Master Sourcing Crane National Vending Machines for Your

Guide to Crane National Vending Machine

- Introduction: Navigating the Global Market for crane national vending machine

- Understanding crane national vending machine Types and Variations

- Key Industrial Applications of crane national vending machine

- Strategic Material Selection Guide for crane national vending machine

- In-depth Look: Manufacturing Processes and Quality Assurance for crane national vending machine

- Comprehensive Cost and Pricing Analysis for crane national vending machine Sourcing

- Spotlight on Potential crane national vending machine Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for crane national vending machine

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the crane national vending machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of crane national vending machine

- Strategic Sourcing Conclusion and Outlook for crane national vending machine

Introduction: Navigating the Global Market for crane national vending machine

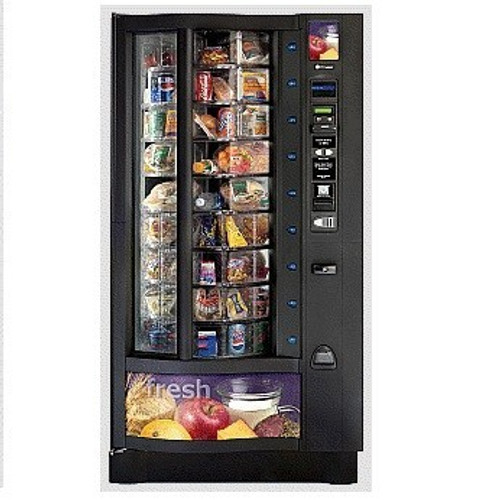

The global market for Crane National Vending Machines is more than just a niche segment; it represents a dynamic intersection of innovation, convenience, and consumer engagement. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe increasingly seek automated solutions, understanding the nuances of this market is critical. Crane National Vending Machines are renowned for their reliability, versatility, and advanced technology, making them a preferred choice for businesses looking to enhance their service offerings.

This comprehensive guide serves as an essential resource for B2B buyers, detailing various aspects of Crane National Vending Machines. It covers the different types of machines available, the materials used in their manufacturing, quality control measures, and insights into reliable suppliers. Additionally, it provides a thorough analysis of costs associated with procurement, market trends, and frequently asked questions that can aid in decision-making.

By equipping buyers with in-depth knowledge and actionable insights, this guide empowers them to make informed sourcing decisions. Whether you’re exploring new vending solutions for a burgeoning market in Saudi Arabia or seeking to optimize operations in Europe, understanding the landscape of Crane National Vending Machines will be pivotal in achieving strategic business objectives. Dive in to discover how to leverage this valuable information for your enterprise’s success in the competitive global market.

Understanding crane national vending machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Snack and Beverage Machines | Offers a variety of snacks and drinks; typically compact | Office break rooms, schools, gyms | Pros: High demand; easy to stock. Cons: Limited product variety can lead to stale inventory. |

| Healthy Option Machines | Focuses on nutritious snacks; often has a modern design | Hospitals, corporate wellness programs | Pros: Appeals to health-conscious consumers; can enhance brand image. Cons: Higher costs for healthier products. |

| Specialty Coffee Machines | Provides a range of coffee beverages; may include fresh brew options | Cafés, hotels, corporate offices | Pros: High profit margins; strong customer loyalty. Cons: Requires regular maintenance and supplies. |

| Multi-Product Machines | Can dispense a variety of items (snacks, drinks, electronics) | Airports, train stations, malls | Pros: Versatile; caters to diverse customer needs. Cons: Complexity can lead to higher maintenance costs. |

| Cashless Payment Machines | Equipped with modern payment systems (credit cards, mobile payments) | Retail environments, public transport | Pros: Enhances convenience; reduces cash handling. Cons: Higher initial investment; potential tech issues. |

Snack and Beverage Machines

These machines are designed to dispense a wide array of snacks and beverages, making them ideal for environments such as offices, schools, and gyms. They are typically compact and user-friendly, allowing for easy access to popular items. When considering a purchase, buyers should evaluate the machine’s capacity, the variety of products it can offer, and the ease of restocking. This type of machine has a high turnover rate, making it a reliable choice for consistent revenue generation.

Healthy Option Machines

Focusing on nutritious snacks, these machines appeal to health-conscious consumers and are often found in hospitals and corporate wellness programs. They can enhance the image of a business by demonstrating a commitment to employee health. Buyers should consider the sourcing of healthy products, as these can be more expensive than traditional snacks. Additionally, the machine’s design should attract customers while ensuring easy access to items.

Specialty Coffee Machines

Specialty coffee vending machines provide a range of coffee beverages, from espresso to cappuccinos, often featuring fresh brewing options. They are commonly used in cafés, hotels, and corporate offices, where the demand for quality coffee is high. Buyers should assess the machine’s brewing capabilities, maintenance requirements, and the cost of coffee supplies. While they can yield high profit margins, the need for regular maintenance and quality control is crucial.

Multi-Product Machines

These versatile machines can dispense a variety of products, including snacks, drinks, and even electronics. They are particularly effective in high-traffic areas such as airports, train stations, and shopping malls, catering to a diverse customer base. When purchasing, buyers should evaluate the machine’s size, product variety, and ease of use. Although they can cater to a wide range of needs, the complexity of these machines may lead to higher maintenance costs.

Cashless Payment Machines

Equipped with advanced payment systems, these machines accept credit cards and mobile payments, making them ideal for retail environments and public transport systems. The convenience of cashless transactions appeals to a growing number of consumers. Buyers should consider the initial investment and potential technical issues that may arise. While they enhance user experience, the reliance on technology necessitates regular updates and maintenance.

Related Video: Crane National Vendors 167 Snack Vending Machine @ UCI Social Ecology 2 – Irvine, CA USA

Key Industrial Applications of crane national vending machine

| Industry/Sector | Specific Application of Crane National Vending Machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Automated snack and beverage dispensing | Increased sales volume, reduced labor costs | Location suitability, machine capacity, product range |

| Education | Campus vending for quick meals and beverages | Enhanced student satisfaction, convenience | User-friendly interface, payment options, maintenance support |

| Transportation & Logistics | Vending solutions at transport hubs (airports, train stations) | Streamlined service, catering to diverse customer needs | Compliance with local regulations, machine durability, product variety |

| Healthcare | Dispensing medical supplies and snacks in hospitals | Improved accessibility for patients and staff | Security features, inventory management, temperature control |

| Corporate Offices | Providing snacks and beverages in office environments | Boosted employee morale, reduced downtime | Payment flexibility, variety of offerings, machine aesthetics |

Retail

In the retail sector, Crane National Vending Machines serve as automated snack and beverage dispensers, strategically placed in high-traffic areas to attract customers. These machines not only increase sales volume by offering 24/7 availability but also reduce labor costs associated with staffing. For international buyers, especially in regions like Africa and South America, it is essential to consider the machine’s capacity and product range to cater to local preferences and purchasing power.

Education

In educational institutions, Crane National Vending Machines provide quick access to meals and beverages, enhancing student satisfaction and convenience. By placing these machines in accessible locations on campuses, schools can ensure that students have healthy snack options available throughout the day. Buyers should focus on user-friendly interfaces and diverse payment options, particularly in the Middle East and Europe, where cashless transactions are increasingly preferred.

Transportation & Logistics

At transport hubs such as airports and train stations, these vending machines streamline service by offering a variety of quick food and beverage options for travelers. This application caters to diverse customer needs, making it easier for passengers to grab essentials on the go. When sourcing machines for this sector, compliance with local regulations regarding food safety and machine durability are critical considerations to ensure operational success.

Healthcare

In healthcare settings, Crane National Vending Machines can dispense medical supplies alongside snacks, improving accessibility for patients and staff. This application addresses the need for quick access to essential items in hospitals, enhancing overall patient care. Buyers in this sector should prioritize security features and effective inventory management, ensuring that the machines remain stocked with necessary supplies while maintaining hygiene standards.

Corporate Offices

In corporate environments, these vending machines provide snacks and beverages to employees, which can significantly boost morale and reduce downtime during work hours. By offering a variety of products, companies can cater to different dietary preferences and promote a healthier workplace culture. Key sourcing considerations include payment flexibility and the machine’s aesthetic appeal, particularly in European markets where design plays a crucial role in workplace ambiance.

Related Video: (New) Crane National Vendors Snack Vending Machine @Four Wheel Parts Store – Riverside, CA USA

Strategic Material Selection Guide for crane national vending machine

When selecting materials for crane national vending machines, international B2B buyers must consider various factors that affect performance, durability, and compliance with regional standards. Below is an analysis of four common materials used in these machines, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

1. Stainless Steel (e.g., AISI 304/316)

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand a wide range of temperatures. Grades like AISI 304 are suitable for general use, while AISI 316 offers enhanced resistance to chlorides, making it ideal for coastal areas.

Pros & Cons:

The durability of stainless steel is a significant advantage, as it can withstand harsh environments without degrading. However, it is more expensive than carbon steel and can be challenging to machine, leading to higher manufacturing costs.

Impact on Application:

Stainless steel is compatible with various media, including food and beverages, making it ideal for vending machines. Its non-reactive nature ensures that the contents remain uncontaminated.

Considerations for International Buyers:

Buyers should ensure compliance with local food safety standards and certifications, such as FDA or EU regulations. Understanding the specific grade’s properties is crucial, as preferences may vary by region.

2. Carbon Steel (e.g., A216 WCB)

Key Properties:

Carbon steel is known for its good strength and toughness. However, it has lower corrosion resistance compared to stainless steel, making it less suitable for humid or corrosive environments.

Pros & Cons:

The primary advantage of carbon steel is its cost-effectiveness, making it a popular choice for budget-conscious projects. On the downside, its susceptibility to corrosion can lead to increased maintenance costs over time.

Impact on Application:

Carbon steel is suitable for non-corrosive fluids and applications where aesthetics are not a primary concern. Its lower durability in harsh environments can limit its use in some regions.

Considerations for International Buyers:

Buyers should be aware of the need for protective coatings to enhance corrosion resistance. Compliance with standards such as ASTM or ISO is essential, depending on the region.

3. Aluminum (e.g., 6061-T6)

Key Properties:

Aluminum is lightweight and has good corrosion resistance. It is also easy to machine and weld, which can simplify manufacturing processes.

Pros & Cons:

The lightweight nature of aluminum is a significant advantage for portable vending machines. However, it is not as strong as steel, which may limit its use in high-load applications.

Impact on Application:

Aluminum is suitable for various media but may not be ideal for high-temperature applications. Its corrosion resistance makes it a good choice for outdoor vending machines in humid environments.

Considerations for International Buyers:

Buyers should verify the aluminum grade to ensure it meets local standards for strength and corrosion resistance. Understanding the local market’s preferences for materials can help in making informed decisions.

4. Polycarbonate

Key Properties:

Polycarbonate is a high-performance plastic known for its impact resistance and transparency. It can withstand a wide temperature range and is lightweight.

Pros & Cons:

The primary advantage of polycarbonate is its durability and resistance to shattering, making it ideal for safety applications. However, it may not be suitable for high-temperature environments and can be more expensive than other plastics.

Impact on Application:

Polycarbonate is often used for protective covers and panels in vending machines. Its clarity allows for visibility of the products inside, enhancing user experience.

Considerations for International Buyers:

Buyers should ensure that the polycarbonate meets relevant safety and environmental standards, such as RoHS compliance. Knowledge of local preferences for materials can influence the choice of polycarbonate grades.

Summary Table

| Material | Typical Use Case for crane national vending machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel (e.g., AISI 304/316) | Food and beverage dispensing, outdoor applications | Excellent corrosion resistance, durability | Higher cost, manufacturing complexity | High |

| Carbon Steel (e.g., A216 WCB) | General structural components, non-corrosive fluids | Cost-effective, good strength | Susceptible to corrosion, higher maintenance costs | Low |

| Aluminum (e.g., 6061-T6) | Portable vending machines, outdoor applications | Lightweight, easy to machine | Lower strength compared to steel | Medium |

| Polycarbonate | Protective covers, panels, visibility features | Impact-resistant, lightweight | Not suitable for high temperatures, costlier than other plastics | Medium |

This guide provides a comprehensive overview of material options for crane national vending machines, helping international B2B buyers make informed decisions based on performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for crane national vending machine

Manufacturing a crane national vending machine involves several critical stages that ensure the final product is efficient, reliable, and meets international quality standards. For B2B buyers, understanding these processes is essential for making informed purchasing decisions, especially when sourcing from diverse regions such as Africa, South America, the Middle East, and Europe.

Manufacturing Process Overview

The manufacturing process of a crane national vending machine typically consists of the following main stages:

-

Material Preparation

– Selection of Materials: High-quality materials such as stainless steel, plastics, and electronic components are chosen based on durability and functionality. Suppliers should provide certifications for the materials used, ensuring compliance with safety and environmental standards.

– Pre-Processing: Materials undergo cutting, welding, and shaping to prepare them for assembly. This stage often involves CNC machining and laser cutting to achieve precise dimensions. -

Forming

– Structural Assembly: The prepared materials are assembled into the machine’s frame. This can involve various techniques such as spot welding, riveting, or bolting, depending on the design specifications.

– Integration of Components: Key components like payment systems, refrigeration units, and dispensing mechanisms are integrated. Manufacturers may use modular assembly techniques to streamline this process, allowing for easier upgrades or repairs in the future. -

Assembly

– Final Assembly: The machine is assembled in a clean environment to avoid contamination. This includes installing the electronic circuitry, touch screens, and any custom branding requested by the buyer.

– Software Installation: Operating software is loaded onto the machine, allowing for user interaction and inventory management. This software must be rigorously tested to ensure it functions seamlessly with the hardware. -

Finishing

– Surface Treatment: The exterior of the vending machine is treated with protective coatings or finishes, such as powder coating or painting, which enhance durability and aesthetics.

– Quality Control Checks: Before the machines leave the factory, they undergo several quality control checks to ensure they meet design specifications and performance standards.

Illustrative Image (Source: Google Search)

Quality Assurance Measures

Quality assurance (QA) is a vital aspect of the manufacturing process that guarantees the vending machines meet both international and industry-specific standards.

International Standards

- ISO 9001: This standard outlines the requirements for a quality management system (QMS). Manufacturers must demonstrate their ability to provide products that consistently meet customer and regulatory requirements.

- CE Marking: For European markets, CE marking indicates conformity with health, safety, and environmental protection standards. This is crucial for B2B buyers in Europe, ensuring the machines are safe to use.

Illustrative Image (Source: Google Search)

Industry-Specific Standards

- API Standards: For machines that may interact with various fluids or gases, adherence to API standards may be necessary. These standards ensure safety and reliability in industrial applications.

Quality Control Checkpoints

Quality control (QC) is integrated throughout the manufacturing process, with specific checkpoints established to monitor quality:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials and components upon arrival at the manufacturing facility. Suppliers should provide certificates of compliance for materials, which can be verified through audits.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, inspections are performed at various stages to ensure that assembly and integration meet quality standards. This may include functional testing of components before they are assembled.

-

Final Quality Control (FQC): Once the machine is fully assembled, a comprehensive inspection is conducted. This includes functional tests, performance checks, and safety assessments. Buyers should request FQC reports to verify compliance with specifications.

Common Testing Methods

Manufacturers employ various testing methods to ensure quality:

- Functional Testing: Machines are powered on, and all functionalities are tested, including payment systems, dispensing mechanisms, and user interfaces.

- Durability Testing: Machines undergo stress tests to ensure they can withstand typical usage conditions without failure.

- Environmental Testing: Vending machines may be tested for performance in different environmental conditions, such as extreme temperatures or humidity levels.

Verifying Supplier Quality Control

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are actionable steps:

- Supplier Audits: Conducting regular audits helps assess the supplier’s adherence to quality standards. Buyers should establish a checklist based on international standards and specific requirements pertinent to their region.

- Quality Reports: Request detailed quality reports, including IQC, IPQC, and FQC documentation. This transparency fosters trust and ensures that the supplier meets established quality benchmarks.

- Third-Party Inspections: Engage third-party inspection services to conduct independent assessments of the manufacturing process and final products. This can provide an unbiased view of the supplier’s quality assurance practices.

Conclusion

Understanding the manufacturing processes and quality assurance standards for crane national vending machines is essential for B2B buyers seeking reliable and compliant products. By focusing on the manufacturing stages, quality control measures, and ways to verify supplier practices, businesses can make informed purchasing decisions that align with their operational needs and regulatory requirements.

Related Video: China’s Top 5 Manufacturing and Mass Production Videos | by @miracleprocess

Comprehensive Cost and Pricing Analysis for crane national vending machine Sourcing

When evaluating the cost structure and pricing for sourcing Crane National vending machines, it is essential to understand the various components that contribute to the overall expenditure. This analysis is particularly relevant for international B2B buyers from regions such as Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The raw materials used in manufacturing vending machines significantly influence the cost. High-quality components like stainless steel for frames and advanced electronic systems for payment processing can elevate the price. Buyers should assess whether the materials meet local standards and regulations, which can also affect costs.

-

Labor: Labor costs vary by region and can be a significant portion of the total manufacturing expense. Countries with higher labor costs may lead to increased pricing. It is advisable to consider the supplier’s location and the corresponding labor market conditions.

-

Manufacturing Overhead: This includes costs associated with production facilities, utilities, equipment maintenance, and indirect labor. Efficient manufacturing processes can lower overhead costs, which may be passed on to buyers.

-

Tooling: Custom tooling for specific machine configurations can incur additional costs. If a buyer requires unique features or sizes, this should be factored into the overall budget.

-

Quality Control (QC): Rigorous quality assurance processes are vital for ensuring the reliability and durability of vending machines. Suppliers that implement stringent QC may charge more, but the long-term benefits, such as reduced maintenance and downtime, often justify the higher upfront costs.

-

Logistics: Shipping costs, including freight, insurance, and handling fees, can vary significantly based on the distance from the supplier and the shipping method chosen. International buyers should be aware of potential import duties and taxes that may apply.

-

Margin: Suppliers typically include a profit margin in their pricing. This margin can vary based on market competition, brand reputation, and the perceived value of the vending machines.

Price Influencers

-

Volume/MOQ: Bulk purchases often lead to better pricing due to economies of scale. Buyers should negotiate minimum order quantities (MOQ) that can maximize their cost savings.

-

Specifications/Customization: Custom specifications can increase costs. Buyers should clearly define their requirements to avoid unnecessary expenses related to modifications.

-

Materials and Quality/Certifications: The choice of materials and the availability of certifications (e.g., ISO) can impact pricing. Machines that meet higher standards may come at a premium but can provide assurance of quality.

-

Supplier Factors: Supplier reputation, reliability, and experience can influence pricing. Established suppliers may charge more but offer better service and support.

-

Incoterms: Understanding the terms of trade (Incoterms) is crucial. These terms dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can significantly affect overall costs.

Buyer Tips

-

Negotiation: Engage in negotiations to secure the best possible price. Leverage competitive quotes from multiple suppliers to strengthen your bargaining position.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes purchase price, operational costs, maintenance, and potential resale value. A lower upfront cost may not always translate to better long-term value.

-

Pricing Nuances: International buyers should be aware of regional pricing strategies, as factors such as currency fluctuations, local demand, and import regulations can affect pricing.

Disclaimer

The prices discussed herein are indicative and may fluctuate based on market conditions and specific buyer requirements. It is advisable for buyers to conduct thorough research and obtain multiple quotes to ensure competitive pricing and optimal value.

Spotlight on Potential crane national vending machine Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘crane national vending machine’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for crane national vending machine

When considering the procurement of a crane national vending machine, understanding its essential technical properties and common trade terminology is crucial for making informed purchasing decisions. This section will outline key specifications and terms that international B2B buyers should be familiar with, particularly those from Africa, South America, the Middle East, and Europe.

Key Technical Properties

-

Material Grade

– Definition: The quality and type of materials used in construction, such as stainless steel or high-grade plastic.

– Importance: Higher material grades ensure durability and longevity, which are essential for machines that will face outdoor elements or heavy usage. Buyers should consider the environmental conditions in their region when selecting material grades. -

Dimensions and Weight Capacity

– Definition: The size of the vending machine and its maximum load-bearing capacity.

– Importance: Understanding the dimensions is critical for space planning in deployment locations. Additionally, knowing the weight capacity helps buyers ensure the machine can accommodate the intended products without risking damage or malfunction. -

Power Requirements

– Definition: The voltage and power consumption specifications of the vending machine.

– Importance: Different regions have varying electrical standards. Buyers must ensure that the machine is compatible with local power supply specifications to avoid operational issues. -

Temperature Range

– Definition: The operational temperature limits within which the vending machine can function effectively.

– Importance: For buyers in regions with extreme temperatures, understanding this property is vital to ensure the machine will operate reliably without overheating or freezing. -

Payment System Compatibility

– Definition: The types of payment methods accepted, such as cash, credit cards, or mobile payments.

– Importance: Compatibility with local payment systems can significantly affect sales volume. Buyers should consider the preferences of their target market when evaluating payment options. -

User Interface Design

– Definition: The layout and functionality of the machine’s interface for customers.

– Importance: A user-friendly interface can enhance customer experience and increase sales. It’s important for buyers to consider the demographics of their target audience when selecting interface features.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Relevance: Buyers should identify if they are purchasing from an OEM or a reseller to understand the quality and warranty implications. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Relevance: Understanding MOQ is essential for budget planning and inventory management. Buyers should negotiate MOQs that align with their purchasing needs. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers requesting a price quotation for specific products or services.

– Relevance: An RFQ is a critical tool for buyers to solicit competitive pricing and terms from multiple suppliers, ensuring the best deal. -

Incoterms (International Commercial Terms)

– Definition: A series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) related to international commercial law.

– Relevance: Familiarity with Incoterms helps buyers understand their responsibilities and liabilities during shipping, reducing risks associated with international trade. -

Lead Time

– Definition: The amount of time taken from placing an order to delivery.

– Relevance: Buyers need to be aware of lead times for planning purposes, especially when launching new products or entering new markets. -

Warranty Terms

– Definition: The conditions under which a manufacturer will repair or replace a defective product.

– Relevance: Understanding warranty terms is crucial for risk management. Buyers should seek warranties that provide adequate coverage for their investment.

By grasping these technical properties and trade terminologies, international B2B buyers can enhance their procurement strategies, ensuring they select the right crane national vending machine for their business needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the crane national vending machine Sector

Market Overview & Key Trends

The crane national vending machine sector is experiencing significant transformation driven by advancements in technology and changing consumer behaviors. Global drivers include the increasing demand for contactless payment systems, which have gained traction in the wake of the COVID-19 pandemic. This shift is particularly evident in regions such as Africa and South America, where mobile payment solutions are becoming mainstream, offering B2B buyers new avenues for transactions.

Emerging B2B tech trends are also reshaping the market landscape. Smart vending machines equipped with IoT capabilities are enabling real-time inventory management and predictive analytics, thus enhancing operational efficiency. Buyers from the Middle East and Europe are increasingly seeking machines that offer personalized customer experiences through data analytics, allowing for tailored product offerings based on consumer preferences.

Additionally, the dynamics of the market are shifting as sustainability becomes a priority. B2B buyers are now more inclined to partner with suppliers who demonstrate a commitment to sustainable practices. This includes sourcing machines made from recycled materials and ensuring energy efficiency in their operation. As competition intensifies, understanding these trends will be crucial for international buyers looking to make informed decisions in their procurement processes.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer a mere trend but a crucial aspect of business operations in the crane national vending machine sector. The environmental impact of vending machines, particularly concerning energy consumption and waste generation, has prompted a shift towards more sustainable practices. Buyers are increasingly focusing on machines that are designed for lower energy consumption and made from environmentally friendly materials.

Ethical supply chains are gaining importance, as buyers seek transparency in sourcing practices. This includes ensuring that materials are obtained from responsible sources and that labor practices meet international standards. B2B buyers should prioritize suppliers who can provide evidence of their sustainability initiatives, such as certifications from recognized environmental organizations.

Furthermore, green certifications are becoming a vital criterion for procurement. Buyers should look for machines that carry certifications such as ENERGY STAR or those recognized under ISO 14001, which indicates a commitment to reducing environmental impact. By aligning procurement strategies with sustainable practices, businesses can not only enhance their brand reputation but also cater to the growing consumer demand for eco-friendly solutions.

Brief Evolution/History

The crane national vending machine sector has evolved significantly since its inception. Originally designed as simple coin-operated devices, these machines have transformed into sophisticated platforms that integrate advanced technology. The introduction of electronic payment systems in the late 20th century marked a pivotal moment, paving the way for cashless transactions.

As technology continued to advance, the integration of telemetry and remote monitoring in the early 2000s allowed operators to manage their machines more efficiently. Today, the focus has shifted towards smart vending solutions that leverage data analytics to optimize inventory and enhance customer engagement. This evolution reflects broader trends in consumer behavior and technological advancements, positioning the crane national vending machine sector for continued growth in the global marketplace.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of crane national vending machine

-

What should I consider when vetting suppliers of Crane National vending machines?

When vetting suppliers, check their reputation, experience in the industry, and customer feedback. Request references from past clients and assess their response times and customer service. Additionally, verify their compliance with international standards and certifications relevant to vending machines. This ensures that you are partnering with a reliable supplier capable of meeting your specific needs. -

Can I customize the features of my Crane National vending machine?

Yes, many suppliers offer customization options. You can often select the machine’s size, color, branding, and product configurations to suit your market needs. Discuss your requirements with the supplier early in the negotiation process to ensure they can meet your expectations. Additionally, inquire about any additional costs associated with customization.

-

What are the typical minimum order quantities (MOQ) and lead times for Crane National vending machines?

MOQs vary by supplier and can range from a single unit to several dozen, depending on the model and customization. Lead times typically range from 4 to 12 weeks, depending on the complexity of the order and the supplier’s production capacity. Always confirm these details upfront to avoid delays in your supply chain. -

What payment terms are common when purchasing Crane National vending machines?

Payment terms can differ significantly among suppliers. Common arrangements include a deposit upon order confirmation, followed by the balance before shipping. Some suppliers may offer financing options or extended payment terms for larger orders. Always clarify payment methods accepted, including bank transfers or letters of credit, to facilitate smooth transactions. -

How can I ensure quality assurance and certifications for the machines?

Request documentation regarding quality assurance processes and certifications, such as ISO 9001 or CE marking, which indicate compliance with international safety and quality standards. Suppliers should provide test results and warranty information. Consider conducting third-party inspections before shipment to verify that the machines meet your quality expectations. -

What logistics considerations should I keep in mind when importing vending machines?

Logistics is crucial when importing vending machines. Assess shipping methods, costs, and estimated delivery times. Ensure the supplier has experience in international shipping and is familiar with customs regulations. It’s also beneficial to engage a reliable freight forwarder who can assist with documentation and handling any potential import challenges. -

What steps should I take if I encounter disputes with a supplier?

In case of a dispute, maintain open communication with the supplier to resolve issues amicably. Refer to your contract for terms regarding dispute resolution, which may include mediation or arbitration. Document all communications and agreements. If necessary, seek legal advice to understand your rights and obligations in the context of international trade. -

How can I effectively manage after-sales support and service for my vending machines?

Before finalizing your purchase, inquire about after-sales support options, including maintenance services and spare parts availability. A good supplier should offer technical assistance and a warranty for parts and labor. Establish a clear line of communication for support issues and ensure that you have access to service manuals and troubleshooting guides to facilitate smooth operations.

Strategic Sourcing Conclusion and Outlook for crane national vending machine

As we conclude our exploration of Crane National Vending Machines, it’s essential to underscore the strategic sourcing insights that can significantly benefit international B2B buyers. The integration of advanced technology, customizable options, and robust support systems makes Crane machines a compelling choice for enhancing vending operations in diverse markets.

Key takeaways include the importance of aligning product specifications with local market demands, understanding regulatory requirements, and leveraging supplier partnerships for optimal service delivery. By focusing on these areas, businesses can achieve greater efficiency and customer satisfaction.

Strategic sourcing not only mitigates risks but also opens avenues for innovation and cost savings. As markets continue to evolve, particularly in regions like Africa, South America, the Middle East, and Europe, staying ahead of trends will be crucial.

Looking ahead, we encourage B2B buyers to actively engage with suppliers, explore new technologies, and consider the long-term benefits of investing in high-quality vending solutions. The future of vending is ripe with opportunities—seize them to ensure your business remains competitive and responsive to consumer needs.