Master Sourcing Ice Vending Machines Near Me for Maximum

Guide to Ice Vending Machines Near Me

- Introduction: Navigating the Global Market for ice vending machines near me

- Understanding ice vending machines near me Types and Variations

- Key Industrial Applications of ice vending machines near me

- Strategic Material Selection Guide for ice vending machines near me

- In-depth Look: Manufacturing Processes and Quality Assurance for ice vending machines near me

- Comprehensive Cost and Pricing Analysis for ice vending machines near me Sourcing

- Spotlight on Potential ice vending machines near me Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for ice vending machines near me

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the ice vending machines near me Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of ice vending machines near me

- Strategic Sourcing Conclusion and Outlook for ice vending machines near me

Introduction: Navigating the Global Market for ice vending machines near me

In the rapidly evolving landscape of global commerce, the demand for ice vending machines is surging, offering lucrative opportunities for B2B buyers across diverse regions. Ice vending machines are not just simple devices; they represent a transformative business model that combines convenience, efficiency, and profitability. As international buyers from Africa, South America, the Middle East, and Europe (including markets like Saudi Arabia and Germany) seek to enhance their offerings, understanding the nuances of sourcing these machines becomes critical.

This comprehensive guide serves as an essential resource, delving into the various types of ice vending machines available, the materials used in their construction, and the manufacturing and quality control standards that define reliability. Buyers will find insights into reputable suppliers, competitive pricing structures, and the overall market landscape, empowering them to make informed decisions that align with their business goals.

Moreover, this guide addresses frequently asked questions, ensuring that buyers have clarity on operational considerations and potential challenges. By equipping B2B buyers with actionable information, this resource not only facilitates effective sourcing but also positions businesses to capitalize on the growing trend of self-service ice vending. As you navigate this global market, the insights provided will help you seize opportunities and maximize your investment in ice vending solutions.

Understanding ice vending machines near me Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

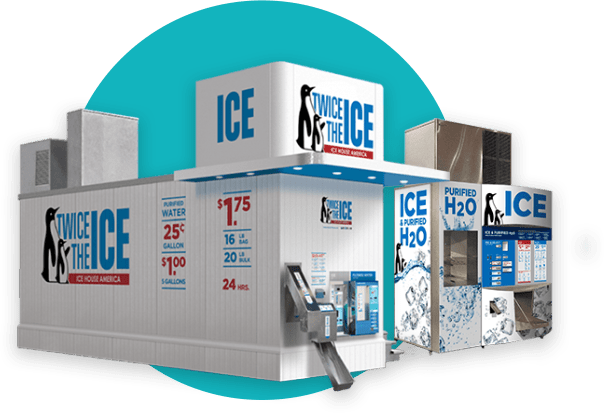

| Self-Service Ice Vending | Automated machines allowing customers to dispense ice directly | Retail, convenience stores, event venues | Pros: 24/7 operation, minimal staffing; Cons: Initial investment can be high. |

| Bulk Ice Vending | Larger machines designed for high-volume sales | Industrial sites, festivals, large events | Pros: High throughput, cost-effective for large quantities; Cons: Requires more space and maintenance. |

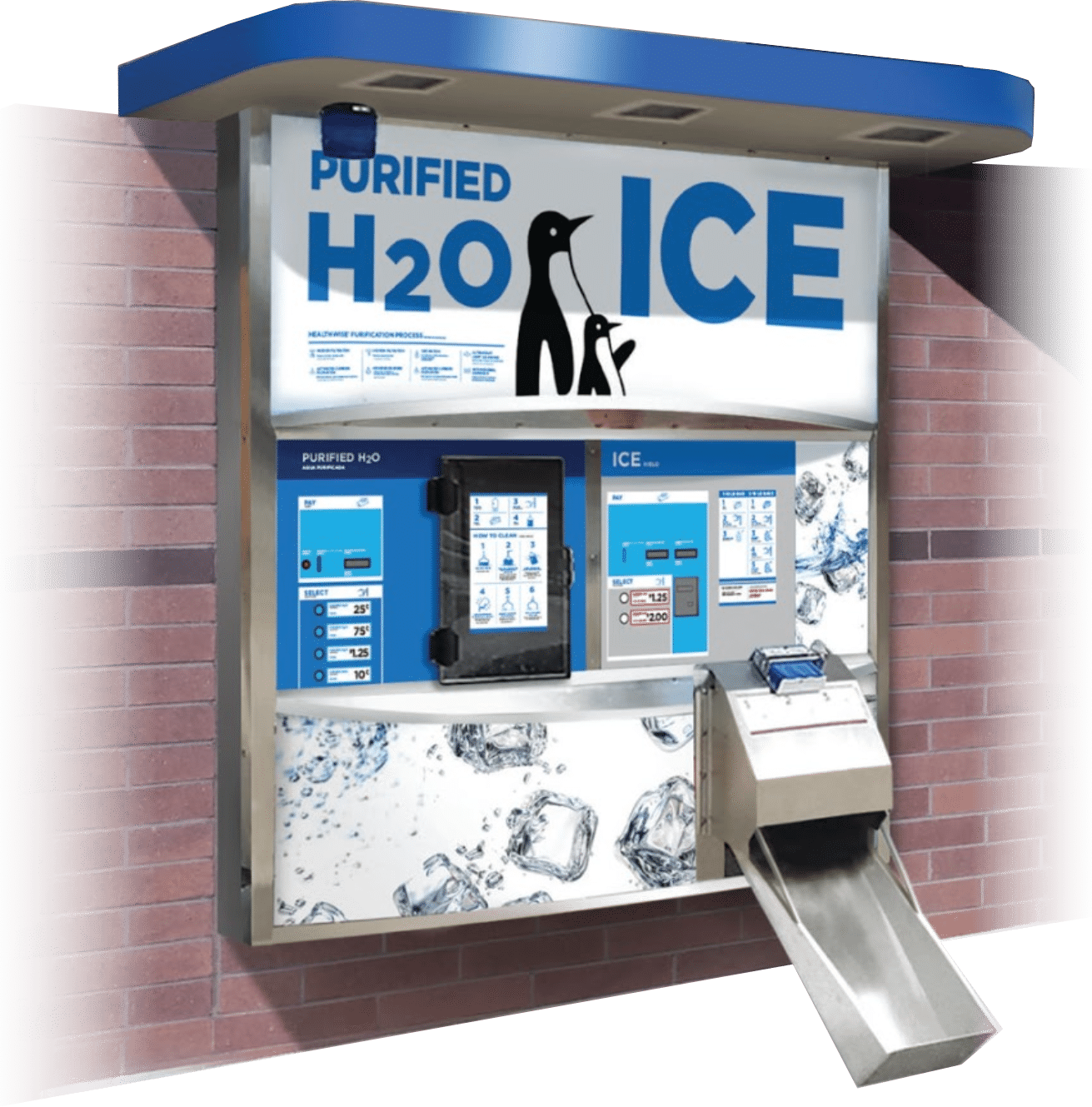

| Ice and Water Vending | Dual functionality for ice and filtered water | Campgrounds, parks, recreational facilities | Pros: Increased customer appeal, versatile; Cons: Potentially higher maintenance needs. |

| Mobile Ice Vending | Portable units for events and temporary locations | Catering, outdoor events, festivals | Pros: Flexibility in location; Cons: Limited capacity compared to fixed units. |

| Eco-Friendly Ice Vending | Machines utilizing renewable energy sources or water recycling | Green businesses, eco-conscious markets | Pros: Attracts environmentally aware customers; Cons: Higher upfront costs and technology complexity. |

Self-Service Ice Vending

Self-service ice vending machines are automated units that allow customers to dispense their own ice. These machines are typically found in retail environments such as convenience stores and gas stations. They operate 24/7, significantly reducing the need for staff presence, which is particularly advantageous for B2B buyers looking to optimize labor costs. When purchasing, consider the machine’s capacity, ease of maintenance, and the technology used for payment processing to ensure a smooth customer experience.

Bulk Ice Vending

Bulk ice vending machines cater to high-volume needs and are commonly located at industrial sites, festivals, and large events. These machines are designed to dispense large quantities of ice quickly, making them ideal for businesses that require a steady supply for operations or events. Key considerations for buyers include the machine’s production capacity, energy efficiency, and the potential need for additional storage solutions to manage inventory effectively.

Ice and Water Vending

Ice and water vending machines provide both ice and filtered water, enhancing their appeal to customers at parks, campgrounds, and recreational facilities. This dual functionality can significantly increase foot traffic and sales. When evaluating these machines, B2B buyers should assess the filtration system’s quality, maintenance requirements, and overall space needed for installation, as these factors can impact profitability and customer satisfaction.

Mobile Ice Vending

Mobile ice vending units are portable machines that can be relocated to various events, making them popular for catering companies and outdoor festivals. Their flexibility allows businesses to reach different customer bases and maximize sales opportunities. Buyers should evaluate the machine’s capacity and ease of transport, as well as any licensing or regulatory requirements for operating in diverse locations.

Eco-Friendly Ice Vending

Eco-friendly ice vending machines utilize renewable energy sources or water recycling technologies to appeal to environmentally conscious consumers. These machines are increasingly popular among businesses aiming to position themselves as sustainable options in the market. Buyers should consider the initial investment and potential long-term savings on energy costs, as well as the machine’s impact on brand reputation and customer loyalty.

Related Video: Kooler Ice Vending Machines – IM600XL vs. IM1000

Key Industrial Applications of ice vending machines near me

| Industry/Sector | Specific Application of ice vending machines near me | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Ice supply for hotels and event venues | 24/7 availability reduces operational costs | Machine capacity, energy efficiency, and service support |

| Food & Beverage | Ice for restaurants and catering services | Enhances customer experience with fresh ice supply | Local water quality, machine durability, and maintenance requirements |

| Construction | Temporary ice supply for concrete curing | Supports project timelines and quality assurance | Compliance with local regulations, machine mobility, and safety features |

| Retail | Ice vending near convenience stores | Increases foot traffic and additional revenue stream | Location analysis, machine visibility, and payment options |

| Agriculture | Ice for transporting perishable goods | Extends product shelf life and reduces spoilage | Temperature control features, machine size, and reliability |

Hospitality

Ice vending machines are an ideal solution for the hospitality sector, particularly in hotels and event venues. They provide a reliable and continuous ice supply, essential for guest services and events. By offering 24/7 access to fresh ice, businesses can significantly reduce labor costs associated with traditional ice delivery. International buyers must consider machine capacity and energy efficiency to ensure they meet peak demand, particularly during high tourist seasons or large events.

Food & Beverage

In the food and beverage industry, ice vending machines serve restaurants and catering services by delivering fresh ice on demand. This convenience not only enhances customer satisfaction but also helps establishments manage their ice inventory more effectively. For B2B buyers in regions with diverse water quality, ensuring that machines can handle local water sources without compromising ice quality is crucial. Additionally, understanding the maintenance requirements can prevent operational disruptions.

Construction

Construction sites often require ice for concrete curing, which is critical for ensuring the integrity of structural projects. Ice vending machines can provide a temporary supply that supports project timelines and enhances quality assurance. Buyers should focus on sourcing machines that comply with local regulations and can be easily transported to various job sites. Safety features and machine mobility are also vital considerations, especially in dynamic construction environments.

Retail

In retail, positioning ice vending machines near convenience stores can attract additional foot traffic and create a new revenue stream. Customers often seek quick access to ice for their beverages or coolers, making these machines a valuable asset. B2B buyers should conduct thorough location analyses to identify high-traffic areas and consider visibility and payment options to enhance customer experience and convenience.

Agriculture

In the agricultural sector, ice vending machines play a crucial role in transporting perishable goods by extending their shelf life. Fresh ice can help maintain optimal temperatures during transport, reducing spoilage and waste. Buyers in this sector must ensure that the machines have effective temperature control features and are robust enough to withstand the rigors of agricultural operations. Reliability and machine size are also important factors to consider, particularly for larger shipments.

Strategic Material Selection Guide for ice vending machines near me

When selecting materials for ice vending machines, it’s crucial to consider their properties, advantages, disadvantages, and how they align with international standards and regulations. Below, we analyze four common materials used in the construction of ice vending machines, focusing on their performance and suitability for various applications.

Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand extreme temperatures. It typically has a temperature rating of up to 800°F (427°C) and can handle high-pressure environments.

Pros & Cons:

The durability of stainless steel makes it ideal for outdoor environments, where exposure to moisture and varying temperatures can be a concern. However, it is more expensive than other materials and may require specialized manufacturing processes, increasing overall costs.

Impact on Application:

Stainless steel is compatible with food-grade applications, making it suitable for ice production and storage. Its non-reactive nature ensures that the ice produced remains uncontaminated.

Considerations for International Buyers:

Buyers in regions like Europe and the Middle East should ensure compliance with food safety regulations, such as those outlined by the European Food Safety Authority (EFSA). Common standards include ASTM A240 and DIN 1.4301.

Aluminum

Key Properties:

Aluminum is lightweight, has good corrosion resistance, and can withstand temperatures up to 400°F (204°C). Its pressure rating is generally lower than that of stainless steel.

Pros & Cons:

Aluminum is cost-effective and easy to manufacture, making it a popular choice for components that do not require high strength. However, it is less durable than stainless steel and can be prone to dents and scratches.

Impact on Application:

Aluminum is suitable for internal components of ice vending machines but may not be ideal for external surfaces exposed to harsh weather conditions.

Considerations for International Buyers:

In regions like Africa and South America, where humidity can be high, aluminum’s corrosion resistance is beneficial. Compliance with local regulations regarding materials in food contact is essential, and standards like ASTM B221 may apply.

Polycarbonate

Key Properties:

Polycarbonate is a high-performance plastic known for its impact resistance and clarity. It can withstand temperatures up to 240°F (116°C) and is lightweight.

Pros & Cons:

While polycarbonate is less expensive than metals, it may not offer the same level of durability and can degrade under UV exposure unless treated. It is easy to mold and manufacture, which can lower production costs.

Impact on Application:

Polycarbonate is often used for protective covers or panels in ice vending machines, providing visibility while protecting internal components.

Considerations for International Buyers:

In regions with high UV exposure, such as parts of Africa and the Middle East, selecting UV-stabilized polycarbonate is crucial. Buyers should also verify compliance with standards like ASTM D635 and local regulations concerning plastic materials.

Carbon Steel

Key Properties:

Carbon steel is known for its high strength and cost-effectiveness. It can withstand high temperatures and pressures but is susceptible to corrosion if not properly coated.

Pros & Cons:

While carbon steel is less expensive than stainless steel, it requires protective coatings to prevent rusting, which can add to maintenance costs. Its strength makes it suitable for structural components.

Impact on Application:

Carbon steel is often used in the framework of ice vending machines, where strength is critical, but it should be avoided in areas exposed to moisture without adequate protection.

Considerations for International Buyers:

In Europe, compliance with standards such as DIN 17100 is important, while buyers in the Middle East should consider the impact of high humidity on carbon steel applications.

Summary Table

| Material | Typical Use Case for ice vending machines near me | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | External casing and food contact surfaces | Excellent corrosion resistance | Higher cost and complex manufacturing | High |

| Aluminum | Internal components and lightweight structures | Cost-effective and easy to manufacture | Less durable, prone to dents | Med |

| Polycarbonate | Protective covers and panels | Impact-resistant and lightweight | UV degradation unless treated | Low |

| Carbon Steel | Structural components and framework | High strength and cost-effective | Requires protective coatings for rusting | Low |

This analysis provides a comprehensive overview of material selection for ice vending machines, helping international B2B buyers make informed decisions based on their specific regional needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for ice vending machines near me

The manufacturing processes and quality assurance for ice vending machines play a critical role in ensuring the reliability, efficiency, and safety of these machines. For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, understanding these processes can help in making informed purchasing decisions. Below is an in-depth analysis of the typical manufacturing stages, key techniques involved, quality control measures, and how buyers can verify supplier quality assurance.

Manufacturing Processes

The manufacturing of ice vending machines generally involves several key stages, each crucial to the final product’s performance and durability.

1. Material Preparation

The first step in the manufacturing process is material preparation. High-quality raw materials, such as stainless steel and high-grade plastics, are sourced to ensure longevity and resistance to corrosion. Key techniques used during this stage include:

- Material Sourcing: Suppliers should be vetted for quality certifications and sustainability practices.

- Material Testing: Before production, materials undergo testing for durability, thermal resistance, and compliance with international standards.

2. Forming

Once materials are prepared, they move to the forming stage. This involves shaping the components that will make up the ice vending machine. Techniques employed include:

- CNC Machining: Computer Numerical Control (CNC) machines are used for precision cutting and shaping of metal components.

- Injection Molding: This technique is often used for plastic parts, ensuring uniformity and strength.

3. Assembly

The assembly stage combines all the pre-formed components into a complete ice vending machine. This is often done in a clean environment to prevent contamination. Key assembly techniques include:

- Modular Assembly: Components are built in modules, which can be tested individually before final assembly.

- Robotic Automation: Many manufacturers utilize robotics for repetitive tasks, improving accuracy and reducing labor costs.

4. Finishing

The final stage of manufacturing is finishing, which includes surface treatment and painting to enhance aesthetics and protect against environmental factors. Techniques involved are:

- Powder Coating: A durable finish that provides resistance to scratches and corrosion.

- Quality Inspections: Each unit is inspected for surface defects, ensuring a high-quality finish.

Quality Assurance (QA)

Quality assurance is an integral part of the manufacturing process for ice vending machines. It ensures that the machines meet specific standards for safety, functionality, and durability.

International Standards

For B2B buyers, understanding the relevant international standards is crucial. Some key certifications include:

- ISO 9001: This standard ensures that manufacturers have quality management systems in place.

- CE Marking: Required for products sold in the European Economic Area, indicating conformity with health, safety, and environmental protection standards.

- API Standards: For manufacturers involved in gas and water supply systems, adhering to American Petroleum Institute (API) standards is essential.

Quality Control Checkpoints

The quality control process typically consists of several checkpoints throughout the manufacturing cycle:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process to identify and rectify defects early.

- Final Quality Control (FQC): A thorough examination of the finished product to ensure it meets all specifications and standards.

Illustrative Image (Source: Google Search)

Common Testing Methods

To ensure the reliability and efficiency of ice vending machines, manufacturers employ various testing methods, such as:

- Functional Testing: Checking the operational capabilities of the machine, including ice production and dispensing mechanisms.

- Durability Testing: Subjecting the machines to stress tests that simulate long-term use.

- Safety Testing: Ensuring that electrical and mechanical components comply with safety regulations.

Verifying Supplier Quality Control

For international B2B buyers, verifying a supplier’s quality control measures is essential to mitigate risks associated with purchasing. Here are actionable steps to take:

- Conduct Supplier Audits: Regular audits can assess the manufacturing processes and quality control systems in place. Ensure that these audits are conducted by reputable third-party organizations.

- Request Quality Assurance Reports: Suppliers should provide documentation on their quality control processes, including results from IQC, IPQC, and FQC phases.

- Engage Third-Party Inspectors: Hiring independent inspectors to evaluate the machines before shipment can ensure compliance with specified standards and reduce the likelihood of defects.

Quality Control Nuances for International Buyers

When sourcing ice vending machines from different regions, buyers should be aware of specific quality control nuances:

- Regulatory Compliance: Different regions have unique regulations that must be adhered to, such as the Gulf Standards in the Middle East or EU regulations in Europe. Buyers should confirm that suppliers are compliant with local laws.

- Cultural Considerations: Understanding cultural differences in business practices can also impact supplier relationships and quality assurance processes. Building strong relationships with suppliers can lead to better transparency and communication regarding quality issues.

- Supply Chain Integrity: Consider the entire supply chain, from raw material sourcing to final assembly. Ensure that each step adheres to quality standards to avoid compromising the final product.

In conclusion, the manufacturing processes and quality assurance for ice vending machines are complex yet critical for ensuring product reliability and safety. By understanding these processes and implementing robust verification methods, international B2B buyers can make well-informed purchasing decisions, ultimately leading to successful business outcomes.

Related Video: INSIDE THE FACTORY HÄAGEN DAZS ICE CREAM MAKING MACHINES

Comprehensive Cost and Pricing Analysis for ice vending machines near me Sourcing

Cost Components of Ice Vending Machines

Understanding the cost structure of ice vending machines is crucial for international B2B buyers. The major cost components include:

-

Materials: This encompasses the cost of high-quality stainless steel, refrigeration units, and components necessary for ice production and storage. Selecting durable materials can affect both initial costs and long-term operational efficiency.

-

Labor: While ice vending machines are designed for minimal human interaction, labor costs can still arise during installation and maintenance phases. It’s important to factor in skilled labor for setup and routine checks.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and administrative expenses. Efficient manufacturing processes can reduce overhead, which in turn impacts pricing.

-

Tooling: The initial investment in specialized tools for production can be significant. This cost is often amortized over the production run, influencing per-unit pricing.

-

Quality Control (QC): Implementing rigorous QC measures ensures that each machine meets industry standards and regulations. While this may add to costs, it protects against future liabilities and enhances product reliability.

-

Logistics: Shipping costs can vary widely depending on the machine’s size and the delivery distance. Buyers should consider the total logistics cost, including customs duties and taxes, particularly for international shipments.

-

Margin: Suppliers typically include a profit margin that reflects their operational costs and market positioning. Understanding this margin helps buyers gauge whether they are receiving a fair price.

Price Influencers

Several factors can influence the pricing of ice vending machines:

-

Volume/MOQ (Minimum Order Quantity): Purchasing in larger quantities can lead to significant discounts. Buyers should negotiate for better rates if they intend to acquire multiple units.

-

Specifications/Customization: Customized features, such as branding or specific ice production capacities, can increase costs. Buyers should clarify their requirements upfront to avoid unexpected expenses.

-

Materials and Quality Certifications: Machines built with superior materials and recognized quality certifications may come at a premium. However, investing in quality can result in lower maintenance costs and longer operational life.

-

Supplier Factors: The supplier’s reputation, experience, and market presence can affect pricing. Established suppliers may charge more due to their proven reliability and support services.

-

Incoterms: Understanding the Incoterms (International Commercial Terms) agreed upon in the purchase contract is crucial. They dictate who bears shipping costs and risks, which can significantly affect the total cost.

Buyer Tips

For international B2B buyers, especially from diverse regions such as Africa, South America, the Middle East, and Europe, the following strategies can enhance cost efficiency:

-

Negotiation: Always negotiate pricing and payment terms. Suppliers may offer discounts for upfront payments or larger orders.

-

Total Cost of Ownership (TCO): Evaluate not just the purchase price but also operational costs, including energy consumption, maintenance, and potential downtime. A lower upfront cost may not always equate to lower overall expenses.

-

Research Supplier Background: Investigate potential suppliers’ histories and customer reviews. A supplier with a strong reputation may provide better after-sales service, reducing future costs.

-

Understand Local Regulations: Familiarize yourself with local laws and regulations regarding food safety and equipment standards to avoid compliance-related expenses.

-

Consider Currency Fluctuations: For international transactions, be mindful of currency exchange rates, which can affect the final cost. Opt for fixed-rate agreements when possible.

Disclaimer

Prices for ice vending machines can vary widely based on the factors mentioned above. The information provided serves as a general guideline and may not reflect actual market prices. Buyers are encouraged to conduct thorough research and request quotes from multiple suppliers to ensure competitive pricing.

Spotlight on Potential ice vending machines near me Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘ice vending machines near me’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for ice vending machines near me

Critical Technical Properties of Ice Vending Machines

When evaluating ice vending machines, understanding their technical specifications is crucial for making informed purchasing decisions. Below are some essential properties that B2B buyers should consider:

- Production Capacity

This refers to the amount of ice the machine can produce within a specific timeframe, often measured in pounds per hour. A higher production capacity is vital for locations with high foot traffic, ensuring that customer demand is met without long wait times.

Illustrative Image (Source: Google Search)

-

Storage Capacity

The volume of ice that can be stored in the machine is another critical property. Machines with larger storage capacities allow for longer operational periods without needing to refill, which is particularly beneficial in peak seasons or during events. -

Energy Efficiency Rating

Energy-efficient machines consume less power, translating to lower operational costs. Look for machines with high energy efficiency ratings (e.g., ENERGY STAR certified) to minimize electricity expenses, particularly in regions where energy costs are high. -

Material Grade

The materials used in construction, such as stainless steel or food-grade plastics, affect durability and hygiene. Stainless steel is generally preferred for its resistance to corrosion and ease of cleaning, which is important for maintaining food safety standards. -

Water Source Compatibility

Most ice vending machines are designed to connect directly to a local water source. Ensure compatibility with local water quality and pressure standards, as poor water quality can lead to subpar ice production and potential health issues. -

Remote Management Capabilities

Many modern ice vending machines come equipped with remote management systems that allow operators to monitor performance, inventory levels, and maintenance needs from afar. This feature enhances operational efficiency and reduces the need for on-site visits.

Common Trade Terminology

Understanding industry jargon can facilitate smoother transactions and better communication among stakeholders. Here are several key terms relevant to ice vending machines:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products that are sold by another company under its brand name. When sourcing ice vending machines, knowing the OEM can help evaluate product quality and reliability. -

MOQ (Minimum Order Quantity)

MOQ specifies the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for budgeting and inventory management, especially for businesses looking to scale operations. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers for specific products. Crafting a detailed RFQ can lead to competitive pricing and better supply chain management. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms (e.g., FOB, CIF) is crucial for understanding shipping costs and liabilities. -

Lead Time

This term refers to the time it takes from placing an order to receiving the product. Understanding lead times is essential for planning inventory and ensuring that machines are available for peak demand periods. -

Warranty and Service Agreement

This refers to the terms under which a manufacturer guarantees the performance of the machine and provides maintenance support. Reviewing warranty and service agreements is vital for ensuring long-term operational reliability and minimizing unexpected repair costs.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions, ultimately enhancing their ice vending operations and profitability.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the ice vending machines near me Sector

Market Overview & Key Trends

The ice vending machine sector is experiencing significant growth, driven by the increasing demand for convenient, cost-effective, and quality ice solutions globally. Several factors are influencing this market, particularly for international B2B buyers from regions like Africa, South America, the Middle East, and Europe. The rise of urbanization and a growing middle class are leading to higher consumption of ice for various applications, including hospitality, events, and food services.

Emerging Technologies: Key technological advancements such as SmartIce Remote Management systems allow operators to monitor and manage machines remotely, enhancing operational efficiency. This technology is particularly appealing in regions with limited access to maintenance services, enabling international buyers to streamline operations and reduce costs.

Sourcing Trends: There is a growing preference for sourcing machines that utilize local water sources, which not only reduces operational costs but also meets regional water supply challenges. Buyers are encouraged to consider manufacturers that offer customizable solutions tailored to local market needs, including machine size, production capacity, and payment systems.

Market Dynamics: The competitive landscape is evolving with new entrants providing innovative machines that require less maintenance and energy. For buyers, this translates to a wider selection of machines that can suit varying budget constraints and operational requirements. Additionally, partnerships with local distributors or service providers can enhance market penetration and support for machine upkeep.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical consideration in the ice vending machine sector. The environmental impact of production and operational processes is under scrutiny, prompting buyers to seek machines that minimize energy consumption and waste generation.

Importance of Ethical Supply Chains: Buyers should prioritize manufacturers that adhere to sustainable practices in their supply chains, such as using recycled materials and ensuring ethical labor conditions. This not only enhances brand reputation but also aligns with the growing consumer demand for environmentally responsible products.

Green Certifications and Materials: Look for machines that come with certifications like Energy Star or similar labels that indicate efficient energy use. Additionally, consider suppliers who utilize eco-friendly refrigerants and materials in their machines. This focus on sustainability can differentiate your offerings in the marketplace, appealing to environmentally conscious consumers and businesses alike.

Brief Evolution/History

The ice vending machine industry has evolved significantly over the past few decades. Initially dominated by traditional ice delivery services, the market began to shift with the advent of self-service vending solutions in the early 2000s. These machines offered a more convenient and cost-effective alternative for consumers, allowing for 24/7 access without the need for human attendants.

As technology advanced, features such as automated bagging and remote monitoring became commonplace, further enhancing the appeal for B2B buyers. This evolution reflects a broader trend toward automation and convenience in the vending sector, making ice vending machines a viable business opportunity across diverse international markets.

In conclusion, international B2B buyers should leverage the latest market trends, prioritize sustainable practices, and understand the historical context of the ice vending machine sector to make informed purchasing decisions.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of ice vending machines near me

-

What should I consider when vetting suppliers for ice vending machines?

When vetting suppliers, prioritize their experience in the industry, customer reviews, and product quality certifications. Request samples of their machines and check for compliance with international standards, especially if you are importing to regions with specific regulations. Ensure they have a solid warranty and after-sales support. Additionally, consider their ability to provide local service and parts, which can be crucial for maintenance and minimizing downtime. -

Can I customize ice vending machines to fit my business needs?

Yes, many suppliers offer customization options for ice vending machines. You can request specific branding, machine sizes, bagging options, and additional features like payment systems or remote monitoring. Discuss your requirements upfront to ensure the supplier can meet your specifications. Customization may affect the lead time and cost, so clarify these details during negotiations. -

What are the minimum order quantities (MOQ) and lead times for ice vending machines?

MOQs can vary significantly between suppliers, with some requiring a single unit while others might have higher thresholds. Typically, lead times range from 4 to 12 weeks, depending on the customization level and supplier location. For international buyers, consider potential delays in shipping and customs clearance. Always confirm these details before placing an order to align your business planning accordingly. -

What payment options are available when purchasing ice vending machines?

Payment options often include wire transfers, letters of credit, and payment through escrow services for larger transactions. Some suppliers may offer financing options or payment plans. It’s essential to discuss payment terms upfront and ensure they are secure and favorable. Be wary of suppliers requesting full payment upfront, particularly if they are new or unverified. -

How can I ensure quality assurance and certifications for ice vending machines?

Request documentation for quality assurance processes and relevant certifications, such as ISO or CE marking. Suppliers should provide test results for their machines, indicating they meet safety and performance standards. Consider asking for references from other international buyers who have purchased similar machines to gauge the supplier’s reliability in delivering quality products. -

What logistics considerations should I keep in mind when sourcing ice vending machines?

Logistics include shipping methods, costs, and timelines. Choose a reputable freight forwarder with experience in international shipping and customs regulations relevant to your country. Discuss with your supplier whether they handle logistics or if you need to arrange shipping. Additionally, consider the local infrastructure to ensure that your machines can be delivered and installed without significant delays or extra costs. -

How should I handle disputes with suppliers regarding ice vending machines?

Establish clear terms in your purchase agreement regarding warranties, maintenance, and return policies to minimize disputes. In case of a disagreement, attempt to resolve it through direct communication first. If that fails, refer to any mediation clauses in your contract or consider arbitration if necessary. Ensure you document all communications and agreements to support your position in any dispute resolution process.

- What are the common challenges faced in the international trade of ice vending machines?

Common challenges include navigating customs regulations, managing shipping delays, and ensuring compliance with local laws. Currency fluctuations can also affect pricing and costs. It’s crucial to conduct thorough market research and possibly engage local experts to understand regional requirements better. Building relationships with reliable suppliers and logistics partners can help mitigate these challenges and ensure a smoother transaction process.

Strategic Sourcing Conclusion and Outlook for ice vending machines near me

As the ice vending machine market continues to grow, international B2B buyers must prioritize strategic sourcing to maximize their investments. Key takeaways include understanding local market dynamics, selecting high-traffic locations, and leveraging innovative technologies to enhance operational efficiency. Ice vending machines offer a unique opportunity to deliver fresh, high-quality ice with minimal overhead costs, making them an attractive option for entrepreneurs looking to establish a sustainable revenue stream.

Investing in reliable suppliers and advanced machine technology can significantly impact profitability. Consider financing options that cater specifically to ice vending businesses, as this will facilitate smoother entry into the market. Collaborating with experienced partners, such as Kooler Ice and Ice House America, can provide valuable insights and resources to ensure a successful launch.

Looking ahead, the demand for convenient, accessible ice solutions will only increase. This presents a golden opportunity for B2B buyers across Africa, South America, the Middle East, and Europe to tap into this lucrative market. Take action now: evaluate potential locations, secure financing, and partner with industry leaders to position your business for success in the ice vending sector.