Master Sourcing Japan Panty Vending Machines for Unique

Guide to Japan Panty Vending Machine

- Introduction: Navigating the Global Market for japan panty vending machine

- Understanding japan panty vending machine Types and Variations

- Key Industrial Applications of japan panty vending machine

- Strategic Material Selection Guide for japan panty vending machine

- In-depth Look: Manufacturing Processes and Quality Assurance for japan panty vending machine

- Comprehensive Cost and Pricing Analysis for japan panty vending machine Sourcing

- Spotlight on Potential japan panty vending machine Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for japan panty vending machine

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the japan panty vending machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of japan panty vending machine

- Strategic Sourcing Conclusion and Outlook for japan panty vending machine

Introduction: Navigating the Global Market for japan panty vending machine

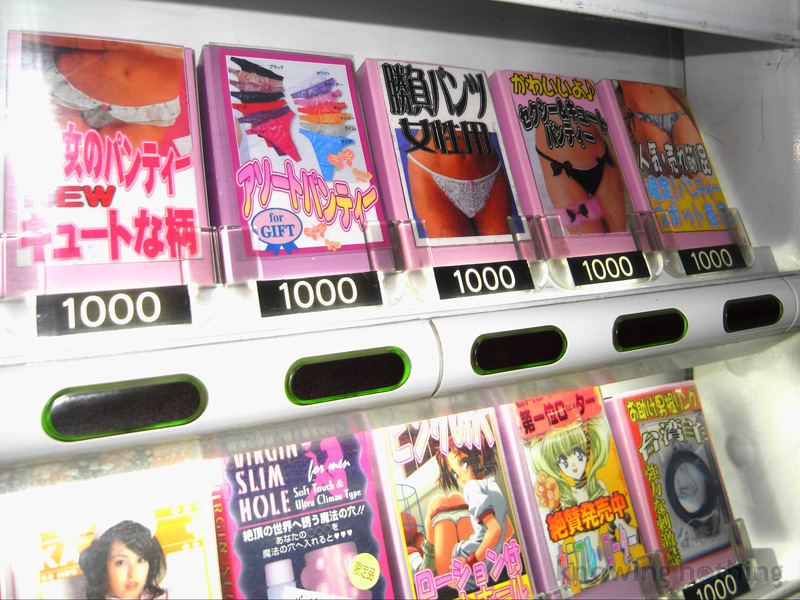

In recent years, the Japan panty vending machine has emerged as a unique and intriguing product in the global vending landscape. These machines, which offer a range of women’s underwear, have captivated markets beyond Japan, appealing to diverse consumer preferences and cultural curiosities. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding this niche market represents a significant opportunity for innovation and differentiation in retail offerings.

This comprehensive guide will delve into the various aspects of sourcing Japan panty vending machines. We will explore different types of machines, the materials used in production, and the manufacturing processes along with quality control measures that ensure product reliability. Buyers will gain insights into potential suppliers, cost structures, and market trends, enabling them to make informed decisions that align with their business strategies.

Additionally, we will address common FAQs that often arise in the purchasing process, ensuring that buyers are well-equipped with the knowledge they need. By thoroughly understanding the intricacies of this unique product category, international B2B buyers can not only enhance their product offerings but also tap into an unconventional market that promises to intrigue and engage consumers in their respective regions. This guide empowers businesses to navigate the complexities of sourcing Japan panty vending machines, ultimately driving success in an increasingly globalized marketplace.

Understanding japan panty vending machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Panty Vending Machine | Basic design with a variety of styles and sizes | Retail, novelty shops | Pros: Affordable, widely available. Cons: Limited customization options. |

| Luxury Panty Vending Machine | High-end materials, customizable options | Upscale boutiques, high-traffic areas | Pros: Attracts affluent customers. Cons: Higher initial investment. |

| Limited Edition Panty Machine | Exclusive designs, themed collections | Special events, pop-up stores | Pros: Unique offerings can drive sales. Cons: May require more frequent restocking. |

| Discreet Panty Vending Machine | Compact design with privacy features | Airports, hotels, convenience stores | Pros: Appeals to discreet buyers. Cons: Smaller inventory capacity. |

| Smart Panty Vending Machine | Digital interface, payment options, inventory tracking | E-commerce integration, tech-savvy markets | Pros: Enhanced customer experience. Cons: Higher maintenance costs. |

Standard Panty Vending Machine

The standard panty vending machine is the most basic model, offering a variety of styles and sizes at competitive prices. This type is ideal for retail environments and novelty shops looking to attract a diverse customer base without significant investment. Buyers should consider the location’s foot traffic and the machine’s product selection to maximize sales potential. While these machines are affordable and widely available, they offer limited customization options, which may not appeal to all markets.

Luxury Panty Vending Machine

Luxury panty vending machines cater to high-end consumers, featuring premium materials and customizable options. These machines are suitable for upscale boutiques or high-traffic areas where an affluent clientele is present. Buyers should focus on the machine’s design and product quality to create a memorable shopping experience. Although the initial investment is higher, the potential for increased profit margins through premium pricing can justify the cost.

Limited Edition Panty Machine

Limited edition panty machines offer exclusive designs and themed collections, making them perfect for special events or pop-up stores. Their unique offerings can drive sales and create buzz among consumers. However, businesses should be prepared for more frequent restocking as these items may sell out quickly. Buyers should assess the target audience’s interests and trends to ensure the selected themes resonate with potential customers while considering the logistics of limited inventory management.

Discreet Panty Vending Machine

Designed with privacy in mind, discreet panty vending machines feature compact designs and privacy screens. These machines are particularly suitable for locations such as airports, hotels, and convenience stores, where customers may prefer a more subtle shopping experience. Buyers should evaluate the machine’s inventory capacity and placement to ensure it meets customer needs. While these machines appeal to discreet buyers, they may have a smaller inventory, requiring careful selection of popular styles.

Smart Panty Vending Machine

Smart panty vending machines incorporate digital interfaces, payment options, and inventory tracking systems, appealing to tech-savvy markets. These machines can enhance the customer experience by providing real-time information about product availability and payment methods. Businesses looking to integrate e-commerce should consider these machines as they can streamline operations. However, buyers must be aware of the higher maintenance costs associated with technology integration, which could impact profitability in the long run.

Related Video: THE TRUTH BEHIND JAPANS USED PANTY VENDING MACHINES

Key Industrial Applications of japan panty vending machine

| Industry/Sector | Specific Application of japan panty vending machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | In-room vending solutions for guests | Enhances guest experience, discreet access to products | Machine reliability, product variety, payment options |

| Retail | Standalone vending units in shopping centers | Attracts niche market, increases foot traffic | Location analysis, local regulations, branding options |

| Events & Entertainment | Pop-up vending at festivals and events | Unique offering, boosts revenue streams | Event duration, product selection, logistical support |

| Health & Wellness | Gynecological health awareness campaigns | Promotes health education, increases product sales | Educational materials, compliance standards, product sourcing |

| Urban Development | Smart city initiatives integrating vending solutions | Supports urban convenience, promotes local products | Technology integration, maintenance support, product sourcing |

Hospitality

In the hospitality sector, Japan panty vending machines can be strategically placed in hotel rooms or lobbies to provide guests with discreet access to intimate apparel. This enhances the overall guest experience, catering to travelers who may require such products unexpectedly. For international buyers, particularly in regions like Africa and the Middle East, it is essential to consider local cultural sensitivities and ensure that the vending machines offer a variety of products that align with customer preferences. Additionally, reliability and ease of use are critical factors in sourcing these machines.

Retail

Standalone vending units in shopping centers can attract a niche market interested in unique products. Japan panty vending machines serve as an innovative retail solution that can increase foot traffic and sales. For B2B buyers in South America and Europe, understanding local consumer behavior is vital. They must consider factors such as location analysis to determine the best spots for placement and compliance with local regulations governing vending operations. Branding options can further enhance visibility and appeal.

Events & Entertainment

Pop-up vending at festivals and events offers a unique opportunity to tap into transient consumer bases. Japan panty vending machines can provide festival-goers with access to intimate apparel, catering to a specific need in a fun and engaging manner. International buyers should evaluate the duration of events, product selection based on attendee demographics, and logistical support for quick setup and maintenance. This application can significantly boost revenue streams for event organizers.

Health & Wellness

Incorporating Japan panty vending machines into gynecological health awareness campaigns can serve dual purposes: promoting health education and providing access to essential products. This is particularly relevant for organizations and NGOs focused on women’s health in regions like Africa and South America. B2B buyers must consider the integration of educational materials alongside the vending machines and ensure compliance with health standards. Sourcing products that are both effective and culturally appropriate is crucial for success in this application.

Urban Development

As cities evolve, integrating smart vending solutions like Japan panty vending machines into urban development initiatives can enhance convenience for residents. These machines can promote local products while addressing the needs of urban dwellers. For international buyers, particularly in Europe and the Middle East, sourcing considerations include technology integration for cashless payments and maintenance support to ensure consistent operation. Understanding the local market’s preferences and needs is essential for successful implementation.

Related Video: Japan’s Biggest Retro Vending Machine Wonderland – Over 100 Machines 🍔 🍭 🍜 🥤

Strategic Material Selection Guide for japan panty vending machine

When selecting materials for Japan panty vending machines, it is essential to consider various factors that influence performance, durability, and compliance with international standards. Below is an analysis of four common materials used in the construction of these machines, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand various temperatures and pressures. It typically has a temperature rating up to 870°C (1600°F) and can handle pressures of up to 50 bar, depending on the specific grade used.

Pros & Cons:

Stainless steel is highly durable and easy to clean, making it suitable for vending machines that require hygiene and longevity. However, it is more expensive than other materials, which can affect the overall cost of the vending machine. Manufacturing complexity is moderate, as stainless steel requires specialized welding and finishing techniques.

Impact on Application:

The corrosion resistance of stainless steel makes it ideal for environments with high humidity or exposure to cleaning agents. This material is compatible with various media, including moisture and temperature fluctuations.

Considerations for International Buyers:

Buyers should ensure compliance with standards such as ASTM A240 for stainless steel. Different regions may have specific preferences for stainless steel grades, impacting sourcing decisions.

2. Carbon Steel

Key Properties:

Carbon steel offers good strength and is typically less expensive than stainless steel. It has a temperature rating up to 400°C (752°F) and can handle moderate pressure levels.

Pros & Cons:

The primary advantage of carbon steel is its cost-effectiveness, making it a popular choice for budget-conscious buyers. However, it is susceptible to corrosion if not adequately protected, which can lead to increased maintenance costs over time. Manufacturing processes are generally straightforward.

Impact on Application:

Carbon steel is suitable for dry environments but may not perform well in humid conditions unless coated or treated. Its compatibility with various media is limited compared to stainless steel.

Considerations for International Buyers:

Buyers should be aware of the need for protective coatings to prevent rust and corrosion. Compliance with standards like ASTM A36 is essential, particularly in regions with strict quality regulations.

3. Aluminum

Key Properties:

Aluminum is lightweight and has good corrosion resistance, with a temperature rating up to 200°C (392°F). It is often used in applications where weight is a critical factor.

Pros & Cons:

The lightweight nature of aluminum makes it easy to transport and install, which can reduce overall logistics costs. However, it is less durable than stainless or carbon steel, making it unsuitable for high-impact applications. Manufacturing complexity is low, as aluminum can be easily extruded and shaped.

Impact on Application:

Aluminum is ideal for applications where weight savings are crucial, but it may not be suitable for environments with high temperatures or physical stress.

Considerations for International Buyers:

Buyers should consider the specific aluminum alloy being used, as different grades offer varying levels of strength and corrosion resistance. Compliance with standards like ASTM B221 is important for ensuring quality.

4. Plastic Composites

Key Properties:

Plastic composites are lightweight, corrosion-resistant, and can be molded into various shapes. They typically perform well in temperatures up to 80°C (176°F).

Pros & Cons:

The primary advantage of plastic composites is their low weight and resistance to corrosion. They are also cost-effective. However, they may not withstand high temperatures or heavy loads, limiting their application in vending machines. Manufacturing processes can be complex due to the need for molding and curing.

Impact on Application:

Plastic composites are suitable for non-load-bearing components and environments where exposure to moisture is a concern. They are not compatible with high-temperature media.

Considerations for International Buyers:

Buyers should ensure compliance with safety and quality standards specific to plastics, such as ASTM D638. Understanding local regulations regarding plastic materials is crucial, especially in regions with stringent environmental laws.

Summary Table

| Material | Typical Use Case for japan panty vending machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural components, exterior casing | Excellent corrosion resistance | Higher cost compared to other materials | High |

| Carbon Steel | Frame and internal components | Cost-effective, good strength | Susceptible to corrosion if unprotected | Low |

| Aluminum | Lightweight structures, non-load-bearing parts | Lightweight and easy to transport | Less durable than steel | Medium |

| Plastic Composites | Non-load-bearing components, decorative elements | Lightweight and corrosion-resistant | Limited temperature and load capacity | Low |

In-depth Look: Manufacturing Processes and Quality Assurance for japan panty vending machine

Manufacturing a Japan panty vending machine involves a series of well-defined processes and quality assurance measures that ensure the final product meets both functionality and safety standards. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding these processes is crucial for making informed purchasing decisions.

Manufacturing Processes

1. Material Preparation

The first stage in the manufacturing process involves selecting high-quality materials suitable for both durability and aesthetics. Common materials include steel or aluminum for the machine casing, high-grade plastics for internal components, and electronic circuitry for operational efficiency. Suppliers often conduct material inspections to ensure compliance with international standards before proceeding.

2. Forming

This stage includes cutting, bending, and shaping the materials into the required components of the vending machine. Techniques such as laser cutting and CNC machining are commonly employed to achieve precise dimensions. These methods not only enhance the quality of the parts but also reduce waste, which is a critical consideration for environmentally conscious buyers.

3. Assembly

Once the components are formed, they undergo assembly. This process can be manual or automated, depending on the scale of production. Automated assembly lines typically use robotics for tasks like screw fastening and component placement, ensuring consistency and reducing human error. B2B buyers should inquire about the assembly methods used by suppliers, as these can significantly impact the machine’s reliability.

4. Finishing

The final stages of manufacturing involve surface treatments like painting, anodizing, or powder coating to enhance durability and aesthetics. This step is crucial for machines that will be exposed to various environmental conditions, particularly in outdoor settings. Buyers should confirm the finishing techniques used, as they can affect the machine’s longevity and maintenance needs.

Quality Assurance

Quality assurance is a fundamental aspect of the manufacturing process for Japan panty vending machines. Understanding the various quality checks and standards can help B2B buyers ensure they are partnering with reputable suppliers.

International Standards

Manufacturers typically adhere to international quality standards such as ISO 9001, which outlines criteria for a quality management system. Compliance with this standard indicates that the manufacturer consistently provides products that meet customer and regulatory requirements. Other relevant certifications may include CE marking for safety within the European market and API standards for components that may require additional scrutiny.

Quality Checkpoints

Quality control involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials before they enter the production line. It ensures that only high-quality materials are used.

-

In-Process Quality Control (IPQC): During assembly, various checks are performed to monitor the quality of the work being done. This includes functional testing of electronic components and mechanical parts.

-

Final Quality Control (FQC): After assembly, each vending machine undergoes a thorough inspection. This includes testing the machine’s operational capabilities, security features, and durability under simulated usage conditions.

Common Testing Methods

Testing methods employed in quality assurance can include:

-

Functional Testing: Ensuring that all electronic and mechanical components operate correctly.

-

Stress Testing: Assessing how well the machine performs under extreme conditions, such as temperature variations or prolonged use.

-

Safety Testing: Verifying that the machine meets safety regulations, particularly in regions with strict compliance laws.

Verifying Supplier Quality Control

For B2B buyers, verifying a supplier’s quality control practices is essential to mitigate risks associated with product defects. Here are several strategies:

-

Conduct Audits: Regular audits of suppliers can help verify adherence to quality standards. Buyers should request access to audit reports and quality certifications.

-

Request Detailed QC Reports: Suppliers should provide documentation that outlines their quality control processes, including results from IQC, IPQC, and FQC.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the manufacturing processes and product quality. This is particularly beneficial for buyers in regions where local expertise may be limited.

Quality Control and Certification Nuances

Understanding the nuances of quality control and certification is vital for international B2B buyers. Different regions may have specific requirements that affect how products must be manufactured and tested. For instance:

-

Africa: Buyers should be aware of local compliance standards that might differ from international certifications. Understanding these can prevent regulatory issues.

-

South America: Some countries may require additional certifications for electronic components, making it essential to work with suppliers familiar with local regulations.

-

Middle East: The Gulf Cooperation Council (GCC) has specific standards for consumer products, and buyers should ensure their suppliers are compliant.

-

Europe: The CE marking is mandatory for machines sold within the EU, and buyers should confirm that their suppliers have the necessary certifications.

By focusing on these manufacturing processes and quality assurance practices, international B2B buyers can better navigate the complexities of sourcing Japan panty vending machines. This knowledge not only aids in selecting reliable suppliers but also ensures that the products meet the necessary standards for success in their respective markets.

Related Video: Honda factory tour – Production in Japan plant

Comprehensive Cost and Pricing Analysis for japan panty vending machine Sourcing

Understanding the cost structure and pricing dynamics of sourcing Japan panty vending machines is essential for international B2B buyers looking to enter this niche market. This section delves into the various cost components involved, the factors influencing pricing, and strategic tips for buyers, particularly in Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The primary materials for panty vending machines include high-quality metals, plastics, and electronic components. The choice of materials significantly affects the machine’s durability and aesthetics, which can influence pricing. Buyers should consider the balance between cost and quality to ensure long-term performance.

-

Labor: Labor costs can vary widely depending on the region of production. Japanese manufacturers may have higher labor costs due to stricter labor laws and higher wage standards. However, outsourcing production to countries with lower labor costs can be a viable option. Buyers should assess the trade-off between labor costs and potential impacts on quality and lead times.

-

Manufacturing Overhead: This encompasses indirect costs associated with production, including utilities, rent, and administrative expenses. These costs can contribute significantly to the final price. Understanding a supplier’s overhead can provide insights into their pricing structure.

-

Tooling: Custom tooling may be required for specific designs or functionalities. This one-time cost can be substantial but is critical for achieving the desired product specifications. Buyers should evaluate the need for custom tooling against the potential return on investment.

Illustrative Image (Source: Google Search)

-

Quality Control (QC): Implementing robust QC processes ensures that machines meet safety and performance standards. This may involve additional costs but is essential for maintaining brand reputation and customer satisfaction.

-

Logistics: Shipping costs can vary based on the destination, shipping method, and volume. International buyers should consider Incoterms to clarify responsibilities and costs associated with transportation.

-

Margin: Suppliers typically incorporate a profit margin into their pricing. Understanding the standard margins in the industry can help buyers negotiate better deals.

Price Influencers

Several factors can influence the pricing of Japan panty vending machines:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to discounts, making it crucial for buyers to assess their needs carefully. Negotiating lower MOQs can also be beneficial for smaller businesses.

-

Specifications/Customization: Custom features or designs can increase costs. Buyers should clearly define their specifications to avoid unexpected expenses.

-

Materials and Quality Certifications: High-quality materials and certifications can elevate the price but may be necessary for compliance and customer assurance.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge a premium for their experience and service levels.

-

Incoterms: Understanding shipping terms (e.g., FOB, CIF) can help buyers anticipate potential costs and responsibilities.

Buyer Tips

-

Negotiation: Effective negotiation requires understanding both the supplier’s cost structure and market rates. Buyers should come prepared with data to support their offers.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO) rather than just the initial purchase price. Factors such as maintenance, operation, and potential downtime should be included in the cost analysis.

-

Pricing Nuances: Be aware of regional pricing variations and currency fluctuations, particularly when sourcing from Japan. It’s advisable to lock in prices early to mitigate risks associated with currency volatility.

-

Supplier Relationships: Building long-term relationships with suppliers can lead to better pricing and terms over time. Trust and reliability are crucial in international trade.

Disclaimer

The prices associated with Japan panty vending machines can vary significantly based on the aforementioned factors. Buyers are encouraged to conduct thorough market research and obtain multiple quotes to ensure competitive pricing.

Spotlight on Potential japan panty vending machine Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for japan panty vending machine.)*

Essential Technical Properties and Trade Terminology for japan panty vending machine

Essential Technical Properties

When considering the procurement of Japan panty vending machines, understanding the key technical specifications is crucial for making informed decisions. Here are some essential properties to consider:

-

Material Grade: The construction materials of the vending machine, typically stainless steel or high-grade plastic, impact durability and maintenance. Stainless steel is preferred for its resistance to corrosion, while high-grade plastics can reduce weight and enhance design aesthetics. For international buyers, selecting robust materials ensures longevity in diverse climates.

-

Weight Capacity: This specification indicates the maximum load the machine can handle. A standard panty vending machine typically supports between 50 to 100 kg. Understanding this property helps in determining the optimal location and installation requirements, ensuring that the machine operates efficiently without risk of damage.

-

Power Supply: Most machines require a standard 110V or 220V electrical supply. Buyers should verify compatibility with local electrical standards to avoid costly modifications. Additionally, machines with energy-efficient designs can lead to lower operational costs, an essential consideration for long-term profitability.

-

Dimensions and Footprint: The physical size of the machine affects its placement and accessibility. Typical dimensions range from 1.5 to 2 meters in height and 0.5 to 1 meter in width. Buyers must consider space constraints in their intended installation sites, ensuring that the machine fits appropriately while still allowing for customer access.

-

Payment Mechanism: Understanding the payment options available (cash, card, mobile payments) is essential. Machines equipped with multiple payment methods cater to a broader customer base, enhancing sales potential. Additionally, ensuring that the payment system is reliable and secure is critical for minimizing transaction issues.

Common Trade Terminology

Familiarity with industry jargon is vital for effective communication and negotiation in international trade. Here are several key terms relevant to the procurement of Japan panty vending machines:

-

OEM (Original Equipment Manufacturer): Refers to a company that produces parts or equipment that may be marketed by another manufacturer. For buyers, partnering with OEMs can ensure high-quality products tailored to specific needs, offering flexibility in design and functionality.

-

MOQ (Minimum Order Quantity): This term indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is critical for budgeting and inventory management. Buyers should negotiate MOQs that align with their purchasing capabilities and market demand to optimize their investment.

-

RFQ (Request for Quotation): A formal process where a buyer requests price quotes from suppliers. An RFQ should include specifications, quantities, and delivery timelines. For international buyers, a well-structured RFQ can facilitate competitive pricing and better terms from suppliers.

-

Incoterms (International Commercial Terms): These are predefined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international shipping. Familiarity with Incoterms (like FOB, CIF, DDP) helps buyers understand shipping costs, risks, and insurance responsibilities, ensuring smooth transactions.

-

Lead Time: This term refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is essential for inventory management and planning for market demand. Buyers should account for potential delays, especially in international shipments.

-

Warranty and Service Agreement: This specifies the terms under which a supplier will repair or replace faulty parts. A comprehensive warranty can provide peace of mind, ensuring that any defects are addressed without significant additional costs. Buyers should carefully review these agreements to avoid future liabilities.

By grasping these technical specifications and trade terms, international B2B buyers can navigate the complexities of sourcing Japan panty vending machines more effectively, ensuring a successful procurement process.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the japan panty vending machine Sector

Market Overview & Key Trends

The Japanese panty vending machine sector has seen a notable evolution, driven by a blend of cultural trends, technological advancements, and shifting consumer behaviors. As global interest in novelty and niche vending products grows, international B2B buyers from regions such as Africa, South America, the Middle East, and Europe are increasingly exploring opportunities in this unique market. The allure of Japanese culture, combined with the novelty factor of panty vending machines, has led to a surge in demand, particularly among younger demographics seeking unique experiences.

Several emerging trends are reshaping the landscape of this sector. Firstly, digitalization is becoming paramount, with many machines now equipped with cashless payment systems and mobile app integrations. This not only enhances customer experience but also provides valuable data analytics for operators. Secondly, customization is gaining traction, allowing buyers to tailor offerings based on local preferences, which can significantly enhance market penetration and customer loyalty.

Moreover, sustainability is emerging as a critical factor for B2B buyers. As consumers become more environmentally conscious, there is a growing expectation for products to be ethically sourced and sustainable. This shift is prompting manufacturers to innovate with eco-friendly materials and production processes. For buyers, understanding these dynamics can lead to better sourcing decisions that align with global trends while catering to local market needs.

Sustainability & Ethical Sourcing in B2B

In the context of the Japanese panty vending machine sector, sustainability and ethical sourcing are not merely trends but essential components of strategic sourcing. The environmental impact of production processes, especially in textile manufacturing, has raised concerns among consumers and businesses alike. B2B buyers must prioritize suppliers who demonstrate a commitment to reducing their carbon footprint and implementing sustainable practices.

Ethical supply chains are increasingly important, as consumers worldwide are more inclined to support brands that prioritize social responsibility. This includes transparent sourcing practices, fair labor conditions, and the use of sustainable materials. Buyers should seek out suppliers that are certified for sustainability—such as those holding OEKO-TEX or Global Organic Textile Standard (GOTS) certifications—which guarantee that products meet rigorous environmental and social standards.

Engaging with suppliers who share a commitment to sustainability can also enhance a buyer’s brand reputation and appeal to a broader customer base. By incorporating green certifications and materials into their offerings, B2B buyers can not only meet consumer demand but also contribute positively to the environment.

Brief Evolution/History

The panty vending machine concept originated in Japan in the late 20th century, primarily as a unique retail solution in urban areas. Initially viewed as a novelty, these machines quickly gained popularity for their innovative approach to convenience and discretion. Over the years, the sector has evolved significantly, influenced by technological advancements, changing consumer attitudes, and an increasing focus on sustainability.

As Japan continues to innovate and adapt to global market demands, international B2B buyers have the opportunity to tap into a niche yet burgeoning market. Understanding the historical context of these machines can provide valuable insights into consumer preferences and operational strategies, informing better sourcing decisions in the modern marketplace.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of japan panty vending machine

-

What should I consider when vetting suppliers of Japanese panty vending machines?

When vetting suppliers, prioritize their reputation, experience, and compliance with international standards. Investigate their manufacturing processes, quality control measures, and customer reviews. Request references from existing clients, particularly those in your region, to ensure they can meet your specific needs. Additionally, verify that they have experience in international shipping and customs clearance to avoid potential delays. -

Can I customize the panty vending machines to suit my market?

Yes, many suppliers offer customization options, including machine design, branding, and product selection. Discuss your specific requirements early in the negotiation process to ensure the supplier can accommodate them. Consider factors such as cultural preferences, pricing strategies, and preferred payment methods in your market. Be clear about your needs to avoid misunderstandings later in the process. -

What are the typical minimum order quantities (MOQ) and lead times for these machines?

MOQs can vary significantly between suppliers, typically ranging from 5 to 50 units. Smaller suppliers may have lower MOQs, while established manufacturers might require larger orders to optimize production costs. Lead times also vary, generally between 4 to 12 weeks, depending on customization and supplier capacity. Always confirm these details before placing an order to ensure they align with your business timelines. -

What payment terms should I expect when ordering from international suppliers?

Payment terms can range from upfront payments to net 30 or 60 days after delivery. Many suppliers prefer a partial upfront payment (commonly 30-50%) with the balance due upon shipment or delivery. Ensure that the payment methods offered are secure and convenient for your operations, such as bank transfers or escrow services, to mitigate risks associated with international transactions. -

How can I ensure quality assurance and certifications for the machines?

Request detailed information on the quality assurance processes employed by the supplier, including ISO certifications and compliance with safety standards. Many reputable suppliers provide documentation of quality checks and testing procedures. If necessary, consider hiring a third-party inspection service to verify the quality of the machines before shipping to safeguard your investment. -

What logistics considerations should I keep in mind when importing these machines?

Logistics can be complex, especially when dealing with bulky machinery. Work with suppliers who have experience in international shipping and can provide guidance on shipping methods, customs documentation, and duties. Factor in the costs of shipping, insurance, and potential tariffs into your budget. Collaborating with a reliable freight forwarder can streamline the process and help you navigate any challenges. -

How should I handle disputes with suppliers?

To minimize disputes, establish clear communication and expectations from the outset. Include detailed terms in your contract regarding timelines, quality standards, and payment terms. If a dispute arises, address it promptly and professionally, preferably through direct communication. Should resolution fail, consider mediation or arbitration as alternatives to litigation, which can be costly and time-consuming.

Illustrative Image (Source: Google Search)

- What are the key market trends influencing the demand for panty vending machines?

The demand for panty vending machines is influenced by changing consumer behaviors, such as the rise in convenience shopping and the growing acceptance of unique vending machine products. Additionally, trends in privacy and personal care can drive interest in these machines. Research market dynamics in your specific region to tailor your marketing strategies and ensure you meet local consumer preferences effectively.

Strategic Sourcing Conclusion and Outlook for japan panty vending machine

As the market for Japan’s panty vending machines continues to evolve, strategic sourcing remains a vital component for international B2B buyers. Key takeaways highlight the importance of understanding local consumer behavior, regulatory considerations, and the technological advancements that enhance user experience. By leveraging data analytics and market research, buyers can identify emerging trends and tailor their offerings to meet diverse cultural preferences across Africa, South America, the Middle East, and Europe.

Moreover, establishing strong relationships with reliable suppliers will ensure product quality and timely delivery, which are critical for maintaining competitive advantage in this niche market. Buyers should also consider the scalability of their investments, as the demand for unique products like panty vending machines is likely to grow in urban centers and tourist hotspots.

Looking ahead, the potential for innovation in this sector is significant. Companies willing to adapt and invest in market-specific strategies will not only capture new customers but also enhance brand loyalty. International B2B buyers are encouraged to seize this opportunity, explore partnerships, and engage with local stakeholders to ensure a successful entry into this intriguing market.