Master Sourcing Ice House Vending Machines for Optimal

Guide to Ice House Vending Machine

- Introduction: Navigating the Global Market for ice house vending machine

- Understanding ice house vending machine Types and Variations

- Key Industrial Applications of ice house vending machine

- Strategic Material Selection Guide for ice house vending machine

- In-depth Look: Manufacturing Processes and Quality Assurance for ice house vending machine

- Comprehensive Cost and Pricing Analysis for ice house vending machine Sourcing

- Spotlight on Potential ice house vending machine Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for ice house vending machine

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the ice house vending machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of ice house vending machine

- Strategic Sourcing Conclusion and Outlook for ice house vending machine

Introduction: Navigating the Global Market for ice house vending machine

In the dynamic landscape of global commerce, the ice house vending machine stands out as a vital innovation for businesses seeking efficient ice distribution solutions. These machines not only cater to the growing demand for ice in various sectors, including hospitality, catering, and retail, but also offer a sustainable and cost-effective means of meeting consumer needs. As B2B buyers from regions like Africa, South America, the Middle East, and Europe (including Turkey and the UAE) navigate this market, understanding the intricacies of ice house vending machines becomes essential for making informed purchasing decisions.

This comprehensive guide delves into a spectrum of crucial topics surrounding ice house vending machines. It covers various types available in the market, including their unique features and functionalities, and explores the materials used in their construction to ensure durability and efficiency. Furthermore, insights into manufacturing processes and quality control standards are provided to help buyers assess supplier capabilities.

Buyers will also find a thorough analysis of cost factors and market trends, enabling them to gauge the financial implications of their investments. Additionally, a dedicated FAQ section addresses common queries, empowering buyers with the knowledge to make strategic sourcing decisions. By leveraging this guide, international B2B buyers can confidently approach their procurement processes, ensuring they select the most suitable ice house vending machines tailored to their specific business requirements.

Understanding ice house vending machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Ice House | Large storage capacity, manual dispensing | Retail, events, and outdoor venues | Pros: High capacity; Cons: Requires manual operation, less efficient. |

| Automated Ice Vending Machine | Fully automated, cashless transactions, real-time inventory tracking | Airports, convenience stores, gas stations | Pros: User-friendly; Cons: Higher initial investment. |

| Mobile Ice Vending Unit | Compact, portable design for temporary setups | Festivals, construction sites, catering | Pros: Flexible location; Cons: Limited storage capacity. |

| Ice Cube Production Machine | Produces ice on-demand, integrated with vending capabilities | Hotels, restaurants, catering services | Pros: Fresh, customizable ice; Cons: Requires regular maintenance. |

| Solar-Powered Ice Vending Machine | Operates using solar energy, eco-friendly design | Remote locations, eco-conscious businesses | Pros: Low operational costs; Cons: Weather-dependent efficiency. |

Traditional Ice House

Traditional ice houses are designed for high-capacity storage and manual dispensing of ice. They are commonly used in retail environments, events, and outdoor venues where large quantities of ice are needed. Buyers should consider the operational costs and labor requirements associated with manual dispensing, as well as the ice house’s ability to meet peak demand periods.

Automated Ice Vending Machine

Automated ice vending machines are equipped with advanced technology that allows for cashless transactions and real-time inventory tracking. They are ideal for high-traffic areas such as airports, convenience stores, and gas stations. Businesses should weigh the advantages of user-friendly operation and reduced labor costs against the higher initial investment and potential technical issues.

Mobile Ice Vending Unit

Mobile ice vending units are compact and portable, making them suitable for temporary setups at festivals, construction sites, and catering events. Their flexibility allows businesses to adapt to changing demands, but buyers must be aware of their limited storage capacity, which may necessitate more frequent restocking.

Ice Cube Production Machine

These machines not only dispense ice but also produce it on-demand, offering fresh and customizable options. Commonly used in hotels, restaurants, and catering services, they provide a reliable source of ice without the need for large storage spaces. However, buyers should consider the maintenance requirements and potential downtime for repairs.

Solar-Powered Ice Vending Machine

Solar-powered ice vending machines are an eco-friendly solution for businesses located in remote areas or those looking to minimize their carbon footprint. They operate on solar energy, which can significantly reduce operational costs. However, buyers need to consider their dependence on weather conditions, which can affect efficiency and ice production rates.

Related Video: Machine Learning in 2024 – Beginner’s Course

Key Industrial Applications of ice house vending machine

| Industry/Sector | Specific Application of Ice House Vending Machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food & Beverage | Retail ice sales for beverages | Increases customer satisfaction and sales volume | Energy efficiency, reliability in high-demand settings |

| Hospitality | On-site ice supply for hotels and restaurants | Enhances guest experience, reduces operational costs | Space requirements, maintenance support, warranty terms |

| Construction | Temporary ice supply for concrete curing | Ensures proper curing conditions, accelerates project timelines | Size and mobility, ice production capacity, power supply |

| Event Management | Ice supply for outdoor events and festivals | Provides convenience, enhances event atmosphere | Weather resistance, ease of transport, service agreements |

| Fishing & Seafood | Ice vending for fishing communities | Preserves catch quality, reduces spoilage | Compliance with health regulations, durability in harsh environments |

In the Food & Beverage sector, ice house vending machines serve as essential retail points for ice sales, especially in hot climates. They enable businesses to meet high consumer demand for chilled beverages, particularly during peak seasons. For international buyers, energy efficiency and operational reliability are crucial factors to consider, as they directly impact profitability and customer satisfaction.

In the Hospitality industry, hotels and restaurants can utilize ice house vending machines to provide a consistent on-site supply of ice. This not only enhances guest experience by ensuring quick access to ice for drinks but also helps reduce operational costs associated with traditional ice procurement methods. Buyers should focus on space requirements and maintenance support when sourcing these machines, ensuring they fit within their operational frameworks.

For the Construction industry, ice house vending machines are invaluable for providing temporary ice supplies necessary for concrete curing. This application ensures that concrete sets correctly, preventing premature hardening and structural issues. Buyers from this sector need to consider the machine’s size, mobility, and ice production capacity to meet project demands effectively.

In Event Management, ice house vending machines can facilitate ice supply for outdoor events and festivals, enhancing the overall attendee experience. These machines offer convenience and can improve the atmosphere of events by providing easy access to ice for beverages and food. When sourcing, event organizers should prioritize weather resistance and ease of transport to ensure reliability during events.

Lastly, in Fishing & Seafood, ice house vending machines are critical for local fishing communities, providing a reliable source of ice to preserve the freshness of catches. This application directly impacts the quality of seafood sold in markets, reducing spoilage and increasing profitability for fishers. Compliance with health regulations and durability in harsh environments should be key considerations for buyers in this industry.

Related Video: Industrial Cleaning Applications for Dry Ice Blasting

Strategic Material Selection Guide for ice house vending machine

Material Analysis for Ice House Vending Machines

When selecting materials for ice house vending machines, international B2B buyers must consider various factors, including performance characteristics, durability, and compliance with industry standards. Below is a detailed analysis of several common materials used in the construction of these machines.

1. Stainless Steel (e.g., 304, 316)

Key Properties:

Stainless steel offers excellent corrosion resistance, high strength, and the ability to withstand extreme temperatures. Grades like 304 are suitable for general use, while 316 provides enhanced resistance to chlorides, making it ideal for coastal regions.

Pros & Cons:

– Pros: Highly durable, easy to clean, and resistant to rust and staining.

– Cons: Higher initial cost compared to other metals and may require specialized welding techniques.

Impact on Application:

Stainless steel is compatible with various media, including water and ice, and maintains structural integrity under thermal cycling.

Considerations for International Buyers:

Buyers from regions like the UAE and Turkey should ensure compliance with ASTM standards for food-grade materials. Local preferences may favor 316 stainless steel due to its enhanced corrosion resistance in humid environments.

2. Carbon Steel (e.g., A36)

Key Properties:

Carbon steel is known for its strength and affordability. It can handle high pressure and is often used in structural applications.

Pros & Cons:

– Pros: Cost-effective and readily available.

– Cons: Susceptible to corrosion without protective coatings, which may lead to increased maintenance costs.

Impact on Application:

While it can be used for structural components, carbon steel is less suitable for direct contact with ice or water unless adequately protected.

Considerations for International Buyers:

Buyers should consider the local climate and potential for corrosion. Compliance with DIN standards is essential in Europe, where carbon steel is often used in structural applications.

3. Polycarbonate

Key Properties:

Polycarbonate is a durable thermoplastic known for its impact resistance and transparency. It can withstand a wide range of temperatures, making it suitable for various applications.

Pros & Cons:

– Pros: Lightweight, excellent insulation properties, and high impact resistance.

– Cons: Less durable than metals and can be prone to scratching.

Impact on Application:

Ideal for transparent panels in vending machines, allowing visibility of the product while providing insulation.

Considerations for International Buyers:

Buyers should verify compliance with JIS standards in Japan or similar regulations in their region. The choice of polycarbonate may also depend on local preferences for aesthetics and functionality.

4. Aluminum (e.g., 6061-T6)

Key Properties:

Aluminum is lightweight and offers good corrosion resistance, especially when anodized. It has a high strength-to-weight ratio, making it suitable for mobile vending machines.

Pros & Cons:

– Pros: Lightweight, corrosion-resistant, and easy to fabricate.

– Cons: Lower strength compared to steel and can be more expensive than carbon steel.

Impact on Application:

Aluminum is suitable for components that require mobility and ease of handling, such as frames and panels.

Considerations for International Buyers:

In regions like South America, where transportation logistics are critical, aluminum’s lightweight nature can be advantageous. Buyers should ensure that materials meet local standards for durability and safety.

Summary Table

| Material | Typical Use Case for ice house vending machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel (e.g., 304, 316) | Structural and contact parts for ice storage | Excellent corrosion resistance | Higher initial cost | High |

| Carbon Steel (e.g., A36) | Structural components and frames | Cost-effective | Susceptible to corrosion | Low |

| Polycarbonate | Transparent panels and insulation | Lightweight and impact-resistant | Prone to scratching | Medium |

| Aluminum (e.g., 6061-T6) | Mobile frames and panels | Lightweight and easy to fabricate | Lower strength compared to steel | Medium |

This guide provides essential insights for international B2B buyers, enabling informed decisions on material selection for ice house vending machines.

In-depth Look: Manufacturing Processes and Quality Assurance for ice house vending machine

Manufacturing Processes for Ice House Vending Machines

1. Material Preparation

The manufacturing process for ice house vending machines begins with the careful selection and preparation of materials. Common materials include stainless steel for durability, high-density polyethylene (HDPE) for insulation, and various electronic components for the vending mechanisms.

- Material Sourcing: International B2B buyers should ensure that suppliers source materials from reputable vendors. Look for certifications indicating quality standards.

- Material Inspection: Incoming materials undergo rigorous inspection to verify compliance with specifications. This can include checking for defects and ensuring that materials meet required standards.

2. Forming

This stage involves shaping the prepared materials into components that will form the vending machine.

- Techniques Used: Various techniques such as laser cutting, CNC machining, and injection molding are utilized. For example, laser cutting is used for precise metal parts, while injection molding is often employed for plastic components.

- Prototype Development: Before mass production, prototypes may be created to test design viability and performance. This step is crucial for identifying potential issues early.

3. Assembly

The assembly stage integrates all components into a cohesive unit.

- Assembly Line Process: A streamlined assembly line is typically employed, enhancing efficiency and reducing labor costs. Workers are trained to handle specific tasks, ensuring consistency.

- Automation: Automation technologies, such as robotic arms, may be incorporated to enhance precision and reduce human error.

4. Finishing

Once assembled, the machines undergo finishing processes to enhance their appearance and functionality.

- Surface Treatment: Techniques such as powder coating or anodizing are used to protect surfaces and improve aesthetics. This is particularly important in regions with high humidity, as it helps prevent rust and corrosion.

- Quality Checks: Final checks are conducted to ensure that all features function correctly and meet design specifications.

Quality Assurance Protocols

Quality assurance is critical in the manufacturing of ice house vending machines to ensure reliability, safety, and compliance with international standards.

International Standards

B2B buyers should familiarize themselves with relevant international quality standards, such as:

- ISO 9001: This standard focuses on quality management systems and is essential for ensuring consistent product quality.

- CE Marking: For machines sold in the European market, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: In certain regions, adherence to American Petroleum Institute (API) standards may be required, especially if the machines interface with fuel systems.

Quality Control Checkpoints

Quality control (QC) checkpoints are established throughout the manufacturing process to ensure compliance with standards:

- Incoming Quality Control (IQC): Checks are performed on materials as they arrive at the facility to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During the assembly process, various checks are conducted to monitor quality and catch defects early.

- Final Quality Control (FQC): Once assembly is complete, machines undergo a final inspection to verify that all components function properly and meet design specifications.

Common Testing Methods

Testing methods used in the QC process include:

- Functional Testing: Ensures that all vending mechanisms operate correctly, including ice dispensing and payment processing.

- Safety Testing: Evaluates electrical safety and compliance with relevant safety standards.

- Durability Testing: Machines are subjected to stress tests to ensure they can withstand expected usage conditions.

Verifying Supplier Quality Control

For international B2B buyers, verifying supplier quality control is essential to ensure product reliability and compliance.

- Supplier Audits: Conducting regular audits of suppliers can provide insight into their manufacturing processes and quality control systems. This may involve on-site visits to assess facilities and practices.

- Quality Reports: Requesting detailed quality reports from suppliers can help verify their adherence to standards. These reports should include data on defect rates, corrective actions taken, and compliance with international standards.

- Third-Party Inspections: Engaging third-party inspection agencies can provide an impartial assessment of the manufacturer’s quality control processes. This is particularly beneficial for buyers in regions with less stringent local regulations.

Navigating Quality Control and Certification Nuances

B2B buyers from Africa, South America, the Middle East, and Europe must navigate various nuances in quality control and certification:

- Regional Standards: Understand the specific regulatory requirements in your region. For instance, the Middle East may have different safety and certification requirements compared to Europe.

- Language Barriers: Ensure that all documentation and communications regarding quality standards are clear and accessible, especially when dealing with suppliers from different linguistic backgrounds.

- Cultural Differences: Be aware of cultural differences in business practices that may affect negotiations and quality assurance processes.

Conclusion

Understanding the manufacturing processes and quality assurance standards for ice house vending machines is vital for international B2B buyers. By focusing on material preparation, forming, assembly, and finishing, along with stringent quality control measures, buyers can ensure they procure reliable and compliant vending machines tailored to their specific market needs. Adhering to international standards and conducting thorough supplier evaluations will enhance buyer confidence and lead to successful partnerships in the global marketplace.

Related Video: Amazing scenes。Top 6 Most Popular Factory Manufacturing Videos in China

Comprehensive Cost and Pricing Analysis for ice house vending machine Sourcing

The cost structure and pricing analysis for sourcing ice house vending machines involves multiple components and influencers. Understanding these elements can help international B2B buyers make informed purchasing decisions.

Cost Components

-

Materials: The primary cost driver in manufacturing ice house vending machines is the raw materials, which typically include steel, insulation materials, refrigeration units, and electronic components. The prices of these materials can fluctuate based on global supply chains and market demand.

-

Labor: Labor costs vary significantly by region. In countries with lower labor costs, such as some in Africa and South America, the manufacturing expenses may be reduced. However, it is essential to consider the skill level and labor regulations in each region, as these can impact the overall cost.

-

Manufacturing Overhead: This encompasses indirect costs such as utilities, rent, and administrative expenses associated with the production facility. Efficient manufacturing practices and economies of scale can help lower these overhead costs.

-

Tooling: Initial investment in tooling for the production process can be substantial. Tooling costs are often amortized over the production volume, making them a critical factor in the pricing strategy. Custom designs may require additional tooling, thus increasing the cost.

-

Quality Control (QC): Implementing robust quality control measures is vital to ensure that the machines meet safety and performance standards. Costs associated with QC processes should be factored into the overall pricing.

-

Logistics: Shipping and handling costs can vary greatly depending on the destination. Factors such as distance, transportation mode, and local tariffs influence these costs. Buyers should also consider potential delays in logistics that could affect delivery timelines.

-

Margin: Suppliers will typically add a markup to cover their costs and ensure profitability. Understanding the typical margins in the industry can help buyers negotiate more effectively.

Price Influencers

-

Volume/MOQ: Minimum order quantities (MOQs) significantly affect pricing. Larger orders may qualify for discounts, while smaller orders could incur higher per-unit costs. Buyers should assess their needs and negotiate accordingly.

-

Specifications/Customization: Custom features or specifications can increase the cost of the vending machines. Buyers should clearly define their requirements to avoid unexpected costs during production.

-

Materials: The choice of materials can greatly influence pricing. Higher quality or specialized materials may increase the initial cost but could lead to lower maintenance and operational costs over time.

-

Quality/Certifications: Machines that meet specific quality standards or certifications may come at a premium. However, investing in certified products can reduce long-term risks and improve reliability.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more due to their proven track record, while newer suppliers might offer lower prices to gain market share.

-

Incoterms: Understanding the terms of shipment and delivery (Incoterms) is crucial. They define the responsibilities of buyers and sellers, impacting overall costs and risks associated with transportation.

Buyer Tips

-

Negotiation: Engage suppliers in discussions about pricing, especially regarding volume discounts and customization options. Establishing a good relationship can lead to better terms.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes not only the purchase price but also maintenance, operational costs, and potential resale value. This comprehensive view can guide better purchasing decisions.

-

Pricing Nuances: International buyers should be aware of currency fluctuations, import duties, and local regulations that may impact pricing. It is advisable to seek local expertise or consultants when entering new markets.

Disclaimer

Prices can vary widely based on numerous factors, including market conditions, order sizes, and supplier negotiations. Therefore, the figures provided in this analysis are indicative and should be confirmed with specific suppliers for accurate quotes.

Spotlight on Potential ice house vending machine Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘ice house vending machine’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for ice house vending machine

Key Technical Properties of Ice House Vending Machines

When considering the procurement of ice house vending machines, understanding their technical specifications is crucial for ensuring quality and suitability for your business needs. Here are several critical specifications to consider:

-

Material Grade

The construction material, often stainless steel or high-grade plastic, is essential for durability and resistance to corrosion. Stainless steel is preferable due to its strength and hygienic properties, making it suitable for outdoor environments where exposure to elements is inevitable. -

Cooling Capacity

This property refers to the machine’s ability to produce and store ice, typically measured in pounds per hour. A higher cooling capacity ensures that the machine can meet demand during peak hours, which is vital for businesses in high-traffic areas. -

Power Consumption

Energy efficiency is increasingly important. Machines should be evaluated based on their energy consumption, usually measured in kilowatts (kW). Efficient machines reduce operational costs and are more environmentally friendly, aligning with global sustainability trends. -

Temperature Range

The operating temperature range indicates the machine’s ability to maintain ice quality. It should ideally operate at sub-zero temperatures to prevent melting. Understanding this range helps in assessing the machine’s performance in various climates, particularly for buyers in warmer regions. -

Tolerance Levels

This specification refers to the allowable deviation in the machine’s performance, such as ice production rates and temperature settings. Tight tolerances are critical in ensuring consistent product quality, which is especially important for businesses that rely on uniform ice sizes and shapes. -

Size and Capacity

The dimensions and storage capacity of the vending machine are vital for space planning and inventory management. A machine that is too large may not fit in designated locations, while one that is too small may not meet demand, leading to lost sales opportunities.

Common Trade Terminology

Understanding industry jargon can facilitate smoother transactions and negotiations. Here are some essential terms to know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of ice house vending machines, knowing the OEM can be beneficial for buyers seeking quality assurance and specific branding options. -

MOQ (Minimum Order Quantity)

The MOQ is the smallest quantity of a product that a supplier is willing to sell. Buyers must be aware of MOQs to avoid overcommitting to inventory they may not need, especially in markets with fluctuating demand. -

RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers asking for price quotes for specific products or services. This is a critical step in the procurement process, allowing businesses to compare costs and negotiate favorable terms. -

Incoterms (International Commercial Terms)

These are standardized trade terms published by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms can help buyers understand shipping costs and liabilities. -

Lead Time

This term refers to the time taken from placing an order to receiving the product. Understanding lead times is crucial for inventory management, especially for businesses that depend on timely ice availability.

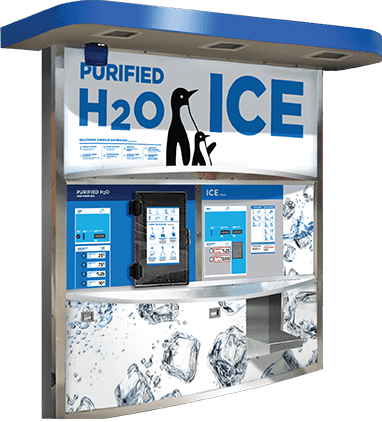

Illustrative Image (Source: Google Search)

- Warranty Period

The warranty period is the time frame during which the manufacturer guarantees the product against defects. Knowing the warranty terms can help buyers mitigate risks associated with equipment failure and ensure long-term investment protection.

In summary, by understanding these essential technical properties and trade terminologies, international B2B buyers can make informed decisions when sourcing ice house vending machines, ultimately leading to better operational efficiency and profitability.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the ice house vending machine Sector

Market Overview & Key Trends

The ice house vending machine sector is experiencing a transformative shift driven by several global factors. The increasing demand for convenience and instant access to products is a primary driver, particularly in urban areas across Africa, South America, the Middle East, and Europe. B2B buyers are increasingly drawn to machines that provide a diverse range of products, from ice to beverages, catering to various consumer needs in a single location.

Emerging technologies are shaping sourcing trends in this sector. Smart vending solutions equipped with IoT capabilities enable remote monitoring, inventory management, and data analytics, allowing operators to optimize their stock based on real-time consumption patterns. Furthermore, contactless payment systems have surged in popularity, providing a seamless transaction experience that aligns with the growing demand for hygiene and safety.

International market dynamics are also influenced by regional preferences and regulations. For instance, buyers from the Middle East may prioritize energy-efficient machines due to rising electricity costs, while European buyers might focus on compliance with stringent environmental regulations. Understanding these regional nuances is crucial for B2B buyers looking to capitalize on market opportunities.

Illustrative Image (Source: Google Search)

Sustainability & Ethical Sourcing in B2B

Sustainability has become a cornerstone of purchasing decisions in the ice house vending machine sector. The environmental impact of manufacturing and operating these machines is significant, prompting buyers to seek solutions that minimize their carbon footprint. This includes investing in machines that utilize energy-efficient technologies, reducing electricity consumption, and incorporating recyclable materials in their construction.

Ethical sourcing plays a critical role in ensuring that supply chains are responsible and sustainable. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to social responsibility, fair labor practices, and transparency in their operations. Certifications such as ISO 14001 for environmental management and Fair Trade can serve as indicators of a supplier’s dedication to sustainability.

Moreover, the integration of green materials, such as biodegradable plastics and energy-efficient refrigeration systems, is becoming a standard expectation. Buyers are encouraged to engage with suppliers who can provide detailed information about the sustainability of their products, ensuring alignment with corporate social responsibility goals.

Brief Evolution/History

The evolution of ice house vending machines can be traced back to the early 20th century when the first mechanical vending machines emerged. Initially, these machines primarily dispensed snacks and beverages. However, as consumer preferences shifted towards convenience, manufacturers began innovating designs to include ice and chilled products.

In recent decades, advancements in technology have significantly enhanced the functionality of these machines. The introduction of digital interfaces and remote monitoring capabilities transformed traditional vending machines into smart solutions capable of meeting modern consumer demands. Today, the focus is not only on convenience but also on sustainability, as industry players adapt to an increasingly eco-conscious market landscape. This historical context is vital for B2B buyers as it highlights the ongoing trends of innovation and sustainability that will shape future purchasing decisions.

Related Video: Is global trade transforming? | Counting the Cost

Frequently Asked Questions (FAQs) for B2B Buyers of ice house vending machine

-

How do I vet suppliers for ice house vending machines?

When sourcing ice house vending machines, it’s crucial to conduct thorough supplier vetting. Start by checking the supplier’s certifications, such as ISO or CE, which indicate adherence to international quality standards. Look for reviews or testimonials from other businesses that have purchased similar products. Additionally, consider visiting the supplier’s facility if feasible or request a virtual tour. Engage in discussions about their production processes and quality control measures to ensure they meet your specific requirements. -

Can I customize the ice house vending machines to fit my brand?

Yes, many suppliers offer customization options for ice house vending machines. This can include branding elements like logos, color schemes, and specific functionalities tailored to your business model. When discussing customization, be clear about your requirements and ask for examples of previous custom projects. Ensure that the supplier can accommodate your needs within a reasonable timeframe and budget. -

What are the minimum order quantities (MOQs) and lead times for these machines?

Minimum order quantities (MOQs) can vary significantly between suppliers, often depending on the complexity of the machine and customization options. Standard MOQs may range from 10 to 50 units. Lead times typically range from 4 to 12 weeks, depending on the supplier’s production capacity and the specifications of your order. Always confirm these details before placing an order to ensure they align with your business timelines. -

What payment terms should I expect when sourcing from international suppliers?

Payment terms can vary widely among suppliers. Common practices include a deposit (usually 30-50%) upfront, with the balance due before shipment or upon delivery. Some suppliers may offer letters of credit or escrow services for added security. Ensure you clarify payment methods accepted (e.g., bank transfer, PayPal) and check for any additional fees related to international transactions. Understanding these terms upfront can help prevent disputes later. -

What quality assurance measures should I look for?

Quality assurance is vital when sourcing ice house vending machines. Inquire about the supplier’s quality control processes, including inspections and testing of machines before shipment. Request documentation for quality certifications and any warranties offered. It’s also beneficial to establish a clear agreement on what constitutes an acceptable quality standard and how any defects or issues will be addressed post-delivery. -

How are logistics and shipping handled for these machines?

Logistics can be complex when importing ice house vending machines. Confirm whether the supplier handles shipping or if you need to arrange it yourself. Discuss shipping methods (e.g., sea, air) and associated costs. Ensure that the supplier provides all necessary documentation for customs clearance. It’s advisable to work with a logistics partner experienced in international shipping to streamline the process and reduce delays. -

What should I do in case of a dispute with the supplier?

Disputes can arise over various issues, from quality concerns to delivery delays. To minimize conflicts, establish clear terms and conditions in your contract, including a dispute resolution process. If a dispute occurs, first attempt to resolve the issue amicably through direct communication. If that fails, consider mediation or arbitration as a next step. Ensure that you document all communications and agreements for reference.

- Are there any certifications or standards I should be aware of?

Depending on your market, certain certifications may be necessary for ice house vending machines. Common standards include CE marking for Europe and NSF certification for food safety in the U.S. Familiarize yourself with local regulations in your target market to ensure compliance. Discuss with suppliers their ability to meet these standards and obtain the necessary certifications before placing an order.

Strategic Sourcing Conclusion and Outlook for ice house vending machine

The strategic sourcing of ice house vending machines presents significant opportunities for international buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. By leveraging strategic sourcing practices, businesses can enhance their supply chain resilience, reduce costs, and ensure access to high-quality products that meet local market demands.

Key Takeaways:

– Supplier Diversification: Engaging multiple suppliers across different regions can mitigate risks associated with supply chain disruptions and price volatility.

– Local Market Insights: Understanding regional preferences and regulatory requirements is crucial for successful market entry and product positioning.

– Technological Integration: Incorporating advanced technologies in vending machines can improve operational efficiency and customer satisfaction, setting businesses apart in competitive markets.

As the demand for convenient ice solutions grows, international buyers are encouraged to embrace a proactive sourcing strategy. By focusing on collaboration with reliable suppliers and adapting to market trends, companies can position themselves advantageously in the global marketplace.

Call to Action: Begin exploring partnerships with suppliers that align with your strategic goals. The future of ice house vending machines is ripe with potential—seize the opportunity to innovate and lead in your market.