Master Sourcing Bulk Vending Machines for Profitable

Guide to Bulk Vending Machines

- Introduction: Navigating the Global Market for bulk vending machines

- Understanding bulk vending machines Types and Variations

- Key Industrial Applications of bulk vending machines

- Strategic Material Selection Guide for bulk vending machines

- In-depth Look: Manufacturing Processes and Quality Assurance for bulk vending machines

- Comprehensive Cost and Pricing Analysis for bulk vending machines Sourcing

- Spotlight on Potential bulk vending machines Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for bulk vending machines

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the bulk vending machines Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of bulk vending machines

- Strategic Sourcing Conclusion and Outlook for bulk vending machines

Introduction: Navigating the Global Market for bulk vending machines

In today’s rapidly evolving marketplace, bulk vending machines have emerged as a pivotal player in the retail landscape, offering a unique blend of convenience and profitability. With their ability to dispense a wide variety of products—from snacks to toys—these machines cater to diverse consumer needs while providing business owners with a low-maintenance revenue stream. For international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, understanding the intricacies of bulk vending machines is essential for making informed purchasing decisions.

This comprehensive guide delves into critical aspects of bulk vending machines, including various types, materials used in manufacturing, quality control standards, and supplier options. Additionally, it addresses cost considerations, market trends, and frequently asked questions that can influence sourcing strategies. By equipping buyers with actionable insights and data, the guide empowers them to navigate the global market effectively and optimize their investment in bulk vending machines.

As you explore this resource, you will gain a deeper understanding of how to select the right machines that align with your business goals, ensuring a competitive edge in your local market. Whether you are in Spain, the UAE, or any other region, this guide is designed to facilitate smarter sourcing decisions and enhance your operational efficiency in the burgeoning vending sector.

Understanding bulk vending machines Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Gravity Feed Machines | Simple design using gravity to dispense products | Schools, offices, and retail stores | Easy to refill and maintain; may jam with certain products. |

| Electronic Machines | Equipped with digital interfaces and payment options | Shopping malls, airports, and events | Higher upfront cost; offers convenience and tracking capabilities. |

| Rotary Machines | Circular dispensing system with multiple product options | Amusement parks, arcades, and fairs | Attracts customers with variety; requires more space. |

| Bulk Candy Machines | Specifically designed for dispensing bulk candy and snacks | Confectionery shops, cinemas | High customer appeal; can lead to impulse purchases but needs regular monitoring. |

| Specialty Vending Machines | Customized for specific products like toys or healthy snacks | Gyms, schools, and niche markets | Tailored to target demographics; potential for higher margins but may have limited appeal. |

Gravity Feed Machines

Gravity feed machines are the simplest form of bulk vending machines. They operate by allowing gravity to dispense products, typically snacks or small toys, into a collection area when a user interacts with the machine. These machines are particularly suitable for environments like schools and offices where quick, low-cost snacks are in demand. B2B buyers should consider the ease of refilling and maintenance, although they may experience issues with jamming if the product sizes vary significantly.

Electronic Machines

Electronic bulk vending machines incorporate digital interfaces, offering advanced features like cashless payment options and inventory tracking. These machines are ideal for high-traffic areas such as shopping malls and airports, where convenience is paramount. While they come with a higher initial investment, the potential for increased sales through digital payment methods and data analytics can justify the cost for B2B buyers. Consideration should also be given to the reliability of electronic components in various climates.

Rotary Machines

Rotary machines feature a circular dispensing mechanism that allows customers to choose from multiple product options in one machine. They are commonly found in amusement parks, arcades, and fairs, where variety and visual appeal are key to attracting customers. For B2B buyers, the main advantages include the ability to offer a broad range of products, although space requirements can be a drawback in smaller locations. Regular maintenance is necessary to ensure smooth operation.

Bulk Candy Machines

Designed specifically for dispensing bulk candy and snacks, these machines capitalize on the impulse purchase behavior of consumers. They are often placed in high-traffic areas such as cinemas and confectionery shops, where they can attract attention and drive sales. B2B buyers should note the high customer appeal of these machines, but they require consistent monitoring and restocking to maintain product availability and freshness.

Specialty Vending Machines

Specialty vending machines can be customized to dispense niche products, such as health-focused snacks or unique toys. They are particularly effective in targeted environments like gyms, schools, and specific market segments. B2B buyers benefit from the potential for higher profit margins due to the tailored offerings, but they should be aware that the limited appeal of specialized products may restrict broader market reach.

Related Video: How Large Language Models Work

Key Industrial Applications of bulk vending machines

| Industry/Sector | Specific Application of bulk vending machines | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Candy and snack vending in supermarkets | Increases impulse purchases, low operational cost | Product selection, machine reliability, payment options |

| Education | Vending machines in schools and universities | Provides convenient access to snacks and drinks | Compliance with health regulations, machine durability |

| Hospitality | Vending solutions in hotels and resorts | Enhances guest experience, generates additional revenue | Custom branding, product variety, maintenance support |

| Transportation | Bulk vending in airports and train stations | Quick service for travelers, reduces queue times | Machine size and placement, energy efficiency |

| Events and Exhibitions | Vending at trade shows and festivals | Attracts attendees, provides quick refreshments | Mobility, ease of setup, payment system integration |

Retail Sector

In supermarkets, bulk vending machines are strategically placed to capture impulse purchases. They offer a wide range of candy, snacks, and other items, making them a convenient choice for shoppers looking for quick snacks. For international buyers, especially in regions like Africa and South America, it is crucial to consider the local preferences in product selection and ensure that machines are equipped to handle diverse payment methods, including mobile payments, to cater to a broader audience.

Education Sector

Schools and universities utilize bulk vending machines to provide students with easy access to snacks and beverages. This not only satisfies students’ cravings but also generates additional revenue for the institution. Buyers in this sector should prioritize machines that comply with health and nutritional guidelines, particularly in Europe and the Middle East, where regulations on food items are stringent. Durability and ease of maintenance are also key considerations to minimize downtime.

Hospitality Sector

In hotels and resorts, bulk vending machines enhance the guest experience by providing 24/7 access to snacks and drinks. This amenity can be a significant revenue generator while also improving guest satisfaction. B2B buyers from the hospitality industry should focus on machines that allow for custom branding to align with the hotel’s aesthetic. Additionally, offering a diverse product range that includes healthier options can cater to various guest preferences, particularly in more health-conscious markets.

Transportation Sector

Airports and train stations benefit from bulk vending machines by offering travelers quick access to snacks and beverages, helping to reduce queue times and improve service efficiency. For buyers in this sector, machine size and placement are critical, as they need to fit within often limited space while accommodating high foot traffic. Energy-efficient machines can also help reduce operational costs, making them a sustainable choice for transport hubs.

Events and Exhibitions Sector

At trade shows and festivals, bulk vending machines can attract attendees looking for quick refreshments. These machines provide a unique opportunity for brands to engage with consumers in a lively setting. Buyers should consider mobility and ease of setup when sourcing machines for events, as well as ensuring that payment systems are integrated for a seamless transaction experience. Additionally, offering a variety of products that cater to different tastes can enhance the overall event experience.

Related Video: Kooler Ice Vending Machines – IM600XL vs. IM1000

Strategic Material Selection Guide for bulk vending machines

When selecting materials for bulk vending machines, international B2B buyers must consider various factors that influence performance, durability, and compliance with regional standards. The following analysis focuses on four common materials used in the construction of bulk vending machines: stainless steel, plastic, aluminum, and glass. Each material has unique properties, advantages, and drawbacks, which can significantly impact the machine’s functionality and marketability.

Stainless Steel

Key Properties: Stainless steel is known for its high corrosion resistance, strength, and ability to withstand a wide range of temperatures. It typically has a temperature rating of up to 870°C (1600°F) and is resistant to rust and staining, making it ideal for environments where hygiene is paramount.

Pros & Cons: The primary advantage of stainless steel is its durability and long lifespan, which can justify its higher initial cost. However, it can be more challenging to manufacture due to its hardness, leading to increased production costs. Additionally, while it is easy to clean, it can be prone to scratches, which may affect its aesthetic appeal over time.

Impact on Application: Stainless steel is suitable for vending machines dispensing food items due to its hygienic properties. It is compatible with a variety of media, including snacks and beverages.

Considerations for International Buyers: Buyers should ensure that the stainless steel complies with standards such as ASTM A240 or DIN 1.4301. In regions like Europe and the UAE, certifications for food safety and hygiene are crucial.

Plastic

Key Properties: Plastic materials, such as polyethylene and polypropylene, are lightweight and offer good chemical resistance. They can typically withstand temperatures ranging from -40°C to 80°C (-40°F to 176°F).

Pros & Cons: The main advantage of plastic is its low cost and ease of manufacturing, which allows for complex shapes and designs. However, plastics may not be as durable as metals and can degrade over time when exposed to UV light, leading to brittleness.

Impact on Application: Plastic is often used for internal components and storage bins in vending machines. It is suitable for non-food items or packaged goods, where exposure to moisture and temperature fluctuations is minimal.

Considerations for International Buyers: Buyers should verify compliance with relevant plastic safety standards, such as FDA regulations in the U.S. or REACH in Europe. Understanding local recycling regulations is also essential, especially in regions with strict environmental policies.

Aluminum

Key Properties: Aluminum is lightweight and has good corrosion resistance, typically rated for temperatures up to 600°C (1112°F). It is also a good conductor of heat, which can be beneficial in certain applications.

Pros & Cons: The key advantage of aluminum is its strength-to-weight ratio, making it an excellent choice for portable vending machines. However, it can be more expensive than plastic and may require protective coatings to enhance corrosion resistance, particularly in humid environments.

Impact on Application: Aluminum is often used for structural components and frames of vending machines. Its lightweight nature makes it suitable for machines that need to be moved frequently.

Considerations for International Buyers: Buyers should ensure that aluminum components meet standards such as ASTM B221 or EN AW-6060. In the Middle East and Africa, where humidity can be high, additional coatings may be necessary to prevent corrosion.

Glass

Key Properties: Glass is a strong, non-porous material that can withstand high temperatures and is resistant to chemical corrosion. It is also aesthetically pleasing, providing a clear view of the products inside.

Pros & Cons: The primary advantage of glass is its durability and the premium look it provides, which can enhance the machine’s appeal. However, glass is heavier and more fragile than other materials, making it susceptible to breakage.

Impact on Application: Glass is commonly used for display panels in vending machines, particularly for high-end products. It is compatible with a wide range of items, including beverages and snacks.

Considerations for International Buyers: Buyers should ensure that glass components comply with safety standards, such as ANSI Z97.1 or EN 12150. In regions with strict safety regulations, such as Europe, using tempered glass may be necessary to prevent injuries from breakage.

| Material | Typical Use Case for bulk vending machines | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food dispensing areas | High durability and corrosion resistance | Higher manufacturing complexity | High |

| Plastic | Internal components and storage bins | Low cost and easy to mold | Less durable, UV degradation | Low |

| Aluminum | Structural frames | Lightweight with good strength | Higher cost, may need coatings | Medium |

| Glass | Display panels | Aesthetic appeal and durability | Heavier and fragile | Medium to High |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling them to make informed decisions when sourcing materials for bulk vending machines. Understanding the properties, advantages, and limitations of each material, along with compliance considerations, is crucial for successful procurement and operational efficiency.

In-depth Look: Manufacturing Processes and Quality Assurance for bulk vending machines

Manufacturing Processes for Bulk Vending Machines

Manufacturing bulk vending machines involves a series of well-defined stages that ensure the final product is functional, durable, and meets market standards. Each stage contributes to the overall quality and reliability of the machines. Here’s an overview of the key manufacturing processes:

1. Material Preparation

The first step in the manufacturing process is the selection and preparation of materials. Common materials used include:

– Metal Components: Steel and aluminum are preferred for their strength and durability.

– Plastic Parts: High-density polyethylene (HDPE) is often used for hoppers and dispensers due to its lightweight and corrosion-resistant properties.

– Electronic Components: Circuit boards and sensors are crucial for the machine’s operation.

Materials undergo thorough inspection to ensure they meet specified standards. Suppliers should provide certificates of compliance, which can be verified during the procurement process.

2. Forming

Once materials are prepared, they are shaped into the desired components through various forming techniques:

– Metal Stamping: This technique is used to create the body and structural components of the vending machine. It involves cutting and shaping metal sheets into precise forms.

– Injection Molding: Used for plastic components, this process involves injecting molten plastic into a mold to create parts like the coin mechanisms and hoppers.

– Laser Cutting: Employed for both metal and plastic parts, laser cutting provides high precision and can handle complex designs.

These processes are essential for achieving the required tolerances and ensuring the components fit together correctly during assembly.

3. Assembly

The assembly process is where all the manufactured components come together. Key steps include:

– Component Integration: Each part, from the mechanical to the electronic components, is assembled in a systematic manner.

– Wiring and Electronics Installation: This involves connecting sensors, motors, and control panels, ensuring that all electrical components function correctly.

– Quality Checks: Throughout assembly, inspections are conducted to catch any defects early, reducing waste and rework.

4. Finishing

The final stage involves applying finishes to enhance the machine’s appearance and protect it from environmental factors. This includes:

– Painting or Powder Coating: These processes provide a protective layer and aesthetic appeal. Powder coating is often preferred for its durability.

– Final Assembly Inspection: A thorough inspection of the completed machine ensures that all components are securely attached and functioning as intended.

Quality Assurance in Manufacturing

Quality assurance (QA) is critical in ensuring that bulk vending machines meet international standards and customer expectations. Implementing robust QA processes can significantly reduce defects and improve customer satisfaction.

International Standards

To align with global best practices, manufacturers often adhere to several international standards, including:

– ISO 9001: This standard focuses on quality management systems, ensuring that manufacturers consistently meet customer and regulatory requirements.

– CE Marking: Essential for products sold in the European Economic Area, it indicates conformity with health, safety, and environmental protection standards.

– API Standards: Particularly relevant for machines that involve complex mechanical systems, these standards ensure that products are safe and reliable.

Quality Control Checkpoints

A structured approach to quality control (QC) involves several checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specifications before production begins.

– In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to catch defects early.

– Final Quality Control (FQC): A comprehensive inspection of the finished product to verify that it meets all specifications and standards.

Common Testing Methods

Testing methods used in quality assurance include:

– Functional Testing: Ensures that all mechanical and electronic components operate correctly.

– Durability Testing: Simulates real-world use to assess the machine’s longevity and resilience.

– Safety Testing: Verifies that the machine complies with safety standards, especially in regions like Europe and the Middle East.

Verifying Supplier Quality Control

For B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, it is essential to verify the quality control practices of suppliers before making a commitment. Here are actionable steps to consider:

-

Conduct Audits: Regular audits of suppliers can help assess their manufacturing processes and quality control measures. This may include both onsite inspections and reviewing their quality management documentation.

-

Request Quality Reports: Suppliers should be able to provide comprehensive reports detailing their quality assurance processes, including any certifications they hold and results from previous audits.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of a supplier’s capabilities and quality assurance practices. This is particularly useful for buyers who may not have the resources to conduct thorough inspections themselves.

-

Understand Certification Nuances: Different regions may have varying requirements for certifications. Buyers should ensure that suppliers meet the specific standards relevant to their market, such as CE marking for Europe or local standards in Africa and South America.

Conclusion

Understanding the manufacturing processes and quality assurance practices of bulk vending machines is crucial for B2B buyers. By focusing on key manufacturing stages, recognizing international standards, and implementing rigorous quality control measures, buyers can ensure they select reliable suppliers that meet their business needs. Adopting a proactive approach to supplier verification will help mitigate risks and enhance the overall purchasing experience.

Related Video: How Nutella Is Made In Factory? Bulk Production Of Chocolate Spread Using Advanced Machines

Comprehensive Cost and Pricing Analysis for bulk vending machines Sourcing

To effectively navigate the sourcing landscape for bulk vending machines, it’s crucial to understand the cost structure and pricing dynamics involved. This knowledge can empower international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, to make informed purchasing decisions.

Cost Components of Bulk Vending Machines

-

Materials: The primary cost driver in bulk vending machines is the raw materials used in their construction, such as metal casings, plastic components, and mechanical parts. The quality and sourcing of these materials can significantly impact the overall price.

-

Labor: Labor costs include wages for skilled and unskilled workers involved in manufacturing. In regions with higher labor costs, such as parts of Europe, this can be a significant factor. Conversely, sourcing from countries with lower labor costs can yield savings.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities, equipment maintenance, and factory rent. Understanding the overhead structure can provide insights into the pricing strategies of suppliers.

-

Tooling: The costs associated with the design and manufacturing of molds and tools necessary for production can be substantial, especially for customized machines. Buyers should consider whether they need standard models or custom designs, as this can affect tooling expenses.

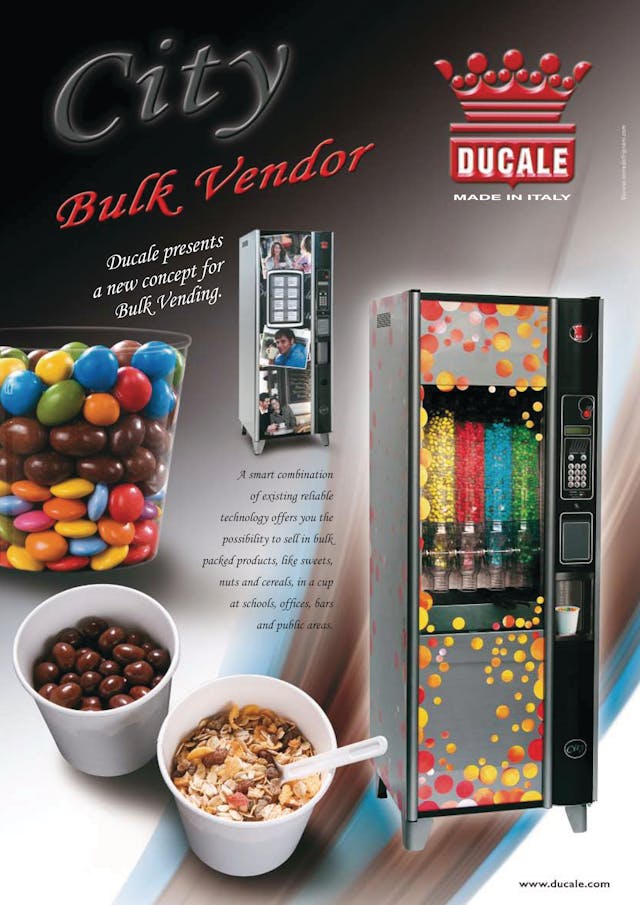

Illustrative Image (Source: Google Search)

-

Quality Control (QC): Ensuring that machines meet specific quality standards incurs costs related to inspection and testing processes. Machines with higher quality certifications may command higher prices but can lead to lower maintenance costs and improved reliability.

-

Logistics: Transportation and shipping costs can vary widely based on the distance, mode of transport, and Incoterms used. Effective logistics planning can mitigate unexpected expenses.

-

Margin: Suppliers will typically apply a profit margin on top of their costs. Understanding industry norms for margins can help buyers gauge whether they are receiving a fair price.

Price Influencers

Several factors influence the pricing of bulk vending machines:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit prices. Buyers should evaluate their needs to negotiate better pricing based on volume.

-

Specifications/Customization: Custom features or specifications can significantly increase costs. Buyers should clearly define their requirements to avoid unnecessary expenses.

-

Materials: The choice of materials directly affects durability and cost. High-quality materials may increase initial costs but can reduce long-term maintenance and replacement expenses.

-

Quality/Certifications: Machines that meet specific industry standards may come at a premium. However, they often result in lower total costs over their lifespan due to enhanced reliability.

-

Supplier Factors: Supplier reputation, reliability, and service levels can influence pricing. Engaging with reputable suppliers may yield better support and warranty services.

-

Incoterms: The agreed-upon Incoterms can shift costs and responsibilities between buyers and sellers, affecting total expenses. Buyers should understand their implications to ensure favorable terms.

Buyer Tips

For international B2B buyers, the following strategies can enhance cost-efficiency:

-

Negotiate: Always negotiate pricing and terms. Building a relationship with suppliers can lead to better deals and terms over time.

-

Consider Total Cost of Ownership (TCO): Evaluate not only the initial purchase price but also maintenance, operation, and potential downtime costs. A lower upfront cost may not always be the best value.

-

Pricing Nuances: Be aware of regional pricing variations and currency fluctuations that may impact costs. Understanding local market conditions in Africa, South America, the Middle East, and Europe is essential for effective budgeting.

-

Request Quotes from Multiple Suppliers: This practice can provide a better understanding of market rates and help identify the best value options.

Disclaimer

Prices for bulk vending machines can vary widely based on specifications, location, and other factors. The insights provided here are intended for indicative purposes only, and buyers should conduct thorough due diligence when engaging with suppliers.

Spotlight on Potential bulk vending machines Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘bulk vending machines’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for bulk vending machines

Key Technical Properties of Bulk Vending Machines

When purchasing bulk vending machines, understanding the technical specifications is crucial for ensuring optimal performance and longevity. Here are some essential properties to consider:

-

Material Grade

The material used in the construction of bulk vending machines, typically stainless steel or high-grade plastic, directly affects durability and resistance to corrosion. Stainless steel is preferred for outdoor or high-traffic areas due to its longevity and ease of cleaning, while high-grade plastic can offer lightweight and cost-effective alternatives for indoor use. For B2B buyers, selecting the appropriate material can significantly impact maintenance costs and machine lifespan. -

Capacity

The capacity of a vending machine refers to the volume it can hold, typically measured in liters or number of products. Machines with larger capacities are ideal for high-traffic locations as they require less frequent restocking. Understanding capacity helps buyers assess the machine’s suitability for their specific business environment and customer demand. -

Power Supply Requirements

Most bulk vending machines operate on standard voltage, but some may require specific electrical configurations. Knowing the power supply requirements ensures that the machine can be installed without additional electrical work, thereby saving time and costs during setup. -

Dimensions and Weight

The physical size and weight of the vending machine are vital for determining its placement in a designated area. Buyers should ensure that the machine fits the intended location, taking into account any space restrictions. Additionally, heavier machines may require sturdier support or specific flooring considerations. -

User Interface and Payment Systems

Modern bulk vending machines often come with advanced user interfaces, including touch screens and various payment options (e.g., cash, credit cards, mobile payments). The ease of use can enhance customer satisfaction and increase sales. For B2B buyers, investing in machines with versatile payment systems can cater to a broader customer base. -

Safety Features

Look for machines equipped with safety features such as tamper-proof locks, anti-theft designs, and compliance with local safety regulations. These features not only protect the investment but also ensure a secure purchasing experience for customers.

Common Trade Terminology in Bulk Vending

Familiarizing yourself with industry jargon can facilitate smoother transactions and negotiations. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. When buying bulk vending machines, understanding whether the vendor is an OEM can indicate the quality and reliability of the product. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for budgeting and inventory management. Buyers should negotiate this term to align with their demand forecasts. -

RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers. It outlines the specifications of the required products. B2B buyers should prepare comprehensive RFQs to receive accurate pricing and product details, ensuring informed purchasing decisions. -

Incoterms (International Commercial Terms)

These are pre-defined commercial terms published by the International Chamber of Commerce that outline the responsibilities of buyers and sellers in international transactions. Understanding Incoterms helps buyers clarify shipping costs, insurance, and liability, reducing potential disputes. -

Lead Time

This term refers to the time taken from placing an order to delivery. Knowing the lead time is crucial for planning inventory and sales strategies, especially in fast-paced markets. Buyers should factor in lead times when evaluating suppliers to ensure timely product availability. -

Warranty and Service Agreements

These agreements outline the terms of service and maintenance provided by the manufacturer. Understanding warranty conditions can protect your investment and ensure that you have support in case of product failure. Buyers should always clarify the duration and coverage of warranties before finalizing a purchase.

Illustrative Image (Source: Google Search)

In summary, being well-versed in the essential technical properties and trade terminology of bulk vending machines empowers B2B buyers to make informed decisions, leading to successful procurement and operational efficiency.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the bulk vending machines Sector

Market Overview & Key Trends

The bulk vending machine sector is experiencing a dynamic transformation driven by several global trends. The rise of cashless payment systems is reshaping consumer interactions with vending machines, making it essential for international B2B buyers to source machines equipped with modern payment technologies. In regions like Africa and South America, where mobile payment adoption is surging, vending machines that support mobile wallets can enhance sales and accessibility.

Moreover, the growing demand for healthy and organic snacks is influencing product offerings within bulk vending machines. This trend presents opportunities for buyers to source machines that can accommodate diverse products, including nuts, dried fruits, and other health-oriented options. The focus on personalized customer experiences is also leading to the integration of IoT technology in vending machines, allowing for real-time inventory management and tailored marketing strategies based on consumer behavior.

Sourcing trends are increasingly leaning towards manufacturers who prioritize innovation and flexibility. Buyers are seeking suppliers who can offer customizable vending solutions that cater to local preferences and market demands. As international logistics continue to evolve, buyers must also consider suppliers with robust distribution networks, especially in emerging markets where efficiency can significantly impact product availability.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a crucial factor for buyers in the bulk vending machine sector. The environmental impact of traditional vending operations—particularly concerning single-use plastics—has prompted a shift towards eco-friendly practices. Buyers are encouraged to seek out machines that utilize sustainable materials and feature energy-efficient components, as these not only reduce environmental footprints but also appeal to increasingly eco-conscious consumers.

Ethical sourcing practices are gaining traction as well. Buyers should prioritize suppliers who demonstrate transparency in their supply chains, ensuring that all materials are sourced responsibly. Certifications such as Fair Trade and Forest Stewardship Council (FSC) can provide assurance regarding the ethical origins of the products offered in vending machines. Emphasizing these certifications can enhance brand reputation and attract customers who value corporate responsibility.

Furthermore, integrating recycling programs within vending operations can significantly enhance sustainability efforts. Encouraging consumers to recycle packaging directly at the vending machine can position businesses as leaders in environmental stewardship, thus fostering customer loyalty and brand trust.

Brief Evolution/History

The bulk vending machine industry has evolved significantly since its inception in the early 20th century. Originally, these machines primarily dispensed simple products like candy and gumballs. However, as consumer preferences shifted towards healthier options, the sector began incorporating more diverse and nutritious products.

The introduction of technology has been pivotal in this evolution. From mechanical coin mechanisms to today’s advanced cashless payment systems and IoT connectivity, the evolution reflects broader technological advancements. This progression not only enhances operational efficiency but also aligns with contemporary consumer demands for convenience and personalization. As the industry continues to innovate, B2B buyers must stay informed about emerging technologies that can drive growth and improve customer engagement.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of bulk vending machines

-

What criteria should I use to vet suppliers of bulk vending machines?

When sourcing bulk vending machines, it’s essential to evaluate suppliers based on their experience, reputation, and certifications. Look for suppliers with a proven track record in international trade, particularly those who understand the regulatory requirements of your region (e.g., Africa, South America, Middle East, Europe). Request client references and check online reviews. Additionally, ensure they provide quality certifications, such as ISO, which can indicate adherence to international quality standards. -

Can I customize the bulk vending machines to fit my business needs?

Yes, many suppliers offer customization options for bulk vending machines. You can request modifications in size, design, color, and product dispensing mechanisms to align with your branding and operational needs. Discuss your specific requirements upfront to ensure the supplier can accommodate your requests. This may also include the type of products you intend to dispense, ensuring the machine is suitable for them. -

What are the typical minimum order quantities (MOQs) and lead times for bulk vending machines?

MOQs for bulk vending machines can vary significantly based on the supplier and the level of customization. Generally, MOQs may range from 10 to 50 units. Lead times can also differ, typically ranging from 4 to 12 weeks, depending on production schedules and shipping times. Always clarify these details during negotiations to avoid potential delays in your supply chain. -

What payment methods are commonly accepted by suppliers?

Most suppliers accept various payment methods, including bank transfers, letters of credit, and online payment platforms. It’s essential to discuss and agree on payment terms before placing an order. Consider using secure payment methods that offer buyer protection, especially when dealing with international suppliers. Establishing a clear payment schedule can also help maintain transparency and trust in the transaction. -

How do I ensure quality assurance and certifications for the machines?

To ensure quality assurance, request detailed product specifications and certifications from your supplier. Quality certifications such as CE, UL, or ISO 9001 indicate compliance with international safety and quality standards. It’s also advisable to conduct factory audits if possible, or request third-party inspections before shipment to verify that the machines meet your quality expectations. -

What logistics considerations should I keep in mind when importing bulk vending machines?

When importing bulk vending machines, consider logistics factors like shipping methods, customs clearance, and potential tariffs. Work with a freight forwarder who has experience in handling similar imports to navigate the complexities of international shipping. Ensure that all necessary documentation, such as commercial invoices and packing lists, is prepared accurately to avoid customs delays. -

How can I resolve disputes with suppliers effectively?

To resolve disputes effectively, maintain clear and open communication with your supplier. Establish a written agreement that outlines terms and conditions, including dispute resolution processes. If a disagreement arises, attempt to resolve it amicably through negotiation. Should that fail, consider mediation or arbitration, as these methods are often faster and less costly than legal proceedings. -

What are the best practices for maintaining bulk vending machines once purchased?

Regular maintenance is crucial for the longevity and efficiency of bulk vending machines. Implement a routine cleaning schedule to prevent product jams and ensure hygiene. Additionally, monitor inventory levels frequently to manage restocking efficiently. Establish a relationship with your supplier for technical support and spare parts availability, ensuring you can address any operational issues promptly.

Strategic Sourcing Conclusion and Outlook for bulk vending machines

In conclusion, strategic sourcing for bulk vending machines is vital for international B2B buyers aiming to optimize their operations and maximize profitability. Key takeaways include understanding the importance of evaluating suppliers based on quality, reliability, and cost-effectiveness. Establishing strong relationships with manufacturers and distributors can yield significant advantages, including better pricing, customized solutions, and enhanced after-sales support.

For buyers in regions such as Africa, South America, the Middle East, and Europe, leveraging local market insights and trends is crucial. Engage with suppliers who understand regional consumer preferences and can provide tailored products that cater to these needs. Additionally, consider the evolving landscape of sustainability, as eco-friendly vending solutions gain traction globally.

As you look ahead, remain proactive in your sourcing strategies. Assess new technologies and market entrants that can enhance your vending machine offerings. By prioritizing strategic sourcing, you position your business for growth and resilience in an increasingly competitive marketplace. Take action now—connect with trusted vendors and explore innovative products to stay ahead in the bulk vending industry.