Master Sourcing Fishing Vending Machines for Optimal B2B

Guide to Fishing Vending Machine

- Introduction: Navigating the Global Market for fishing vending machine

- Understanding fishing vending machine Types and Variations

- Key Industrial Applications of fishing vending machine

- Strategic Material Selection Guide for fishing vending machine

- In-depth Look: Manufacturing Processes and Quality Assurance for fishing vending machine

- Comprehensive Cost and Pricing Analysis for fishing vending machine Sourcing

- Spotlight on Potential fishing vending machine Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for fishing vending machine

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the fishing vending machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of fishing vending machine

- Strategic Sourcing Conclusion and Outlook for fishing vending machine

Introduction: Navigating the Global Market for fishing vending machine

In an era where convenience and innovation shape consumer expectations, fishing vending machines have emerged as a transformative solution within the aquaculture and retail sectors. These automated units not only provide fresh seafood directly to consumers but also streamline supply chains for businesses, ensuring that quality products reach the market swiftly and efficiently. For international B2B buyers, understanding the landscape of fishing vending machines is crucial to capitalizing on this growing trend.

This guide offers a comprehensive overview of the fishing vending machine market, tailored specifically for buyers in Africa, South America, the Middle East, and Europe, including regions like Thailand and Kenya. We delve into various types of machines available, the materials used in their construction, and the manufacturing processes that ensure quality control. Furthermore, we will highlight reliable suppliers and provide insights into pricing structures, enabling you to make informed purchasing decisions.

The importance of this guide cannot be overstated. By equipping yourself with knowledge about the fishing vending machine market, you empower your business to meet consumer demand effectively while enhancing your competitive edge. Whether you are looking to diversify your offerings or streamline operations, the insights provided here will guide you through the complexities of sourcing and implementing fishing vending machines in your business model. Prepare to navigate this evolving market with confidence and strategic clarity.

Understanding fishing vending machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Automated Fish Dispenser | Offers fresh fish or seafood with temperature control | Restaurants, supermarkets | Fresh product offering; high maintenance costs |

| Bait Vending Machine | Dispenses live bait or fishing supplies | Fishing shops, marinas | Convenient for anglers; limited inventory options |

| Fishing Gear Vending Machine | Stocks various fishing equipment and accessories | Outdoor retailers, camping sites | Diverse product range; potential theft risk |

| Ice Vending Machine | Provides ice for preserving catches | Fish markets, seafood processing | Essential for freshness; requires regular maintenance |

| Mobile Fishing Vending Unit | Compact unit for remote fishing locations | Pop-up markets, festivals | Flexible placement; lower inventory capacity |

Automated Fish Dispenser

Automated fish dispensers are designed to provide fresh seafood while maintaining optimal temperature control. These machines can be found in restaurants and supermarkets, catering to consumers who prefer fresh over frozen options. When considering a purchase, B2B buyers should evaluate the machine’s energy efficiency, maintenance requirements, and the quality of the seafood provided. While these machines can attract a health-conscious clientele, they often come with higher maintenance costs due to the need for regular cleaning and temperature monitoring.

Bait Vending Machine

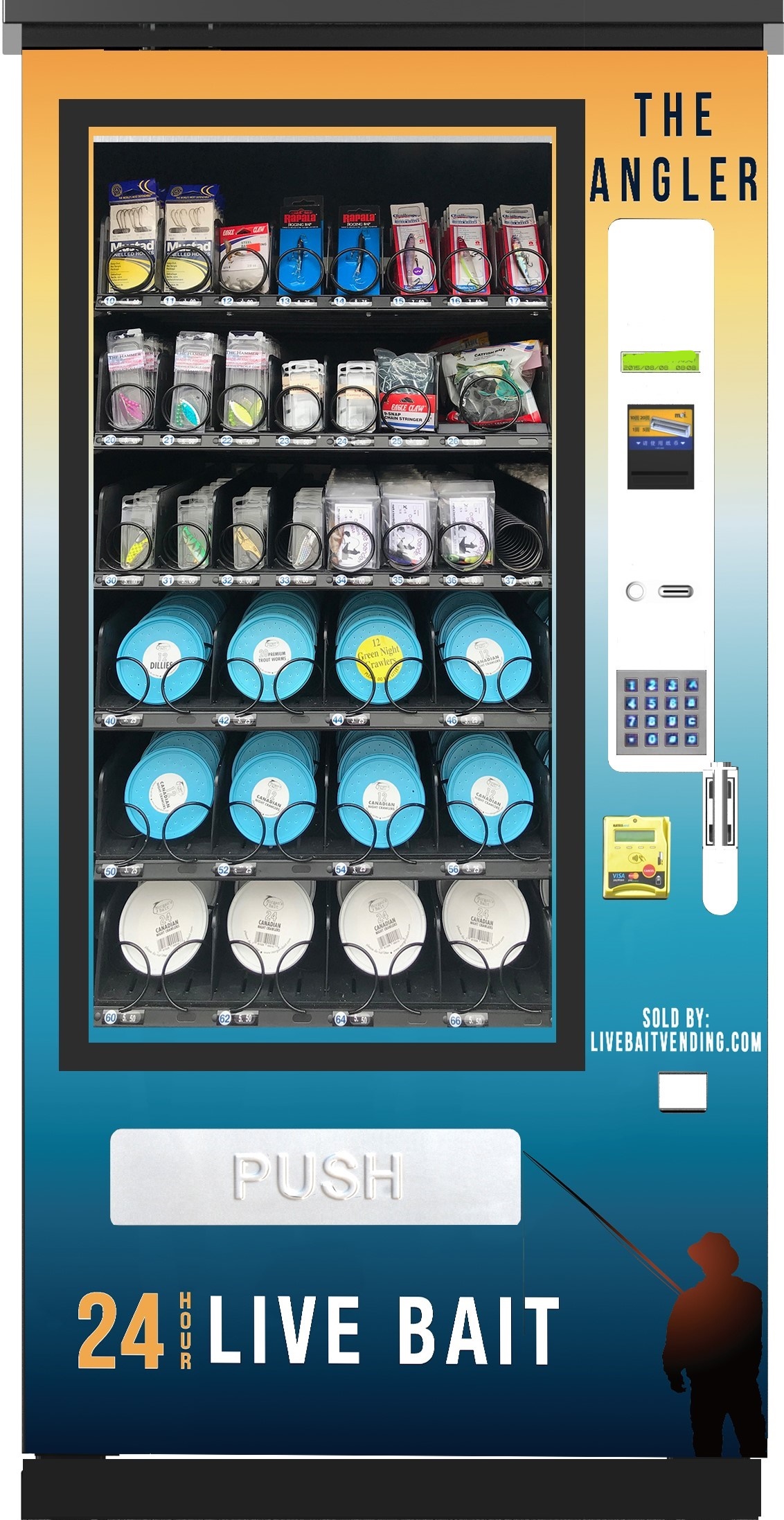

Bait vending machines are tailored for dispensing live bait and essential fishing supplies. Commonly located at fishing shops and marinas, they serve as a convenient option for anglers looking to stock up before heading out. Buyers should consider the machine’s capacity, ease of use, and the types of bait it can store. Although these machines offer convenience, they may have limitations regarding the variety of bait available, which could affect customer satisfaction.

Fishing Gear Vending Machine

These machines offer a wide range of fishing gear, including rods, reels, and tackle. Found in outdoor retailers and camping sites, fishing gear vending machines cater to both casual and serious anglers. B2B buyers must assess the machine’s inventory management system and the security features to prevent theft. While these machines provide a diverse product range, they can be vulnerable to pilferage, necessitating robust security measures to protect the investment.

Ice Vending Machine

Ice vending machines are crucial for maintaining the freshness of catches, particularly in fish markets and seafood processing facilities. They provide a reliable source of ice, which is essential for preserving seafood quality. B2B buyers should evaluate the machine’s production capacity, energy consumption, and maintenance needs. While these machines are vital for freshness, they require regular maintenance to ensure consistent operation and ice quality.

Mobile Fishing Vending Unit

Mobile fishing vending units are compact and designed for use in remote fishing locations or during outdoor events. These units can be easily transported and set up at pop-up markets or festivals, making them a flexible option for B2B buyers. When considering such a unit, buyers should look at the range of products offered and potential inventory limitations. While they provide a unique selling proposition by reaching customers in various locations, their lower inventory capacity may limit sales opportunities.

Related Video: World’s First Fishing Lure VENDING MACHINE w/ LIVE BAIT (BIG FISH!)

Key Industrial Applications of fishing vending machine

| Industry/Sector | Specific Application of fishing vending machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Automated seafood sales in urban areas | Increased sales through 24/7 accessibility | Location suitability, machine maintenance, and stock supply |

| Hospitality | On-demand fresh fish supply for restaurants | Enhanced menu quality and freshness | Supplier reliability, product variety, and pricing |

| Fishing Industry | Direct sales from local fisheries to consumers | Supports local economies and reduces supply chain costs | Compliance with local regulations and sustainability practices |

| Food Processing | Bulk vending for seafood processing facilities | Streamlined procurement and reduced waste | Quality control, storage conditions, and supplier certifications |

| Tourism | Vending machines at tourist hotspots for local delicacies | Unique selling proposition and enhanced customer experience | Machine design for high foot traffic, payment systems, and local partnerships |

In the retail sector, fishing vending machines are revolutionizing seafood sales, especially in urban settings where fresh fish may be hard to find. These machines provide consumers with 24/7 access to fresh seafood, significantly increasing sales opportunities for retailers. For international buyers, considerations include ensuring machines are strategically placed for optimal visibility and foot traffic, as well as establishing reliable maintenance schedules to keep the vending machines operational.

In the hospitality industry, restaurants are increasingly turning to fishing vending machines to enhance their menus with fresh seafood options. This application not only ensures that the fish served is of the highest quality but also allows for greater flexibility in sourcing. Buyers in this sector should focus on the reliability of suppliers and the variety of products available, as well as cost-effectiveness, to maintain competitive pricing while offering premium dishes.

The fishing industry itself benefits directly from fishing vending machines, which facilitate the sale of catch from local fisheries directly to consumers. This application not only supports local economies by reducing reliance on intermediaries but also helps maintain fish freshness. For international buyers, compliance with local regulations regarding seafood sales and sustainability practices is critical to ensure successful operation and acceptance in the market.

In food processing, fishing vending machines can serve as bulk vending solutions for processing facilities. This setup streamlines procurement processes and minimizes waste by allowing for precise inventory management. Buyers must consider factors such as quality control measures, storage conditions, and supplier certifications to ensure that the seafood remains safe and meets industry standards.

Finally, in the tourism sector, placing fishing vending machines at popular tourist destinations can provide visitors with a unique culinary experience featuring local seafood delicacies. This not only enhances the customer experience but also creates a new revenue stream for local businesses. Key considerations for buyers include designing machines that can handle high foot traffic and integrating seamless payment systems, as well as forming partnerships with local seafood suppliers to ensure a diverse product offering.

Related Video: LABORATORY APPARATUS AND THEIR USES

Strategic Material Selection Guide for fishing vending machine

When selecting materials for fishing vending machines, international B2B buyers must consider various factors that impact performance, durability, and cost. Below is an analysis of four common materials used in these machines, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

Stainless Steel

Key Properties: Stainless steel is renowned for its excellent corrosion resistance, high strength, and ability to withstand varying temperatures. Common grades like 304 and 316 are often used, with 316 offering superior resistance to saltwater environments.

Pros & Cons: The primary advantage of stainless steel is its durability and resistance to rust, making it ideal for outdoor use. However, it can be more expensive than other materials and may require specialized manufacturing processes, which can increase costs.

Impact on Application: Stainless steel is compatible with a wide range of media, including fresh and saltwater, making it suitable for fishing vending machines that dispense various aquatic products.

Considerations for International Buyers: Buyers should ensure compliance with local standards, such as ASTM for the U.S. or EN for Europe. In regions like Africa and South America, where corrosion from environmental factors is a concern, opting for higher-grade stainless steel could be beneficial.

Aluminum

Key Properties: Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity. It is often used in vending machines to reduce overall weight and improve portability.

Pros & Cons: The key advantage of aluminum is its low weight, which facilitates easier installation and maintenance. However, it is less durable than stainless steel and can be prone to dents and scratches. Additionally, its thermal expansion properties may require careful design considerations.

Impact on Application: Aluminum is suitable for vending machines that operate in moderate environments but may not be ideal for harsh, corrosive conditions, especially in coastal areas.

Considerations for International Buyers: Buyers should be aware of the specific aluminum grades and their compliance with international standards. In regions like the Middle East, where high temperatures may affect material performance, selecting the right alloy is crucial.

Polycarbonate

Key Properties: Polycarbonate is a high-impact, transparent plastic that offers excellent strength and clarity. It is resistant to UV light and can withstand a range of temperatures.

Pros & Cons: The main advantage of polycarbonate is its lightweight and shatter-resistant properties, making it ideal for protective covers and viewing panels. However, it may not be suitable for high-heat applications and can be more susceptible to scratching compared to metals.

Impact on Application: Polycarbonate is often used for transparent components in vending machines, allowing customers to see the products inside. Its chemical resistance is generally good, but compatibility with certain solvents should be evaluated.

Considerations for International Buyers: Buyers should ensure that polycarbonate components meet relevant safety and quality standards in their respective regions. In Europe, for instance, compliance with REACH regulations is essential.

Galvanized Steel

Key Properties: Galvanized steel is carbon steel that has been coated with a layer of zinc to enhance corrosion resistance. It is commonly used in outdoor applications where exposure to moisture is a concern.

Pros & Cons: The key advantage of galvanized steel is its cost-effectiveness and reasonable durability. However, the zinc coating can wear off over time, especially in harsh environments, leading to potential corrosion.

Impact on Application: Galvanized steel is suitable for structural components of vending machines that are exposed to the elements but may not be ideal for parts in direct contact with water or food products.

Considerations for International Buyers: Buyers should check for compliance with local standards regarding food safety and corrosion resistance. In regions with high humidity, like parts of Africa and South America, additional protective coatings may be advisable.

Summary Table

| Material | Typical Use Case for fishing vending machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural and contact components | Excellent corrosion resistance | Higher cost, manufacturing complexity | High |

| Aluminum | Lightweight components, panels | Low weight, good corrosion resistance | Less durable, prone to dents | Medium |

| Polycarbonate | Transparent covers, viewing panels | Shatter-resistant, lightweight | Susceptible to scratching, heat limits | Medium |

| Galvanized Steel | Structural components exposed to the elements | Cost-effective, reasonable durability | Zinc coating can wear off | Low |

This guide provides a comprehensive overview of material options for fishing vending machines, emphasizing the importance of selecting the right material based on specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for fishing vending machine

The manufacturing of fishing vending machines involves a series of intricate processes designed to ensure that the final product is durable, efficient, and meets the specific needs of various markets. For B2B buyers, understanding these processes and the quality assurance protocols in place is crucial for making informed purchasing decisions.

Manufacturing Processes

1. Material Preparation

The first stage in manufacturing fishing vending machines is the careful selection and preparation of materials. Common materials used include stainless steel for durability and corrosion resistance, tempered glass for visibility, and high-quality plastics for internal components. Buyers should ensure that suppliers use materials compliant with international standards, which can significantly affect the machine’s longevity and performance.

Key Techniques:

– Material Sourcing: Establish relationships with suppliers who provide certified materials (e.g., ISO 14001 for environmental management).

– Pre-Treatment: Materials may undergo processes like sandblasting or chemical treatments to enhance adhesion for coatings.

2. Forming

Once materials are prepared, the forming stage involves shaping them into parts that will constitute the vending machine. This can include cutting, bending, and molding operations.

Key Techniques:

– CNC Machining: Computer Numerical Control (CNC) machines are often used for precision cutting and shaping of metal components, ensuring high accuracy.

– Injection Molding: For plastic components, injection molding is common, allowing for complex shapes and rapid production.

3. Assembly

The assembly process is critical as it determines the functionality and reliability of the vending machine. This includes the integration of mechanical, electrical, and software components.

Key Techniques:

– Modular Assembly: Using a modular approach allows for easier repairs and upgrades, which is an attractive feature for B2B buyers.

– Automated Assembly Lines: Automation can enhance efficiency and reduce labor costs, but buyers should also consider the supplier’s ability to provide human oversight to ensure quality.

4. Finishing

Finishing touches are applied to enhance both aesthetics and functionality. This includes painting, coating, and quality checks.

Key Techniques:

– Powder Coating: A popular finishing technique that provides a durable finish resistant to scratching and fading.

– Quality Inspection: Each machine should undergo rigorous inspections during this stage to ensure compliance with specifications.

Quality Assurance

Quality assurance is paramount in the manufacturing of fishing vending machines. Adhering to international standards not only enhances product quality but also builds trust with buyers.

International Standards

- ISO 9001: This standard focuses on quality management systems and is a strong indicator of a supplier’s commitment to quality.

- CE Marking: Indicates that the product meets EU safety, health, and environmental protection requirements. This is particularly important for buyers in Europe.

- API Standards: For certain components that interact with water or food, ensuring compliance with API standards can be critical.

Quality Control Checkpoints

Quality control can be divided into several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Inspection of raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Ongoing checks during the manufacturing process to catch defects early.

- Final Quality Control (FQC): A comprehensive inspection of the finished product to ensure it meets all quality standards before shipping.

Common Testing Methods

B2B buyers should be aware of common testing methods used to ensure quality:

- Functional Testing: Each machine should be tested for functionality to ensure it operates as intended.

- Durability Testing: Machines should be subjected to conditions that simulate real-world use to assess their durability.

- Safety Testing: Ensuring that all electrical and mechanical components comply with safety standards.

Verifying Supplier Quality Control

B2B buyers must conduct due diligence to verify that suppliers maintain robust quality control processes. Here are several methods to do so:

- Supplier Audits: Conduct regular audits of suppliers to ensure they follow their stated quality control processes and standards.

- Quality Reports: Request detailed quality assurance reports from suppliers, which should include test results and compliance certifications.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s manufacturing and quality control processes.

Quality Control and Certification Nuances

For international B2B buyers, especially those operating in diverse markets like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification is vital:

- Regional Compliance: Different regions may have varying compliance requirements. For instance, while CE marking is essential in Europe, local certifications may be required in African or South American markets.

- Cultural Considerations: Work with suppliers who understand and respect local regulations and cultural practices, which can affect product acceptance.

- Language Barriers: Ensure that all documentation, including quality reports and compliance certificates, are available in a language that is accessible to the buyer.

By understanding the manufacturing processes and quality assurance measures associated with fishing vending machines, B2B buyers can better navigate the complexities of international sourcing, ensuring they select reliable suppliers that meet their quality expectations.

Related Video: Awesome Satisfying Manufacturing Machines | Ingenious Tools & Industrial Factory Production Insights

Comprehensive Cost and Pricing Analysis for fishing vending machine Sourcing

Understanding the comprehensive cost and pricing structure of fishing vending machines is crucial for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. The cost components and pricing influencers can significantly impact sourcing decisions, ultimately affecting profitability and operational efficiency.

Cost Components

-

Materials

– The primary materials used in fishing vending machines include durable metals, plastics, and electronic components. Sourcing high-quality materials is essential for ensuring longevity and reliability, especially in diverse environments. Buyers should consider local suppliers to reduce material costs while maintaining quality. -

Labor

– Labor costs can vary widely depending on the manufacturing location. For instance, countries in Asia might offer lower labor costs, while Europe could present higher wage standards. It’s important to assess the skill level required for assembly and maintenance when evaluating labor costs. -

Manufacturing Overhead

– This includes utilities, rent, and administrative expenses associated with the production facility. Manufacturers may pass these costs on to buyers, so understanding the overhead structure can provide insights into pricing strategies. -

Tooling

– Tooling costs are often incurred for custom designs or specific functionalities in vending machines. If unique features are required, these costs can significantly increase the initial investment. Buyers should evaluate the necessity of these features against potential returns. -

Quality Control (QC)

– Rigorous quality control processes ensure machines meet international standards. Buyers should inquire about the QC measures implemented by suppliers, as these can affect both cost and reliability. -

Logistics

– Shipping costs can fluctuate based on distance, shipping method, and current fuel prices. For international buyers, understanding Incoterms is vital for clarifying responsibilities for shipping costs, insurance, and risks. -

Margin

– Supplier profit margins will vary based on market conditions and competitive pressures. Understanding the typical margin for fishing vending machines can help buyers gauge whether quotes are reasonable.

Price Influencers

-

Volume/MOQ

– Minimum order quantities (MOQs) can affect pricing significantly. Higher volume orders often lead to lower per-unit costs. Buyers should negotiate favorable MOQs to achieve better pricing. -

Specifications/Customization

– Custom features can increase costs. Buyers should balance the need for customization with the benefits of standard models, which might offer better pricing. -

Materials and Quality Certifications

– Higher-quality materials and certifications such as ISO or CE can lead to increased costs but may provide assurance of durability and compliance. Buyers should weigh the benefits of these certifications against their budget constraints. -

Supplier Factors

– Supplier reliability, experience, and reputation can influence pricing. Established suppliers may charge a premium but can offer better support and warranty services. -

Incoterms

– The choice of Incoterms affects the total landed cost. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is essential for budget planning.

Buyer Tips

-

Negotiation: Engage in open discussions with suppliers to negotiate pricing based on volume and long-term partnerships. Consider leveraging relationships with local suppliers for better terms.

-

Cost-Efficiency: Assess the total cost of ownership, including installation, maintenance, and operational costs. Lower upfront costs may lead to higher long-term expenses.

-

Pricing Nuances: Be aware that prices may fluctuate due to currency exchange rates and geopolitical factors. Buyers should consider hedging strategies or agreements that protect against price volatility.

Disclaimer

Prices mentioned in this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. Always seek multiple quotes and conduct thorough due diligence before making procurement decisions.

Spotlight on Potential fishing vending machine Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for fishing vending machine.)*

Essential Technical Properties and Trade Terminology for fishing vending machine

Key Technical Properties for Fishing Vending Machines

When considering the procurement of fishing vending machines, international B2B buyers should focus on several critical technical specifications that ensure the equipment meets operational demands and market standards.

1. Material Grade

The material grade of a fishing vending machine refers to the quality and type of materials used in its construction. Stainless steel is often preferred for its durability and resistance to corrosion, especially in humid or wet environments. Choosing the right material grade is crucial for longevity and maintenance costs, impacting the total cost of ownership.

2. Power Consumption

This specification indicates the amount of electrical power required to operate the machine. Lower power consumption is not only cost-effective, reducing electricity bills, but it also aligns with sustainability goals. Buyers should evaluate energy efficiency ratings and consider machines that offer lower consumption without compromising performance.

3. Capacity and Size

The capacity of a fishing vending machine refers to how much product it can hold and dispense at a time. Size is equally important, as it determines the space needed for installation. For B2B buyers, understanding the target market’s demand can help select the right capacity to maximize revenue without overstocking or underutilizing the machine.

4. Temperature Control

For vending machines that dispense perishable products, effective temperature control is vital. Buyers should look for machines equipped with advanced refrigeration systems that ensure optimal storage conditions. This specification is essential for preserving product quality and complying with health regulations.

5. Payment Systems

Modern fishing vending machines should support multiple payment systems, including cash, credit cards, and mobile payment applications. The flexibility of payment options enhances customer convenience and can significantly increase sales. Buyers should assess the compatibility of the payment system with local banking and mobile payment services.

6. User Interface

The user interface includes the display and controls that customers interact with when using the vending machine. An intuitive, user-friendly interface can improve customer satisfaction and reduce the need for technical support. B2B buyers should consider machines with customizable interfaces that can cater to local languages and preferences.

Common Trade Terminology

Understanding industry-specific terminology is essential for effective communication and negotiation in the procurement process. Here are some key terms that B2B buyers should be familiar with:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. When sourcing fishing vending machines, buyers may encounter OEMs that offer custom machines or components tailored to specific needs. Understanding OEM relationships can lead to better pricing and exclusive features.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers to understand, as it directly affects inventory management and cash flow. Negotiating MOQs can lead to favorable terms and allow buyers to test products in smaller quantities before committing to larger orders.

3. RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers for specific products or services. Buyers should prepare detailed RFQs that outline their requirements to ensure they receive accurate and competitive pricing. This process is essential for budget planning and supplier selection.

Illustrative Image (Source: Google Search)

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers involved in shipping goods. Understanding these terms ensures clarity on shipping costs, risk, and delivery points. Familiarity with Incoterms can help buyers negotiate better shipping arrangements and avoid unexpected costs.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the goods. This metric is vital for inventory management and planning. Buyers should inquire about lead times during negotiations to align their purchasing schedules with business needs.

By understanding these essential specifications and trade terms, international B2B buyers can make informed decisions that align with their operational goals and market strategies in the fishing vending machine sector.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the fishing vending machine Sector

Market Overview & Key Trends

The fishing vending machine sector is experiencing transformative growth driven by several global factors. Increasing urbanization, coupled with a rising demand for convenience, has propelled the adoption of automated retail solutions. International B2B buyers should note that regions such as Africa and South America are seeing a surge in entrepreneurial ventures, where local businesses are leveraging fishing vending machines to provide fresh seafood directly to consumers.

Current trends indicate a shift towards smart technology integration in vending machines. Features such as IoT connectivity and cashless payment systems are becoming standard, enhancing user experience and operational efficiency. Additionally, the emphasis on freshness and quality is leading manufacturers to innovate with refrigeration technologies that extend the shelf life of seafood products. Buyers must remain vigilant about these technological advancements to stay competitive in their respective markets.

Emerging markets, particularly in the Middle East and parts of Europe, are increasingly recognizing the potential of fishing vending machines for tourism and local consumption. The growth of eco-tourism is driving demand for local seafood, making it essential for B2B buyers to source machines that not only meet the local regulatory standards but also align with consumer preferences for sustainability and freshness. As competition intensifies, understanding local market dynamics and consumer behavior will be crucial for successful market entry and growth.

Sustainability & Ethical Sourcing in B2B

Sustainability has emerged as a cornerstone for the fishing vending machine sector, with both consumers and businesses increasingly prioritizing eco-friendly practices. The environmental impact of overfishing and unsustainable sourcing methods is prompting B2B buyers to seek suppliers who adhere to ethical fishing practices. Engaging with suppliers that are certified by organizations such as the Marine Stewardship Council (MSC) or the Aquaculture Stewardship Council (ASC) can enhance a company’s reputation and customer trust.

Moreover, the use of green materials in the manufacturing of vending machines is gaining traction. Buyers should look for machines constructed from recyclable materials and equipped with energy-efficient technologies. Certifications such as ISO 14001 (Environmental Management) can also serve as indicators of a supplier’s commitment to sustainability. Implementing these practices not only mitigates environmental impact but can also lead to cost savings in energy consumption and waste management.

B2B buyers targeting markets in Africa, South America, the Middle East, and Europe should also consider the social implications of their sourcing decisions. Supporting local fisheries that implement responsible fishing practices can contribute to community development and economic resilience, further enhancing brand loyalty among consumers who value ethical consumption.

Brief Evolution/History

The concept of vending machines dates back to ancient Greece, but the fishing vending machine sector is a relatively recent innovation, emerging primarily in the late 20th century. Initially, these machines offered limited selections of preserved seafood. However, advancements in refrigeration and automation have significantly transformed the landscape, allowing for fresh seafood offerings.

Today, fishing vending machines are equipped with advanced technology, such as touchless payment systems and real-time inventory management, reflecting broader trends in retail automation. This evolution is particularly relevant for B2B buyers looking to invest in state-of-the-art solutions that meet modern consumer demands. As the industry continues to evolve, staying informed about historical developments can provide valuable insights into future trends and opportunities.

Related Video: Is global trade transforming? | Counting the Cost

Frequently Asked Questions (FAQs) for B2B Buyers of fishing vending machine

-

What key factors should I consider when vetting suppliers for fishing vending machines?

When vetting suppliers, prioritize their industry experience, track record, and customer reviews. Assess their production capabilities by requesting detailed product specifications and previous case studies. Verify certifications relevant to safety and quality standards in your region. Utilize platforms like Alibaba or Global Sources to find reputable suppliers and look for verified trade assurances. Establish direct communication to gauge responsiveness and willingness to customize products according to your needs. -

Can fishing vending machines be customized to fit specific regional requirements?

Yes, many manufacturers offer customization options tailored to regional preferences, including size, design, and functionality. Discuss your unique requirements, such as local currency acceptance, language settings, and preferred product offerings. Ensure that the supplier can accommodate these changes without significantly increasing the lead time or costs. Request samples or prototypes to verify that the machines meet your specifications before bulk ordering. -

What are the typical minimum order quantities (MOQs) and lead times for fishing vending machines?

Minimum order quantities can vary significantly by supplier and machine type. Generally, MOQs range from 10 to 50 units, depending on the complexity of the machine. Lead times typically span from 4 to 12 weeks, influenced by customization needs and shipping logistics. Always confirm these details before placing an order to ensure they align with your business timelines and inventory management strategies. -

What payment options are commonly accepted by fishing vending machine suppliers?

Most suppliers accept various payment methods, including bank transfers, credit cards, and escrow services. For larger transactions, consider using letter of credit (LC) for added security. Establish clear payment terms upfront, including deposits and final payments, to avoid misunderstandings. Be aware of currency exchange rates and international transaction fees, especially when dealing with suppliers in different regions. -

How can I ensure the quality of fishing vending machines before making a purchase?

Request quality assurance (QA) documentation and relevant certifications from your supplier, such as ISO 9001 or CE marking. Consider conducting factory inspections or hiring third-party inspection services to verify product quality before shipment. Additionally, ask for samples or conduct pilot tests in your target market to assess functionality and durability. Establish clear quality expectations in your contract to safeguard your investment. -

What logistics considerations should I be aware of when importing fishing vending machines?

Logistics play a crucial role in the successful importation of fishing vending machines. Evaluate shipping options, including air freight for faster delivery or sea freight for cost-effectiveness. Understand the customs regulations in your country to avoid unexpected tariffs or delays. Collaborate with a reliable freight forwarder who can assist with documentation and ensure compliance with local import laws. -

How should I handle disputes or issues with my supplier?

Establish a clear communication protocol to address disputes promptly. Document all interactions and agreements in writing to provide a reference point if issues arise. If a problem occurs, engage in direct dialogue with your supplier to seek a resolution. If necessary, consider involving a mediator or legal advisor familiar with international trade laws to facilitate a fair outcome. Always approach disputes professionally to maintain a positive business relationship. -

Are there regional market trends affecting the demand for fishing vending machines?

Yes, market trends can vary by region. In Africa, increased urbanization and tourism are driving demand for accessible food options, including fishing vending machines. South America shows a growing interest in sustainable fishing practices, influencing product offerings. The Middle East is witnessing a rise in automated solutions amid labor shortages. In Europe, health-conscious consumers are pushing for fresh, locally-sourced seafood. Stay informed about these trends to tailor your offerings and marketing strategies effectively.

Strategic Sourcing Conclusion and Outlook for fishing vending machine

The strategic sourcing of fishing vending machines presents a unique opportunity for international B2B buyers aiming to innovate within the seafood distribution sector. By identifying reliable suppliers and focusing on quality, cost-effectiveness, and technological advancements, businesses can enhance their operational efficiency and customer satisfaction. Key takeaways include the importance of understanding local market dynamics, ensuring compliance with food safety regulations, and utilizing data analytics to optimize inventory management.

Investing in fishing vending machines not only streamlines the supply chain but also meets the growing consumer demand for fresh, accessible seafood. For buyers in regions like Africa, South America, the Middle East, and Europe, aligning with local suppliers and leveraging regional distribution networks can significantly improve market penetration and brand loyalty.

Looking ahead, the market for fishing vending machines is poised for growth, driven by technological innovations and changing consumer preferences. Companies that proactively engage in strategic sourcing and remain adaptable to market trends will be well-positioned to capitalize on this emerging opportunity. Now is the time to explore partnerships and invest in solutions that will set your business apart in the competitive seafood landscape.