Master Sourcing Self Serve Ice Vending Machines for Your

Guide to Self Serve Ice Vending Machines

- Introduction: Navigating the Global Market for self serve ice vending machines

- Understanding self serve ice vending machines Types and Variations

- Key Industrial Applications of self serve ice vending machines

- Strategic Material Selection Guide for self serve ice vending machines

- In-depth Look: Manufacturing Processes and Quality Assurance for self serve ice vending machines

- Comprehensive Cost and Pricing Analysis for self serve ice vending machines Sourcing

- Spotlight on Potential self serve ice vending machines Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for self serve ice vending machines

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the self serve ice vending machines Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of self serve ice vending machines

- Strategic Sourcing Conclusion and Outlook for self serve ice vending machines

Introduction: Navigating the Global Market for self serve ice vending machines

In today’s fast-paced business environment, the demand for self-serve ice vending machines is surging across diverse markets, from bustling urban centers in Africa to coastal resorts in Europe and beyond. These innovative machines offer not only convenience but also a cost-effective solution for businesses needing ice on demand. Whether it’s for restaurants, hotels, or convenience stores, understanding the nuances of self-serve ice vending machines can significantly enhance operational efficiency.

This guide serves as a comprehensive resource tailored specifically for international B2B buyers, focusing on critical aspects such as types of machines, materials used, manufacturing and quality control standards, supplier options, and cost considerations. By delving into the intricacies of the market, buyers will be better equipped to make informed sourcing decisions that align with their unique business needs.

Furthermore, this guide addresses frequently asked questions and provides insights into market trends, empowering buyers to navigate the complexities of sourcing self-serve ice vending machines with confidence. For businesses in regions like Africa, South America, the Middle East, and Europe—especially in countries like Italy and Spain—having access to detailed information about these machines is crucial for strategic investment and long-term success. By leveraging the insights offered here, buyers can streamline their purchasing processes and capitalize on the growing demand for ice vending solutions in their respective markets.

Understanding self serve ice vending machines Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Ice Vending Machine | Simple mechanical operation, produces cube ice | Convenience stores, gas stations | Pros: Low maintenance, easy to use. Cons: Limited ice variety. |

| Flake Ice Vending Machine | Produces soft, flake ice ideal for seafood preservation | Fish markets, restaurants | Pros: Excellent for food preservation. Cons: Slower production rate. |

| Block Ice Vending Machine | Creates large blocks of ice, suitable for shipping | Seafood distributors, event venues | Pros: Long-lasting, versatile. Cons: Requires more storage space. |

| Bulk Ice Vending Machine | High-capacity dispensing, customizable ice size | Festivals, outdoor events | Pros: Cost-effective for high demand. Cons: Higher initial investment. |

| Portable Ice Vending Machine | Compact, mobile design, battery-operated options | Remote locations, temporary events | Pros: Flexibility and mobility. Cons: Limited output capacity. |

Traditional Ice Vending Machine

Traditional ice vending machines are designed for straightforward operation, typically producing standard cube ice. They are commonly found in convenience stores and gas stations, catering to consumers looking for quick ice access. B2B buyers should consider the machine’s low maintenance needs and ease of use, which can minimize operational disruptions. However, the limited variety of ice types can restrict appeal in markets that require specialized ice forms.

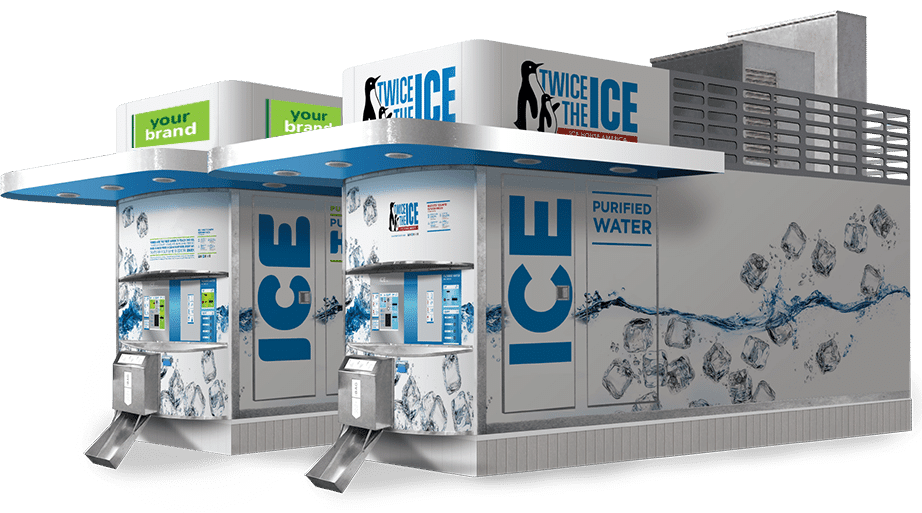

Illustrative Image (Source: Google Search)

Flake Ice Vending Machine

Flake ice vending machines produce soft, flake ice, which is particularly beneficial for seafood preservation and display. These machines are ideal for fish markets and restaurants that prioritize food freshness. When purchasing, B2B buyers should weigh the benefits of superior preservation against the slower production rate compared to cube machines. This type of ice is less suitable for beverages but excels in food applications.

Block Ice Vending Machine

Block ice vending machines create substantial blocks of ice suitable for various applications, including shipping and event cooling. They are often used by seafood distributors and at large venues where ice is needed in bulk. Buyers should consider the long-lasting nature of block ice, which reduces the frequency of replenishment. However, these machines require more storage space and are less convenient for small-scale operations.

Bulk Ice Vending Machine

Bulk ice vending machines are designed for high-capacity dispensing, allowing for customizable ice sizes to meet diverse customer needs. They are frequently utilized at festivals and outdoor events where large quantities of ice are demanded. For B2B buyers, the cost-effectiveness of these machines makes them an attractive option, despite the higher initial investment required. It’s essential to assess the expected demand to justify the purchase.

Portable Ice Vending Machine

Portable ice vending machines feature a compact design, often battery-operated, making them suitable for remote locations and temporary events. These machines provide flexibility and mobility, allowing businesses to set up ice vending wherever needed. However, buyers should be aware of the limited output capacity, which may not meet high-volume demands. The adaptability of these machines can be a significant advantage in dynamic market environments.

Related Video: 5 Amusing Ice Cream Vending Machines

Key Industrial Applications of self serve ice vending machines

| Industry/Sector | Specific Application of Self Serve Ice Vending Machines | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Ice supply for hotels and restaurants | Enhances guest experience, reduces labor costs | Energy efficiency, maintenance requirements, capacity |

| Events & Catering | On-site ice for large gatherings and events | Immediate supply, flexibility for varying demand | Mobility features, size and storage capacity |

| Food & Beverage | Ice for food preservation and beverage cooling | Improved product quality, extended shelf life | Compliance with food safety standards, ice quality |

| Healthcare | Ice for medical applications and patient care | Essential for patient comfort and treatment effectiveness | Sterilization capabilities, reliability under pressure |

| Construction | Ice for concrete cooling and curing | Prevents cracking, ensures structural integrity | Durability in harsh environments, ease of transport |

Hospitality

In the hospitality sector, self-serve ice vending machines provide hotels and restaurants with a convenient and efficient ice supply solution. These machines enhance guest experience by ensuring that ice is readily available for drinks and food presentations, while also reducing labor costs associated with manual ice distribution. For international buyers, particularly in regions like Africa and the Middle East, sourcing machines with energy-efficient features is crucial to minimize operational costs in hot climates.

Events & Catering

Self-serve ice vending machines are invaluable for event organizers and catering services, allowing for on-demand ice supply during large gatherings. This flexibility helps manage varying demands throughout events, ensuring that guests have access to ice without delays. Buyers should consider the mobility features of these machines, as well as their size and storage capacity, to accommodate different venue sizes and event types.

Food & Beverage

In the food and beverage industry, self-serve ice vending machines play a key role in maintaining the quality of products. Ice is essential for preserving food freshness and cooling beverages, which directly impacts customer satisfaction. Buyers must ensure that the machines comply with food safety standards and deliver high-quality ice to meet hygiene requirements. This is particularly important for businesses operating in Europe, where regulations may be stricter.

Healthcare

Self-serve ice vending machines find critical applications in healthcare settings, where ice is often needed for patient comfort and medical procedures. The availability of ice can enhance treatment effectiveness, especially in emergency care situations. Buyers in this sector should prioritize machines with sterilization capabilities and reliability under pressure, ensuring that they meet the specific needs of healthcare environments.

Construction

In the construction industry, self-serve ice vending machines are used for cooling and curing concrete, a vital process to prevent cracking and ensure structural integrity. The ability to easily access ice on-site can significantly enhance workflow efficiency. When sourcing these machines, buyers should focus on durability, particularly in harsh environments, as well as the ease of transport to different job sites.

Related Video: Kooler Ice Vending Machines – IM600XL vs. IM1000

Strategic Material Selection Guide for self serve ice vending machines

When selecting materials for self-serve ice vending machines, it is essential to consider properties such as temperature resistance, corrosion resistance, and overall durability. This section analyzes four common materials used in the construction of these machines, providing insights relevant to international B2B buyers from regions like Africa, South America, the Middle East, and Europe.

Stainless Steel

Key Properties: Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand extreme temperatures. It typically has a temperature rating of up to 800°F (427°C) and performs well under pressure.

Pros & Cons: The primary advantage of stainless steel is its durability and resistance to rust and corrosion, making it ideal for environments where moisture is prevalent. However, it is more expensive than other materials and can be challenging to machine, increasing manufacturing complexity.

Impact on Application: Stainless steel is suitable for contact with food and ice, ensuring hygiene and safety. Its corrosion resistance makes it compatible with various cleaning agents, which is crucial for maintaining equipment in high-usage environments.

Considerations for International Buyers: Compliance with standards such as ASTM A240 for stainless steel is essential. Buyers in Europe and the Middle East may prefer specific grades like AISI 304 or 316 due to their superior corrosion resistance in coastal areas.

Carbon Steel

Key Properties: Carbon steel is known for its high tensile strength and ability to withstand heavy loads. It is typically rated for temperatures up to 600°F (316°C) but is less resistant to corrosion compared to stainless steel.

Pros & Cons: Carbon steel is cost-effective and easy to fabricate, making it a popular choice for structural components. However, it requires protective coatings to prevent rust, which can add to maintenance costs and complexity.

Impact on Application: While suitable for non-corrosive environments, carbon steel is not ideal for direct contact with ice or water unless adequately protected. This limitation can affect the longevity of the equipment.

Considerations for International Buyers: Buyers should be aware of the need for protective coatings and compliance with standards like ASTM A36. In regions with high humidity, such as parts of Africa and South America, the risk of corrosion must be factored into the purchasing decision.

Polycarbonate

Key Properties: Polycarbonate is a lightweight, impact-resistant plastic with a temperature resistance of up to 240°F (116°C). It is also transparent, allowing for visibility of the ice levels.

Pros & Cons: The primary advantage of polycarbonate is its high impact resistance and lower weight compared to metals, making it easier to install. However, it is less durable under extreme temperatures and can become brittle over time.

Impact on Application: Polycarbonate is suitable for transparent panels and components where visibility is essential. However, it may not be suitable for high-temperature applications or areas exposed to direct sunlight for extended periods.

Considerations for International Buyers: Buyers should ensure that the polycarbonate used meets safety standards such as ASTM D5767. In regions with high UV exposure, additional treatments may be necessary to prevent degradation.

Aluminum

Key Properties: Aluminum is lightweight and has good corrosion resistance, with a temperature rating of up to 400°F (204°C). It is also highly malleable, allowing for various shapes and designs.

Pros & Cons: The advantages of aluminum include its low weight and resistance to corrosion, making it suitable for portable ice vending machines. However, it is softer than steel, which can lead to dents and scratches.

Impact on Application: Aluminum is suitable for components that require frequent handling or transportation. Its lightweight nature enhances the mobility of vending machines, but it may not be ideal for high-stress structural applications.

Considerations for International Buyers: Compliance with standards such as ASTM B221 is important. Buyers should also consider local preferences for aluminum alloys, as certain grades may be favored in specific markets.

Summary Table

| Material | Typical Use Case for self serve ice vending machines | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural components, ice storage bins | Excellent corrosion resistance, durable | Higher cost, manufacturing complexity | High |

| Carbon Steel | Framework, non-corrosive parts | Cost-effective, strong | Susceptible to rust, requires coatings | Low |

| Polycarbonate | Transparent panels, protective covers | Lightweight, impact-resistant | Less durable under high temperatures, brittle | Medium |

| Aluminum | Portable components, frames | Lightweight, good corrosion resistance | Softer than steel, prone to dents | Medium |

This strategic material selection guide provides actionable insights for international B2B buyers, helping them make informed decisions based on performance, cost, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for self serve ice vending machines

Manufacturing Processes for Self-Serve Ice Vending Machines

The manufacturing process for self-serve ice vending machines involves several critical stages, each essential to ensuring a high-quality final product. Understanding these stages can help B2B buyers make informed decisions when sourcing equipment.

1. Material Preparation

The first step involves sourcing and preparing high-quality materials. Stainless steel is commonly used for the exterior and internal components due to its durability and resistance to corrosion. Other materials like plastic and aluminum may also be utilized, particularly in non-structural components.

- Material Inspection: Before processing, materials undergo rigorous inspection to ensure they meet specified standards. This includes checking for defects and compliance with industry standards such as ISO 9001.

2. Forming

The forming stage typically involves several techniques to shape the materials into the desired components.

- CNC Machining: This technique allows for precise shaping of metal parts, ensuring that each component fits perfectly within the overall assembly.

- Injection Molding: Used for producing plastic parts, this method enables the production of complex shapes with high accuracy.

- Sheet Metal Fabrication: Essential for creating the exterior casing and other flat components, this process includes cutting, bending, and assembling metal sheets.

3. Assembly

Once individual components are ready, they are brought together in the assembly stage.

- Automated Assembly Lines: Many manufacturers use robotics to streamline assembly, improving efficiency and consistency. Automation reduces human error and speeds up production.

- Manual Assembly: Critical components such as electronics and sensors are often assembled manually to ensure precision. Technicians may conduct final fittings and adjustments.

4. Finishing

The finishing stage enhances both the aesthetic appeal and functionality of the ice vending machines.

- Surface Treatment: Processes like powder coating or anodizing improve the durability of metal surfaces, while also providing a visually appealing finish.

- Quality Checks: Each unit undergoes a final inspection to ensure it meets all design specifications and quality standards.

Quality Assurance (QA) in Manufacturing

Quality assurance is paramount in manufacturing self-serve ice vending machines, ensuring safety, reliability, and customer satisfaction. The QA process includes compliance with international standards and internal checkpoints.

International Standards

B2B buyers should prioritize suppliers that adhere to recognized international standards, such as:

- ISO 9001: This quality management standard focuses on meeting customer expectations and delivering satisfaction.

- CE Certification: Essential for compliance within the European market, CE marking indicates that products meet EU safety, health, and environmental protection requirements.

- API Standards: Particularly relevant for components that may interact with food or beverages, these standards ensure safety and hygiene.

Quality Control Checkpoints

Quality control (QC) involves multiple checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Inspects raw materials upon arrival to ensure they meet required specifications.

- In-Process Quality Control (IPQC): Conducts checks during manufacturing to identify defects early, reducing waste and ensuring quality.

- Final Quality Control (FQC): Involves comprehensive testing of the finished product, ensuring it meets all operational and safety standards.

Common Testing Methods

B2B buyers should be aware of various testing methods employed during QC:

- Functional Testing: Ensures that all features of the ice vending machine operate correctly, including the ice-making and dispensing functions.

- Durability Testing: Assesses the machine’s performance under various environmental conditions, simulating real-world usage.

- Safety Testing: Verifies compliance with safety standards, focusing on electrical safety and mechanical reliability.

Verifying Supplier Quality Control

When sourcing self-serve ice vending machines, B2B buyers should take proactive steps to verify supplier quality control measures:

- Conduct Supplier Audits: Regularly auditing suppliers can provide insights into their manufacturing processes and quality control systems.

- Request Quality Assurance Reports: Suppliers should provide documentation demonstrating compliance with international standards and internal QC processes.

- Engage Third-Party Inspectors: Utilizing independent inspectors can help validate the quality of products before they are shipped, reducing the risk of defects upon arrival.

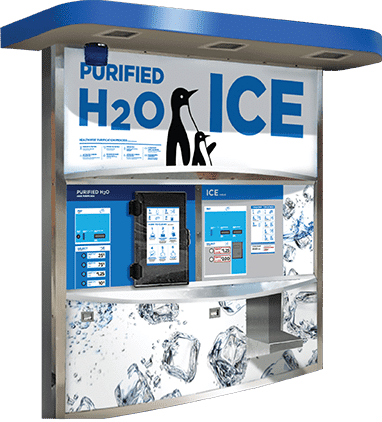

Illustrative Image (Source: Google Search)

Regional Considerations for B2B Buyers

For international buyers, particularly from Africa, South America, the Middle East, and Europe (e.g., Italy, Spain), it is crucial to understand regional nuances in manufacturing and quality assurance.

- Import Regulations: Familiarize yourself with local regulations regarding the importation of vending machines, including any certifications required for operation in your market.

- Cultural Preferences: Different regions may have varying preferences for design and functionality, which can impact the choice of suppliers and product specifications.

- Supply Chain Reliability: Consider the logistics involved in sourcing equipment from different regions, ensuring that suppliers have robust supply chains to minimize delays.

Conclusion

Understanding the manufacturing processes and quality assurance practices behind self-serve ice vending machines is vital for B2B buyers seeking reliable and high-quality equipment. By prioritizing suppliers who adhere to international standards and implementing thorough quality control measures, buyers can ensure a successful purchase that meets their operational needs.

Related Video: INSIDE THE FACTORY HÄAGEN DAZS ICE CREAM MAKING MACHINES

Comprehensive Cost and Pricing Analysis for self serve ice vending machines Sourcing

To effectively navigate the landscape of sourcing self-serve ice vending machines, understanding the cost structure and pricing dynamics is crucial for international B2B buyers. This analysis breaks down the key components of costs and the factors influencing pricing, tailored specifically for buyers in regions such as Africa, South America, the Middle East, and Europe, including Italy and Spain.

Cost Components

-

Materials: The primary materials used in the production of self-serve ice vending machines include stainless steel, refrigeration components, electronic parts, and insulation materials. The quality and sourcing of these materials can significantly affect the overall cost. For instance, opting for high-grade stainless steel may increase costs but enhance durability and corrosion resistance.

-

Labor: Labor costs vary by region and manufacturing practices. In countries with lower labor costs, such as some South American nations, the manufacturing cost can be lower. However, it is essential to consider the skill level of the workforce, as more skilled labor may lead to higher initial costs but can result in better-quality machines.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and administrative expenses. Efficient manufacturing processes can help minimize overhead, contributing to more competitive pricing.

-

Tooling: The initial setup for production, including molds and specialized machinery, can be a significant upfront cost. Buyers should inquire about the tooling costs and whether they are amortized over the production run, which can affect unit pricing.

-

Quality Control (QC): Implementing rigorous quality control measures is crucial for ensuring the reliability and safety of the machines. These costs should not be overlooked, as they can prevent potential losses from defective products.

-

Logistics: Transportation and shipping costs can vary greatly depending on the destination and the chosen Incoterms. For international shipments, these costs can significantly impact the total price, particularly for bulky items like vending machines.

-

Margin: Suppliers will typically add a margin to cover their costs and ensure profitability. Understanding the standard margin in the industry can help buyers negotiate better terms.

Price Influencers

-

Volume/MOQ: Pricing often benefits from economies of scale. Ordering in larger quantities can lead to lower per-unit costs. Buyers should assess their demand forecasts to optimize their order sizes.

-

Specifications/Customization: Custom features or specifications can lead to higher costs. Buyers should clearly define their requirements to avoid unexpected price hikes.

-

Materials and Quality/Certifications: Higher-quality materials and certifications (such as ISO or CE) typically command higher prices. However, these can enhance the machine’s longevity and reliability, impacting the Total Cost of Ownership (TCO).

-

Supplier Factors: The reputation, reliability, and financial stability of the supplier can influence pricing. Established suppliers may offer better warranties and support, which can justify higher costs.

-

Incoterms: Understanding the shipping terms (e.g., FOB, CIF) is vital. Different Incoterms can lead to varying responsibilities and costs, affecting the total landed cost of the machines.

Buyer Tips

-

Negotiation: Engage in negotiations with suppliers to secure the best possible pricing. Leverage competitive quotes from multiple suppliers to strengthen your position.

-

Cost-Efficiency: Consider the TCO rather than just the initial purchase price. Evaluate maintenance costs, energy consumption, and expected lifespan to make a more informed decision.

-

Pricing Nuances: Be aware of regional pricing differences and currency fluctuations that can impact costs. For buyers in Africa and South America, understanding local market conditions is crucial for effective budgeting.

-

Customization Considerations: While customization can enhance machine utility, it can also inflate costs. Assess the true necessity of custom features against budget constraints.

Disclaimer

The prices discussed in this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. It’s advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure they are making well-informed purchasing decisions.

Spotlight on Potential self serve ice vending machines Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘self serve ice vending machines’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for self serve ice vending machines

Key Technical Properties of Self-Serve Ice Vending Machines

Understanding the essential technical properties of self-serve ice vending machines is crucial for B2B buyers aiming to ensure product quality and operational efficiency. Here are some critical specifications to consider:

-

Material Grade

– Definition: The quality of materials used in construction, typically stainless steel or food-grade plastic.

– Importance: High-grade materials resist corrosion, enhance durability, and ensure safety in food handling, which is essential for maintaining hygiene standards. -

Ice Production Rate

– Definition: The amount of ice produced per hour, usually measured in kilograms or pounds.

– Importance: A higher production rate ensures that the machine can meet demand, particularly in high-traffic locations, thus maximizing revenue potential. -

Energy Efficiency Rating

– Definition: A measure of the machine’s energy consumption relative to its output, often indicated by an Energy Star rating.

– Importance: Energy-efficient machines reduce operational costs, appealing to buyers focused on sustainability and long-term savings. -

Temperature Control Range

– Definition: The range of temperatures the machine can maintain to ensure optimal ice quality.

– Importance: Precise temperature control prevents the formation of ice clumps and ensures consistent quality, which is vital for customer satisfaction. -

Water Filtration System

– Definition: The technology used to purify water before it is turned into ice, including carbon filters and reverse osmosis systems.

– Importance: A good filtration system enhances ice quality and taste, which is critical for establishments like restaurants and cafes that prioritize customer experience. -

Safety Features

– Definition: Includes mechanisms such as automatic shut-off, emergency stop buttons, and child safety locks.

– Importance: Safety features protect users and minimize liability, making the machine more appealing to potential buyers.

Common Trade Terminology in Self-Serve Ice Vending Machines

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B space. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Context: Buyers often engage with OEMs for customized machines tailored to specific operational needs. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Context: Understanding MOQ is crucial for budgeting and inventory management, especially for smaller businesses looking to minimize upfront costs. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers asking for a price quote on specific products or services.

– Context: An RFQ helps buyers compare prices and terms from different suppliers, facilitating informed purchasing decisions. -

Incoterms (International Commercial Terms)

– Definition: A series of pre-defined commercial terms published by the International Chamber of Commerce (ICC).

– Context: Familiarity with Incoterms is essential for understanding shipping responsibilities, costs, and risks, particularly for international transactions. -

Lead Time

– Definition: The time it takes from placing an order to receiving the product.

– Context: Knowing the lead time helps businesses plan their inventory and operations, ensuring that they can meet customer demand without delay. -

Warranty Period

– Definition: The duration for which the manufacturer guarantees the machine against defects.

– Context: A longer warranty period can indicate higher product reliability and lower long-term costs, making it an important consideration for buyers.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions, ensuring they select the right self-serve ice vending machines to meet their operational needs and customer expectations.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the self serve ice vending machines Sector

Market Overview & Key Trends

The self-serve ice vending machine sector is experiencing dynamic growth driven by increasing demand for convenience, efficiency, and hygiene, particularly in urban areas across Africa, South America, the Middle East, and Europe. As consumers shift towards contactless solutions post-pandemic, businesses are investing in automated systems that offer easy access to ice without human interaction. This trend is further fueled by advancements in technology, such as IoT-enabled machines that allow operators to monitor usage, maintenance needs, and inventory remotely, enhancing operational efficiency.

Emerging B2B sourcing trends highlight a growing preference for integrated solutions that combine ice production with vending capabilities, reducing the need for separate machines and minimizing space requirements. Additionally, international buyers are increasingly looking for suppliers that offer customizable solutions tailored to local market needs, which can include varying ice types (e.g., nugget or flake) and machine sizes to suit different business environments from restaurants to convenience stores.

Market dynamics also reflect a competitive landscape where businesses seek to differentiate themselves through innovative features such as energy-efficient designs and advanced filtration systems that ensure the purity of the ice produced. For international buyers, this means a focus on suppliers that not only meet quality standards but also offer robust after-sales support and warranty options, essential for maintaining machine longevity and operational reliability.

Sustainability & Ethical Sourcing in B2B

In today’s eco-conscious marketplace, sustainability is a critical consideration for B2B buyers in the self-serve ice vending machine sector. The environmental impact of ice production, particularly in terms of energy consumption and water usage, is under scrutiny. Buyers are increasingly prioritizing suppliers that utilize energy-efficient technologies and sustainable practices, such as recycling wastewater and using eco-friendly refrigerants that minimize greenhouse gas emissions.

Ethical sourcing also plays a pivotal role in the decision-making process. Buyers are encouraged to select vendors that adhere to ethical supply chain practices, ensuring that materials used in machine construction are sourced responsibly. Certifications such as Energy Star, ISO 14001, and other green labels provide assurance of a supplier’s commitment to sustainability. By opting for machines that meet these criteria, businesses can not only enhance their brand reputation but also attract environmentally conscious consumers.

Furthermore, the integration of sustainable materials in manufacturing processes—such as recyclable plastics and metals—can significantly reduce the ecological footprint of self-serve ice vending machines. This shift not only aligns with global sustainability goals but also meets the increasing consumer demand for environmentally responsible products.

Brief Evolution/History

The evolution of self-serve ice vending machines dates back to the early 2000s when the first units began to appear in convenience stores and gas stations, primarily in North America. Initially, these machines offered basic functionality with limited features. Over the years, technological advancements have transformed these machines into sophisticated units equipped with touchless interfaces, real-time monitoring systems, and energy-efficient components.

As the demand for convenience and hygiene grew, particularly during the COVID-19 pandemic, the sector witnessed a surge in innovation, leading to the development of machines that not only produce but also dispense ice in various forms. This evolution reflects a broader trend within the B2B landscape, where automation and technology integration are reshaping traditional business models, providing new opportunities for international buyers seeking modern solutions.

In summary, the self-serve ice vending machine sector is rapidly evolving, driven by technological advancements and an increasing emphasis on sustainability, making it an attractive area for international B2B buyers to explore innovative sourcing strategies.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of self serve ice vending machines

-

1. What criteria should I consider when vetting suppliers for self-serve ice vending machines?

When vetting suppliers, prioritize their experience in the industry, customer reviews, and financial stability. Assess their production capacity and capabilities to meet your specific needs, such as customization options. Verify their compliance with international quality standards and certifications relevant to your region. It’s also beneficial to request references from previous clients and consider visiting their facilities if feasible to ensure they meet your quality expectations. -

2. Can I customize self-serve ice vending machines to suit my business needs?

Yes, many suppliers offer customization options for self-serve ice vending machines. This can include branding, machine size, ice production capacity, and payment methods. When discussing customization, be specific about your requirements and ensure that the supplier can accommodate them. Request samples or prototypes if possible, to evaluate the final product before making a bulk purchase. -

3. What are the typical minimum order quantities (MOQ) and lead times for these machines?

Minimum order quantities vary by supplier and can range from a single unit to several dozen. Lead times typically depend on the complexity of the order and supplier location, often ranging from 4 to 12 weeks. To avoid delays, communicate your timeline clearly and confirm the supplier’s ability to meet your deadlines. It’s also wise to consider potential delays due to shipping or customs, particularly for international orders. -

4. What payment methods are commonly accepted when sourcing ice vending machines?

Most suppliers accept a variety of payment methods, including bank transfers, letters of credit, and sometimes credit cards. Ensure you understand the payment terms, including deposits, progress payments, and final payments. Consider using escrow services for large transactions to protect your investment. Always clarify any additional fees that may arise, such as currency conversion or international transaction fees. -

5. How can I ensure quality assurance and certifications for the machines?

Request documentation that verifies the machines meet international standards, such as ISO certifications or CE marking for products sold in Europe. Ask about the supplier’s quality control processes, including testing procedures before shipment. Consider arranging third-party inspections or audits to verify compliance and quality. Establish clear quality expectations in your contract to mitigate disputes later. -

6. What are the logistics considerations when importing these machines?

Logistics play a crucial role in the procurement process. Confirm the supplier’s shipping methods and options for insurance during transit. Understand the import regulations and duties in your country to avoid unexpected costs. It’s advisable to work with a freight forwarder who has experience in handling machinery imports, as they can assist with customs clearance and ensure timely delivery. -

7. How can I handle disputes with suppliers regarding my order?

To manage disputes effectively, establish clear communication channels and document all agreements and correspondences. Include a dispute resolution clause in your contract, specifying mediation or arbitration procedures. If issues arise, approach the supplier directly with your concerns and seek a collaborative solution. If resolution fails, consider legal options based on the terms outlined in your agreement and the jurisdiction specified. -

8. Are there specific maintenance requirements for self-serve ice vending machines?

Yes, regular maintenance is essential to ensure optimal performance and longevity of the machines. This typically includes cleaning the ice production and storage areas, checking water filters, and inspecting electrical components. Suppliers often provide maintenance guidelines and schedules; ensure you understand these requirements. Training your staff on proper usage and maintenance can help prevent operational issues and extend the machine’s lifespan.

Strategic Sourcing Conclusion and Outlook for self serve ice vending machines

In conclusion, the strategic sourcing of self-serve ice vending machines presents a unique opportunity for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. Key takeaways include understanding the importance of supplier reliability, product quality, and the integration of innovative technology to enhance user experience. A well-structured procurement strategy can significantly reduce costs, improve service delivery, and ensure compliance with local regulations.

Investing in self-serve ice vending machines not only meets the growing consumer demand for convenience but also aligns with sustainability trends by reducing waste and energy consumption. As the market evolves, buyers should prioritize suppliers who demonstrate a commitment to quality and innovation, ensuring they remain competitive in an increasingly crowded marketplace.

Looking ahead, the future of self-serve ice vending machines is promising, with advancements in technology and sustainability driving growth. We encourage B2B buyers to leverage these insights and engage with reputable suppliers to capitalize on this expanding market. Your proactive approach in strategic sourcing will be pivotal in securing a competitive edge.