Master Sourcing Live Bait Vending Machines for Your B2B

Guide to Live Bait Vending Machine

- Introduction: Navigating the Global Market for live bait vending machine

- Understanding live bait vending machine Types and Variations

- Key Industrial Applications of live bait vending machine

- Strategic Material Selection Guide for live bait vending machine

- In-depth Look: Manufacturing Processes and Quality Assurance for live bait vending machine

- Comprehensive Cost and Pricing Analysis for live bait vending machine Sourcing

- Spotlight on Potential live bait vending machine Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for live bait vending machine

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the live bait vending machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of live bait vending machine

- Strategic Sourcing Conclusion and Outlook for live bait vending machine

Introduction: Navigating the Global Market for live bait vending machine

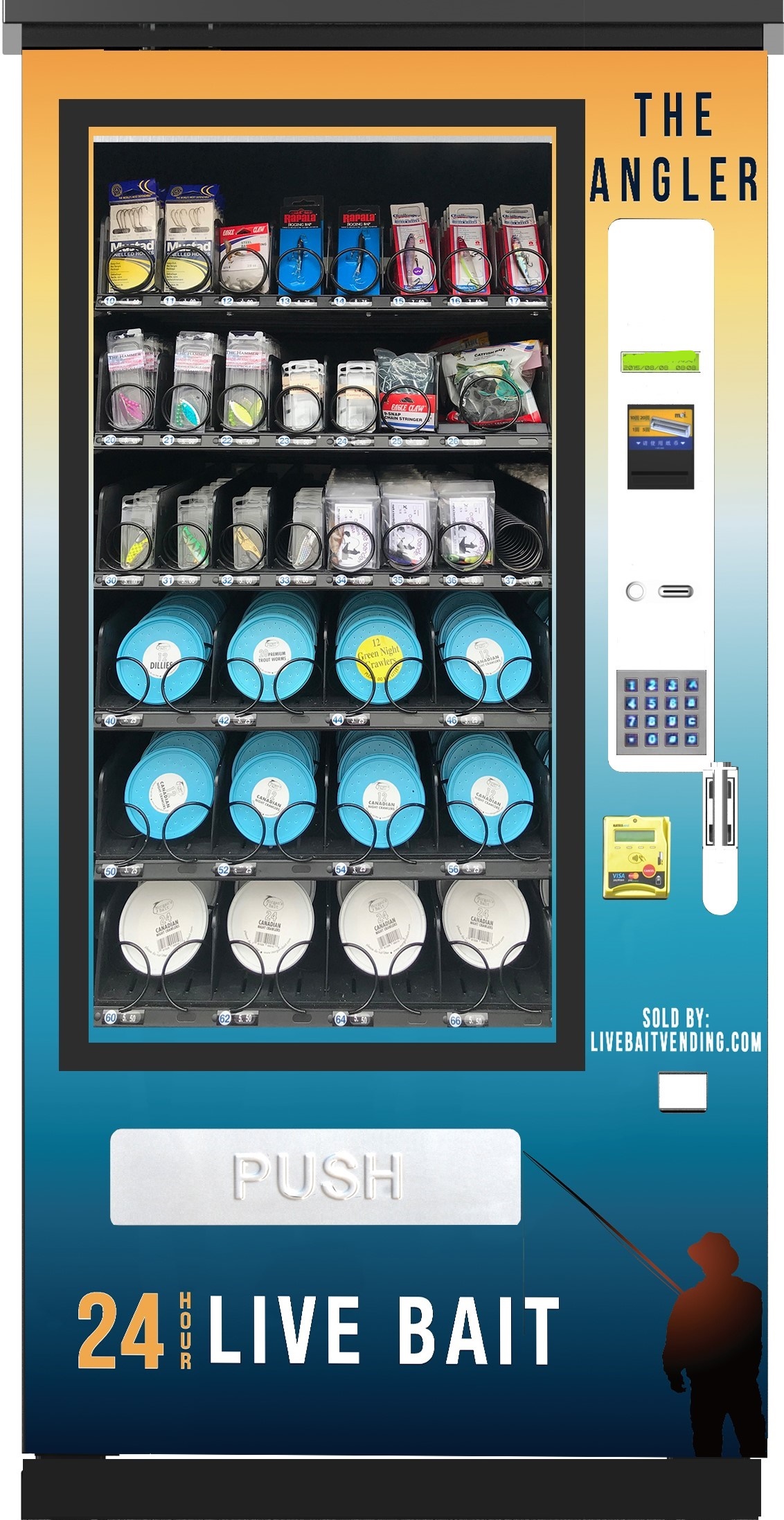

In the rapidly evolving landscape of the fishing industry, live bait vending machines have emerged as a transformative solution for both commercial and recreational anglers. These innovative machines not only provide convenient access to live bait but also enhance operational efficiency for businesses catering to fishing enthusiasts. As demand for sustainable fishing practices increases, the importance of reliable live bait sources cannot be overstated, making these vending machines a critical investment for suppliers and retailers alike.

This comprehensive guide serves as your roadmap through the global market for live bait vending machines. It explores a variety of essential topics, including the different types of machines available, the materials used in their construction, manufacturing standards, and quality control processes. Additionally, we will cover key suppliers, pricing structures, and market trends, ensuring that you have a holistic understanding of the options at your disposal.

By delving into these insights, international B2B buyers from regions such as Africa, South America, the Middle East, and Europe—particularly Poland and Germany—will be empowered to make informed sourcing decisions. This guide will equip you with the knowledge needed to navigate the complexities of purchasing live bait vending machines, ultimately enhancing your business offerings and meeting the needs of your customers efficiently. Embrace the opportunity to elevate your operations with strategic insights that lead to impactful investments in this niche market.

Understanding live bait vending machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Live Bait Machine | Traditional design with multiple compartments | Fishing supply stores, bait shops | Pros: Easy to use, well-known; Cons: Limited customization options. |

| Refrigerated Live Bait Machine | Temperature-controlled for preserving bait quality | Retail fishing outlets, convenience stores | Pros: Extends bait lifespan; Cons: Higher energy costs, maintenance needed. |

| Mobile Live Bait Vending Unit | Compact, portable design for events and festivals | Fishing tournaments, outdoor events | Pros: Flexibility and mobility; Cons: Limited capacity compared to stationary units. |

| Automated Live Bait Dispenser | High-tech options with touchscreens and payment systems | Tech-savvy retail environments | Pros: Enhanced customer experience; Cons: Higher initial investment. |

| Customizable Live Bait Machine | Tailored designs to meet specific business needs | Specialized bait shops, niche markets | Pros: Meets unique requirements; Cons: Longer lead times, potentially higher costs. |

Standard Live Bait Machine

The standard live bait vending machine is a staple in the fishing industry, featuring multiple compartments to house various types of bait. These machines are easy to operate and maintain, making them ideal for fishing supply stores and bait shops. B2B buyers should consider the volume of sales and the types of bait they plan to offer, as this model typically has limited customization options. Its reliability and familiarity to users can lead to consistent sales.

Refrigerated Live Bait Machine

Refrigerated live bait machines are designed with temperature control features that keep bait fresh for extended periods. This is crucial for retailers who want to provide high-quality live bait to their customers, especially in regions with warmer climates. While these machines help maintain bait viability, buyers must be aware of the increased energy costs and the necessity for regular maintenance. This investment is beneficial for businesses looking to enhance their product offerings and customer satisfaction.

Mobile Live Bait Vending Unit

Mobile live bait vending units are portable solutions that cater to fishing tournaments, outdoor events, and even pop-up markets. Their compact design allows for easy transportation and setup, making them a versatile option for businesses wanting to reach customers in various locations. However, potential buyers should consider the limited capacity of these units compared to stationary machines, which may affect sales during busy events.

Automated Live Bait Dispenser

Automated live bait dispensers incorporate advanced technology such as touchscreens and digital payment systems, providing a modern shopping experience. These machines are particularly appealing to tech-savvy retailers looking to attract a younger demographic. While they can enhance customer engagement and streamline transactions, the initial investment is typically higher, and businesses must ensure they have the technical support to maintain such systems.

Customizable Live Bait Machine

Customizable live bait machines offer tailored designs to meet the specific needs of niche markets or specialized bait shops. These units can include unique features such as branding options, specialized compartments, or additional functionalities. B2B buyers should weigh the benefits of having a machine that perfectly fits their business model against the longer lead times and potentially higher costs associated with customization. This option is ideal for businesses seeking a competitive edge in a crowded market.

Key Industrial Applications of live bait vending machine

| Industry/Sector | Specific Application of live bait vending machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fishing & Aquaculture | Retail and distribution of live bait | Increased sales through 24/7 accessibility; reduced labor costs | Machine durability, bait preservation technology, local regulations |

| Outdoor Recreation | Convenience for anglers at popular fishing spots | Enhanced customer experience; immediate access to bait | Location strategy, machine visibility, payment system integration |

| Sports Fishing Tournaments | On-site vending for competitors | Fast service; ensures availability of high-demand bait | Capacity for high turnover, variety of bait offered, maintenance support |

| Marine Research | Supply of live specimens for studies | Streamlined specimen acquisition; improved research efficiency | Customization for specific bait types, compliance with research standards |

| Hospitality & Tourism | Bait vending in resorts and lodges | Attraction of fishing tourists; additional revenue stream | Aesthetic design, integration with existing services, local partnerships |

Fishing & Aquaculture

In the fishing and aquaculture sector, live bait vending machines serve as a pivotal resource for retail and distribution. They allow businesses to offer a wide variety of live bait options at all hours, increasing sales potential while minimizing labor costs. For international buyers, especially in regions with strict regulations, it is crucial to ensure that the machines comply with local laws regarding the sale and preservation of live bait. Additionally, sourcing machines that incorporate advanced bait preservation technology can enhance product longevity and quality.

Outdoor Recreation

Outdoor recreation companies utilize live bait vending machines to provide convenience to anglers at popular fishing locations. These machines can be strategically placed near lakes, rivers, or coastal areas, offering immediate access to bait without the need for staffing. This enhances the customer experience, allowing anglers to focus on their fishing rather than sourcing bait. B2B buyers should consider the visibility and accessibility of the machines in high-traffic areas, as well as the integration of user-friendly payment systems to cater to diverse customer preferences.

Sports Fishing Tournaments

During sports fishing tournaments, live bait vending machines can offer on-site solutions for competitors. These machines ensure that participants have quick access to high-demand bait, which can significantly impact their performance. For businesses involved in tournament organization or sponsorship, investing in these machines can enhance service delivery and participant satisfaction. Key sourcing considerations include the machine’s capacity to handle high turnover rates and the variety of bait offered, which should cater to the specific needs of different fishing techniques.

Marine Research

In marine research, live bait vending machines facilitate the streamlined acquisition of live specimens for studies. Researchers often require specific types of live bait, and having a reliable, automated source can significantly improve operational efficiency. International buyers in this sector must focus on sourcing machines that can be customized to accommodate various bait types and ensure compliance with research standards. The ability to maintain optimal conditions for live specimens is also critical for research integrity.

Hospitality & Tourism

In the hospitality and tourism industry, particularly in resorts and lodges near fishing hotspots, live bait vending machines can serve as an attractive amenity for guests. By providing easy access to bait, these machines not only enhance the fishing experience but also create an additional revenue stream for the business. When sourcing these machines, B2B buyers should prioritize aesthetic design and integration with existing services to ensure they align with the overall guest experience. Forming local partnerships can also enhance the appeal and functionality of the vending service.

Related Video: DIY Vending Machine – Arduino based Mechatronics Project

Strategic Material Selection Guide for live bait vending machine

When selecting materials for live bait vending machines, international B2B buyers must consider various factors that influence both performance and compliance with regional standards. Below is a detailed analysis of four common materials used in the construction of these machines, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

Stainless Steel

Key Properties: Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand various environmental conditions. It typically has a temperature rating of up to 500°F (260°C) and can handle moderate pressure levels.

Pros & Cons: The primary advantage of stainless steel is its durability and low maintenance requirements, making it suitable for outdoor use. However, it is more expensive than other materials, which can affect initial investment costs. Manufacturing complexity can also be higher due to the need for specialized equipment.

Impact on Application: Stainless steel is compatible with a wide range of media, including water and various bait types, ensuring that the bait remains fresh and uncontaminated.

Considerations for International Buyers: Buyers in Europe, particularly in Germany and Poland, should ensure compliance with DIN standards for food safety. In Africa and South America, local corrosion factors, such as humidity and salinity, should be assessed to select the appropriate grade of stainless steel.

Polyethylene (PE)

Key Properties: Polyethylene is a lightweight, flexible thermoplastic with good chemical resistance and a temperature range of -40°F to 120°F (-40°C to 49°C). It is not suitable for high-pressure applications but performs well in moderate conditions.

Pros & Cons: The main advantage of polyethylene is its cost-effectiveness and ease of manufacturing, which allows for rapid production and customization. However, it is less durable than metals and may degrade under UV exposure over time.

Impact on Application: Polyethylene is suitable for water-based bait systems but may not be ideal for environments with extreme temperatures or mechanical stress.

Considerations for International Buyers: Buyers should be aware of local regulations regarding plastic materials, especially in Europe where there are stringent guidelines on plastic usage. In the Middle East, UV resistance may be a critical factor due to high sun exposure.

Aluminum

Key Properties: Aluminum is a lightweight metal with good corrosion resistance and thermal conductivity. It can withstand temperatures up to 400°F (204°C) and is suitable for moderate pressure applications.

Pros & Cons: Aluminum’s lightweight nature makes it easy to transport and install. It is also relatively affordable compared to stainless steel. However, it is more prone to dents and scratches, which can affect its longevity in harsh environments.

Impact on Application: Aluminum is compatible with various bait types, but its susceptibility to corrosion in certain environments (e.g., salty or acidic conditions) must be considered.

Considerations for International Buyers: Compliance with ASTM standards is essential for buyers in the U.S. and Europe. In regions like Africa and South America, buyers should evaluate local environmental conditions to determine the suitability of aluminum for their specific applications.

Fiberglass Reinforced Plastic (FRP)

Key Properties: FRP is a composite material that offers excellent corrosion resistance and can withstand a wide range of temperatures, typically from -40°F to 200°F (-40°C to 93°C). It is lightweight and has good mechanical strength.

Pros & Cons: The primary advantage of FRP is its resistance to corrosion and chemicals, making it ideal for wet environments. However, it can be more expensive than traditional plastics and may require specialized manufacturing techniques.

Impact on Application: FRP is particularly suitable for live bait vending machines that require a high level of hygiene and resistance to various chemicals.

Considerations for International Buyers: Buyers should ensure that FRP materials meet local standards for food safety and environmental regulations. In Europe, compliance with REACH regulations is crucial, while buyers in Africa and South America should assess the availability of FRP suppliers.

Summary Table

| Material | Typical Use Case for live bait vending machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | High-durability applications in outdoor environments | Excellent corrosion resistance | Higher initial investment cost | High |

| Polyethylene (PE) | Cost-effective, lightweight applications | Easy to manufacture and customize | Less durable, UV degradation potential | Low |

| Aluminum | Lightweight, moderate-duty applications | Affordable and easy to transport | Prone to dents and scratches | Medium |

| Fiberglass Reinforced Plastic (FRP) | High-hygiene, corrosion-resistant applications | Excellent chemical resistance | Higher cost and manufacturing complexity | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for live bait vending machine

Understanding Manufacturing Processes for Live Bait Vending Machines

The manufacturing of live bait vending machines involves several critical stages that ensure the final product is both functional and durable. Each stage not only influences the machine’s performance but also its ability to meet quality standards that are crucial for international markets.

Main Stages of Manufacturing

-

Material Preparation

– Selection of Materials: The manufacturing process begins with selecting high-quality materials that are resistant to corrosion, especially since these machines often operate in humid or wet environments. Common materials include stainless steel for the body and high-density polyethylene for internal components.

– Pre-Processing: Materials are cut, shaped, and treated to enhance durability. This may involve processes such as cutting, welding, or molding to create various components that will be used in the assembly phase. -

Forming

– Component Fabrication: Techniques like injection molding and CNC machining are employed to form parts with precision. For instance, the vending mechanisms and dispensers need to be crafted to handle live bait delicately while ensuring efficiency in dispensing.

– Surface Treatment: Parts undergo surface treatment processes such as powder coating or anodizing to improve resistance against environmental factors and enhance aesthetic appeal. -

Assembly

– Integration of Components: Skilled technicians assemble the fabricated components, ensuring that mechanical, electrical, and software systems work seamlessly together. This stage is critical as it directly impacts the machine’s operational reliability.

– Wiring and Electronics: The integration of electronic controls, sensors, and payment systems is performed, ensuring that all electrical interfaces are secure and functional. -

Finishing

– Final Adjustments: After assembly, machines undergo final adjustments to ensure all parts function correctly. This may involve calibrating sensors and testing the vending mechanisms.

– Quality Inspection: Each unit is inspected for finish quality, ensuring that there are no scratches, dents, or manufacturing defects. This is also the stage where branding and labeling are applied.

Quality Assurance in Manufacturing

Quality assurance (QA) is a vital aspect of the manufacturing process, particularly for international buyers who require adherence to various standards. Understanding these standards and the QA process can help buyers make informed decisions.

Relevant International and Industry-Specific Standards

- ISO 9001: This international standard outlines requirements for a quality management system (QMS). Manufacturers seeking ISO 9001 certification demonstrate their commitment to quality and customer satisfaction.

- CE Marking: In the European market, CE marking is crucial as it indicates compliance with health, safety, and environmental protection standards for products sold within the European Economic Area (EEA).

- API Standards: For machines that may interact with aquatic ecosystems, adherence to American Petroleum Institute (API) standards may also be relevant, especially regarding environmental impact.

Quality Control Checkpoints

-

Incoming Quality Control (IQC)

– Material Inspection: Before production begins, incoming materials are inspected to ensure they meet specified standards. This includes checking for defects and verifying conformity with material specifications. -

In-Process Quality Control (IPQC)

– Ongoing Monitoring: During the manufacturing process, quality control checks are performed at various stages. This may involve measuring dimensions, testing for mechanical properties, and ensuring that assembly processes adhere to prescribed protocols. -

Final Quality Control (FQC)

– End-of-Line Testing: Once the machines are assembled, final testing is conducted to verify functionality. This includes running diagnostic checks on electronic components, ensuring the vending mechanism operates correctly, and validating that the machine can dispense live bait without issues.

Common Testing Methods

- Functional Testing: Ensures that all features of the machine operate as intended under various conditions.

- Durability Testing: Machines are subjected to stress tests to assess their resistance to wear and environmental factors.

- Safety Testing: Electrical safety tests are conducted to ensure compliance with regional safety standards.

Verifying Supplier Quality Control

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is critical. Here are actionable steps to ensure due diligence:

Illustrative Image (Source: Google Search)

-

Supplier Audits

– Conduct regular audits of potential suppliers to assess their manufacturing processes and quality assurance practices. This includes visiting their facilities to observe operations firsthand. -

Request Quality Reports

– Ask suppliers for detailed quality assurance reports, including results from IQC, IPQC, and FQC processes. This documentation should outline the methodologies used for testing and any corrective actions taken in response to defects. -

Third-Party Inspections

– Engage independent third-party inspection services to evaluate the supplier’s quality control processes. This can provide an unbiased assessment of the manufacturing practices and product quality. -

Certification Verification

– Confirm that suppliers possess relevant certifications (e.g., ISO 9001, CE) by checking with the certifying bodies. This helps ensure that the supplier adheres to industry standards.

Navigating Quality Control Nuances for International Buyers

International buyers must navigate various quality control nuances depending on their region. For example:

- In Europe: Emphasis on CE compliance means that machines must not only meet safety standards but also environmental regulations.

- In Africa and South America: Buyers should be aware of local regulatory requirements and may need to adapt to varying levels of enforcement and compliance.

- In the Middle East: Understanding regional certifications can be crucial, as some countries may have specific requirements for equipment used in fishing and aquaculture.

In conclusion, understanding the manufacturing processes and quality assurance measures for live bait vending machines is essential for international B2B buyers. By prioritizing quality control and verifying supplier practices, buyers can ensure they invest in reliable, high-quality machines that meet international standards.

Related Video: SMART Quality Control for Manufacturing

Comprehensive Cost and Pricing Analysis for live bait vending machine Sourcing

When sourcing live bait vending machines, understanding the comprehensive cost structure and pricing dynamics is essential for international B2B buyers in regions like Africa, South America, the Middle East, and Europe (e.g., Poland, Germany). This analysis will delve into the various cost components involved, influential pricing factors, and actionable buyer tips to enhance negotiation outcomes.

Cost Components

-

Materials: The choice of materials significantly impacts the overall cost. High-quality, durable materials are essential for outdoor machines that can withstand varying weather conditions. Common materials include stainless steel, UV-resistant plastics, and advanced electronic components. Sourcing raw materials locally can reduce costs but may compromise quality.

-

Labor: Labor costs vary widely depending on the manufacturing location. Countries with lower labor costs may offer competitive pricing; however, this may come at the expense of craftsmanship and quality assurance. Buyers should consider the balance between cost and the skill level of the workforce.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, rent, and administrative expenses. Efficient manufacturing processes can help minimize these overheads, which are often reflected in the final product price.

-

Tooling: Custom tooling for machine components can be a significant upfront expense. Buyers should assess whether they require custom features or if standard designs will suffice, as this can lead to substantial savings.

-

Quality Control (QC): Implementing rigorous QC processes ensures that machines meet safety and performance standards, which is crucial for international markets. While this adds to the initial cost, it can prevent costly recalls and enhance brand reputation.

-

Logistics: Shipping and transportation costs can vary significantly based on distance, shipping methods, and current global logistics challenges. Understanding Incoterms is vital in defining responsibilities and risks related to shipping costs.

-

Margin: Suppliers typically include a profit margin in their pricing. This margin can vary based on market demand, competition, and the supplier’s position in the industry. Being aware of typical margins can help buyers negotiate more effectively.

Price Influencers

-

Volume/MOQ: Minimum Order Quantities (MOQs) can affect pricing. Higher volumes generally lead to lower per-unit costs due to economies of scale. Buyers should consider their market demand to negotiate favorable terms.

-

Specifications/Customization: Custom features increase production complexity and costs. Buyers should clearly define their requirements to avoid unnecessary expenses and ensure that the final product aligns with their operational needs.

-

Materials: The choice of materials directly correlates with the machine’s durability and performance. High-quality materials may incur higher initial costs but can lead to lower maintenance and replacement costs over time.

-

Quality/Certifications: Machines that meet international safety and quality standards may command higher prices. Buyers in regulated markets must prioritize certified suppliers to ensure compliance.

-

Supplier Factors: The supplier’s reputation, experience, and history in the market can influence pricing. Established suppliers may offer premium pricing due to their reliability and service levels, while emerging suppliers may be more flexible.

-

Incoterms: Understanding different Incoterms (e.g., FOB, CIF) is crucial. They define the responsibilities of buyers and sellers in shipping, which can significantly influence landed costs.

Buyer Tips

-

Negotiation: Leverage the insights gained from understanding cost components and price influencers to negotiate better terms. Don’t hesitate to ask for discounts on bulk orders or longer payment terms.

-

Cost-Efficiency: Focus on the Total Cost of Ownership (TCO) rather than just the initial purchase price. This includes maintenance, operational costs, and resale value, which can drastically influence long-term profitability.

-

Pricing Nuances: Be aware of the economic conditions in suppliers’ countries, as these can affect pricing strategies. Currency fluctuations and trade tariffs may also alter the effective cost of acquisition.

-

Local Market Research: Conduct thorough market research to understand local preferences and regulations, especially in diverse regions like Africa and South America. This knowledge can help tailor your purchasing strategy and supplier selection.

Disclaimer

The prices and cost structures mentioned are indicative and may vary based on specific requirements, market conditions, and supplier negotiations. Always conduct due diligence and obtain multiple quotes to ensure competitive pricing.

Spotlight on Potential live bait vending machine Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for live bait vending machine.)*

Essential Technical Properties and Trade Terminology for live bait vending machine

When considering the procurement of live bait vending machines, international B2B buyers must understand the essential technical properties and relevant trade terminology that influence their purchasing decisions. This knowledge is critical not only for ensuring product quality but also for navigating the complexities of international trade.

Key Technical Properties

-

Material Grade

– The material used in manufacturing live bait vending machines significantly affects durability and maintenance. Common materials include stainless steel for corrosion resistance and high-density polyethylene (HDPE) for lightweight durability. Buyers should prioritize machines made from high-grade materials to ensure longevity, especially in humid or outdoor environments. -

Temperature Control

– A reliable temperature control system is crucial for maintaining the viability of live bait. Machines should be equipped with refrigeration units that can maintain specific temperatures, typically between 5°C and 10°C, depending on the type of bait. B2B buyers should verify the efficiency of the cooling system to prevent bait from dying, which can lead to revenue loss. -

Capacity and Size

– The capacity of a vending machine refers to the amount of live bait it can hold at one time. This is often measured in liters or cubic feet. Buyers must assess the size of the machine relative to their sales volume and location. A larger capacity may be necessary for high-demand areas, while smaller units can suffice for niche markets. -

User Interface and Payment System

– A user-friendly interface and versatile payment options (cash, card, mobile payments) are essential for customer satisfaction. Machines should feature intuitive displays and easy navigation to enhance user experience. B2B buyers should consider the integration of modern payment systems to cater to diverse customer preferences. -

Energy Efficiency

– Energy-efficient machines not only reduce operational costs but also support sustainability initiatives. Look for models that comply with energy efficiency standards, which can lead to lower electricity bills and a smaller carbon footprint. This aspect is increasingly important for businesses aiming to improve their environmental impact.

Illustrative Image (Source: Google Search)

- Warranty and Support

– A robust warranty and reliable after-sales support can significantly reduce operational risks. Buyers should inquire about warranty terms, including coverage duration and what it entails. Establishing a good relationship with the supplier for ongoing support can prevent potential downtime and maintenance issues.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– An OEM refers to a company that produces components that may be marketed by another manufacturer. Understanding this term helps buyers identify the source of the machine components and assess quality standards. -

MOQ (Minimum Order Quantity)

– MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Buyers must consider their sales forecasts and inventory capacity when negotiating MOQs to avoid overcommitting resources. -

RFQ (Request for Quotation)

– An RFQ is a standard business process where a buyer requests pricing and terms from suppliers. This document helps streamline the purchasing process by detailing specifications and quantities, allowing suppliers to provide competitive quotes. -

Incoterms

– Incoterms are international commercial terms that define the responsibilities of buyers and sellers in shipping agreements. Familiarity with these terms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is essential for understanding shipping costs and risk during transit. -

Lead Time

– Lead time refers to the duration from placing an order to its delivery. Understanding lead times is crucial for inventory management and ensuring that the machines are available when needed, particularly in seasonal markets. -

Certification Standards

– Compliance with local and international certification standards (e.g., CE marking in Europe) is vital for ensuring product safety and reliability. Buyers should verify that the machines meet applicable regulations to avoid legal complications and ensure customer safety.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions and enhance their procurement strategies for live bait vending machines, ultimately leading to increased operational efficiency and customer satisfaction.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the live bait vending machine Sector

Market Overview & Key Trends

The live bait vending machine sector is experiencing notable growth driven by several global factors. Increasing participation in recreational fishing, particularly in emerging markets like Africa and South America, is creating a robust demand for accessible live bait solutions. Moreover, the rise of urbanization has led to a growing trend of placing vending machines in strategic locations—such as parks, lakes, and fishing spots—making live bait more readily available to consumers.

Emerging technologies are also shaping the sector. Innovations such as IoT-enabled machines provide real-time data on product availability and machine health, enhancing operational efficiency. Additionally, advancements in payment systems, including contactless and mobile payments, are attracting a broader customer base and improving user experience. For international B2B buyers, staying abreast of these technological developments is crucial for making informed sourcing decisions.

Market dynamics are influenced by regional characteristics. In Europe, for example, there is a strong emphasis on quality and sustainability, with buyers increasingly favoring suppliers that can demonstrate eco-friendly practices. Conversely, in regions like Africa and South America, cost-effectiveness and local sourcing are often prioritized due to economic constraints. Understanding these regional nuances is essential for international buyers looking to establish successful partnerships.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a pivotal consideration in the live bait vending machine sector. The environmental impact of sourcing live bait, including overfishing and habitat destruction, necessitates a focus on ethical supply chains. International buyers should prioritize suppliers who adhere to sustainable practices, such as using bait sourced from certified sustainable fisheries or aquaculture operations.

Moreover, ‘green’ certifications and the use of eco-friendly materials in the manufacturing of vending machines can enhance a company’s marketability. Certifications such as the Marine Stewardship Council (MSC) or the Aquaculture Stewardship Council (ASC) signal a commitment to sustainability, appealing to environmentally conscious consumers. Buyers are encouraged to conduct due diligence by requesting documentation of sustainability practices from suppliers, ensuring that their sourcing aligns with their corporate social responsibility goals.

Adopting sustainable practices not only mitigates environmental impact but can also lead to cost savings in the long run. For instance, energy-efficient machines reduce operational costs, while a sustainable image can enhance brand loyalty and attract a growing demographic of eco-aware consumers.

Brief Evolution/History

The concept of vending machines for live bait has evolved significantly over the past few decades. Initially, these machines were limited in functionality and primarily found in specialized locations. However, as fishing gained popularity globally, especially in regions like Europe and North America, the demand for convenient access to live bait surged.

The integration of technology has further transformed the sector. Early machines offered basic functionality, but modern versions now include features such as temperature regulation, inventory tracking, and advanced payment options. This evolution reflects a broader trend in the vending industry where convenience, technology, and consumer preferences drive innovation. For B2B buyers, understanding this historical context can provide valuable insights into the quality and features to expect from suppliers today.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of live bait vending machine

-

What criteria should I use to vet suppliers of live bait vending machines?

When vetting suppliers, consider their industry experience, reputation, and customer reviews. Verify their manufacturing capabilities, including certifications such as ISO or CE, which ensure product quality and safety standards. Request references from previous clients to gauge their reliability. Additionally, assess their customer service responsiveness and support structure, as these factors will significantly impact your ongoing relationship and operational efficiency. -

Can live bait vending machines be customized to fit my specific market needs?

Yes, many manufacturers offer customization options tailored to your market requirements. This may include machine size, design, branding, and the types of live bait available. Discuss your specific needs during initial conversations to ensure the supplier can accommodate them. Engaging in a detailed consultation process will help you align the product with local regulations and consumer preferences, enhancing market acceptance. -

What is the typical minimum order quantity (MOQ) and lead time for live bait vending machines?

MOQs can vary widely among suppliers but typically range from 5 to 20 units, depending on the manufacturer’s production capacity. Lead times also depend on the complexity of the customization and the supplier’s current workload, generally ranging from 6 to 12 weeks. Always confirm these details upfront and explore the possibility of negotiating MOQs, especially if you are a new buyer or testing the market. -

What payment terms should I expect when purchasing live bait vending machines internationally?

Payment terms can vary, but common practices include a deposit of 30-50% upfront with the balance due upon shipment or delivery. Consider using secure payment methods such as letters of credit or escrow services to mitigate risks. It’s crucial to discuss these terms clearly before finalizing the contract to ensure both parties are aligned and to avoid future disputes. -

What quality assurance measures should I look for in live bait vending machines?

Ensure that the supplier follows stringent quality assurance (QA) protocols, including regular inspections and testing of machines before shipment. Request documentation of compliance with international standards and relevant certifications. It’s wise to inquire about warranty terms and after-sales support, as these will provide you with additional assurances regarding the longevity and reliability of the machines. -

How should I plan for logistics and shipping of live bait vending machines?

Logistics planning is critical for ensuring successful delivery. Discuss shipping options with your supplier, considering factors like cost, speed, and reliability. Understand the import regulations in your country, including customs duties and taxes. It may be beneficial to work with a freight forwarder who specializes in international shipping to navigate these complexities efficiently. -

What should I do if a dispute arises with my supplier?

In the event of a dispute, first attempt to resolve the issue amicably through direct communication with the supplier. If this fails, refer to the terms outlined in your contract regarding dispute resolution methods, such as mediation or arbitration. Keep thorough documentation of all communications and agreements, as this will support your case if legal action becomes necessary. Establishing a clear communication channel from the outset can also help prevent misunderstandings. -

Are there specific regulations or certifications I need to be aware of when importing live bait vending machines?

Yes, importing live bait vending machines may be subject to regulations related to environmental protection, health standards, and product safety. Check with local authorities to ensure compliance with any necessary certifications and documentation, such as CE marking in Europe. Understanding these regulations beforehand can prevent costly delays and ensure that your products meet market standards.

Strategic Sourcing Conclusion and Outlook for live bait vending machine

In summary, the strategic sourcing of live bait vending machines offers significant opportunities for international B2B buyers, particularly in markets across Africa, South America, the Middle East, and Europe. By understanding local consumer preferences, regulatory considerations, and technological advancements, businesses can make informed purchasing decisions that enhance operational efficiency and customer satisfaction.

Key Takeaways:

- Local Insights: Tailor your offerings to regional fishing practices and preferences to ensure higher sales and customer loyalty.

- Supplier Relationships: Establish strong partnerships with reliable suppliers to secure quality products and favorable terms.

- Technology Adoption: Leverage innovative technologies for improved machine functionality, inventory management, and customer engagement.

As the market for live bait vending machines continues to evolve, focusing on these strategic sourcing elements will position your business for sustainable growth. The future holds promise with the potential for expanding into underserved regions and adapting to emerging trends in the fishing industry.

Call to Action: Engage with local stakeholders, explore diverse sourcing options, and stay ahead of market trends to capitalize on the growing demand for live bait solutions. The time to invest in strategic sourcing is now—position your business at the forefront of this evolving market.