as mobile payment options and internet connectivity.

Over the past decade, the focus has shifted towards enhancing user experience and operational efficiency. The introduction of IoT has enabled real-time monitoring and data collection, allowing businesses to optimize inventory and reduce downtime. This evolution reflects a broader trend towards automation and digitization in retail, providing B2B buyers with solutions that not only meet contemporary demands but also anticipate future trends in consumer behavior.

In summary, international B2B buyers in the tap card vending machine sector must navigate market dynamics, embrace sustainability, and remain aware of the historical context to make informed purchasing decisions that align with both current needs and future innovations.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of tap card vending machine

-

What factors should I consider when vetting suppliers for tap card vending machines?

When vetting suppliers, prioritize their experience in the industry and check for customer references. Assess their production capabilities and technology used in manufacturing tap card vending machines. Verify certifications, such as ISO or CE, that demonstrate compliance with international standards. Additionally, consider their financial stability and the availability of after-sales support, which is crucial for maintenance and troubleshooting. -

Can I customize the tap card vending machines to fit my specific needs?

Yes, many suppliers offer customization options for tap card vending machines. This can include branding with your logo, specific color schemes, and the integration of unique features such as payment options or software enhancements. Discuss your requirements with potential suppliers early in the negotiation process to ensure they can meet your specifications without significant delays. -

What is the minimum order quantity (MOQ) for tap card vending machines, and how does it affect pricing?

The MOQ varies by supplier but typically ranges from 10 to 50 units. Higher MOQs often lead to better pricing per unit due to economies of scale. If your business requires fewer machines, inquire about potential pricing adjustments or seek suppliers who offer flexible MOQ options. Consider the total cost, including shipping and taxes, when calculating your budget. -

What are the typical lead times for ordering tap card vending machines?

Lead times can vary significantly based on the supplier’s location, order volume, and customization requirements. Generally, expect lead times of 4 to 12 weeks. It’s advisable to confirm lead times before placing an order and maintain open communication with your supplier to manage expectations, especially if your business relies on timely deliveries for launch or events. -

What quality assurance measures should I expect from suppliers?

Reputable suppliers should have robust quality assurance (QA) processes in place, including regular inspections and testing at various production stages. Ask for details about their QA protocols and any certifications they hold that validate their quality standards. Request samples before committing to larger orders to evaluate the machines’ functionality and durability firsthand. -

Are there specific certifications I should look for when sourcing tap card vending machines?

Look for certifications that indicate compliance with safety and operational standards, such as CE, UL, or ISO 9001. These certifications ensure the machines meet industry norms for quality and safety. Additionally, consider certifications specific to payment processing, such as PCI-DSS, which ensures secure transactions for users of tap card vending machines. -

What logistics considerations should I keep in mind when importing tap card vending machines?

Logistics is crucial when importing tap card vending machines. Evaluate shipping methods, customs regulations, and potential tariffs in your country. Work with suppliers who provide assistance with logistics to ensure smooth transportation. Additionally, consider warehousing options and the costs associated with delivery to your final destination to avoid unexpected expenses. -

How can I resolve disputes with suppliers if issues arise during the procurement process?

To mitigate disputes, establish clear terms and conditions in your contract, including delivery timelines and payment schedules. Maintain open communication throughout the process to address potential issues early. If disputes occur, start with direct negotiation. If unresolved, consider mediation or arbitration as alternative dispute resolution methods, which are often less costly and quicker than litigation.

Strategic Sourcing Conclusion and Outlook for tap card vending machine

In conclusion, the strategic sourcing of tap card vending machines presents a significant opportunity for international B2B buyers. Key takeaways highlight the importance of understanding regional market dynamics, ensuring compliance with local regulations, and selecting suppliers that prioritize innovation and reliability. The integration of advanced technologies, such as contactless payment systems and IoT capabilities, not only enhances user experience but also optimizes operational efficiency.

As buyers from Africa, South America, the Middle East, and Europe seek to expand their service offerings, leveraging strategic sourcing can lead to cost savings and improved service delivery. It’s vital to engage with suppliers who demonstrate a commitment to sustainability and customer support, ensuring a long-term partnership that drives growth.

Looking ahead, the demand for tap card vending machines is poised to grow as urbanization and cashless transactions become more prevalent. Now is the time to act—evaluate your sourcing strategies, explore partnerships with innovative manufacturers, and position your business to capitalize on this evolving market. Embrace the future of vending solutions and secure your competitive edge today.