Master Sourcing High-Quality Soap Vending Machines for Your

Guide to Soap Vending Machine

- Introduction: Navigating the Global Market for soap vending machine

- Understanding soap vending machine Types and Variations

- Key Industrial Applications of soap vending machine

- Strategic Material Selection Guide for soap vending machine

- In-depth Look: Manufacturing Processes and Quality Assurance for soap vending machine

- Comprehensive Cost and Pricing Analysis for soap vending machine Sourcing

- Spotlight on Potential soap vending machine Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for soap vending machine

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the soap vending machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of soap vending machine

- Strategic Sourcing Conclusion and Outlook for soap vending machine

Introduction: Navigating the Global Market for soap vending machine

The global market for soap vending machines is experiencing a transformative shift as businesses increasingly recognize the value of hygiene solutions in various public and private spaces. With the rise in consumer demand for convenient access to personal care products, soap vending machines have become critical fixtures in environments ranging from healthcare facilities to educational institutions and retail settings. These machines not only cater to the need for cleanliness but also offer a sustainable business model that aligns with modern consumer preferences.

This comprehensive guide is designed to empower international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, with essential insights into the soap vending machine market. We will explore various types of machines, the materials used in their manufacturing, and best practices for quality control. Additionally, we will provide a detailed overview of reliable suppliers, cost considerations, market trends, and frequently asked questions to facilitate informed sourcing decisions.

By understanding the intricacies of this industry, buyers can leverage the latest innovations in soap vending technology, ensuring they meet customer expectations while enhancing operational efficiency. Whether you are a seasoned buyer or new to the market, this guide serves as a vital resource to navigate the complexities of sourcing soap vending machines effectively. Your journey towards informed procurement starts here, enabling you to capitalize on the growing demand for hygiene solutions in your region.

Understanding soap vending machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Manual Soap Vending Machine | Requires user interaction for dispensing soap | Gyms, schools, public restrooms | Pros: Cost-effective, low maintenance. Cons: Slower service, user-dependent. |

| Automatic Soap Vending Machine | Sensor-operated, touchless dispensing system | Hospitals, hotels, airports | Pros: Hygienic, quick service. Cons: Higher initial investment, potential technical issues. |

| Liquid Soap Dispenser | Dispenses liquid soap via pump mechanism | Restaurants, cafes, office buildings | Pros: Versatile, can dispense various liquid soaps. Cons: Requires refills, can clog. |

| Foam Soap Vending Machine | Dispenses foamed soap, often with a lower soap concentration | Spas, salons, schools | Pros: Less soap waste, appealing texture. Cons: Foam quality can vary, specific soap compatibility needed. |

| Multi-Product Soap Vending Machine | Offers a variety of soap types and fragrances in one unit | Retail stores, shopping malls | Pros: Attracts diverse customers, customizable options. Cons: Higher maintenance, complex inventory management. |

Manual Soap Vending Machine

Manual soap vending machines are the simplest form of dispensing soap, requiring users to operate a lever or button to release the product. These machines are ideal for environments like gyms, schools, and public restrooms where cost-effectiveness is a priority. The main advantage is their low maintenance and operational costs; however, they can be slower and depend on user interaction, which might lead to inconsistent usage patterns.

Automatic Soap Vending Machine

These machines utilize sensors to dispense soap without any physical contact, making them a popular choice in environments that prioritize hygiene, such as hospitals, hotels, and airports. The automatic feature allows for quick service, reducing wait times for users. While they are more hygienic and convenient, the initial investment is higher, and potential technical issues can arise, necessitating reliable customer support.

Liquid Soap Dispenser

Liquid soap dispensers are designed to dispense liquid soap through a pumping mechanism. They are commonly found in restaurants, cafes, and office buildings, offering versatility by accommodating various types of liquid soaps. While they allow for easy refilling and are user-friendly, they require regular maintenance to prevent clogging and ensure consistent performance.

Foam Soap Vending Machine

Foam soap vending machines provide a unique user experience by dispensing foamed soap, which is often more appealing and less wasteful than liquid soap. These machines are suitable for spas, salons, and schools, where a pleasant sensory experience is valued. The key consideration for buyers is the compatibility of the soap used; not all soaps foam equally, and some may require specific formulations.

Multi-Product Soap Vending Machine

Multi-product soap vending machines can dispense a variety of soap types and fragrances, catering to a broad audience in retail environments such as shopping malls and stores. This flexibility can attract diverse customers and enhance sales. However, the complexity of inventory management and higher maintenance requirements are significant considerations for buyers, who must ensure that they can efficiently manage the various products offered.

Related Video: I Put A SOAP Vending Machine In A Laundromat And Made $_

Key Industrial Applications of soap vending machine

| Industry/Sector | Specific Application of Soap Vending Machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Hotel guest amenities | Enhances guest experience and hygiene standards | Durability, ease of refilling, and compatibility with various soap types |

| Healthcare | Hospitals and clinics | Promotes hygiene, reduces infection rates | Compliance with health regulations, easy maintenance, and refill options |

| Education | Schools and universities | Encourages hygiene among students | Robust construction, user-friendly design, and capacity for high traffic |

| Public Transport | Airports and train stations | Provides convenient access to hand hygiene | Weather resistance, vandalism-proof design, and high capacity |

| Retail | Shopping malls and supermarkets | Increases foot traffic and promotes hygiene | Custom branding options, ease of use, and refill logistics |

Hospitality Sector

In the hospitality industry, soap vending machines are increasingly deployed in hotels to provide guests with convenient access to hygiene products. These machines can dispense various types of soaps, including liquid, foam, and bar soaps, enhancing the guest experience while promoting cleanliness. For international B2B buyers, considerations include the machine’s durability to withstand frequent use, ease of refilling, and compatibility with different soap formulations to cater to diverse guest preferences. Ensuring compliance with local health regulations is also crucial.

Healthcare Applications

In healthcare settings, such as hospitals and clinics, soap vending machines play a vital role in promoting hygiene and reducing the spread of infections. These machines can be strategically placed in waiting areas, restrooms, and patient rooms, ensuring that hand hygiene is always accessible. Buyers from the healthcare sector must prioritize machines that comply with health regulations, are easy to maintain, and offer refill options that align with the facility’s hygiene standards. The ability to dispense antibacterial soaps can further enhance their effectiveness in infection control.

Educational Institutions

Schools and universities can benefit significantly from soap vending machines by encouraging students to practice good hygiene. These machines can be installed in restrooms and common areas, providing easy access to soap before meals or after using the facilities. For international buyers in the education sector, the key requirements include robust construction to withstand heavy usage, user-friendly designs suitable for children and young adults, and sufficient capacity to accommodate high traffic during peak hours.

Public Transport

In public transport settings, such as airports and train stations, soap vending machines offer travelers convenient access to hand hygiene products, especially in high-traffic areas. These machines can help mitigate the spread of germs among travelers, enhancing overall public health. Buyers in this sector should consider factors such as weather resistance to ensure functionality in outdoor environments, vandalism-proof designs to protect the investment, and high capacity to meet the demands of busy transport hubs.

Retail Environments

In retail environments like shopping malls and supermarkets, soap vending machines can increase foot traffic by providing customers with easy access to hygiene products while they shop. This not only promotes cleanliness but also enhances the overall shopping experience. B2B buyers in retail should look for machines that offer custom branding options to align with their store’s image, ease of use for customers, and efficient logistics for soap refills. These features can significantly contribute to customer satisfaction and brand loyalty.

Related Video: Kooler Ice Vending Machines – IM600XL vs. IM1000

Strategic Material Selection Guide for soap vending machine

When selecting materials for soap vending machines, international B2B buyers must consider various factors, including durability, cost, and compatibility with the media being dispensed. The following analysis examines four common materials used in the construction of soap vending machines, highlighting their properties, advantages, disadvantages, and specific considerations relevant to buyers in Africa, South America, the Middle East, and Europe.

1. Stainless Steel

Key Properties:

Stainless steel is renowned for its excellent corrosion resistance, high strength, and ability to withstand a wide range of temperatures. It typically has a temperature rating of up to 800°F (427°C) and can handle moderate pressure.

Pros & Cons:

Stainless steel is highly durable and resistant to rust and staining, making it suitable for environments with high humidity and exposure to cleaning chemicals. However, it can be more expensive than other materials and may require specialized manufacturing techniques, which can increase production costs.

Impact on Application:

This material is compatible with a variety of soaps and cleaning agents, ensuring that it does not react adversely with the products dispensed.

Specific Considerations:

International buyers should ensure compliance with food safety standards such as FDA regulations in the U.S. or EU regulations in Europe. The common grades, like 304 and 316, are recognized globally, but variations may exist in different regions.

2. Polypropylene (PP)

Key Properties:

Polypropylene is a thermoplastic polymer with a melting point of around 320°F (160°C) and good chemical resistance. It is lightweight and flexible, which can be advantageous in certain designs.

Pros & Cons:

This material is cost-effective and easy to mold into complex shapes, making it suitable for high-volume production. However, its lower temperature resistance and potential for UV degradation can limit its lifespan in outdoor applications.

Impact on Application:

Polypropylene is suitable for dispensing liquid soaps and sanitizers, but care must be taken with solvents or highly acidic products, which may degrade the material.

Specific Considerations:

Buyers should consider local regulations regarding plastic use, especially in regions with stringent environmental laws. Compliance with standards such as ASTM D638 for tensile properties is also essential.

3. Aluminum

Key Properties:

Aluminum is lightweight, with a good strength-to-weight ratio, and has a melting point of around 1220°F (660°C). It offers moderate corrosion resistance, especially when anodized.

Pros & Cons:

Aluminum is relatively inexpensive and easy to work with, making it a popular choice for many manufacturers. However, it is less durable than stainless steel and can corrode over time if not properly treated, especially in humid environments.

Impact on Application:

This material is generally compatible with soap products but may not be suitable for highly corrosive substances.

Specific Considerations:

International buyers should ensure that the aluminum used is of a grade that meets local standards, such as JIS or DIN, particularly if the machines are to be used in coastal areas where salt exposure is a concern.

4. Glass

Key Properties:

Glass is non-reactive and can withstand high temperatures, making it suitable for a variety of liquids. It is typically rated for temperatures up to 500°F (260°C).

Pros & Cons:

Glass offers excellent aesthetic appeal and is easy to clean, making it ideal for high-end installations. However, it is fragile and can break easily, which may lead to higher replacement costs and safety concerns.

Impact on Application:

Glass is compatible with most soap formulations, but care must be taken to prevent breakage during use.

Specific Considerations:

Buyers should consider the weight of glass, which may affect shipping costs and installation. Compliance with safety standards, such as those governing shatter-resistant glass, is also crucial.

Summary Table

| Material | Typical Use Case for soap vending machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | High-end, durable machines for public spaces | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Polypropylene | Budget-friendly, lightweight dispensers | Cost-effective and easy to mold | Lower temperature resistance | Low |

| Aluminum | Lightweight dispensers for indoor use | Inexpensive and easy to work with | Less durable and susceptible to corrosion | Medium |

| Glass | Aesthetic dispensers for premium locations | Non-reactive and easy to clean | Fragile and higher replacement costs | Medium |

This strategic material selection guide equips international B2B buyers with the necessary insights to make informed decisions when sourcing soap vending machines, ensuring compatibility, compliance, and cost-effectiveness.

In-depth Look: Manufacturing Processes and Quality Assurance for soap vending machine

Manufacturing Processes for Soap Vending Machines

The manufacturing of soap vending machines involves several critical stages, ensuring that the final product meets both functional and aesthetic requirements. Understanding these stages can help B2B buyers from diverse markets, including Africa, South America, the Middle East, and Europe, make informed purchasing decisions.

1. Material Preparation

The first step in the manufacturing process is the selection and preparation of materials. Common materials used include:

- Metal: Typically stainless steel for durability and corrosion resistance.

- Plastic: High-density polyethylene (HDPE) or polycarbonate for lightweight components.

- Electronic Components: Sensors, microcontrollers, and payment systems.

Material preparation involves sourcing high-quality raw materials from reputable suppliers. Buyers should ensure that suppliers provide certifications for material quality, particularly for metals and plastics that comply with international safety standards.

2. Forming

In this stage, raw materials are shaped into components of the soap vending machine. Techniques used include:

- CNC Machining: Computer Numerical Control (CNC) machines cut and shape metal parts with precision, ensuring consistent quality and design fidelity.

- Injection Molding: This process is used for creating plastic components, where molten plastic is injected into molds and cooled to form the desired shapes.

- Sheet Metal Fabrication: Sheets of metal are cut, bent, and assembled into the machine’s outer casing.

B2B buyers should look for manufacturers that utilize advanced forming technologies to ensure high precision and minimal waste.

3. Assembly

The assembly stage involves putting together the various components to create the final product. This includes:

- Mechanical Assembly: Attaching the outer casing, internal frameworks, and compartments for soap storage.

- Electrical Assembly: Integrating sensors, wiring, and control systems that enable the machine’s functionality.

- Testing Integration: Preliminary testing is often conducted at this stage to ensure that all components function together seamlessly.

Buyers should inquire about the assembly processes used by suppliers, including the qualifications of assembly personnel and whether they adhere to lean manufacturing principles to minimize defects.

4. Finishing

Finishing processes enhance the appearance and functionality of the soap vending machine. This includes:

- Surface Treatment: Techniques such as powder coating or anodizing for metal parts to improve corrosion resistance and aesthetics.

- Quality Control Checks: Final inspections are conducted to ensure all components meet specified requirements before packaging.

A well-executed finishing process can significantly impact the durability and visual appeal of the product, which is crucial for attracting customers in various markets.

Quality Assurance in Manufacturing

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that soap vending machines meet international standards and customer expectations.

Relevant International Standards

B2B buyers should be familiar with various quality standards that apply to soap vending machines, including:

- ISO 9001: A global standard for quality management systems, ensuring that manufacturers consistently provide products that meet customer and regulatory requirements.

- CE Marking: Required for products sold in the European Economic Area, indicating conformity with health, safety, and environmental protection standards.

- API Standards: For machines that may dispense liquid soap or similar substances, adherence to American Petroleum Institute (API) standards may be necessary.

Understanding these standards helps buyers assess the credibility of suppliers and their commitment to quality.

Quality Control Checkpoints

Quality control involves multiple checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Inspection of raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing checks during the manufacturing stages to identify and rectify defects early.

- Final Quality Control (FQC): Comprehensive testing of the finished product to verify that it meets all quality and safety standards.

Buyers should request documentation of these quality control processes to verify that suppliers maintain high standards.

Common Testing Methods

Manufacturers typically employ several testing methods to ensure product quality:

- Functional Testing: Ensures that the vending machine operates as intended, including payment processing and dispensing mechanisms.

- Durability Testing: Evaluates the machine’s performance under various conditions to assess its longevity.

- Safety Testing: Checks for electrical safety, ensuring compliance with relevant standards.

Buyers can enhance their supplier selection process by asking for test reports and certifications that validate these testing methodologies.

Verifying Supplier Quality Control

B2B buyers should implement strategies to verify the quality control practices of potential suppliers:

- Supplier Audits: Conducting on-site audits can provide insights into the manufacturing processes and quality assurance practices of suppliers.

- Requesting Quality Reports: Buyers should ask for comprehensive quality reports that detail the results of IQC, IPQC, and FQC processes.

- Engaging Third-Party Inspectors: Utilizing independent inspection services can provide an unbiased evaluation of the manufacturer’s quality processes and product integrity.

Quality Control and Certification Nuances for International Buyers

International buyers must navigate specific nuances when dealing with quality control and certification:

- Regulatory Compliance: Different countries have varying regulations regarding product safety and quality. It is essential for buyers to understand these requirements based on their target market.

- Cultural Considerations: Communication styles and negotiation tactics may differ across regions, impacting the clarity of quality expectations. Buyers should be culturally aware to foster effective supplier relationships.

- Logistical Challenges: Importing machines from different regions can introduce complexities related to customs and regulatory compliance. Buyers should work closely with suppliers to ensure all necessary certifications are in order before shipping.

By understanding the manufacturing processes and quality assurance measures associated with soap vending machines, B2B buyers can make informed decisions that align with their business needs and market demands.

Related Video: How to make bar soap in factory, soap manufacturing process, automatic laundry soap production line

Comprehensive Cost and Pricing Analysis for soap vending machine Sourcing

In the process of sourcing soap vending machines, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers. Below is an analysis that outlines the primary cost components, price influencers, and actionable tips for effective negotiation and purchasing.

Cost Components

-

Materials: The primary components of soap vending machines include the chassis, dispensing mechanisms, electronic components, and software for operational functions. The choice of materials—whether standard or high-grade—affects the overall cost significantly. Buyers should seek suppliers that balance durability and cost-effectiveness.

-

Labor: Labor costs vary by region and can impact the price of the vending machines. Countries with higher labor costs may lead to increased manufacturing expenses. Understanding local labor markets is essential for buyers, as it can influence the pricing of machines sourced from different geographical locations.

-

Manufacturing Overhead: This includes costs associated with factory maintenance, utilities, and administrative expenses. Manufacturers often calculate overhead as a percentage of direct costs, which can vary significantly based on location and operational efficiency.

-

Tooling: Custom designs or modifications require specialized tooling, which can add to the initial costs. Buyers seeking customized solutions should budget for these additional expenses, as they can be substantial.

-

Quality Control (QC): Ensuring that machines meet quality standards requires investment in QC processes. This might include testing, inspections, and certifications. Buyers should inquire about the QC measures in place to ensure the reliability and safety of the machines.

-

Logistics: Transportation costs are influenced by the distance from the manufacturing facility to the buyer’s location. Additionally, customs duties and tariffs can add to the total logistics cost. Understanding Incoterms is vital for managing these expenses effectively.

-

Margin: Suppliers will include their profit margins in the pricing. These margins can vary widely based on the supplier’s market position, brand reputation, and the competitive landscape.

Price Influencers

-

Volume/MOQ: Purchasing larger quantities often results in lower per-unit costs. Buyers should consider negotiating minimum order quantities (MOQ) to leverage better pricing.

-

Specifications/Customization: Custom features will typically increase costs. Buyers must assess their needs versus budget constraints to find the right balance.

-

Materials: The choice of materials directly impacts the machine’s durability and cost. High-quality materials may raise the initial price but can reduce long-term maintenance costs.

-

Quality/Certifications: Machines that comply with international standards and certifications may have higher upfront costs but can save money over time through reduced failures and maintenance.

-

Supplier Factors: Supplier reputation, reliability, and service capabilities can influence pricing. Established suppliers may charge a premium for their experience and support services.

-

Incoterms: Understanding the terms of shipping and delivery can affect total costs. Buyers should clarify whether costs include shipping, insurance, and other fees to avoid unexpected expenses.

Buyer Tips

-

Negotiation: Always negotiate terms and pricing. Suppliers may have flexibility, especially for bulk purchases or long-term contracts.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO) rather than just the initial purchase price. This includes maintenance, energy consumption, and expected lifespan.

-

Pricing Nuances: Different regions may have varying pricing structures due to economic conditions, demand, and currency fluctuations. Buyers from Africa, South America, the Middle East, and Europe should be aware of these factors and adjust their strategies accordingly.

-

Research and Compare: Always obtain multiple quotes and compare not only prices but also the services offered. This helps in identifying the best value.

Disclaimer

Prices mentioned in discussions about soap vending machines are indicative and can vary widely based on specific requirements, market conditions, and supplier negotiations. Always conduct thorough market research and engage directly with suppliers to obtain accurate pricing.

Spotlight on Potential soap vending machine Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘soap vending machine’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for soap vending machine

Key Technical Properties of Soap Vending Machines

When considering the purchase of soap vending machines, international B2B buyers should prioritize several essential technical properties that influence performance, durability, and overall cost-effectiveness. Here are critical specifications to evaluate:

-

Material Grade

The material used in the construction of the vending machine is crucial for ensuring longevity and resistance to environmental factors. Stainless steel is often preferred for its corrosion resistance, hygiene, and ease of cleaning. Buyers should confirm compliance with local health regulations, especially in food and personal care sectors. -

Capacity

This refers to the volume of soap that the machine can hold. Capacity is often measured in liters or the number of individual soap units (e.g., bars or dispensers). A higher capacity can reduce the frequency of restocking, making it more efficient for high-traffic areas such as airports or shopping malls. -

Dispensing Mechanism

The type of dispensing mechanism—manual, electronic, or touchless—affects user experience and hygiene. Touchless dispensers, for instance, minimize contact, which is essential in promoting cleanliness and reducing the spread of germs, especially in public spaces. -

Power Supply

Understanding the power requirements is essential for installation and operational efficiency. Some machines are battery-operated, while others require a direct electrical connection. Buyers should consider the availability of power sources in their intended locations. -

Tolerance Levels

This specification indicates the acceptable limits for various dimensions and functions, such as how much soap can be dispensed at once. Precision in tolerance levels ensures consistent performance and reduces malfunction risks, impacting customer satisfaction. -

User Interface

The design of the user interface, including buttons, screens, and accessibility features, plays a critical role in customer interaction. A user-friendly interface can enhance the customer experience and increase sales, particularly in diverse markets with varying technological familiarity.

Common Trade Terms in the Soap Vending Machine Industry

Understanding the terminology used in the soap vending machine industry can streamline communication and negotiation processes for B2B buyers. Here are several key terms:

-

OEM (Original Equipment Manufacturer)

Refers to companies that produce parts or equipment that may be marketed by another manufacturer. For soap vending machines, this means that buyers can source machines or components from manufacturers that specialize in specific technologies. -

MOQ (Minimum Order Quantity)

This term indicates the smallest number of units that a supplier is willing to sell. Understanding MOQ is essential for budgeting and inventory planning, especially for new market entrants. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing information for specific products. This is critical for comparing costs across different vendors and ensuring that the buyer receives the best deal.

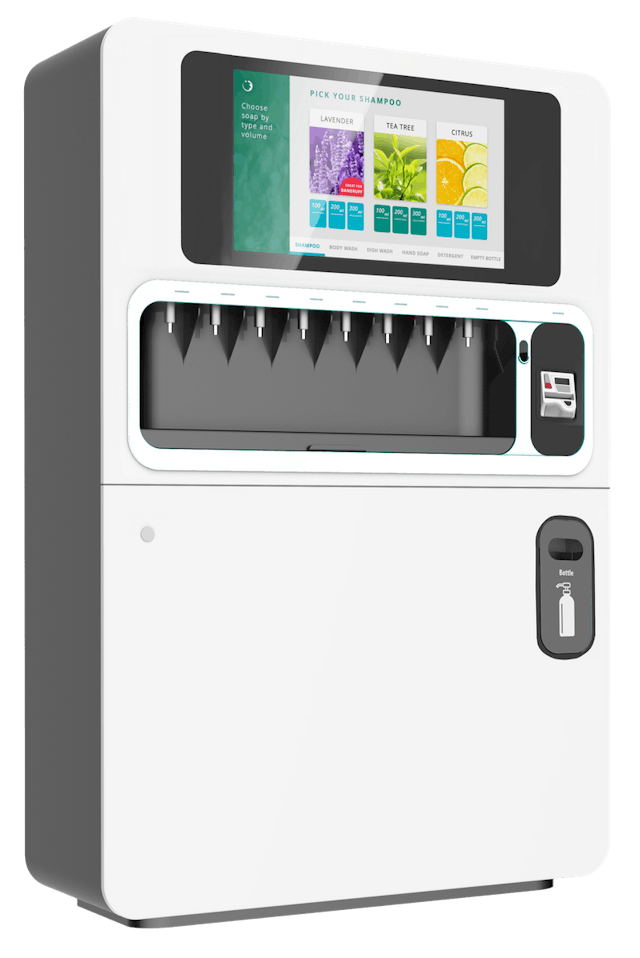

Illustrative Image (Source: Google Search)

-

Incoterms (International Commercial Terms)

These are predefined commercial terms published by the International Chamber of Commerce, defining the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is vital for understanding shipping costs and logistics. -

Lead Time

This refers to the amount of time from when an order is placed until it is fulfilled. Knowing the lead time helps buyers plan their inventory and manage customer expectations effectively. -

Warranty Period

The warranty period indicates the duration during which the manufacturer guarantees the machine’s performance and will cover repairs or replacements. A longer warranty period can signify confidence in product durability, offering buyers peace of mind.

Illustrative Image (Source: Google Search)

By focusing on these technical properties and trade terms, international B2B buyers can make informed decisions, ensuring that their investments in soap vending machines meet their operational needs and market demands.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the soap vending machine Sector

Market Overview & Key Trends

The soap vending machine sector is experiencing significant growth, driven by global trends toward hygiene and convenience. As urbanization accelerates in regions such as Africa and South America, the demand for easily accessible hygiene products has risen. Key markets are witnessing a surge in self-service solutions that cater to busy lifestyles, particularly in public spaces like airports, malls, and schools.

Emerging technologies are reshaping the industry landscape. Innovations such as contactless payment systems and IoT-enabled machines are enhancing user experience and operational efficiency. For international B2B buyers, particularly from the Middle East and Europe, integrating advanced technology into vending solutions can provide a competitive edge. Additionally, the rise of mobile apps that allow users to locate nearby vending machines is a trend worth noting, as it enhances customer engagement and accessibility.

Sourcing strategies are also evolving. Buyers are increasingly looking for suppliers who can provide high-quality, customizable machines that meet specific regional needs. This is particularly relevant in diverse markets where consumer preferences vary widely. Furthermore, the trend towards localized sourcing is gaining traction, as companies aim to reduce lead times and foster community ties.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a cornerstone of business practices within the soap vending machine sector. The environmental impact of packaging and product sourcing is under scrutiny, prompting buyers to seek solutions that minimize waste and carbon footprints. Implementing eco-friendly materials, such as biodegradable packaging and refillable soap containers, can significantly enhance a brand’s appeal to environmentally conscious consumers.

The importance of ethical supply chains cannot be overstated. International buyers must ensure that their suppliers adhere to fair labor practices and sustainable sourcing of raw materials. Certifications such as Fair Trade and Organic can serve as valuable indicators of a supplier’s commitment to sustainability. By prioritizing these certifications, B2B buyers can not only mitigate reputational risks but also appeal to a growing demographic that values corporate responsibility.

Additionally, adopting a circular economy approach—where products are designed for reuse and recycling—can lead to innovative vending solutions. This shift not only aligns with global sustainability goals but also meets the expectations of a more informed consumer base.

Brief Evolution/History

The concept of vending machines dates back to the late 19th century, originally offering simple products like gum and cigarettes. Over the decades, the vending industry has evolved dramatically, with technological advancements leading to more sophisticated machines capable of dispensing a variety of products, including hygiene items like soap.

In recent years, the soap vending machine has gained traction, particularly in response to public health crises that emphasize the importance of hand hygiene. The evolution reflects broader societal changes, where convenience, technology, and sustainability converge to meet the needs of today’s consumers. As the market continues to grow, international B2B buyers are well-positioned to leverage these trends for strategic sourcing and partnership opportunities.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of soap vending machine

-

How do I vet suppliers for soap vending machines?

When sourcing soap vending machines, it’s crucial to conduct thorough supplier vetting. Start by checking their business licenses and certifications relevant to your region. Request references from previous clients and assess their experience in the industry. Utilize platforms like Alibaba or TradeKey to find verified suppliers and read reviews. Additionally, consider visiting their facilities if possible, or opt for a third-party inspection service to ensure the quality and compliance of their products. -

Can I customize the soap vending machines to fit my brand?

Most reputable suppliers offer customization options for soap vending machines, allowing you to tailor features like branding, design, and functionality. When discussing customization, specify your requirements clearly, including colors, logos, and any specific software needs. Ensure that the supplier has a proven track record of delivering customized products and inquire about any additional costs or lead times associated with these modifications. -

What are the typical minimum order quantities (MOQ) and lead times?

Minimum order quantities (MOQ) for soap vending machines can vary significantly among suppliers. Generally, MOQs range from 10 to 100 units, depending on the supplier’s production capabilities. Lead times also differ based on customization and order size, typically ranging from 4 to 12 weeks. Always confirm these details upfront to avoid delays and ensure that your business timeline aligns with the supplier’s schedule. -

What payment methods are recommended for international transactions?

For international transactions, consider secure payment methods such as Letter of Credit (LC), PayPal, or bank transfers. These methods provide varying degrees of buyer protection. It’s advisable to negotiate payment terms that include a deposit upfront (usually 30-50%) and the balance upon delivery or inspection. Additionally, ensure that the payment terms are clearly outlined in the contract to mitigate disputes. -

How can I ensure the quality of the soap vending machines?

To ensure quality, request samples of the soap vending machines before placing a bulk order. Verify if the supplier complies with international quality standards, such as ISO certifications. Additionally, consider implementing a Quality Assurance (QA) process that includes inspections during production and before shipment. Establishing clear quality criteria in your contract can also help mitigate potential issues. -

What certifications should I look for in soap vending machines?

When sourcing soap vending machines, look for certifications relevant to safety, quality, and environmental standards. Common certifications include CE (Conformité Européenne) for European markets, ISO certifications for manufacturing quality, and RoHS (Restriction of Hazardous Substances) compliance. These certifications not only ensure product safety but can also enhance your brand’s credibility in the market. -

What logistics options should I consider for shipping soap vending machines?

Shipping logistics for soap vending machines can be complex due to their size and weight. Consider working with freight forwarders experienced in handling such products. Options include sea freight for cost-effectiveness or air freight for speed. Ensure you understand the customs regulations and duties applicable in your country. Discuss packaging requirements with the supplier to prevent damage during transit. -

How can I resolve disputes with suppliers?

To resolve disputes effectively, establish clear communication channels and maintain documentation of all agreements and correspondence. If issues arise, attempt to resolve them amicably through negotiation. If necessary, refer to the dispute resolution clause in your contract, which may include mediation or arbitration. For international buyers, consider including a neutral third-party mediator in the agreement to facilitate resolution.

Strategic Sourcing Conclusion and Outlook for soap vending machine

In the evolving landscape of hygiene solutions, soap vending machines present a unique opportunity for international B2B buyers. By leveraging strategic sourcing, businesses can enhance their product offerings, ensure supply chain resilience, and meet increasing consumer demands for convenience and hygiene. Key takeaways include the importance of selecting reliable suppliers, understanding regional market dynamics, and aligning product features with consumer preferences.

Investing in high-quality soap vending machines not only elevates customer experience but also drives profitability. For buyers in Africa, South America, the Middle East, and Europe, the focus should be on sourcing machines that are adaptable to local needs, equipped with payment flexibility, and capable of offering eco-friendly soap options.

As the market expands, fostering partnerships with innovative manufacturers will be crucial. Embrace the potential of soap vending machines to position your business ahead of the curve. Act now—explore supplier options, assess market trends, and invest in solutions that will enhance hygiene accessibility and elevate your brand in the competitive landscape. The future of hygiene solutions is here; seize the opportunity to lead the change.