Master Sourcing Fishing Bait Vending Machines for Maximum

Guide to Fishing Bait Vending Machines

- Introduction: Navigating the Global Market for fishing bait vending machines

- Understanding fishing bait vending machines Types and Variations

- Key Industrial Applications of fishing bait vending machines

- Strategic Material Selection Guide for fishing bait vending machines

- In-depth Look: Manufacturing Processes and Quality Assurance for fishing bait vending machines

- Comprehensive Cost and Pricing Analysis for fishing bait vending machines Sourcing

- Spotlight on Potential fishing bait vending machines Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for fishing bait vending machines

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the fishing bait vending machines Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of fishing bait vending machines

- Strategic Sourcing Conclusion and Outlook for fishing bait vending machines

Introduction: Navigating the Global Market for fishing bait vending machines

In today’s evolving fishing industry, the demand for innovative solutions is surging, and fishing bait vending machines are at the forefront of this transformation. These automated dispensers not only streamline the purchasing process for anglers but also present a lucrative opportunity for B2B buyers looking to enhance their offerings in diverse markets. With the rise of urban fishing and increased interest in recreational activities, the ability to provide convenient access to bait can set businesses apart in a competitive landscape.

This comprehensive guide delves into the multifaceted world of fishing bait vending machines, equipping international B2B buyers from regions such as Africa, South America, the Middle East, and Europe with the essential knowledge needed to make informed sourcing decisions. We will explore various types of machines available in the market, the materials that ensure durability and efficiency, and the critical aspects of manufacturing and quality control that buyers should consider. Additionally, we will provide insights into leading suppliers and a detailed breakdown of costs associated with these machines.

By navigating through the complexities of this niche market, buyers will gain a strategic advantage, enabling them to identify reliable partners and optimize their supply chains. Our goal is to empower businesses with actionable insights and practical FAQs, ensuring they can confidently invest in fishing bait vending machines that meet the evolving needs of their customers and communities.

Understanding fishing bait vending machines Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Bait Vending Machine | Manual selection, typically stocked with live bait | Fishing supply stores, marinas | Pros: Simple operation, familiar to users. Cons: Limited automation, requires regular maintenance. |

| Automated Bait Dispenser | Touchscreen interface, automated dispensing systems | High-traffic fishing locations | Pros: Reduces labor costs, enhances user experience. Cons: Higher initial investment, requires power supply. |

| Mobile Bait Vending Kiosk | Portable units, often solar-powered | Remote fishing spots, events | Pros: Flexibility, easy transportation. Cons: Limited stock capacity, potential weather vulnerability. |

| Ice Bait Vending Machine | Refrigeration system for live bait preservation | Coastal areas, ice fishing locations | Pros: Extends bait freshness, appeals to niche markets. Cons: Maintenance of refrigeration system can be costly. |

| Customized Bait Vending Solutions | Tailored options for specific regional needs | Local fishing communities, specialty shops | Pros: Meets unique customer demands, potential for high margins. Cons: Longer lead times for production, may require higher investment. |

Traditional Bait Vending Machine

Traditional bait vending machines are often manually operated and stocked with live bait, making them a staple in fishing supply stores and marinas. Their straightforward design appeals to customers familiar with the concept of vending machines. B2B buyers should consider the ease of restocking and maintenance requirements, as these machines can demand regular attention to ensure bait freshness. While they are cost-effective, they lack the automation and convenience of more modern solutions.

Automated Bait Dispenser

Automated bait dispensers feature advanced technology such as touchscreen interfaces and automated dispensing systems. These machines are ideal for high-traffic fishing locations, offering a streamlined user experience and reducing labor costs. B2B buyers should assess the initial investment and ongoing power requirements, as well as the potential for increased sales through enhanced customer convenience. While they offer significant advantages, the complexity of the technology may require specialized maintenance.

Mobile Bait Vending Kiosk

Mobile bait vending kiosks are designed for portability and can be solar-powered, making them suitable for remote fishing spots and events. Their flexibility allows businesses to reach a broader customer base without the need for permanent installation. Buyers should evaluate stock capacity and the machine’s durability against varying weather conditions. While they offer unique selling opportunities, the limited storage may restrict the variety of bait offered.

Ice Bait Vending Machine

Ice bait vending machines incorporate refrigeration systems to preserve live bait, catering to coastal areas and ice fishing enthusiasts. These machines enhance the freshness of the bait, appealing to niche markets. B2B buyers must consider the additional maintenance costs associated with the refrigeration system and the need for a stable power source. Despite the higher operational costs, the potential for attracting dedicated fishing customers can justify the investment.

Customized Bait Vending Solutions

Customized bait vending solutions are designed to meet the specific needs of local fishing communities or specialty shops. These tailored machines can address unique regional demands, allowing businesses to differentiate themselves in the market. Buyers should be prepared for longer lead times and potentially higher upfront costs. However, the ability to cater to distinct customer preferences can lead to increased sales and customer loyalty, making it a worthwhile investment for specialized retailers.

Related Video: World’s First Fishing Lure VENDING MACHINE w/ LIVE BAIT (BIG FISH!)

Key Industrial Applications of fishing bait vending machines

| Industry/Sector | Specific Application of fishing bait vending machines | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Recreational Fishing | Automated bait distribution at fishing hotspots | Increases sales, reduces labor costs, enhances customer convenience | Machine durability, local regulations, bait preservation technology |

| Aquaculture | Supply of live bait for fish farms | Ensures availability of high-quality bait, optimizes feeding schedules | Sourcing of live bait species, environmental impact, compliance with local laws |

| Marine Research | Provision of bait for research vessels | Facilitates data collection, improves research efficiency | Machine adaptability to various bait types, ease of transport, power supply requirements |

| Tourism and Hospitality | Bait vending at tourist fishing locations | Attracts tourists, boosts local economy, enhances visitor experience | Location accessibility, machine visibility, payment options for tourists |

| Retail Fishing Supplies | Bait vending in fishing gear shops | Expands product offerings, maximizes customer footfall, increases impulse purchases | Inventory management, compatibility with existing shop systems, machine aesthetics |

Recreational Fishing

Fishing bait vending machines are increasingly used at popular fishing spots to provide anglers with easy access to live bait. This application addresses the common issue of bait availability, especially during peak fishing seasons. For B2B buyers in this sector, it is essential to consider machine durability and compliance with local regulations regarding bait types. By offering convenient access to bait, businesses can boost sales and enhance customer satisfaction, ultimately driving repeat visits.

Aquaculture

In aquaculture, fishing bait vending machines serve as a reliable source of live bait for fish farms, ensuring that fish are fed optimally throughout their growth cycle. This application helps farm operators maintain consistent feeding schedules and improve the health of their stock. Buyers in this sector must focus on sourcing live bait species that meet the nutritional needs of their fish while also considering the environmental impact of their operations. Compliance with local laws regarding bait sourcing and usage is crucial to avoid legal complications.

Marine Research

Research vessels utilize fishing bait vending machines to streamline the provision of bait for scientific studies. This application facilitates efficient data collection by ensuring that researchers have immediate access to the bait necessary for various experiments. For B2B buyers involved in marine research, it is important to consider the adaptability of the machines to accommodate different bait types and their transportability to remote locations. Power supply requirements should also be evaluated to ensure the machines function effectively in diverse environments.

Tourism and Hospitality

Fishing bait vending machines are an attractive addition to tourist fishing locations, providing visitors with quick access to bait. This application not only enhances the overall fishing experience for tourists but also contributes to the local economy by encouraging fishing-related activities. B2B buyers in the tourism sector should focus on the accessibility of these machines, ensuring they are placed in high-traffic areas. Additionally, offering various payment options can cater to a diverse customer base, enhancing convenience and driving sales.

Retail Fishing Supplies

In retail environments, fishing bait vending machines can complement existing fishing gear offerings, creating a one-stop-shop for anglers. This application allows retailers to maximize customer footfall and increase impulse purchases, particularly in busy fishing seasons. Buyers in this sector should consider how the machines integrate with current inventory management systems and their aesthetic appeal to attract customers. Ensuring a seamless customer experience will ultimately enhance profitability and customer loyalty.

Related Video: 25 Amazing Uses for IBC Totes

Strategic Material Selection Guide for fishing bait vending machines

When selecting materials for fishing bait vending machines, it’s crucial to consider the specific requirements of the application, including environmental conditions, durability, and cost-effectiveness. Below are analyses of four common materials used in the construction of these machines, highlighting their properties, advantages, disadvantages, and relevant considerations for international buyers.

1. Stainless Steel

Key Properties: Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand varying temperatures. Common grades like 304 and 316 are often used, with 316 providing superior resistance to chlorides, making it ideal for coastal regions.

Pros & Cons: The primary advantage of stainless steel is its durability and long lifespan, which can reduce maintenance costs. However, it is relatively expensive compared to other materials and can be challenging to machine and fabricate, increasing manufacturing complexity.

Impact on Application: Stainless steel is compatible with various media, including live bait and frozen products. Its non-reactive nature ensures that bait quality is maintained.

Considerations for International Buyers: Buyers should ensure compliance with local standards, such as ASTM or DIN, and consider the availability of specific grades in their region. In markets like Europe, certification for food safety may also be necessary.

2. Aluminum

Key Properties: Aluminum is lightweight, has good corrosion resistance, and can be anodized for enhanced durability. Its thermal conductivity is also beneficial for temperature-sensitive applications.

Pros & Cons: The lightweight nature of aluminum makes it easy to transport and install, which can reduce overall project costs. However, it is less durable than stainless steel and may not withstand heavy impacts or extreme environments.

Impact on Application: Aluminum is suitable for applications where weight is a concern, such as portable vending machines. However, it may not be ideal for areas with high salinity, as it can corrode over time.

Considerations for International Buyers: Buyers should be aware of local recycling regulations as aluminum is highly recyclable. Compliance with standards like JIS for aluminum products may also be relevant, especially in Japan and other Asian markets.

3. High-Density Polyethylene (HDPE)

Key Properties: HDPE is a thermoplastic known for its high strength-to-density ratio and excellent resistance to impact, moisture, and chemicals.

Pros & Cons: HDPE is cost-effective and easy to mold, which simplifies manufacturing processes. However, it has a lower temperature resistance compared to metals and may not be suitable for high-temperature applications.

Impact on Application: HDPE is ideal for components that require good moisture resistance, such as storage bins for bait. Its lightweight nature makes it easy to handle but may limit its use in more robust structural applications.

Considerations for International Buyers: Buyers should check for compliance with food safety regulations, as HDPE is often used in food-grade applications. Different countries may have varying standards for plastic materials, so awareness of local regulations is essential.

4. Galvanized Steel

Key Properties: Galvanized steel is carbon steel coated with zinc to enhance corrosion resistance. It offers good strength and is suitable for outdoor applications.

Pros & Cons: The primary advantage of galvanized steel is its cost-effectiveness and decent durability. However, the zinc coating can wear off over time, leading to potential corrosion issues if not properly maintained.

Impact on Application: Galvanized steel is suitable for structural components of vending machines that are exposed to the elements. However, it may not be ideal for areas where high levels of moisture or salt are present.

Considerations for International Buyers: Buyers should ensure that galvanized steel meets local standards for corrosion resistance and structural integrity. In regions with high humidity or salt exposure, additional protective coatings may be necessary.

Summary Table

| Material | Typical Use Case for fishing bait vending machines | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural components exposed to moisture | Excellent durability and corrosion resistance | Higher cost and manufacturing complexity | High |

| Aluminum | Portable vending machines | Lightweight and easy to transport | Less durable under heavy impacts | Medium |

| High-Density Polyethylene (HDPE) | Storage bins for bait | Cost-effective and moisture resistant | Lower temperature resistance | Low |

| Galvanized Steel | Outdoor structural components | Cost-effective with decent durability | Zinc coating may wear off over time | Medium |

This guide provides a comprehensive overview of material options for fishing bait vending machines, equipping international B2B buyers with the insights necessary to make informed purchasing decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for fishing bait vending machines

Understanding the Manufacturing Process for Fishing Bait Vending Machines

The production of fishing bait vending machines involves several critical stages, each contributing to the overall quality and functionality of the final product. Below is a breakdown of the typical manufacturing process:

1. Material Preparation

Selection of Materials

The initial phase focuses on sourcing high-quality materials that can withstand various environmental conditions. Common materials include stainless steel for durability, high-density polyethylene (HDPE) for the outer casing, and tempered glass for the vending window.

Material Inspection

Before processing, materials undergo rigorous inspections to ensure compliance with international standards. This includes checking for material specifications, certifications, and any potential defects.

2. Forming

Techniques Used

The forming stage involves shaping the raw materials into components of the vending machine. Techniques such as:

- Metal Stamping: Used for creating metal parts quickly and accurately.

- Injection Molding: Commonly used for producing plastic components.

- CNC Machining: Provides precision in shaping various machine parts.

Each method is selected based on the component requirements, ensuring that the final pieces fit together seamlessly.

3. Assembly

Component Integration

The assembly process combines all manufactured components into a cohesive unit. This often involves:

- Mechanical Assembly: Fitting together parts using screws, bolts, and other fasteners.

- Electrical Assembly: Installing the vending machine’s electronic systems, including payment processors and sensors.

Quality Checks During Assembly

As components are assembled, manufacturers conduct in-process inspections (IPQC) to identify any defects early in the process. This proactive approach reduces waste and ensures higher quality in the final product.

4. Finishing

Surface Treatment

Once assembled, the machine undergoes finishing processes such as painting, powder coating, or anodizing. These treatments not only enhance aesthetics but also provide corrosion resistance and durability.

Final Inspection

Before the machines are packaged for shipping, they undergo a thorough final quality check (FQC) to ensure they meet all specifications and performance standards.

Quality Assurance Measures

Quality assurance is integral to the manufacturing of fishing bait vending machines. Adhering to international standards and industry-specific regulations ensures that the product is reliable and safe for use.

International Standards

- ISO 9001: This standard focuses on quality management systems and is crucial for manufacturers aiming to enhance customer satisfaction through effective quality management practices.

- CE Marking: Required for products sold in the European Economic Area, indicating conformity with health, safety, and environmental protection standards.

Industry-Specific Standards

- API Standards: Relevant for components that may be exposed to water, ensuring they meet specific performance criteria.

Quality Control Checkpoints

Quality control is carried out at various stages of the manufacturing process:

- Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Ongoing inspections during assembly to catch defects early.

- Final Quality Control (FQC): A comprehensive review of the finished product before it is shipped.

Common Testing Methods

Bait vending machines are subjected to various testing methods to ensure their durability and functionality:

- Functional Testing: Verifying that all vending machine components operate correctly, including payment systems and dispensing mechanisms.

- Environmental Testing: Assessing how the machine performs under different weather conditions, ensuring it can withstand humidity, rain, and temperature fluctuations.

- Safety Testing: Ensuring that the machine complies with safety regulations to prevent any risk to users.

Verifying Supplier Quality Control

For international B2B buyers, ensuring that suppliers adhere to strict quality control standards is paramount. Here are actionable steps to verify QC measures:

- Supplier Audits: Conduct on-site audits to evaluate the manufacturing processes and quality control systems in place. This firsthand assessment can reveal a lot about a supplier’s commitment to quality.

- Request Quality Reports: Suppliers should provide documentation of their quality control processes, including inspection reports and compliance certificates. Look for adherence to ISO and other relevant standards.

- Third-Party Inspections: Consider hiring independent inspection agencies to evaluate the manufacturing facility and the final products. This adds an extra layer of assurance regarding quality and compliance.

Quality Control and Certification Nuances

When dealing with international suppliers, especially those in Africa, South America, the Middle East, and Europe, it is crucial to understand regional variations in quality standards and certifications. Here are some considerations:

- Regional Standards: Different regions may have varying compliance requirements. Familiarize yourself with local regulations that could impact the import and operation of vending machines.

- Language Barriers: Ensure that all quality documentation is available in a language you understand to avoid misinterpretations.

- Cultural Differences: Be mindful of different business practices and quality expectations across regions. Building a strong relationship with suppliers can facilitate better communication regarding quality standards.

Conclusion

Manufacturing fishing bait vending machines involves a complex interplay of material preparation, forming, assembly, and finishing, all supported by rigorous quality assurance measures. For B2B buyers, understanding these processes and the importance of quality control can lead to more informed purchasing decisions. By actively engaging with suppliers and verifying their compliance with international standards, buyers can ensure they invest in reliable, high-quality vending machines that meet market demands.

Related Video: The Production Planning Process

Comprehensive Cost and Pricing Analysis for fishing bait vending machines Sourcing

When considering the sourcing of fishing bait vending machines, understanding the cost structure and pricing dynamics is crucial for international B2B buyers. A comprehensive analysis of the cost components and price influencers will aid in making informed decisions that align with business objectives, especially for buyers from Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The choice of materials significantly affects the overall cost. High-quality, durable materials like stainless steel can increase initial costs but may result in lower maintenance expenses and longer lifespan. Buyers should assess the trade-off between upfront material costs and long-term durability.

-

Labor: Labor costs vary by region and are influenced by local wage standards and skill levels. In regions like Africa and South America, labor may be less expensive, potentially lowering production costs. However, it’s essential to ensure that the labor force has the necessary skills for high-quality manufacturing.

-

Manufacturing Overhead: This includes utilities, facility costs, and indirect labor. Understanding a supplier’s overhead structure can provide insights into their pricing strategy. Suppliers in regions with lower operating costs may offer more competitive pricing.

-

Tooling: Custom tooling for specific machine designs can be a significant initial investment. Buyers should inquire about tooling costs and whether these can be amortized over larger order volumes to reduce per-unit costs.

-

Quality Control (QC): Implementing a robust QC process ensures the machines meet safety and operational standards. While this adds to the cost, it can prevent losses from defective products and enhance customer satisfaction.

-

Logistics: Transportation costs vary widely based on distance, shipping method, and local regulations. Understanding logistics, including customs duties and import taxes, is vital for calculating total expenses.

-

Margin: Supplier margins will vary based on market conditions and competition. It’s advisable to compare several suppliers to identify those with reasonable margins that do not compromise on quality.

Price Influencers

-

Volume/MOQ (Minimum Order Quantity): Bulk purchasing can lead to significant discounts. Buyers should evaluate their demand to negotiate better terms based on higher order volumes.

-

Specifications/Customization: Customized machines tailored to specific needs may incur higher costs. Buyers should clearly define specifications to avoid unexpected expenses.

-

Materials and Quality Certifications: Machines with recognized quality certifications (e.g., ISO, CE) may be priced higher but can be more reliable. Buyers should weigh the benefits of certified products against budget constraints.

-

Supplier Factors: The reputation and experience of the supplier can influence pricing. Established suppliers may charge a premium but often provide better reliability and service.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is critical for clarifying who bears the risk and costs at each stage of shipping. Buyers should negotiate terms that minimize their risks and expenses.

Buyer Tips

-

Negotiation: Engage in open discussions about pricing and terms. Suppliers may be willing to adjust prices based on long-term business relationships or larger order commitments.

-

Cost-Efficiency: Consider not just the purchase price but the Total Cost of Ownership (TCO), which includes maintenance, operation, and disposal costs. Investing in higher-quality machines can yield savings over time.

-

Pricing Nuances: Be aware of regional pricing variations. For instance, suppliers in Europe may have different pricing structures compared to those in the Middle East or Africa due to varying economic conditions.

-

Market Research: Conduct thorough market research to understand competitive pricing and emerging trends in the fishing bait vending machine sector. This knowledge can empower buyers during negotiations.

In conclusion, a detailed understanding of the cost structure, pricing influencers, and strategic negotiation tactics is essential for B2B buyers seeking fishing bait vending machines. By considering these factors, international buyers can make informed decisions that align with their operational needs and budgetary constraints.

Disclaimer: Prices mentioned are indicative and may vary based on specific supplier agreements and market conditions. Always conduct due diligence before finalizing transactions.

Spotlight on Potential fishing bait vending machines Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘fishing bait vending machines’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for fishing bait vending machines

Key Technical Properties of Fishing Bait Vending Machines

When considering the procurement of fishing bait vending machines, understanding the critical technical properties is essential for making informed purchasing decisions. Here are some of the most important specifications:

-

Material Grade

– Definition: This refers to the quality of materials used in the construction of the vending machine, which can include stainless steel, aluminum, or specialized plastics.

– B2B Importance: High-grade materials enhance durability and resistance to environmental factors, such as corrosion and UV exposure, which is crucial for machines placed in outdoor settings. -

Tolerance Levels

– Definition: Tolerance levels indicate the permissible limits of variation in dimensions and weight of machine components.

– B2B Importance: Precision in manufacturing ensures that parts fit together correctly and function optimally. This is particularly important in the context of vending mechanisms that require reliability for user satisfaction. -

Power Consumption

– Definition: This property measures the amount of electricity the machine uses during operation.

– B2B Importance: Understanding power consumption helps buyers evaluate operational costs, especially in regions where electricity rates may be high. Energy-efficient machines can reduce long-term expenses and support sustainability initiatives. -

Capacity

– Definition: Capacity refers to the volume of bait that the machine can hold and dispense, typically measured in liters or kilograms.

– B2B Importance: A higher capacity allows for fewer restocking intervals, which is vital for businesses aiming to maximize uptime and service availability, especially in popular fishing areas. -

User Interface

– Definition: This encompasses the design and functionality of the machine’s control panel, including features like touchscreen displays and payment acceptance methods.

– B2B Importance: An intuitive user interface can enhance customer experience, making it easier for users to select and purchase bait, thus potentially increasing sales. -

Weather Resistance Rating

– Definition: This rating indicates the machine’s ability to withstand various weather conditions, including rain, snow, and extreme temperatures.

– B2B Importance: For regions with harsh climates, selecting machines with high weather resistance ratings is crucial to ensure longevity and reduce maintenance costs.

Common Trade Terminology

Navigating the procurement process effectively also requires familiarity with industry jargon. Here are key terms that B2B buyers should understand:

-

OEM (Original Equipment Manufacturer)

– Definition: This term refers to a company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships can help buyers identify reliable sources for components and ensure quality in the machines they purchase. -

MOQ (Minimum Order Quantity)

– Definition: MOQ is the smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ is essential for budgeting and inventory management. It allows buyers to gauge whether they can meet purchase requirements without overcommitting financially. -

RFQ (Request for Quotation)

– Definition: An RFQ is a document sent to suppliers requesting pricing and terms for specific quantities of goods.

– Importance: Issuing an RFQ helps buyers compare prices and terms from multiple suppliers, facilitating more informed purchasing decisions. -

Incoterms (International Commercial Terms)

– Definition: These are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers in shipping goods.

– Importance: Familiarity with Incoterms is crucial for understanding shipping costs, liability, and risk management. This knowledge is especially beneficial for international transactions. -

Lead Time

– Definition: Lead time refers to the amount of time it takes from placing an order to receiving the goods.

– Importance: Understanding lead times helps buyers plan their inventory and sales strategies, ensuring that they can meet customer demand without delays.

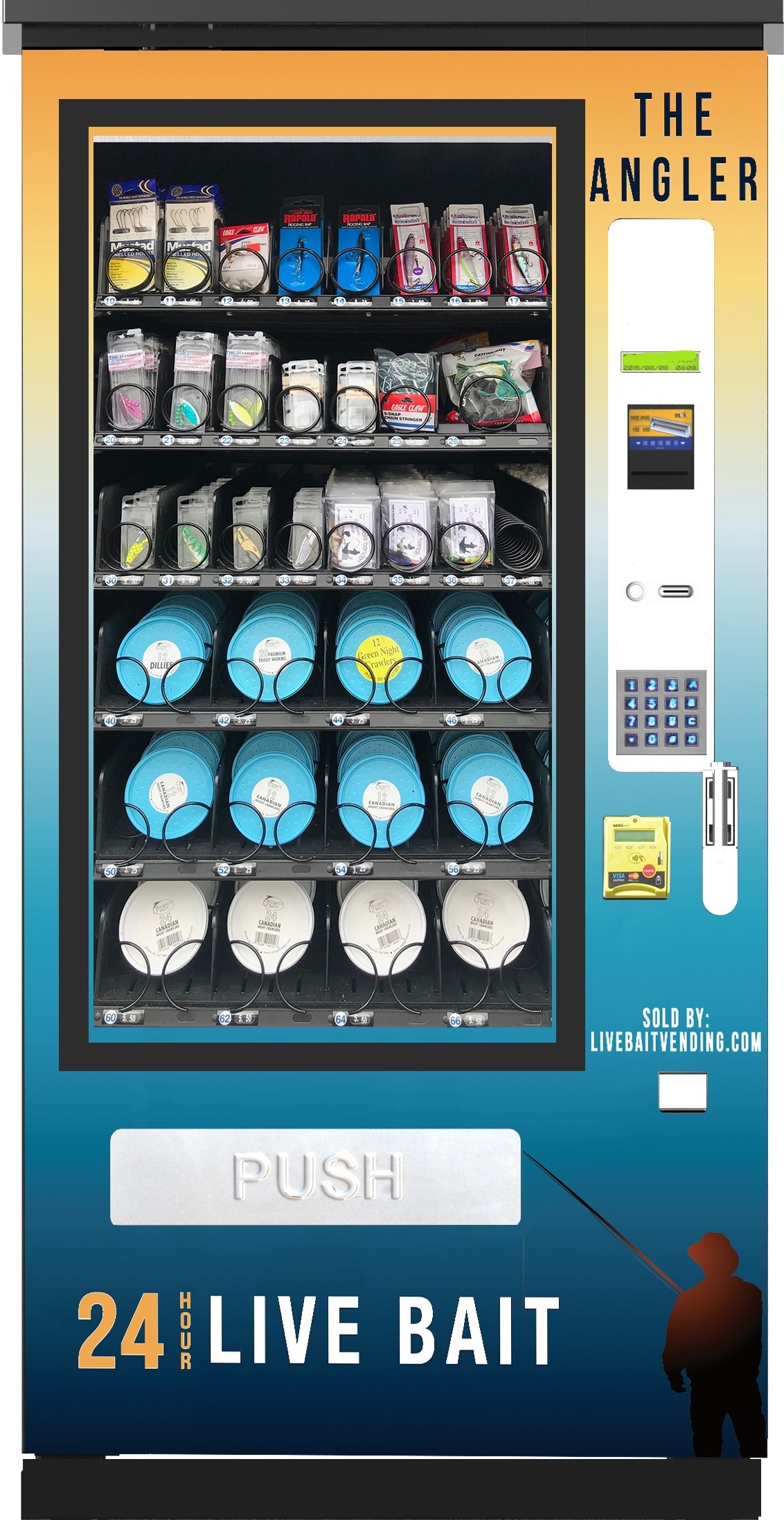

Illustrative Image (Source: Google Search)

- Warranty Period

– Definition: The warranty period is the duration during which the manufacturer guarantees the machine against defects and malfunctions.

– Importance: A clear warranty period can provide peace of mind and protect buyers from unexpected repair costs, making it a vital consideration in purchasing decisions.

By grasping these technical properties and trade terminologies, international B2B buyers can navigate the complexities of acquiring fishing bait vending machines with greater confidence and effectiveness.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the fishing bait vending machines Sector

Market Overview & Key Trends

The fishing bait vending machines sector is experiencing significant growth, driven by the rising popularity of recreational fishing and the increasing demand for convenience. Technological advancements are reshaping the landscape, with smart vending solutions integrating IoT capabilities, allowing real-time inventory tracking and user analytics. This shift is particularly appealing to international B2B buyers looking to optimize operations and enhance customer experience.

In regions like Africa and South America, where traditional fishing practices are still prevalent, the introduction of vending machines can bridge the gap between local fishers and modern fishing needs. Emerging markets are witnessing a surge in urbanization and disposable income, which fuels demand for accessible fishing supplies. Meanwhile, in Europe and the Middle East, a focus on premium products and innovative bait solutions is gaining traction, as consumers seek quality and sustainability.

Key sourcing trends include a shift toward localized supply chains to reduce lead times and transportation costs. Buyers are increasingly prioritizing suppliers that offer flexible, tailored solutions that can cater to regional preferences. Additionally, the integration of digital payment systems in vending machines aligns with the global move towards cashless transactions, enhancing user convenience and security.

Sustainability & Ethical Sourcing in B2B

As environmental concerns continue to rise, sustainability has become a pivotal factor for international B2B buyers in the fishing bait vending machines sector. The industry faces scrutiny regarding the sourcing of materials and the environmental impact of bait production. Ethical supply chains are crucial, with buyers expected to ensure that their suppliers adhere to sustainable practices, from raw material sourcing to end-product delivery.

Investing in green certifications such as ISO 14001 can enhance a company’s reputation and appeal to environmentally conscious consumers. Utilizing sustainable materials, such as biodegradable packaging and eco-friendly bait options, not only reduces environmental impact but also aligns with the values of a growing segment of the market. In regions like Europe, where regulatory frameworks are stringent, compliance with sustainability standards can be a key differentiator.

Moreover, transparency in sourcing is essential. B2B buyers should seek partnerships with suppliers who provide clear information about their supply chain practices, ensuring that they are not contributing to overfishing or habitat destruction. This commitment to sustainability not only supports the environment but also fosters customer loyalty and enhances brand reputation.

Brief Evolution/History

The fishing bait vending machine concept has evolved significantly over the past few decades. Initially, these machines were simple contraptions, primarily dispensing live bait and basic fishing supplies. However, advancements in technology and a shift in consumer behavior have transformed them into sophisticated units equipped with smart technology.

Today, these machines offer a diverse range of products, including artificial lures, fishing gear, and bait, catering to the evolving preferences of anglers. The integration of digital payment systems and real-time inventory management reflects the broader trends in retail and e-commerce, making fishing supplies more accessible to a wider audience. As fishing continues to grow in popularity globally, the evolution of vending machines is poised to meet both traditional and modern fishing needs, positioning them as a viable business opportunity for B2B buyers.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of fishing bait vending machines

-

What should I consider when vetting suppliers of fishing bait vending machines?

When vetting suppliers, prioritize their industry experience and reputation. Look for manufacturers with proven track records in delivering quality vending machines, especially those tailored for fishing bait. Verify their certifications and compliance with international standards. Request references from existing clients, particularly those in your region, to understand their reliability. Additionally, assess their customer support structure to ensure you have assistance post-purchase. -

Can fishing bait vending machines be customized to suit local needs?

Yes, many manufacturers offer customization options to cater to specific regional demands. This may include adapting the machine size, type of bait dispensed, or payment methods that resonate with local consumers. Discuss your unique requirements with suppliers during the initial stages of communication. Customization may involve additional costs, so ensure you get a detailed quote and timeline for modifications. -

What are the typical minimum order quantities (MOQs) and lead times for these machines?

MOQs can vary significantly among suppliers, generally ranging from one unit for custom machines to larger quantities for standard models. Lead times also depend on factors such as customization, supplier location, and shipping logistics. Expect lead times to be between 4 to 12 weeks. Always confirm these details upfront and factor in potential delays, especially for international shipments. -

What payment methods are commonly accepted, and are there any risks involved?

Most suppliers accept a variety of payment methods, including bank transfers, letters of credit, and online payment platforms. Each method has its pros and cons; for instance, letters of credit can provide security but may incur additional fees. To mitigate risks, conduct due diligence on the supplier’s financial stability and reputation. Consider using escrow services for large transactions to protect your investment until you receive the machines. -

How can I ensure quality assurance and necessary certifications for fishing bait vending machines?

Request documentation that demonstrates compliance with relevant safety and quality standards, such as ISO certifications or regional regulatory approvals. A reputable supplier should readily provide these certifications. Additionally, inquire about their quality control processes, including inspections and testing protocols. You may also consider third-party audits to verify the supplier’s claims about quality standards. -

What logistics considerations should I keep in mind when importing these machines?

Logistics can be complex, especially when importing heavy machinery like vending machines. Research freight options, including air and sea transport, and assess which method balances cost and speed. Factor in duties, taxes, and potential customs delays in your budget. Collaborate with a reliable freight forwarder who understands regulations in your region to streamline the import process. -

How should I handle disputes or issues with suppliers?

Establish clear communication channels with your supplier from the outset. In case of disputes, start by addressing the issue directly with them to seek a resolution. If informal discussions fail, refer to the terms of your contract, which should outline dispute resolution procedures, including mediation or arbitration. It is advisable to keep records of all communications and agreements to support your case if needed. -

What are the best practices for maintenance and support of fishing bait vending machines?

Regular maintenance is crucial for the longevity of vending machines. Discuss with your supplier the recommended maintenance schedule and any training they offer for your staff. Ensure you have access to spare parts and technical support, especially for remote locations. Establish a partnership with local technicians who can assist with repairs or routine checks, reducing downtime and improving service reliability.

Strategic Sourcing Conclusion and Outlook for fishing bait vending machines

In summary, the strategic sourcing of fishing bait vending machines presents a unique opportunity for international B2B buyers, particularly in Africa, South America, the Middle East, and Europe. By focusing on high-quality suppliers, conducting thorough market research, and leveraging technology for efficient inventory management, businesses can enhance their operational efficiency and customer satisfaction.

Key Takeaways:

– Supplier Diversity: Engaging with a diverse range of suppliers can mitigate risks associated with supply chain disruptions and ensure a steady flow of quality products.

– Market Insights: Understanding regional fishing practices and preferences is crucial for tailoring vending machine offerings to meet local demands.

– Technological Integration: Investing in smart vending solutions not only improves user experience but also streamlines operations through data analytics.

As the global demand for fishing bait vending machines continues to grow, proactive sourcing strategies will be essential. By adopting a forward-thinking approach and embracing innovation, businesses can position themselves for success in an evolving marketplace. Now is the time to explore partnerships and expand your offerings to capture the emerging opportunities in this dynamic sector.