Master Sourcing Bouncy Ball Vending Machines for Maximum

Guide to Bouncy Ball Vending Machine

- Introduction: Navigating the Global Market for bouncy ball vending machine

- Understanding bouncy ball vending machine Types and Variations

- Key Industrial Applications of bouncy ball vending machine

- Strategic Material Selection Guide for bouncy ball vending machine

- In-depth Look: Manufacturing Processes and Quality Assurance for bouncy ball vending machine

- Comprehensive Cost and Pricing Analysis for bouncy ball vending machine Sourcing

- Spotlight on Potential bouncy ball vending machine Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for bouncy ball vending machine

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the bouncy ball vending machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of bouncy ball vending machine

- Strategic Sourcing Conclusion and Outlook for bouncy ball vending machine

Introduction: Navigating the Global Market for bouncy ball vending machine

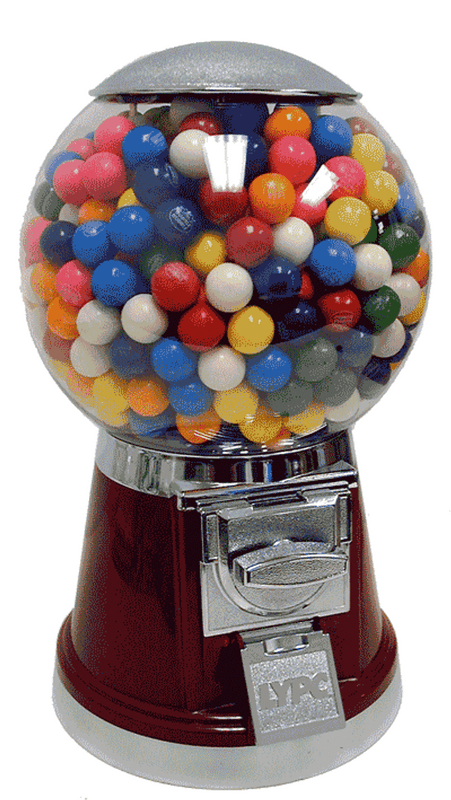

In the vibrant world of amusement and entertainment, bouncy ball vending machines stand out as a lucrative investment opportunity for B2B buyers across diverse global markets. These machines not only enhance customer engagement in venues such as arcades, shopping malls, and playgrounds but also serve as a source of recurring revenue. As international buyers from regions like Africa, South America, the Middle East, and Europe explore new avenues for profit, understanding the nuances of bouncy ball vending machines becomes crucial.

This comprehensive guide delves into the multifaceted landscape of bouncy ball vending machines, covering various types and materials, manufacturing processes, and quality control measures. It highlights key suppliers and provides insights into cost structures, enabling buyers to make informed decisions that align with their business objectives.

With a focus on the unique needs and preferences of international markets, this guide empowers B2B buyers to navigate the complexities of sourcing bouncy ball vending machines effectively. From understanding market trends to addressing frequently asked questions, it serves as a valuable resource for those looking to capitalize on this engaging and profitable venture. By leveraging the insights provided, businesses can enhance their competitive edge and drive success in an increasingly dynamic global marketplace.

Understanding bouncy ball vending machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Capsule Machine | Simple design, typically holds 1-inch bouncy balls | Shopping malls, amusement parks | Pros: Easy to maintain, low cost. Cons: Limited variety of products. |

| Electronic Vending Machine | Digital interface, accepts cash and cards | Retail stores, arcades | Pros: Attracts tech-savvy customers, higher sales potential. Cons: Higher initial investment and maintenance costs. |

| Toy & Prize Machine | Dispenses a mix of toys and bouncy balls | Family entertainment centers | Pros: Increased engagement, diverse offerings. Cons: Requires regular restocking and inventory management. |

| Multi-Product Vending Machine | Offers various types of bouncy balls and other items | Events, festivals | Pros: Versatile, can cater to different customer preferences. Cons: Complexity in inventory and management. |

| Customizable Vending Machine | Personalization options for branding and product selection | Corporate events, trade shows | Pros: Enhances brand visibility, tailored offerings. Cons: Higher upfront cost and longer lead time for customization. |

Classic Capsule Machine

The classic capsule machine is a staple in the vending industry, characterized by its straightforward design that typically dispenses 1-inch bouncy balls. These machines are commonly found in shopping malls and amusement parks, making them an ideal choice for businesses looking to attract families and children. The primary considerations for B2B buyers include ease of maintenance and low operational costs, although the limited product variety may not appeal to all markets.

Electronic Vending Machine

Electronic vending machines are equipped with digital interfaces and can accept various payment methods, including cash and credit cards. These machines are increasingly popular in retail stores and arcades, appealing to a tech-savvy clientele. While they offer higher sales potential and can attract more customers, buyers must weigh the benefits against higher initial investments and ongoing maintenance costs.

Toy & Prize Machine

Toy and prize machines provide a mix of bouncy balls and small toys, enhancing customer engagement through diverse offerings. These machines are typically found in family entertainment centers and can significantly boost foot traffic. B2B buyers should consider the need for regular restocking and effective inventory management, as the appeal of these machines relies on a fresh selection of prizes.

Multi-Product Vending Machine

Multi-product vending machines can dispense various types of bouncy balls along with other items, making them suitable for events and festivals. Their versatility allows businesses to cater to different customer preferences, increasing potential sales. However, the complexity of inventory management can be a drawback, as it requires careful planning to ensure a balanced offering that meets customer demands.

Customizable Vending Machine

Customizable vending machines allow businesses to personalize branding and product selection, making them ideal for corporate events and trade shows. This feature enhances brand visibility and can create a unique customer experience. However, buyers should be prepared for higher upfront costs and a longer lead time for customization, which may not be feasible for all businesses.

Related Video: AI, Machine Learning, Deep Learning and Generative AI Explained

Key Industrial Applications of bouncy ball vending machine

| Industry/Sector | Specific Application of bouncy ball vending machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | In-store entertainment for children | Increases foot traffic and customer engagement | Location suitability, machine size, and product variety |

| Amusement Parks | Game prizes and rewards | Enhances visitor experience and encourages repeat visits | Durability, maintenance support, and product sourcing |

| Schools and Educational Institutions | Fundraising and school events | Generates additional revenue for programs and activities | Compliance with safety standards, product customization |

| Recreation Centers | Family entertainment zones | Attracts families and increases overall patronage | Machine reliability, ease of operation, and service options |

| Event Venues | Prize distribution at festivals and fairs | Boosts event engagement and provides memorable experiences | Custom branding options, machine aesthetics, and logistics |

Retail

In retail environments, bouncy ball vending machines serve as an engaging entertainment option for children, which can significantly increase foot traffic. By placing these machines near checkout counters or waiting areas, retailers can keep children occupied, leading to longer shopping durations for parents. International buyers should consider the local preferences for colors and themes in bouncy balls to ensure product appeal, alongside machine size and compliance with safety regulations.

Amusement Parks

At amusement parks, bouncy ball vending machines can be used as game prizes, adding an element of fun and reward for visitors. This not only enhances the overall visitor experience but also encourages families to return for more entertainment. Buyers in this sector should focus on the durability of the machines and the ease of maintenance, as high foot traffic can lead to wear and tear. Additionally, sourcing vibrant and diverse ball designs can enhance the attraction’s appeal.

Schools and Educational Institutions

Bouncy ball vending machines can be a creative fundraising tool for schools during events or as part of their regular offerings. They provide a fun way for students to engage while supporting school programs. Buyers in this field need to ensure compliance with safety standards, particularly in terms of materials used, as well as the option for customization to reflect school branding or themes.

Recreation Centers

In recreation centers, bouncy ball vending machines can be strategically placed within family entertainment zones to attract visitors. These machines not only provide entertainment but also encourage families to spend more time at the facility, ultimately increasing revenue. Key considerations for international buyers include the reliability of the machines and the availability of service options to minimize downtime.

Event Venues

At event venues, bouncy ball vending machines can be utilized for prize distribution during festivals and fairs, enhancing engagement and creating memorable experiences for attendees. These machines can be customized with branding to fit specific events, making them visually appealing. When sourcing for this application, buyers should focus on aesthetics and logistics to ensure timely delivery and setup, as well as the ability to handle high volumes of transactions during peak times.

Related Video: How to Make Vending Machine with Gumball

Strategic Material Selection Guide for bouncy ball vending machine

When selecting materials for bouncy ball vending machines, it is essential to consider various factors that influence performance, durability, and compliance with international standards. Below is an analysis of four common materials used in the construction of these machines, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

1. Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance and high strength. It can withstand a wide range of temperatures and pressures, making it suitable for various environments.

Pros & Cons:

– Advantages: Durable and resistant to rust and corrosion, which is crucial for vending machines exposed to outdoor conditions or high humidity environments. Additionally, it offers a sleek appearance, enhancing the machine’s aesthetic appeal.

– Disadvantages: Higher initial cost compared to carbon steel or plastic. Manufacturing can be complex due to the need for specialized tools and techniques.

Impact on Application:

Stainless steel is compatible with various media, including food products, which is essential for vending machines that dispense items like candy or snacks.

Considerations for International Buyers:

Buyers should ensure compliance with food safety standards (e.g., FDA in the U.S., EU regulations) and verify that the stainless steel grades used meet local requirements, such as ASTM or DIN standards.

2. Carbon Steel

Key Properties:

Carbon steel is characterized by its high tensile strength and durability but is susceptible to corrosion without proper treatment.

Pros & Cons:

– Advantages: Cost-effective and readily available, making it a popular choice for many manufacturers. It is relatively easy to machine and fabricate.

– Disadvantages: Requires protective coatings to prevent rust and corrosion, especially in humid or outdoor environments.

Impact on Application:

While it can be used in the construction of bouncy ball vending machines, its susceptibility to corrosion may limit its application in environments where moisture is prevalent.

Considerations for International Buyers:

Buyers should consider the need for protective coatings and ensure compliance with local standards for structural materials, such as JIS or ASTM.

3. Polycarbonate

Key Properties:

Polycarbonate is a strong, lightweight thermoplastic known for its high impact resistance and optical clarity.

Pros & Cons:

– Advantages: Lightweight and shatter-resistant, making it ideal for transparent sections of vending machines. It is also easy to mold and shape, allowing for creative designs.

– Disadvantages: Less resistant to scratching compared to other materials and can degrade under prolonged exposure to UV light unless treated.

Impact on Application:

Polycarbonate is suitable for parts of the vending machine that require visibility, such as the display area for the bouncy balls.

Considerations for International Buyers:

Buyers should check for compliance with safety standards regarding plastic materials and UV resistance, especially in regions with high sunlight exposure.

4. Aluminum

Key Properties:

Aluminum is lightweight and has good corrosion resistance due to the formation of a protective oxide layer.

Pros & Cons:

– Advantages: Offers a good strength-to-weight ratio and is easy to fabricate. It is also resistant to corrosion, making it suitable for various environments.

– Disadvantages: Can be more expensive than carbon steel and may not provide the same structural strength in heavy-duty applications.

Impact on Application:

Aluminum is often used for machine frames and structural components, where weight savings are essential without compromising durability.

Considerations for International Buyers:

Buyers should ensure that the aluminum grades used comply with international standards and consider the environmental impact of aluminum production and recycling.

Summary Table

| Material | Typical Use Case for bouncy ball vending machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural components, outer casing | Excellent corrosion resistance and durability | Higher initial cost, complex manufacturing | High |

| Carbon Steel | Structural components, internal framework | Cost-effective and strong | Susceptible to corrosion, requires coatings | Low |

| Polycarbonate | Transparent sections, display areas | Lightweight and shatter-resistant | Less scratch-resistant, UV degradation risks | Medium |

| Aluminum | Frames, structural components | Good strength-to-weight ratio | Higher cost than carbon steel, less strength | Medium |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling informed decisions when sourcing materials for bouncy ball vending machines.

In-depth Look: Manufacturing Processes and Quality Assurance for bouncy ball vending machine

Manufacturing Processes for Bouncy Ball Vending Machines

The manufacturing of bouncy ball vending machines involves several critical stages, each essential for ensuring the durability and functionality of the final product. For international B2B buyers, understanding these processes can help in selecting reliable suppliers and ensuring product quality.

1. Material Preparation

The first stage involves sourcing and preparing the materials required for the vending machines. Common materials include:

- Metal Components: Steel or aluminum for the frame and internal mechanisms.

- Plastic: High-density polyethylene (HDPE) for the ball dispensing mechanism and housing.

- Electronic Components: Wiring, coin acceptors, and displays.

Suppliers must ensure that materials meet international standards for safety and durability. Buyers should look for suppliers who provide certificates of compliance for materials used, particularly if sourcing from regions with varying manufacturing standards.

2. Forming

In the forming stage, raw materials are shaped into parts using various techniques. Key techniques include:

- Stamping: Metal sheets are stamped to create precise shapes for the machine’s body and components.

- Injection Molding: Plastic parts are produced by injecting molten plastic into molds, allowing for complex designs and high-volume production.

Buyers should inquire about the machinery and technology used in this stage, as modern equipment can enhance precision and reduce defects.

3. Assembly

The assembly stage combines all the formed parts into a functioning unit. This typically involves:

- Mechanical Assembly: Components such as the vending mechanism, coin acceptor, and display are assembled.

- Electrical Assembly: Wiring and electronic components are integrated, ensuring that all electronic parts function correctly.

Quality during assembly is crucial, as improper assembly can lead to mechanical failures. B2B buyers should confirm that suppliers use skilled labor and automated systems where applicable to enhance accuracy.

4. Finishing

Finishing processes improve the aesthetics and durability of the vending machines. Techniques include:

- Painting and Coating: Protective coatings are applied to metal parts to prevent corrosion, while paint enhances visual appeal.

- Quality Inspection: Each unit undergoes a thorough inspection to ensure it meets design specifications.

B2B buyers should ask about the types of coatings used and their compliance with environmental regulations.

Quality Assurance in Manufacturing

Quality assurance (QA) is vital in ensuring that bouncy ball vending machines meet both international and industry-specific standards.

International Standards

- ISO 9001: This standard focuses on quality management systems, ensuring that manufacturers consistently meet customer and regulatory requirements.

- CE Marking: For machines sold in Europe, compliance with safety, health, and environmental protection standards is mandatory.

- API Standards: If applicable, these standards focus on safety and reliability in manufacturing processes.

Illustrative Image (Source: Google Search)

QC Checkpoints

Quality control (QC) involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Inspects raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Monitors the production process to catch defects early.

- Final Quality Control (FQC): Conducts comprehensive testing of finished products to ensure they meet all specifications.

Each checkpoint should have documented procedures and results, which buyers can request from suppliers.

Common Testing Methods

To ensure that the vending machines function as intended, several testing methods are typically employed:

- Functional Testing: Verifies that all components operate correctly.

- Durability Testing: Assesses the machine’s ability to withstand environmental stressors, such as humidity and temperature changes.

- Safety Testing: Ensures that machines comply with safety regulations, including electrical safety tests.

B2B buyers should ensure that their suppliers have robust testing protocols in place and that they can provide documentation of these tests.

Verifying Supplier Quality Control

B2B buyers can take several steps to verify the quality control practices of potential suppliers:

- Audits: Conduct regular audits of suppliers’ manufacturing facilities to assess compliance with quality standards.

- Reports: Request detailed QC reports that outline inspection and testing results.

- Third-Party Inspections: Engage independent agencies to conduct inspections and provide unbiased evaluations of the supplier’s quality processes.

QC and Certification Nuances for International Buyers

When dealing with international suppliers, particularly from regions like Africa, South America, the Middle East, and Europe, it is essential to understand specific nuances:

- Cultural Differences: Business practices and quality expectations may vary significantly. It’s crucial to communicate clearly and establish mutual expectations.

- Regulatory Compliance: Different regions may have unique regulatory requirements. Buyers should ensure that suppliers are familiar with the necessary certifications for their specific markets.

- Supply Chain Transparency: Request transparency about the supply chain, including the sourcing of materials and the steps taken to ensure quality at each stage.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing bouncy ball vending machines, ensuring they receive high-quality products that meet international standards.

Related Video: Amazing scenes。Top 6 Most Popular Factory Manufacturing Videos in China

Comprehensive Cost and Pricing Analysis for bouncy ball vending machine Sourcing

When sourcing bouncy ball vending machines, understanding the comprehensive cost structure and pricing dynamics is crucial for B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. This analysis covers the key cost components, price influencers, and strategic buyer tips to ensure informed purchasing decisions.

Cost Components

-

Materials: The primary cost component includes the raw materials used to manufacture the vending machines. Common materials include metal for the frame, plastic for the housing, and glass for the display. Prices can vary significantly based on material quality and availability.

-

Labor: Labor costs encompass wages for skilled workers involved in manufacturing and assembly. Depending on the region, labor costs can fluctuate due to local wage standards and worker availability.

- Manufacturing Overhead: This includes indirect costs related to production, such as utilities, rent, and equipment depreciation. Efficient production practices can help minimize these costs.

- Tooling: The initial investment in tools and molds necessary for manufacturing can be substantial. Buyers should consider these costs, especially if they require custom designs.

-

Quality Control (QC): Implementing rigorous QC processes ensures that the machines meet safety and performance standards. This can involve additional costs but is essential for maintaining product reliability.

-

Logistics: Shipping costs depend on the distance from the manufacturer to the buyer and the chosen transportation mode. Incoterms will dictate who bears these costs, affecting overall pricing.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding industry standards for margins can aid in negotiating better terms.

Price Influencers

-

Volume/MOQ: The minimum order quantity (MOQ) can significantly impact pricing. Larger orders often lead to discounts due to economies of scale.

-

Specifications/Customization: Custom features or specifications will generally increase costs. Buyers should evaluate the necessity of customization against their budget.

-

Materials Quality/Certifications: Higher-quality materials and certifications (e.g., CE, ISO) may command higher prices but can enhance durability and safety, making them a worthwhile investment.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more but offer better quality assurance and service.

-

Incoterms: The choice of Incoterms affects cost allocation between buyer and seller, influencing the final price. Understanding these terms is vital for accurate budgeting.

Buyer Tips

-

Negotiation: Effective negotiation can yield better pricing and terms. Buyers should be prepared to discuss volume, payment terms, and delivery schedules to secure favorable conditions.

-

Cost-Efficiency: Evaluate the total cost of ownership (TCO), which includes not just the purchase price but also maintenance, operational costs, and potential resale value.

-

Pricing Nuances for International Buyers: Buyers from different regions should be aware of currency fluctuations, import duties, and local taxes that can affect the final cost of the vending machines.

-

Research and Compare: Conduct thorough market research and compare multiple suppliers to gauge competitive pricing. This can also provide leverage during negotiations.

Disclaimer

Prices for bouncy ball vending machines can vary widely based on the factors outlined above. It is advisable for buyers to obtain detailed quotes from multiple suppliers and consider all associated costs before making a purchasing decision.

Spotlight on Potential bouncy ball vending machine Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘bouncy ball vending machine’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for bouncy ball vending machine

Key Technical Properties of Bouncy Ball Vending Machines

When evaluating bouncy ball vending machines, several technical specifications are critical for ensuring quality and functionality. Here are the essential properties to consider:

-

Material Grade

– The materials used in construction, typically steel or high-grade plastic, determine the machine’s durability and resistance to wear and tear. High-quality materials can withstand harsh environmental conditions, making them ideal for outdoor settings. -

Capacity

– This refers to the number of bouncy balls the machine can hold, usually measured in units (e.g., 200 or 400 balls). A higher capacity allows for less frequent refilling, which is essential for businesses with high foot traffic, ensuring continuous operation. -

Dimensions and Weight

– The size and weight of the vending machine affect its placement and stability. Compact designs are more suitable for smaller spaces, while heavier models may require additional support. Understanding these specifications helps buyers select machines that fit their intended locations. -

Locking Mechanism

– A secure locking mechanism is vital for preventing theft and ensuring the safety of the contents. Buyers should look for machines with robust locks, preferably with key or combination access, to safeguard their investments. -

Dispensing Mechanism

– The method by which balls are dispensed is crucial for user experience. Machines can utilize gravity-fed or motorized dispensing mechanisms. Reliable mechanisms minimize jams and ensure that customers receive their products smoothly. -

Payment System Compatibility

– Vending machines may accept various payment methods, including coins, bills, or digital payments. Compatibility with modern payment systems can enhance user convenience and increase sales.

Common Trade Terms in the Vending Machine Industry

Understanding industry-specific jargon can significantly streamline communication and negotiation processes. Here are several essential terms:

-

OEM (Original Equipment Manufacturer)

– Refers to companies that produce parts or equipment that may be marketed by another manufacturer. For buyers, partnering with an OEM can ensure high-quality, customized machines tailored to specific needs. -

MOQ (Minimum Order Quantity)

– This is the smallest number of units a supplier is willing to sell. Knowing the MOQ helps buyers assess their budget and inventory requirements, especially for bulk purchases. -

RFQ (Request for Quotation)

– A document sent to suppliers asking for a price quote on specific products. An RFQ allows buyers to compare costs and terms from different vendors, facilitating better decision-making. -

Incoterms (International Commercial Terms)

– A set of predefined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, risks, and responsibilities. -

Lead Time

– The time taken from placing an order to delivery. Understanding lead times is crucial for inventory management and planning, especially for businesses that rely on timely product availability. -

Warranty

– A guarantee provided by the manufacturer regarding the condition of the product and the terms of repair or replacement. A robust warranty can offer peace of mind for buyers, ensuring they are covered in case of defects or issues.

By familiarizing themselves with these specifications and terms, international B2B buyers can make informed purchasing decisions and optimize their vending machine operations across various markets, including Africa, South America, the Middle East, and Europe.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the bouncy ball vending machine Sector

Market dynamics and sourcing trends in the bouncy ball vending machine sector are shaped by various global drivers and regional demands. The growing popularity of vending machines as a retail solution, particularly in urban areas, is a significant factor. In regions like Africa and South America, where traditional retail spaces may be limited, bouncy ball vending machines offer an accessible and engaging way to reach consumers, especially children. The rise of mobile payments and contactless transactions has also transformed the vending experience, allowing for seamless transactions and attracting a tech-savvy demographic.

Emerging B2B technology trends include the integration of IoT (Internet of Things) capabilities in vending machines, enabling real-time inventory tracking and data analytics. This advancement allows operators to optimize stock levels and respond to consumer preferences more effectively. Additionally, the increasing use of digital signage on vending machines can enhance marketing strategies by promoting specific products based on location and audience demographics. For international buyers, particularly from Europe and the Middle East, understanding these technological advancements is crucial for making informed purchasing decisions.

Another noteworthy trend is the shift towards customization and personalization in vending offerings. Buyers are increasingly seeking machines that can accommodate a diverse range of products beyond traditional bouncy balls, such as toys, snacks, and beverages, to cater to varying consumer tastes. This diversification can significantly enhance profitability and appeal to a broader audience.

Illustrative Image (Source: Google Search)

Sustainability & Ethical Sourcing in B2B

In the bouncy ball vending machine sector, sustainability and ethical sourcing are becoming paramount concerns for B2B buyers. The environmental impact of production processes, particularly in the plastic industry, has led to increased scrutiny from consumers and regulators alike. B2B buyers must consider the lifecycle of products, including how they are produced, used, and disposed of. This emphasis on sustainability encourages manufacturers to adopt eco-friendly materials, such as biodegradable plastics or recycled materials, which can significantly reduce the environmental footprint of vending machines.

Additionally, ethical supply chains are critical. Buyers should prioritize suppliers who adhere to fair labor practices and environmental regulations. Certifications such as ISO 14001 (Environmental Management) and Fair Trade can help in assessing the sustainability and ethical standards of suppliers. Furthermore, opting for ‘green’ materials not only enhances a company’s brand image but also meets the growing consumer demand for environmentally responsible products.

Brief Evolution/History

The bouncy ball vending machine has evolved significantly since its inception. Initially simple mechanical devices, these machines have transformed into sophisticated, tech-driven solutions that cater to a wide array of consumer preferences. The introduction of electronic payment systems and digital displays has modernized the user experience, while the incorporation of IoT technologies offers real-time data management. This evolution reflects broader trends in consumer behavior, where convenience and technological integration are paramount. For B2B buyers, understanding this history is essential for recognizing the potential of modern vending solutions in enhancing customer engagement and profitability.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of bouncy ball vending machine

-

What should I consider when vetting suppliers for bouncy ball vending machines?

When vetting suppliers, prioritize their experience in the industry, production capabilities, and reputation. Check for certifications that meet international standards, such as ISO 9001, which indicates quality management practices. Request references from previous clients to gauge reliability. Additionally, assess their communication responsiveness and willingness to customize products to your specific needs, as this can significantly impact your partnership. -

Can I customize the design and features of the bouncy ball vending machines?

Yes, many suppliers offer customization options to align the machines with your branding and operational needs. This can include color, graphics, coin mechanisms, and the type of bouncy balls dispensed. Discuss your requirements upfront and inquire about any additional costs associated with customization. Ensure that the supplier can provide samples or mock-ups before finalizing the order. -

What are the typical minimum order quantities (MOQ) and lead times for these machines?

MOQs can vary widely among suppliers, typically ranging from 10 to 50 units, depending on the manufacturer’s capacity and your customization requests. Lead times are generally between 4 to 12 weeks, influenced by factors such as order size and customization complexity. Always confirm these details during initial discussions to avoid unexpected delays in your supply chain. -

What payment terms are commonly offered for international orders?

Payment terms can differ based on the supplier’s policies and your negotiation. Common options include a deposit (30-50%) upfront, with the balance due prior to shipping. Some suppliers may accept letters of credit or escrow services to mitigate risk. Ensure you understand the terms and any associated fees, especially for international transactions, to maintain cash flow and budget control. -

How can I ensure quality assurance for the machines I purchase?

Request quality assurance documentation from suppliers, including test reports and inspection certificates. It’s advisable to conduct pre-shipment inspections through third-party services, especially when ordering large quantities. Familiarize yourself with the supplier’s quality control processes to ensure they align with your standards. Consider including quality clauses in your contract to protect your interests. -

What certifications should I look for in bouncy ball vending machines?

Look for certifications that demonstrate compliance with safety and environmental standards, such as CE marking for European markets or UL certification for North America. These certifications ensure that the machines meet specific safety and operational standards. Additionally, inquire about any relevant local certifications that may be required in your target market to avoid compliance issues. -

What logistics considerations should I keep in mind when importing these machines?

Understand the shipping methods available, such as sea freight or air freight, and their respective costs and transit times. Collaborate with a logistics provider experienced in handling large machinery to navigate customs regulations and duties. Ensure the supplier provides necessary documentation, such as commercial invoices and packing lists, to streamline the import process and prevent delays. -

How should I handle disputes with suppliers during the procurement process?

Establish clear communication channels and document all agreements to minimize misunderstandings. If disputes arise, attempt to resolve them amicably through discussion. If necessary, refer to the terms outlined in your contract regarding dispute resolution, which may include mediation or arbitration. It’s advisable to seek legal counsel experienced in international trade to assist with complex disputes, ensuring your interests are protected.

Strategic Sourcing Conclusion and Outlook for bouncy ball vending machine

In conclusion, strategic sourcing for bouncy ball vending machines is essential for international B2B buyers aiming to optimize their investment and maximize profitability. Understanding the diverse supplier landscape across regions such as Africa, South America, the Middle East, and Europe enables buyers to leverage competitive pricing and innovative product features. By prioritizing quality, supplier reliability, and after-sales support, businesses can enhance customer satisfaction and drive repeat sales.

Key takeaways include the importance of conducting thorough market research, establishing strong relationships with suppliers, and staying informed about industry trends. Additionally, integrating technology into vending solutions can offer significant advantages in operational efficiency and customer engagement.

Looking ahead, the demand for bouncy ball vending machines is poised to grow, driven by trends in entertainment and retail. Buyers are encouraged to act now, aligning their sourcing strategies with these emerging market opportunities. By doing so, they can secure a competitive edge and foster sustainable business growth in an evolving marketplace.