Master Sourcing Snack Vending Machine Parts for Optimal

Guide to Snack Vending Machine Parts

- Introduction: Navigating the Global Market for snack vending machine parts

- Understanding snack vending machine parts Types and Variations

- Key Industrial Applications of snack vending machine parts

- Strategic Material Selection Guide for snack vending machine parts

- In-depth Look: Manufacturing Processes and Quality Assurance for snack vending machine parts

- Comprehensive Cost and Pricing Analysis for snack vending machine parts Sourcing

- Spotlight on Potential snack vending machine parts Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for snack vending machine parts

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the snack vending machine parts Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of snack vending machine parts

- Strategic Sourcing Conclusion and Outlook for snack vending machine parts

Introduction: Navigating the Global Market for snack vending machine parts

In today’s fast-paced global economy, snack vending machines have become essential for businesses aiming to meet consumer demand for convenience and variety. As a B2B buyer, understanding the critical components of these machines is paramount. Snack vending machine parts are not merely accessories; they are the backbone of operational efficiency, customer satisfaction, and ultimately, profitability.

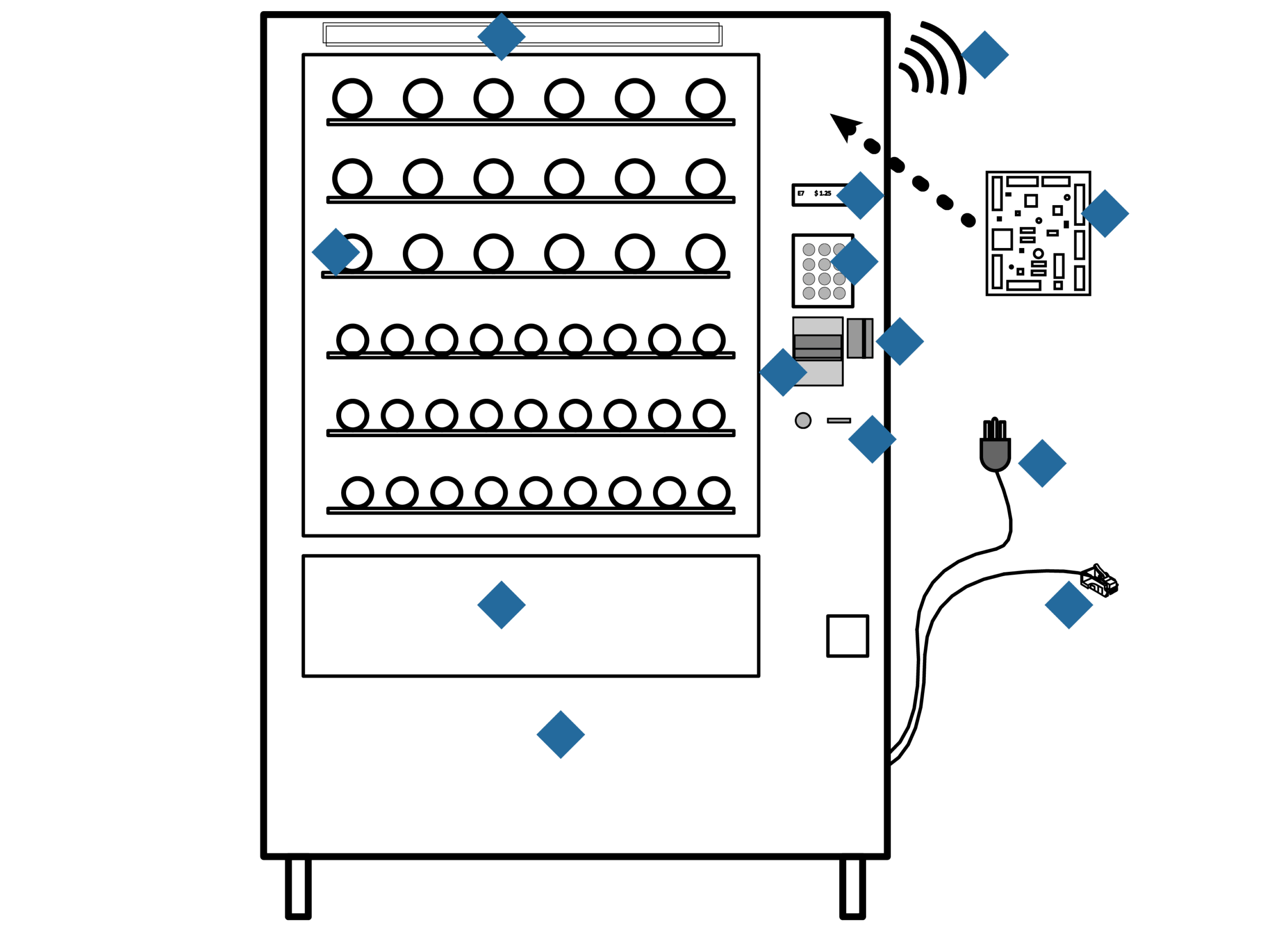

This guide serves as a comprehensive resource, covering everything from types of parts—such as dispensers, controllers, and payment systems—to the materials used in their manufacture. We delve into the intricacies of manufacturing and quality control processes, ensuring that buyers can source parts that not only meet their functional requirements but also adhere to international standards.

Furthermore, we explore various suppliers, providing insights into cost structures and market trends across regions, particularly focusing on the unique needs of buyers from Africa, South America, the Middle East, and Europe. By addressing common FAQs, we empower you to make informed decisions, mitigating risks associated with sourcing from unfamiliar markets.

With this guide, you will gain the knowledge necessary to navigate the complexities of the snack vending machine parts market, ensuring that your procurement strategies are both effective and economically sound. Equip yourself with the insights needed to enhance your business operations and cater to the ever-evolving preferences of consumers worldwide.

Understanding snack vending machine parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Compressor Unit | Powers refrigeration; ensures snack freshness | Food service, convenience stores | Pros: Efficient cooling; Cons: Requires regular maintenance. |

| Control Board | Manages user interface and machine functions | Retail, corporate offices | Pros: Centralized control; Cons: Can be costly to replace. |

| Vending Mechanism | Dispenses products; varies by product type | Public spaces, schools, hospitals | Pros: Versatile; Cons: Mechanical failures can disrupt service. |

| Coin Acceptor | Accepts various currencies and coins | Retail, transportation hubs | Pros: Enhances transaction options; Cons: Vulnerable to jams. |

| Display Panel | Shows product information and pricing | All vending applications | Pros: User-friendly; Cons: Can suffer from screen damage. |

Compressor Unit

The compressor unit is essential for maintaining the freshness of snacks by powering the refrigeration system within the vending machine. It is particularly suitable for locations requiring perishable item storage, such as food service establishments and convenience stores. When considering a compressor unit, B2B buyers should focus on energy efficiency and maintenance requirements, as these can significantly impact operational costs.

Control Board

The control board serves as the brain of the vending machine, managing user interactions and machine operations. It is widely used in retail environments and corporate offices. Buyers should evaluate the compatibility of the control board with existing systems and consider the ease of software updates and troubleshooting, as a malfunction can lead to significant downtime.

Vending Mechanism

The vending mechanism is responsible for dispensing snacks and can vary in design depending on the type of products offered. This part is crucial in public spaces, schools, and hospitals where quick access to snacks is necessary. Buyers should consider the mechanism’s reliability and ease of maintenance, as mechanical failures can lead to customer dissatisfaction and lost revenue.

Coin Acceptor

A coin acceptor allows machines to accept various currencies and coins, making it vital for retail environments and transportation hubs. Its key features include the ability to handle multiple denominations and provide change. B2B buyers should assess the durability and security of the coin acceptor, as jams or theft can lead to operational disruptions.

Display Panel

The display panel communicates product information and pricing to users, enhancing the customer experience. It is used across all vending applications, from schools to corporate settings. Buyers should prioritize the panel’s visibility and durability, as damage can hinder user interaction and affect sales. Considering technology upgrades, such as touchscreens, may also be beneficial for enhancing user engagement.

Related Video: How to Make KitKat Skittles OREO Vending Machine

Key Industrial Applications of snack vending machine parts

| Industry/Sector | Specific Application of Snack Vending Machine Parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Automated snack dispensing in convenience stores | Increases sales through 24/7 availability | Reliability of parts, ease of maintenance |

| Hospitality | Guest service in hotels and resorts | Enhances guest experience, reduces staff workload | Customization options, energy efficiency |

| Education | Snack provision in schools and universities | Provides convenient access to food for students | Compliance with health regulations, variety of options |

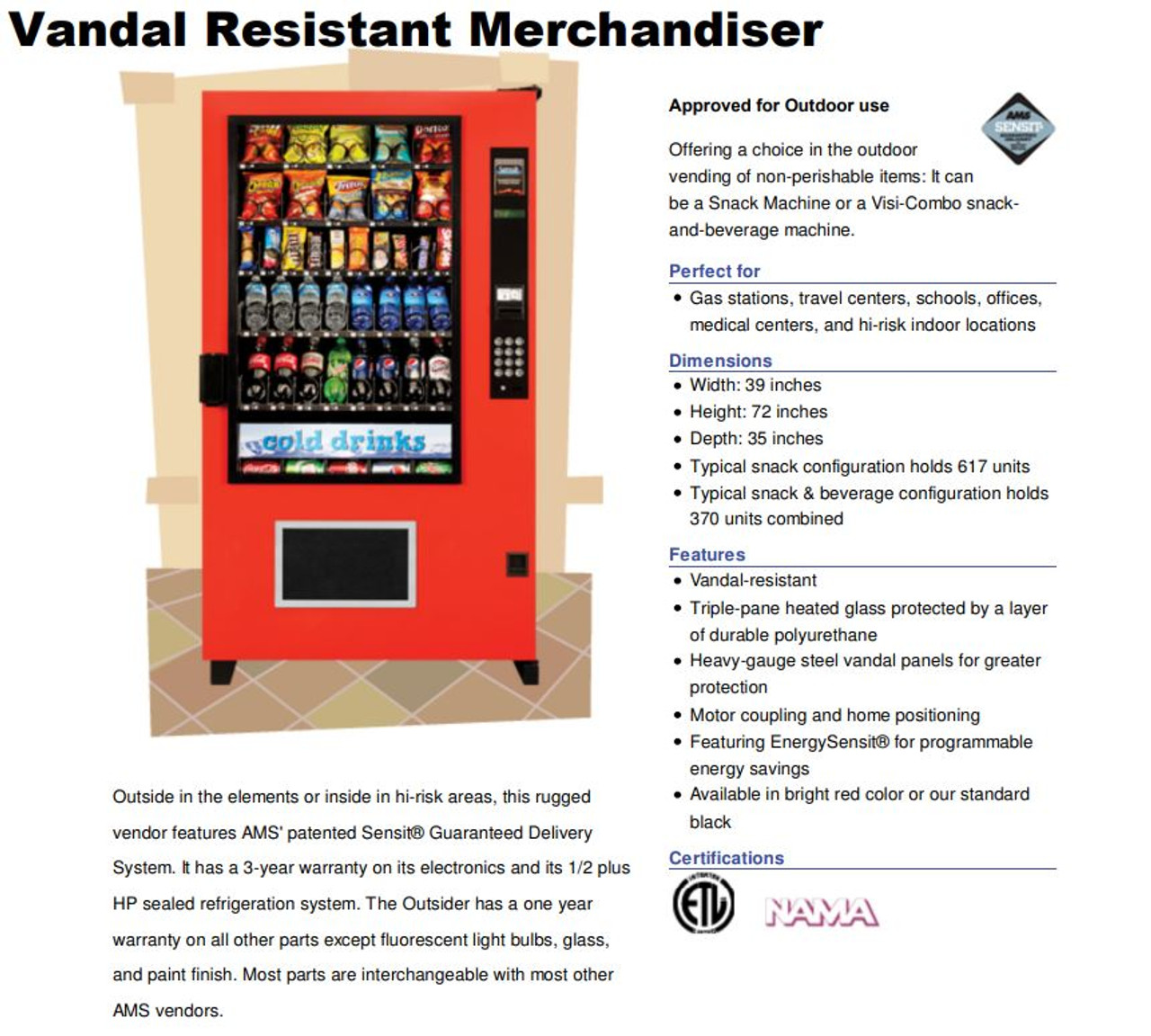

| Transportation | Snack vending in airports and train stations | Captures impulse purchases, improves customer satisfaction | Durability, resistance to vandalism |

| Healthcare | Nutritional options in hospitals and clinics | Supports patient wellness, offers healthy choices | Hygiene standards, supply chain reliability |

Retail

In the retail sector, snack vending machines are increasingly utilized in convenience stores to provide customers with ready access to snacks, drinks, and other quick bites. The parts used in these machines, such as dispensing mechanisms and payment systems, are crucial for ensuring a seamless transaction experience. International buyers, particularly from Africa and South America, should consider the reliability and maintenance requirements of these parts to minimize downtime and maximize sales.

Hospitality

Hotels and resorts often deploy snack vending machines to enhance guest services, allowing patrons to access snacks without waiting for room service or visiting the dining area. The parts of these machines must cater to customization, such as branding and product selection, to align with the hotel’s image. B2B buyers in the Middle East and Europe should prioritize energy-efficient components to reduce operational costs while enhancing guest satisfaction.

Education

In educational institutions, snack vending machines serve the dual purpose of providing convenience and promoting healthier eating habits among students. Parts must comply with local health regulations and standards, ensuring food safety. Buyers from various regions, especially Europe, should focus on sourcing machines that offer a diverse range of healthy snack options, as this aligns with growing health consciousness among younger demographics.

Transportation

Airports and train stations utilize snack vending machines to capture impulse purchases from travelers. The durability of parts is paramount in these high-traffic environments, as machines must withstand frequent use and potential vandalism. For international buyers, especially from Africa and South America, sourcing machines with robust security features and easy-to-use interfaces can significantly enhance customer satisfaction and revenue.

Healthcare

In healthcare settings, vending machines that provide nutritional snacks and drinks are essential for supporting patient wellness. The components of these machines must adhere to strict hygiene standards to ensure food safety. B2B buyers in this sector should prioritize sourcing parts that guarantee reliability and ease of cleaning, as well as those that can accommodate a variety of dietary needs, which is increasingly important in modern healthcare facilities.

Strategic Material Selection Guide for snack vending machine parts

Material Analysis for Snack Vending Machine Parts

When selecting materials for snack vending machine parts, it’s essential to consider various factors including durability, cost, and compliance with international standards. Below, we analyze four common materials used in the manufacturing of these components.

1. Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand high temperatures. It typically has a temperature rating of up to 800°C and can handle significant pressure.

Pros & Cons:

Stainless steel is highly durable and resistant to rust and staining, making it suitable for environments where hygiene is critical. However, it is more expensive than other materials and can be challenging to machine, which may increase manufacturing complexity.

Impact on Application:

Stainless steel is compatible with various media, including food products, making it ideal for parts that come into direct contact with snacks. Its hygienic properties are crucial in preventing contamination.

Considerations for International Buyers:

Buyers from regions like Africa and South America should ensure that the stainless steel grades used comply with local and international standards, such as ASTM or DIN. The higher cost may be justified by its longevity and maintenance-free nature.

2. Polycarbonate

Key Properties:

Polycarbonate is a high-impact thermoplastic with excellent transparency and UV resistance. It can withstand temperatures up to 120°C and is known for its toughness.

Pros & Cons:

The main advantage of polycarbonate is its lightweight nature and impact resistance, which makes it suitable for parts like viewing panels. However, it is less resistant to scratches and can degrade under prolonged UV exposure, limiting its application in outdoor settings.

Impact on Application:

Polycarbonate is compatible with various snack types, ensuring that visibility and product appeal are maintained. Its clear nature allows consumers to see the products inside, enhancing sales.

Considerations for International Buyers:

Buyers should consider the environmental regulations regarding plastic use in their respective regions. Compliance with standards such as JIS or ISO can also impact the choice of polycarbonate grades.

3. Aluminum

Key Properties:

Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity. It can handle temperatures up to 400°C, depending on the alloy.

Pros & Cons:

Aluminum is cost-effective and easy to machine, which reduces manufacturing complexity. However, it may not be as durable as stainless steel and can be prone to denting and scratching.

Impact on Application:

Aluminum is suitable for parts that require lightweight construction, such as frames and structural components. Its corrosion resistance makes it ideal for humid environments.

Considerations for International Buyers:

When sourcing aluminum parts, buyers should be aware of the specific alloy grades that meet their requirements. Compliance with standards like ASTM or EN is essential to ensure quality and safety.

4. ABS Plastic

Key Properties:

Acrylonitrile Butadiene Styrene (ABS) is a thermoplastic known for its toughness and impact resistance. It can operate effectively at temperatures up to 80°C.

Pros & Cons:

ABS is cost-effective and easy to mold, making it suitable for complex shapes. However, it has lower heat resistance compared to other materials and may warp under high temperatures.

Impact on Application:

ABS is often used for non-structural components, such as trays and housing, where flexibility and ease of manufacturing are priorities. Its chemical resistance also makes it suitable for various snack types.

Considerations for International Buyers:

International buyers should ensure that ABS complies with food safety regulations in their markets. Understanding local standards for plastic usage is crucial, especially in regions with stringent regulations.

Summary Table

| Material | Typical Use Case for snack vending machine parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural components, trays, and dispensing mechanisms | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Polycarbonate | Viewing panels and product displays | Lightweight and impact-resistant | Scratches easily and UV degradation | Medium |

| Aluminum | Frames and structural components | Cost-effective and easy to machine | Less durable, prone to denting | Medium |

| ABS Plastic | Trays, housing, and non-structural components | Easy to mold and cost-effective | Lower heat resistance | Low |

This guide provides a comprehensive overview of material options for snack vending machine parts, equipping international B2B buyers with the insights needed to make informed purchasing decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for snack vending machine parts

Manufacturing snack vending machine parts involves a series of intricate processes designed to ensure the final product meets both functional and aesthetic requirements. This section outlines the typical manufacturing stages and the quality assurance measures that B2B buyers should consider when sourcing these parts, especially from diverse regions like Africa, South America, the Middle East, and Europe.

Manufacturing Processes

1. Material Preparation

The first stage in the manufacturing process is material preparation. This involves selecting the appropriate raw materials, which can include metals, plastics, and electronic components.

- Key Techniques:

- Material Selection: High-grade steel or aluminum for structural components; durable plastics for outer casings.

- Pre-Processing: Cutting, machining, and treating materials to ensure they meet specifications. Processes such as laser cutting and CNC machining are common.

2. Forming

After material preparation, the next step is forming the components. This stage involves shaping the raw materials into the desired forms.

- Key Techniques:

- Molding: Injection molding for plastic parts and die casting for metal components.

- Stamping: Used for creating flat metal parts, ensuring precise dimensions and weight.

3. Assembly

Once the components are formed, they are assembled into sub-units or complete vending machine parts.

- Key Techniques:

- Mechanical Assembly: Using screws, bolts, and welding techniques to join parts.

- Electronic Integration: Installing circuit boards, sensors, and other electronic components, often requiring specialized skills.

4. Finishing

The final manufacturing stage involves finishing processes that enhance the appearance and durability of the parts.

- Key Techniques:

- Surface Treatment: Painting, powder coating, or plating to provide corrosion resistance and aesthetic appeal.

- Quality Control Checks: Ensuring dimensions and surface finishes meet standards before proceeding to packaging.

Quality Assurance

Quality assurance (QA) is a critical component of the manufacturing process for snack vending machine parts. It ensures that products meet specified standards and regulations, which is especially important for international B2B buyers.

Relevant International Standards

- ISO 9001: This standard outlines the requirements for a quality management system (QMS) and is essential for manufacturers aiming to ensure consistent quality.

- CE Marking: Required for products sold in the European Economic Area, indicating conformity with health, safety, and environmental protection standards.

- API Standards: Relevant for components that require specific industry standards, particularly for electronic parts.

QC Checkpoints

Quality control checkpoints are crucial for monitoring the manufacturing process at various stages:

- Incoming Quality Control (IQC): Verification of raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to detect and correct defects early.

- Final Quality Control (FQC): Comprehensive testing of finished products to ensure they meet both functional and aesthetic standards.

Common Testing Methods

Various testing methods are employed to validate the quality of snack vending machine parts:

- Dimensional Inspection: Using calipers and gauges to ensure parts meet specified dimensions.

- Functional Testing: Verifying the operation of electronic components and mechanical assemblies.

- Durability Testing: Simulating real-world conditions to assess the longevity and performance of parts.

Verifying Supplier Quality Control

B2B buyers should take proactive steps to verify the quality control measures employed by suppliers. Here are some actionable insights:

- Conduct Audits: Regular audits of suppliers can help ensure compliance with quality standards. These can be performed in-person or remotely.

- Request Quality Reports: Suppliers should provide detailed reports on their quality control processes, including results from IQC, IPQC, and FQC stages.

- Utilize Third-Party Inspections: Engaging independent third-party inspectors can offer unbiased assessments of a supplier’s quality control practices and product quality.

- Review Certifications: Check for relevant certifications (like ISO 9001 or CE marking) to confirm that the supplier adheres to recognized quality standards.

QC and Certification Nuances for International Buyers

International B2B buyers must navigate various nuances regarding quality control and certification:

- Regional Standards: Be aware that different regions may have specific standards and certifications that must be adhered to. For instance, CE marking is essential for Europe, while UL certification might be relevant in North America.

- Understanding Local Regulations: Buyers should familiarize themselves with local regulations in their target markets to ensure compliance.

- Cultural Considerations: Understanding cultural differences in business practices can aid in establishing effective communication and collaboration with suppliers.

Conclusion

Manufacturing processes and quality assurance for snack vending machine parts are complex and multifaceted. By understanding the key stages of manufacturing and implementing robust quality control measures, B2B buyers can ensure they source high-quality products that meet their needs. Engaging with suppliers who prioritize quality and compliance will not only enhance operational efficiency but also build long-term partnerships in the global market.

Related Video: Parle-G Biscuits Manufacturing process – Food Factory Tour- Modern Food factory, Mega Factory II

Comprehensive Cost and Pricing Analysis for snack vending machine parts Sourcing

When sourcing snack vending machine parts, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers. This analysis covers key cost components, influential pricing factors, and practical tips for optimizing procurement strategies.

Cost Components

-

Materials: The primary cost driver in snack vending machine parts. Common materials include plastic, metal, and electronic components. The choice of materials significantly affects durability and performance, impacting long-term value.

-

Labor: Labor costs vary by region, with some manufacturers in Asia offering lower rates compared to Europe or North America. Consideration of labor costs is essential, especially for complex assemblies requiring skilled technicians.

Illustrative Image (Source: Google Search)

-

Manufacturing Overhead: This includes indirect costs such as utilities, rent, and administrative expenses associated with production. Efficient manufacturing processes can reduce overhead, positively influencing overall costs.

-

Tooling: The initial investment in tools and molds for production can be significant, particularly for custom parts. Buyers should consider amortizing these costs over larger production runs to lower per-unit prices.

-

Quality Control (QC): Ensuring that parts meet quality standards incurs additional costs. Investing in robust QC processes can prevent costly returns and replacements, thus enhancing the overall cost-effectiveness of the procurement.

-

Logistics: Shipping costs depend on factors such as distance, shipping method, and volume. International buyers should factor in customs duties and tariffs, which can significantly impact the total landed cost.

-

Margin: Suppliers typically build a profit margin into their pricing. Understanding industry benchmarks for margins can help buyers negotiate better deals.

Price Influencers

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower prices per unit due to economies of scale. Buyers should evaluate their needs and consider bulk purchasing to maximize savings.

-

Specifications/Customization: Custom parts designed to specific requirements may incur higher costs. Buyers should weigh the benefits of customization against potential price increases.

-

Materials: The choice of high-quality versus standard materials can influence pricing. Premium materials may offer better performance but at a higher cost.

-

Quality/Certifications: Parts that meet certain quality standards or certifications (like ISO) may command higher prices. However, these certifications can also reduce risks associated with failures.

-

Supplier Factors: The supplier’s reputation, reliability, and production capabilities can affect pricing. Established suppliers with proven track records may charge a premium but offer better assurance of quality and service.

-

Incoterms: Understanding the shipping terms (e.g., FOB, CIF) is critical as they define the responsibilities of buyers and sellers, impacting overall costs and risks during transportation.

Buyer Tips

-

Negotiation: Leverage your purchasing power by negotiating terms and prices, especially when placing large orders. Building long-term relationships with suppliers can also yield better pricing.

-

Cost-Efficiency: Analyze the total cost of ownership (TCO), not just the initial purchase price. Consider maintenance, replacement frequency, and potential downtime when evaluating parts.

-

Pricing Nuances: For international buyers, be aware of currency fluctuations and how they can impact pricing. Additionally, understanding local market conditions and supplier capabilities can provide a competitive edge.

-

Disclaimer on Indicative Prices: Always remember that prices can fluctuate based on market conditions, demand, and supplier capabilities. Obtain multiple quotes and conduct thorough market research to ensure you are making informed purchasing decisions.

By understanding the comprehensive cost structure and pricing dynamics of snack vending machine parts, international B2B buyers can make strategic decisions that enhance their procurement processes and contribute to their overall business success.

Spotlight on Potential snack vending machine parts Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘snack vending machine parts’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for snack vending machine parts

When engaging in the procurement of snack vending machine parts, understanding the essential technical properties and terminology is crucial for making informed purchasing decisions. This knowledge can help international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, navigate the complexities of the supply chain effectively.

Critical Technical Properties

-

Material Grade

– Definition: Refers to the classification of materials used in manufacturing parts, such as stainless steel, plastic, or aluminum. Each material has specific properties that influence durability, weight, and cost.

– Importance: Selecting the appropriate material grade is vital for ensuring the longevity and functionality of vending machines, especially in varying climates and usage levels. -

Tolerance

– Definition: The permissible limit of variation in a physical dimension, which is crucial for parts that must fit together precisely.

– Importance: Proper tolerance levels ensure that parts operate smoothly without excessive wear or failure. This is particularly critical for components like motors and dispensers that require precision. -

Weight Capacity

– Definition: The maximum load that a vending machine part can support, often specified for shelves and trays.

– Importance: Understanding weight capacity is essential for ensuring that the machine can hold the intended product types without risk of failure or damage. -

Temperature Resistance

– Definition: The ability of materials to withstand certain temperature ranges without degrading.

– Importance: Vending machines may operate in environments with varying temperatures; hence, selecting components with appropriate temperature resistance is crucial for maintaining product quality and machine performance. -

Electrical Specifications

– Definition: Details regarding voltage, current, and power ratings for electrical components like motors and lights.

– Importance: Ensuring compatibility with local electrical standards is essential to prevent operational failures and ensure safety. -

Corrosion Resistance

– Definition: The ability of a material to withstand deterioration due to chemical reactions, particularly in humid environments.

– Importance: For machines placed in outdoor settings or areas with high humidity, corrosion-resistant materials extend the machine’s lifespan and reduce maintenance costs.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts and equipment that may be marketed by another manufacturer.

– Importance: Understanding whether parts are OEM can affect quality assurance and compatibility with existing machines. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ helps buyers assess the feasibility of placing an order based on their needs and budget constraints. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers to request pricing and terms for specific parts or services.

– Importance: An RFQ allows buyers to compare prices and terms from multiple suppliers, ensuring competitive procurement. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions.

– Importance: Familiarity with Incoterms helps buyers understand shipping responsibilities, risk management, and cost implications. -

Lead Time

– Definition: The time it takes from placing an order to the delivery of goods.

– Importance: Understanding lead times is critical for inventory planning and ensuring that vending machines are stocked and operational when needed. -

Warranty

– Definition: A guarantee provided by the manufacturer regarding the condition of the product and the terms under which repairs or replacements will be made.

– Importance: Knowledge of warranty terms is essential for buyers to assess risk and understand the support they can expect after purchase.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions, ensuring that the parts they procure meet their operational needs while optimizing costs and efficiency.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the snack vending machine parts Sector

Market Overview & Key Trends

The snack vending machine parts sector is experiencing significant growth, driven by the increasing demand for convenient food options and the integration of technology into vending solutions. Factors such as urbanization, rising disposable incomes, and changing consumer lifestyles are propelling this market forward. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should note the following key trends:

-

Smart Vending Technology: The incorporation of IoT (Internet of Things) in vending machines is revolutionizing operations. Features like cashless payments, inventory tracking, and remote monitoring are becoming standard, enhancing the customer experience and operational efficiency.

-

Customization and Personalization: There is a growing demand for personalized vending experiences, where machines can offer tailored snack options based on consumer preferences. This trend is particularly relevant in diverse markets, where cultural tastes vary significantly.

-

Sourcing from Local Suppliers: International buyers are increasingly looking to source parts from local suppliers to reduce lead times and transportation costs. This trend is reinforced by the need for more agile supply chains, especially in the wake of global disruptions.

-

E-commerce Integration: The rise of e-commerce platforms for B2B transactions is simplifying the procurement process. Buyers can easily compare prices, access product reviews, and communicate directly with suppliers, making sourcing more efficient.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a cornerstone of procurement strategies in the snack vending machine parts sector. The environmental impact of manufacturing processes and material sourcing is under scrutiny, prompting buyers to seek sustainable alternatives. Key considerations include:

-

Ethical Supply Chains: Buyers should prioritize suppliers that adhere to ethical labor practices and environmental standards. This not only mitigates risks associated with supply chain disruptions but also enhances brand reputation.

-

Green Certifications: Look for suppliers that offer products with recognized green certifications, such as ISO 14001 (Environmental Management) or FSC (Forest Stewardship Council) for materials. These certifications indicate a commitment to sustainable practices.

-

Sustainable Materials: Increasingly, parts made from recycled or biodegradable materials are gaining traction. Investing in such options can significantly reduce the environmental footprint of vending operations.

By adopting sustainable practices, businesses not only comply with regulatory requirements but also appeal to a growing segment of environmentally-conscious consumers.

Brief Evolution/History

The snack vending machine parts industry has evolved significantly over the last few decades. Initially dominated by mechanical components, the sector has transitioned towards electronic and digital solutions, reflecting broader technological advancements. The introduction of cashless payment systems and smart technology has transformed traditional vending machines into sophisticated retail platforms. This evolution has been further accelerated by the COVID-19 pandemic, which emphasized the need for contactless transactions and hygienic solutions. As the market continues to grow, B2B buyers must stay informed about these changes to leverage new opportunities and meet customer expectations effectively.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of snack vending machine parts

-

How can I effectively vet suppliers for snack vending machine parts?

When sourcing snack vending machine parts, it’s crucial to conduct thorough supplier vetting. Start by researching the supplier’s reputation through reviews and ratings on platforms such as Alibaba or Global Sources. Verify their business licenses and certifications to ensure compliance with international standards. Request references from previous clients and consider visiting their facilities if possible. Engaging a local agent can also facilitate better communication and trust-building, particularly in regions like Africa and South America, where local market knowledge is essential. -

Are custom parts available for snack vending machines?

Yes, many suppliers offer customization options for snack vending machine parts. When inquiring, specify your requirements, including dimensions, materials, and features unique to your vending machines. Customization can enhance machine efficiency and customer satisfaction. However, be mindful that custom parts may have longer lead times and may require a higher minimum order quantity (MOQ). Discuss these details with the supplier upfront to ensure they can meet your specific needs. -

What are the typical minimum order quantities (MOQs) and lead times for parts?

MOQs for snack vending machine parts vary widely among suppliers, usually ranging from 50 to 500 units. Lead times can also differ based on the complexity of the parts and the supplier’s production capacity, generally falling between 4 to 12 weeks. It’s advisable to negotiate these terms before placing an order. If you’re considering bulk purchases, inquire about volume discounts, which can significantly reduce your overall costs. -

What payment methods are common in international transactions for vending machine parts?

Common payment methods for international B2B transactions include bank transfers, PayPal, and letters of credit (LC). Using a letter of credit can provide additional security, ensuring that payment is only released when the agreed conditions are met. It’s important to clarify the payment terms with the supplier, including the percentage of advance payment required. Always ensure the payment method aligns with your company’s financial practices and risk management strategies. -

How do I ensure quality assurance and certifications for parts?

To ensure quality assurance, request detailed specifications and certifications from the supplier, such as ISO 9001 or CE marking, which demonstrate compliance with international quality standards. Conducting a factory audit or hiring a third-party inspection service can also help verify the quality of parts before shipment. Additionally, consider requesting samples prior to placing a bulk order to assess the quality firsthand.

Illustrative Image (Source: Google Search)

-

What logistics considerations should I keep in mind when importing parts?

Logistics is a crucial aspect of importing snack vending machine parts. Evaluate shipping options based on cost, speed, and reliability. Consider using freight forwarders who specialize in international shipping, as they can handle customs clearance and documentation. Be aware of potential tariffs and duties in your country, which can impact the total cost. Lastly, ensure that the supplier provides tracking information to monitor your shipment’s progress. -

How should I handle disputes with suppliers?

Handling disputes with suppliers requires a structured approach. Start by documenting all communications and agreements related to the order. If a disagreement arises, initiate a discussion with the supplier to seek a resolution. If direct negotiation fails, consider mediation or arbitration, which can be less costly and faster than legal action. Always refer to the contract terms, which should specify the process for resolving disputes to ensure both parties adhere to the agreed-upon procedures. -

What are the best practices for maintaining a long-term relationship with suppliers?

Building a long-term relationship with suppliers is beneficial for consistent quality and better pricing. Communicate regularly and provide constructive feedback to help suppliers understand your needs. Recognize their efforts through positive reinforcement and timely payments, which fosters trust. Additionally, consider involving them in your product development process to create a sense of partnership. By nurturing these relationships, you can secure better terms and priority service in future transactions.

Strategic Sourcing Conclusion and Outlook for snack vending machine parts

In the dynamic landscape of snack vending machine parts, strategic sourcing emerges as a critical driver for international B2B buyers. By prioritizing relationships with reliable suppliers, companies can ensure not only the quality of components but also cost-effectiveness and timely delivery. Establishing a robust sourcing strategy allows buyers to navigate market fluctuations, mitigating risks associated with supply chain disruptions.

Buyers from Africa, South America, the Middle East, and Europe should focus on sourcing parts that meet regional compliance and consumer preferences, leveraging local suppliers when possible to enhance responsiveness and support sustainability initiatives. Additionally, investing in technology for inventory management and supplier relationship management can yield significant operational efficiencies.

Looking ahead, the vending machine sector is poised for innovation, driven by advancements in technology and changing consumer behaviors. International B2B buyers are encouraged to stay informed about emerging trends, such as contactless payments and healthier snack options, which will shape the future of vending solutions. By adopting a proactive approach to sourcing and collaboration, companies can position themselves for success in this evolving market. Embrace the opportunity to enhance your supply chain today and secure a competitive advantage for tomorrow.