Master Sourcing Strategies for Once Human Vending Machines

Guide to Once Human Vending Machine

- Introduction: Navigating the Global Market for once human vending machine

- Understanding once human vending machine Types and Variations

- Key Industrial Applications of once human vending machine

- Strategic Material Selection Guide for once human vending machine

- In-depth Look: Manufacturing Processes and Quality Assurance for once human vending machine

- Comprehensive Cost and Pricing Analysis for once human vending machine Sourcing

- Spotlight on Potential once human vending machine Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for once human vending machine

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the once human vending machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of once human vending machine

- Strategic Sourcing Conclusion and Outlook for once human vending machine

Introduction: Navigating the Global Market for once human vending machine

The once human vending machine represents a transformative shift in how businesses approach automated retail solutions. With its ability to serve a variety of products—from snacks to electronics—this innovative machine caters to the growing demand for contactless, efficient, and user-friendly consumer experiences. For international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe, understanding the significance of this technology is paramount.

This comprehensive guide delves into the various types of once human vending machines available, the materials used in their construction, and the manufacturing and quality control processes that ensure reliability and longevity. Additionally, it provides insights into potential suppliers, cost considerations, and current market trends that can impact purchasing decisions.

By equipping buyers with essential knowledge and actionable insights, this guide empowers businesses to make informed sourcing decisions. Whether you’re a retailer looking to enhance customer engagement or a distributor aiming to diversify your product offerings, understanding the once human vending machine landscape will enable you to capitalize on emerging opportunities. Get ready to unlock the potential of automated retail solutions and elevate your business strategy in today’s global marketplace.

Understanding once human vending machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Vending Machine | Standard design, accepts cash or cards | Offices, schools, public spaces | Widely recognized, easy to use; limited product variety |

| Smart Vending Machine | IoT-enabled, real-time inventory tracking | Retail, airports, universities | Enhanced data analytics; higher upfront costs |

| Micro Market Vending | Self-service kiosks with open product displays | Corporate campuses, factories | Flexible product selection; requires space and management |

| Healthy Snack Vending | Offers nutritious options with clear labeling | Health clubs, schools, workplaces | Appeals to health-conscious consumers; often higher prices |

| Customized Vending Solutions | Tailored machines for specific products/services | Niche markets, events, exhibitions | Unique offerings; potential for high ROI; complex logistics |

Traditional Vending Machine

Traditional vending machines are the most recognizable type, typically featuring a straightforward design that accepts cash and card payments. They are commonly found in offices, schools, and public spaces, providing convenience to users seeking snacks and beverages. While they are easy to use and maintain, the product variety may be limited, which can affect customer satisfaction. B2B buyers should consider the machine’s location and target audience to ensure product selection aligns with consumer preferences.

Smart Vending Machine

Smart vending machines integrate IoT technology, enabling real-time inventory tracking and data analytics. These machines are increasingly popular in retail environments, airports, and universities, where consumer behavior insights can drive sales. The primary advantage is the ability to adjust inventory dynamically based on demand, but buyers should be prepared for higher initial costs associated with technology integration. Understanding the target demographic and their purchasing habits is crucial for optimizing product offerings.

Micro Market Vending

Micro market vending consists of self-service kiosks that display a variety of products in an open layout, allowing customers to browse freely. This model is particularly effective in corporate campuses and factories, where employees appreciate having access to a diverse range of food options. While micro markets can provide flexibility in product selection, they require more space and management than traditional vending machines. B2B buyers should assess the space available and the potential for employee engagement in selecting products.

Healthy Snack Vending

Healthy snack vending machines focus on offering nutritious options, often prominently featuring clear labeling to inform consumers about their choices. These machines are ideally suited for health clubs, schools, and workplaces that prioritize wellness. While they cater to the growing demand for healthier snacks, they may come with higher price points. B2B buyers should consider the health trends in their target market and ensure that the product offerings resonate with health-conscious consumers.

Customized Vending Solutions

Customized vending solutions are designed to meet the specific needs of niche markets, events, or exhibitions. These machines can be tailored to dispense unique products or services, making them appealing for businesses looking to differentiate themselves. While they can offer a high return on investment, buyers must navigate complex logistics related to product sourcing and machine maintenance. Understanding the unique value proposition of the offering is essential for attracting the right customer base.

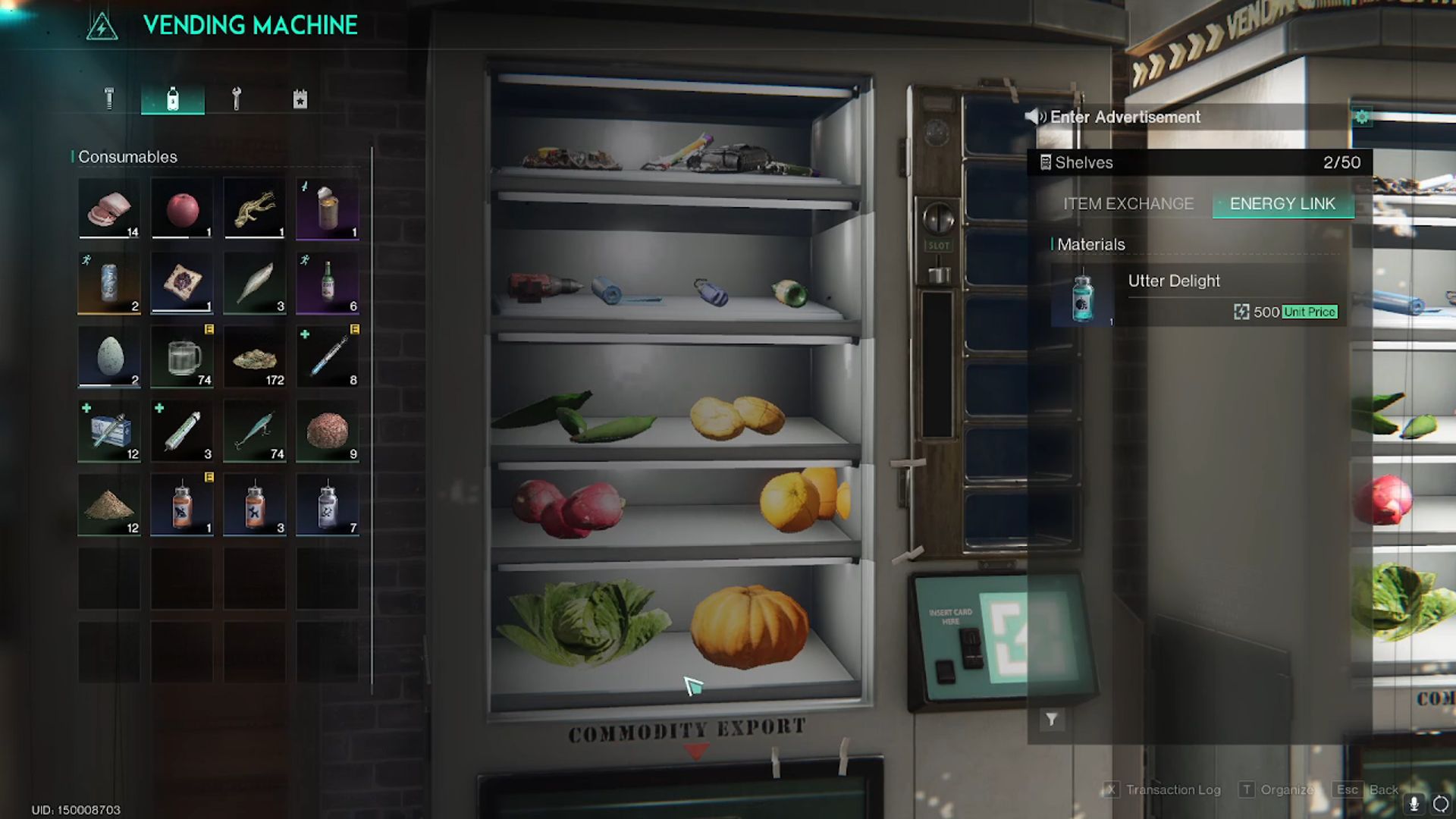

Related Video: Once Human | Vending Machine Shop Base Build & Setup Guide | Get Rich $$ | Tips & Tricks

Key Industrial Applications of once human vending machine

| Industry/Sector | Specific Application of once human vending machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Automated product dispensing | Increased efficiency, reduced labor costs | Machine capacity, product compatibility, and maintenance support |

| Healthcare | Medicine and supplies dispensing | Enhanced patient care, reduced waiting times | Compliance with health regulations, temperature control features |

| Hospitality | Food and beverage services | 24/7 service availability, reduced staffing needs | Food safety certifications, payment processing options |

| Education | Station for educational materials | Easy access for students, reduced distribution costs | Durability, ease of use, and inventory management systems |

| Transportation | Ticket and pass vending | Streamlined passenger experience, reduced queue times | Integration with local payment systems, reliability in various environments |

Retail

In the retail sector, once human vending machines are utilized to automate product dispensing, allowing businesses to operate efficiently with minimal staffing. These machines can dispense a wide range of products, from snacks to electronics, addressing the challenge of high labor costs and staffing shortages. For international buyers, especially from regions like Africa and South America, sourcing machines that can handle diverse products and withstand local climate conditions is crucial. Additionally, considerations around machine capacity and maintenance support are essential for ensuring continuous operation.

Healthcare

In healthcare, once human vending machines serve as automated dispensers for medicines and medical supplies, significantly enhancing patient care by reducing waiting times. These machines can be strategically placed in hospitals and clinics, providing easy access to essential items. International buyers must ensure that the machines comply with local health regulations and include features like temperature control for sensitive medications. Additionally, the ability to track inventory and integrate with existing hospital systems is a key requirement.

Hospitality

The hospitality industry leverages once human vending machines for food and beverage services, offering 24/7 access to guests without the need for constant staffing. This application not only enhances guest satisfaction but also reduces operational costs associated with traditional food service. Buyers in this sector should prioritize sourcing machines that meet food safety certifications and offer multiple payment processing options, especially in diverse markets across Europe and the Middle East.

Education

In educational institutions, once human vending machines can dispense educational materials such as textbooks, stationery, and learning aids, providing students with easy access to necessary resources. This reduces distribution costs and ensures that students have what they need at their fingertips. For international buyers, durability and ease of use are critical, as well as effective inventory management systems to keep track of supplies and ensure availability.

Transportation

In the transportation sector, once human vending machines are used for ticket and pass vending, streamlining the passenger experience by reducing queue times. These machines can be placed in strategic locations like train stations and airports, enhancing operational efficiency. Buyers should consider the integration capabilities with local payment systems and the reliability of machines in varying environmental conditions, particularly in regions like Africa and South America where infrastructure may vary.

Related Video: TRADING with THE VENDING MACHINE in ONCE HUMAN

Strategic Material Selection Guide for once human vending machine

When selecting materials for a once human vending machine, it is crucial to consider the specific requirements and environmental conditions in which the machine will operate. Below, we analyze four common materials used in the construction of these machines, focusing on their properties, advantages, disadvantages, and considerations for international buyers.

1. Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand high temperatures and pressures. Common grades such as 304 and 316 are often used, with 316 offering superior corrosion resistance, particularly in saline or acidic environments.

Pros & Cons:

The durability of stainless steel makes it ideal for high-traffic areas, as it can withstand wear and tear. However, it is more expensive than other materials, which can increase the overall cost of the vending machine. Manufacturing complexity can also be higher due to the need for specialized tools and techniques.

Impact on Application:

Stainless steel is compatible with a wide range of media, including food products, beverages, and cleaning agents. Its non-reactive nature ensures that it will not contaminate the contents of the vending machine.

Considerations for International Buyers:

Buyers in Africa, South America, the Middle East, and Europe should ensure compliance with local food safety standards and certifications such as ISO 22000. Preference for stainless steel can vary by region, influenced by local climate conditions and the availability of alternatives.

2. Aluminum

Key Properties:

Aluminum is lightweight, with good corrosion resistance and thermal conductivity. It is often anodized to enhance its protective layer, making it suitable for various applications.

Pros & Cons:

The primary advantage of aluminum is its low weight, which facilitates easier installation and transport. However, it is less durable than stainless steel and can be prone to denting and scratching. Cost-wise, aluminum is generally more affordable than stainless steel.

Impact on Application:

Aluminum is suitable for non-corrosive environments and can be used for components that do not require heavy-duty performance. Its compatibility with various media is acceptable, but care must be taken with acidic substances.

Considerations for International Buyers:

Compliance with standards like ASTM and DIN is essential, especially regarding food-grade aluminum. Buyers should also consider the local market’s acceptance of aluminum versus stainless steel based on regional preferences.

3. Polycarbonate

Key Properties:

Polycarbonate is a robust thermoplastic known for its high impact resistance and clarity. It can withstand a wide temperature range and is often used in transparent sections of vending machines.

Pros & Cons:

The transparency of polycarbonate allows for visibility of the products inside, enhancing consumer interaction. However, it is susceptible to scratching and UV degradation over time. It is typically less expensive than metals but may require more frequent replacement.

Impact on Application:

Polycarbonate is ideal for display panels and protective covers, as it can resist impacts from vandalism or accidental damage. It is not suitable for high-temperature applications, which limits its use in certain environments.

Considerations for International Buyers:

Buyers should ensure that polycarbonate complies with local safety and environmental regulations. The material’s performance in high UV exposure areas, such as those common in Africa and South America, should also be evaluated.

4. Carbon Steel

Key Properties:

Carbon steel is known for its high strength and durability. It is typically coated with a protective layer to enhance corrosion resistance, as it is susceptible to rusting.

Pros & Cons:

Carbon steel is cost-effective and offers excellent structural integrity, making it suitable for the frame and support structures of vending machines. However, without proper coating, it can corrode quickly in humid or wet environments, which may lead to increased maintenance costs.

Impact on Application:

While carbon steel can support heavy loads and is suitable for various media, its corrosion resistance is a significant concern in environments with high moisture or exposure to chemicals.

Considerations for International Buyers:

Buyers should consider local climate conditions and ensure that the protective coatings used on carbon steel meet relevant standards. Compliance with ASTM or ISO standards for structural integrity is also essential.

Summary Table

| Material | Typical Use Case for once human vending machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural components, food and beverage contact | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Aluminum | Frame and non-load bearing parts | Lightweight and cost-effective | Less durable, prone to dents | Medium |

| Polycarbonate | Display panels and protective covers | High impact resistance and visibility | Susceptible to scratches and UV damage | Medium |

| Carbon Steel | Structural frame and support | Cost-effective and strong | Prone to corrosion without coating | Low |

This strategic material selection guide provides essential insights for international B2B buyers looking to make informed decisions regarding the materials used in once human vending machines.

In-depth Look: Manufacturing Processes and Quality Assurance for once human vending machine

The manufacturing processes and quality assurance (QA) for a “once human vending machine” involve a series of structured stages designed to ensure high-quality products that meet international standards. Understanding these processes is crucial for B2B buyers, especially in diverse markets such as Africa, South America, the Middle East, and Europe.

Manufacturing Process

1. Material Preparation

The first step in manufacturing a once human vending machine involves sourcing high-quality materials. Key components typically include:

– Metal Framework: Usually steel or aluminum for structural integrity.

– Electronics: Circuit boards, sensors, and payment systems sourced from reliable suppliers.

– Plastic Components: For the exterior and user interface, often using durable, UV-resistant materials.

Illustrative Image (Source: Google Search)

Key Techniques:

– Supplier Vetting: B2B buyers should conduct thorough assessments of suppliers to ensure materials meet specified standards.

– Material Testing: Each batch of materials should undergo testing for durability and compliance with safety regulations.

2. Forming

In this stage, raw materials are shaped into the desired forms through various techniques:

– Metal Stamping: Used for creating panels and brackets.

– Injection Molding: Commonly applied for plastic parts.

– CNC Machining: Precision parts are crafted, ensuring high accuracy.

Key Techniques:

– Die Casting: This method is often used for creating complex metal parts with high fidelity.

– Laser Cutting: Provides clean edges and precise cuts, especially for intricate designs.

3. Assembly

The assembly process is critical as it combines all components into a functional unit:

– Sub-Assembly: Individual components like the payment system, cooling mechanisms, and display units are pre-assembled.

– Main Assembly: The various sub-assemblies are then integrated into the vending machine chassis.

Key Techniques:

– Automation: Utilizing robotic arms for repetitive tasks can enhance efficiency.

– Manual Assembly: Skilled workers are essential for quality checks and handling delicate components.

4. Finishing

This final stage involves applying protective coatings and aesthetic finishes:

– Painting and Coating: To protect against corrosion and enhance appearance.

– Quality Checks: Each finished product undergoes final inspections to ensure it meets design specifications.

Key Techniques:

– Powder Coating: Provides a durable finish that is resistant to scratches and fading.

– Screen Printing: Used for branding and user interface markings.

Quality Assurance

International Standards

Compliance with international quality standards is vital for market acceptance and safety:

– ISO 9001: This standard ensures a quality management system is in place, focusing on continuous improvement and customer satisfaction.

– CE Marking: Essential for products sold in the European Economic Area, indicating compliance with safety, health, and environmental protection standards.

– API Standards: If applicable, standards related to electronic components should be adhered to.

QC Checkpoints

Quality control (QC) is integrated into various stages of production:

– Incoming Quality Control (IQC): Checks raw materials and components upon receipt.

– In-Process Quality Control (IPQC): Inspections during manufacturing to catch defects early.

– Final Quality Control (FQC): Comprehensive testing of the finished product before shipment.

Common Testing Methods

B2B buyers should be aware of several testing methods used to ensure product quality:

– Functional Testing: Verifying that all electronic components operate correctly.

– Safety Testing: Ensuring compliance with electrical safety standards.

– Durability Testing: Assessing the machine’s performance under various environmental conditions.

Verifying Supplier Quality Control

B2B buyers can take several steps to verify the quality control measures of their suppliers:

– Supplier Audits: Regularly scheduled audits of suppliers’ facilities can help verify adherence to quality standards.

– Quality Reports: Requesting detailed quality assurance reports can provide insights into the supplier’s processes and outcomes.

– Third-Party Inspections: Engaging independent inspectors to evaluate product quality before shipment adds an extra layer of assurance.

QC and Certification Nuances for International Buyers

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification is essential:

– Local Regulations: Familiarize yourself with local regulations that may affect product acceptance in your market.

– Cultural Considerations: Different regions may have varying expectations regarding quality and compliance, so it’s essential to adapt your approach accordingly.

– Supply Chain Transparency: Ensure that your suppliers maintain transparency throughout their manufacturing processes, especially regarding materials sourcing and quality assurance practices.

By understanding the manufacturing processes and quality assurance protocols for once human vending machines, B2B buyers can make informed purchasing decisions that enhance their operational efficiency and ensure compliance with international standards.

Comprehensive Cost and Pricing Analysis for once human vending machine Sourcing

Cost Structure for Once Human Vending Machines

When sourcing once human vending machines, it is crucial to understand the detailed cost structure that influences pricing. The primary components of cost include:

-

Materials: This encompasses the raw materials used in manufacturing the vending machines, such as metal for the chassis, electronic components, and touchscreen interfaces. The choice of materials can significantly impact the durability and functionality of the machines.

-

Labor: Labor costs involve wages for skilled workers who assemble the machines. The complexity of the machine design and the level of craftsmanship required will affect labor costs. Countries with higher labor costs may see a direct impact on the overall pricing.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, rent, and administrative salaries. Efficient manufacturing processes can help reduce these costs, impacting the final price offered to buyers.

-

Tooling: Tooling costs cover the expense of molds and machinery necessary for production. Custom designs may require specialized tooling, leading to higher initial costs.

-

Quality Control (QC): Ensuring product quality involves testing and inspections, which add to the overall manufacturing cost. High-quality standards often translate to higher costs but can enhance the product’s marketability.

-

Logistics: This includes transportation, warehousing, and handling costs associated with shipping the machines from the manufacturer to the buyer. The geographical location of suppliers and buyers can significantly influence these costs.

-

Margin: Suppliers typically add a profit margin to their costs. Understanding the margin can help buyers gauge the reasonableness of the pricing offered.

Price Influencers

Several factors can influence the pricing of once human vending machines:

-

Volume/MOQ (Minimum Order Quantity): Purchasing in larger quantities often leads to reduced prices per unit. Buyers should consider their demand forecasts to negotiate better terms.

-

Specifications and Customization: Machines tailored to specific needs or with unique features will incur additional costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials Quality and Certifications: Higher-quality materials and adherence to industry certifications can increase costs. Buyers should balance quality needs with budget constraints.

-

Supplier Factors: The reliability, reputation, and location of the supplier can affect pricing. Engaging with suppliers who have a proven track record can lead to better pricing and service.

-

Incoterms: The terms of shipping (e.g., FOB, CIF) can influence the total cost of ownership. Understanding these terms helps buyers anticipate additional costs related to logistics and customs.

Buyer Tips for Cost Efficiency

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should consider the following tips for effective sourcing:

-

Negotiation: Engage in discussions with suppliers to negotiate better pricing based on volume and long-term relationships. Leverage competitive quotes to enhance negotiation outcomes.

-

Total Cost of Ownership (TCO): Assess not just the purchase price but also the long-term costs associated with maintenance, energy consumption, and parts replacement. This holistic view can guide smarter purchasing decisions.

-

Pricing Nuances: Be aware of currency fluctuations, tariffs, and trade regulations that could affect costs. Establishing contracts in stable currencies can mitigate risks.

-

Market Research: Conduct thorough research on suppliers in different regions to understand pricing trends. This knowledge can empower buyers to make informed decisions and identify the best value options.

In conclusion, while the costs associated with once human vending machines can vary widely, understanding the components and influencers of pricing will enable buyers to make strategic sourcing decisions. It’s important to approach the procurement process with a comprehensive view, considering both immediate costs and long-term implications.

- Disclaimer: The prices mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific requirements.*

Spotlight on Potential once human vending machine Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘once human vending machine’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for once human vending machine

Key Technical Properties of Once Human Vending Machines

When considering the procurement of once human vending machines, it is essential to understand several critical technical properties that can significantly impact operational efficiency and product quality. Below are key specifications to consider:

-

Material Grade: The construction materials of the vending machine should comply with industry standards, such as stainless steel for durability and resistance to corrosion. High-grade materials ensure longevity and reduce maintenance costs, which is crucial for businesses operating in diverse climates, particularly in regions like Africa and South America.

-

Power Consumption: Vending machines should have energy-efficient designs. A low power consumption rating not only reduces operational costs but also aligns with sustainability goals. This is increasingly important for businesses looking to enhance their green credentials, especially in European markets where environmental regulations are stringent.

-

Temperature Range: For vending machines that dispense perishable goods, the ability to maintain an optimal temperature range is critical. Machines should be able to operate efficiently across various ambient temperatures, ensuring the freshness of the products. This is particularly important in hotter climates found in parts of the Middle East and Africa.

-

Connectivity Options: Modern vending machines often come equipped with IoT capabilities, allowing for remote monitoring and management. Features like Wi-Fi or cellular connectivity can facilitate real-time data analysis, improving inventory management and customer interaction. This is essential for businesses aiming to optimize operations and enhance customer experience.

-

User Interface: The design of the user interface should cater to a diverse customer base, with considerations for language options and accessibility. A well-designed interface can improve user satisfaction and increase sales, making it a crucial feature for international markets.

-

Payment Systems: The machine should support various payment methods, including cash, credit/debit cards, and mobile payments. Given the diverse payment preferences across different regions, this flexibility can significantly enhance consumer adoption and satisfaction.

Common Trade Terminology in the Vending Machine Industry

Understanding industry-specific jargon is crucial for effective communication and negotiation in the B2B space. Here are some common terms that buyers should be familiar with:

-

OEM (Original Equipment Manufacturer): Refers to companies that manufacture products for other brands to sell under their name. In the vending machine sector, working with an OEM can ensure that you receive high-quality, branded products tailored to your specifications.

-

MOQ (Minimum Order Quantity): This term defines the smallest order amount that a supplier is willing to accept. Understanding MOQ is vital for budgeting and inventory management, particularly for businesses looking to minimize upfront costs.

-

RFQ (Request for Quotation): A formal process where buyers solicit price quotes from suppliers for specific products or services. An RFQ helps in comparing suppliers and ensuring competitive pricing, which is crucial for maintaining profitability.

-

Incoterms (International Commercial Terms): A set of international rules governing the delivery of goods. Familiarity with Incoterms is essential for understanding shipping responsibilities, risks, and costs, particularly for international transactions involving vending machines.

-

Lead Time: This term refers to the time taken from placing an order to delivery. Understanding lead times is essential for effective planning and inventory management, ensuring that your vending machines are available when needed.

-

Warranty and Service Agreements: These are contracts that outline the responsibilities of the manufacturer regarding repairs, replacements, and maintenance of the vending machines. Knowing the warranty terms can help buyers assess the long-term value and reliability of their investment.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions that align with their operational goals and market demands.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the once human vending machine Sector

Market Overview & Key Trends

The once human vending machine sector is witnessing significant transformation driven by technological advancements and shifting consumer behaviors. Globally, the demand for automated solutions is increasing, fueled by the need for contactless service options, especially in the wake of the COVID-19 pandemic. B2B buyers from regions like Africa, South America, the Middle East, and Europe are particularly interested in these vending machines for their ability to reduce labor costs and streamline operations. Emerging technologies such as AI, IoT, and mobile payment systems are becoming standard features, enhancing customer engagement and operational efficiency.

In terms of sourcing trends, international buyers are increasingly looking for suppliers who can provide customizable vending solutions that cater to local tastes and preferences. This is especially relevant in diverse markets like Brazil and Vietnam, where localized offerings can significantly impact sales. Additionally, the rise of data analytics is allowing businesses to better understand consumer behavior and optimize inventory management. As a result, B2B buyers should prioritize partnerships with manufacturers that offer robust data analytics capabilities and flexible supply chain solutions.

Furthermore, sustainability is becoming a key market driver. Buyers are not only focused on the functionality of vending machines but also on their environmental impact. This shift is prompting manufacturers to explore eco-friendly materials and energy-efficient technologies, ensuring that their products align with the growing consumer demand for sustainable practices.

Sustainability & Ethical Sourcing in B2B

Sustainability is increasingly influencing purchasing decisions within the once human vending machine sector. The environmental impact of production, operation, and disposal of vending machines cannot be overlooked. As B2B buyers, it is crucial to consider suppliers who prioritize reducing their carbon footprint and employ sustainable manufacturing practices. This includes using recyclable materials, minimizing waste during production, and adopting energy-efficient technologies.

Ethical sourcing is another critical aspect. Buyers should seek suppliers that adhere to fair labor practices and maintain transparency within their supply chains. Certifications such as ISO 14001 for environmental management and Fair Trade can provide assurance of a supplier’s commitment to sustainability and ethical practices. Additionally, incorporating ‘green’ certifications into the procurement process not only enhances brand reputation but also meets the increasing consumer expectation for responsible business practices.

Investing in sustainable vending solutions can lead to long-term cost savings and increased customer loyalty. By choosing suppliers who focus on sustainability, B2B buyers can contribute to a more sustainable future while also differentiating their offerings in a competitive market.

Brief Evolution/History

The concept of vending machines dates back to the first century AD when a Greek engineer, Hero of Alexandria, created a device that dispensed holy water. However, the modern vending machine as we know it began to take shape in the early 20th century, primarily offering snacks and beverages. The introduction of automated payment systems revolutionized the industry, leading to increased convenience and accessibility.

In recent years, the evolution has accelerated with the integration of digital technologies, transforming traditional vending machines into smart, user-friendly solutions. Today’s once human vending machines are equipped with touch screens, mobile payment options, and inventory tracking systems, allowing for a seamless consumer experience. This evolution reflects broader trends in automation and consumer expectations, marking a significant shift in how businesses engage with their customers. For B2B buyers, understanding this history is essential for recognizing the potential and future directions of the sector.

Related Video: Is global trade transforming? | Counting the Cost

Frequently Asked Questions (FAQs) for B2B Buyers of once human vending machine

-

What factors should I consider when vetting suppliers for once human vending machines?

When vetting suppliers, prioritize their industry experience, reputation, and client testimonials. Verify certifications such as ISO standards, which indicate quality management practices. Conduct background checks on their financial stability and operational capacity to ensure they can meet your demands. Additionally, request samples or prototypes to assess product quality firsthand, and consider visiting their production facilities if possible. -

Can I customize the once human vending machines according to my brand specifications?

Yes, most suppliers offer customization options, including branding, design, and functionality features. Discuss your specific requirements early in the negotiation process to determine the extent of customization available. Be clear about your brand colors, logos, and any unique features you want integrated. Ensure that the supplier provides a detailed plan and timeline for the customization process to avoid delays. -

What is the typical minimum order quantity (MOQ) and lead time for once human vending machines?

The MOQ can vary significantly depending on the supplier and the complexity of the machines. Generally, it ranges from 10 to 50 units for bulk orders. Lead times also fluctuate; expect anywhere from 4 to 12 weeks after placing an order. Always confirm these details in writing and discuss potential penalties for delays to protect your investment. -

What payment terms are commonly accepted by suppliers of once human vending machines?

Most suppliers accept various payment methods, including bank transfers, letters of credit, and online payment platforms. Standard payment terms often involve a deposit (20-50%) upfront, with the balance due upon shipment or delivery. Negotiate terms that align with your cash flow needs, and consider using escrow services for larger transactions to mitigate risk. -

What quality assurance and certification standards should I look for?

Ensure that the supplier complies with international quality standards such as ISO 9001 for quality management and CE marking for compliance with European health, safety, and environmental protection standards. Request documentation proving compliance and consider third-party quality inspections before shipment. This can help prevent receiving substandard products that do not meet your requirements. -

How should I handle logistics and shipping for importing once human vending machines?

Discuss logistics options with your supplier, including shipping methods (air vs. sea freight) and who will handle customs clearance. Ensure you understand all associated costs, including tariffs and taxes. Partnering with a reliable freight forwarder can help streamline the process and mitigate delays. Always track shipments and maintain communication with your supplier to address any potential issues promptly. -

What steps should I take if there is a dispute with the supplier?

Begin by reviewing the contract terms and conditions regarding disputes. Attempt to resolve the issue amicably through direct communication with the supplier. If unresolved, consider mediation or arbitration, as many contracts include clauses specifying these methods. Document all correspondence and agreements, as this information will be crucial if legal action becomes necessary. -

Are there any specific regulations or compliance issues I need to be aware of when importing once human vending machines?

Yes, regulations vary by country and region. Research import regulations specific to your market, including safety standards and electrical certifications. In the European Union, for example, CE marking is mandatory. Consult with local authorities or customs brokers to ensure compliance with all legal requirements, which can help avoid penalties and ensure smooth importation of your machines.

Strategic Sourcing Conclusion and Outlook for once human vending machine

The emergence of the once human vending machine represents a significant leap in automated retail technology, offering unparalleled convenience and efficiency. For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, strategic sourcing of these machines is essential to leverage their full potential. Key takeaways include the importance of understanding local market dynamics, ensuring compliance with regional regulations, and selecting suppliers that prioritize sustainability and innovation.

Investing in once human vending machines can enhance customer engagement, reduce operational costs, and streamline inventory management. By strategically sourcing these solutions, businesses can not only improve their bottom line but also adapt to the evolving consumer landscape that increasingly favors contactless and automated interactions.

Looking ahead, international buyers should prioritize partnerships with manufacturers and distributors that offer robust support and customization options. As the market evolves, staying informed about technological advancements and consumer preferences will be crucial. Embrace this opportunity to redefine your retail strategy and position your business at the forefront of the automated retail revolution. Engage with trusted suppliers today to capitalize on the immense potential of once human vending machines in your region.

Illustrative Image (Source: Google Search)