Master Sourcing Automatic Food Vending Machines for Your

Guide to Automatic Food Vending Machine

- Introduction: Navigating the Global Market for automatic food vending machine

- Understanding automatic food vending machine Types and Variations

- Key Industrial Applications of automatic food vending machine

- Strategic Material Selection Guide for automatic food vending machine

- In-depth Look: Manufacturing Processes and Quality Assurance for automatic food vending machine

- Comprehensive Cost and Pricing Analysis for automatic food vending machine Sourcing

- Spotlight on Potential automatic food vending machine Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for automatic food vending machine

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the automatic food vending machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of automatic food vending machine

- Strategic Sourcing Conclusion and Outlook for automatic food vending machine

Introduction: Navigating the Global Market for automatic food vending machine

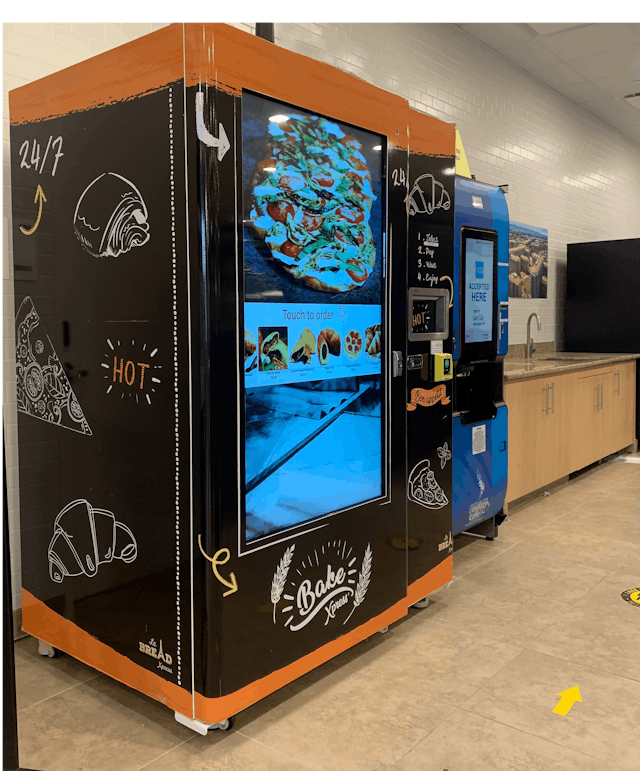

In today’s fast-paced world, automatic food vending machines represent a vital intersection of convenience, innovation, and consumer demand. As urban lifestyles evolve, these machines not only provide quick access to meals and snacks but also address diverse dietary preferences and cultural tastes. For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of this market is essential for making informed sourcing decisions.

This comprehensive guide delves into the myriad aspects of automatic food vending machines, covering various types available, the materials used in their construction, and the manufacturing and quality control processes that ensure reliability and safety. Additionally, we will provide insights into top suppliers, cost considerations, and the current market trends influencing buyer choices.

By equipping you with critical information and addressing frequently asked questions, this guide aims to empower you to navigate the complexities of sourcing automatic food vending machines. Whether you are looking to enhance your current offerings or explore new market opportunities, understanding this sector can lead to strategic advantages in an increasingly competitive landscape. Embrace the potential of automatic food vending machines to meet the evolving needs of your customers and drive your business forward.

Understanding automatic food vending machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Snack Vending | Offers a variety of packaged snacks and beverages | Offices, schools, public areas | Pros: Easy to operate; low maintenance. Cons: Limited healthy options; can become outdated. |

| Fresh Food Vending | Provides perishable items like sandwiches and salads | Airports, hospitals, universities | Pros: Appeals to health-conscious consumers; high turnover. Cons: Requires regular restocking; higher spoilage risk. |

| Automated Coffee Machines | Specializes in brewing and dispensing coffee beverages | Cafés, offices, hotels | Pros: Customizable drinks; high demand for coffee. Cons: Higher initial investment; maintenance can be complex. |

| Smart Vending Machines | Uses IoT technology for inventory management and sales tracking | Retail stores, tech hubs | Pros: Real-time data analytics; enhanced customer engagement. Cons: Higher cost; requires reliable internet connection. |

| Healthy Snack Vending | Focuses on nutritious snacks and beverages | Gyms, corporate wellness programs | Pros: Meets increasing demand for healthy options; attracts health-focused clients. Cons: May have lower sales volume compared to traditional snacks. |

Traditional Snack Vending

Traditional snack vending machines are designed to dispense a variety of packaged snacks and beverages. These machines are commonly found in offices, schools, and public areas where convenience is key. Buyers appreciate their ease of operation and low maintenance requirements. However, they often lack healthier options, which can be a drawback in today’s health-conscious market.

Fresh Food Vending

Fresh food vending machines offer perishable items such as sandwiches, salads, and fruits. They are particularly suited for high-traffic locations like airports, hospitals, and universities where quick, healthy meal options are in demand. While they can achieve high turnover rates and appeal to health-conscious consumers, these machines require regular restocking and carry a higher risk of spoilage.

Automated Coffee Machines

Automated coffee machines focus on brewing and dispensing various coffee beverages, catering to the growing coffee culture. They are ideal for cafés, offices, and hotels where coffee consumption is high. These machines allow for customizable drinks, making them appealing to a wide range of customers. However, they require a higher initial investment and can involve complex maintenance.

Smart Vending Machines

Smart vending machines utilize Internet of Things (IoT) technology to enhance user experience and streamline operations. They can track inventory in real-time and provide valuable sales analytics. These machines are increasingly popular in retail stores and tech hubs. Despite their advantages, smart vending machines come with a higher cost and depend on a reliable internet connection for optimal performance.

Healthy Snack Vending

Healthy snack vending machines focus on providing nutritious snacks and beverages, catering to the growing demand for health-oriented options. They are often found in gyms and corporate wellness programs, attracting health-focused clients. While they meet consumer demand for healthier choices, these machines may experience lower sales volumes compared to their traditional counterparts.

Related Video: AI, Machine Learning, Deep Learning and Generative AI Explained

Key Industrial Applications of automatic food vending machine

| Industry/Sector | Specific Application of automatic food vending machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Patient and staff meal services | Streamlined meal distribution, reduced wait times | Compliance with health regulations, temperature control capabilities |

| Education | Campus dining solutions | Increased accessibility to meals, reduced labor costs | Customization options, payment system integration |

| Corporate Offices | Employee snack and beverage services | Enhanced employee satisfaction, increased productivity | Variety of products offered, machine maintenance services |

| Transportation Hubs | Quick service food options at airports and stations | Improved customer experience, reduced congestion | Durable design for high traffic, payment method flexibility |

| Retail | 24/7 convenience food sales | Increased sales opportunities, reduced staffing needs | Inventory management systems, product freshness monitoring |

Healthcare Applications

In healthcare settings, automatic food vending machines are essential for providing quick meal services to patients and staff. These machines can be strategically placed in waiting areas or near patient rooms, offering nutritious meal options that cater to various dietary needs. They help solve the problem of long wait times for food service, especially in facilities with limited staff. Buyers in this sector should ensure compliance with health regulations and look for machines equipped with temperature control features to maintain food safety.

Educational Institutions

In educational environments, such as universities and colleges, automatic food vending machines serve as a convenient dining solution for students. By offering a variety of meal options, these machines cater to the fast-paced lifestyle of students who may not have time to sit down for a meal. The benefit lies in increased accessibility to food, which can lead to higher student satisfaction and retention rates. B2B buyers should consider customization options that reflect local tastes and dietary preferences, alongside seamless payment system integration for ease of use.

Corporate Offices

For corporate offices, automatic food vending machines provide employees with quick access to snacks and beverages, promoting workplace satisfaction and productivity. These machines can be stocked with healthy options, catering to the growing demand for nutritious snacks in the workplace. The reduction in labor costs associated with traditional cafeteria services is another significant advantage. Buyers should focus on the variety of products offered and consider the availability of maintenance services to ensure the machines remain operational.

Transportation Hubs

In transportation hubs like airports and train stations, automatic food vending machines play a critical role in enhancing customer experience. They offer travelers quick access to meals and snacks, alleviating congestion in busy terminals. The machines need to be designed for high traffic and must accommodate various payment methods, including cashless options. International buyers should prioritize durable designs that can withstand constant use and consider logistics for product replenishment to ensure freshness.

Retail Sector

In the retail sector, automatic food vending machines provide 24/7 access to convenience food, catering to late-night shoppers or those looking for quick meal solutions. This application opens up new sales opportunities and reduces the need for extensive staffing during off-peak hours. Buyers should focus on inventory management systems that monitor product freshness and ensure a diverse range of offerings to meet customer demands. Additionally, understanding local regulations regarding food sales is crucial for compliance.

Related Video: Kooler Ice Vending Machines – IM600XL vs. IM1000

Strategic Material Selection Guide for automatic food vending machine

Material Analysis for Automatic Food Vending Machines

When selecting materials for automatic food vending machines, it’s essential to consider various factors such as durability, cost, and compliance with international standards. Below is an analysis of four common materials used in the construction of these machines, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

1. Stainless Steel (e.g., AISI 304)

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand high temperatures. It typically has a temperature rating up to 870°C and can handle pressures up to 2000 psi, making it suitable for various environments.

Pros & Cons:

Stainless steel is highly durable and easy to clean, making it ideal for food-related applications. However, it can be more expensive than other materials, and its manufacturing process may involve complex machining and welding techniques.

Impact on Application:

Stainless steel is compatible with a wide range of food products and is resistant to staining and rust, ensuring hygiene and safety in food dispensing.

Specific Considerations for International Buyers:

Buyers should ensure compliance with food safety standards such as FDA regulations in the U.S. or EU regulations in Europe. The material’s certification, such as ASTM or DIN standards, is crucial for international trade.

2. Polycarbonate

Key Properties:

Polycarbonate is a lightweight, impact-resistant plastic that can withstand temperatures ranging from -40°C to 120°C. It has a high tensile strength and is resistant to UV radiation.

Pros & Cons:

The material is cost-effective and offers excellent transparency, making it suitable for display panels. However, it may not be as durable as metals and can scratch easily, which may affect its aesthetic appeal over time.

Impact on Application:

Polycarbonate is ideal for transparent components in vending machines, allowing customers to see the products inside. It is also resistant to a variety of chemicals, enhancing its versatility.

Specific Considerations for International Buyers:

Buyers should check for compliance with environmental regulations, such as REACH in Europe, as polycarbonate can contain BPA, which is subject to scrutiny.

3. Aluminum

Key Properties:

Aluminum is lightweight, corrosion-resistant, and has a good strength-to-weight ratio. It can withstand temperatures up to 600°C and is often used in various structural applications.

Pros & Cons:

Aluminum is relatively inexpensive and easy to machine, making it a popular choice for many applications. However, it may not be as strong as stainless steel and can be prone to denting.

Impact on Application:

Aluminum is suitable for structural components of vending machines, providing a good balance between weight and strength, which is essential for mobility and installation.

Specific Considerations for International Buyers:

International buyers should consider the alloy grade and its compliance with standards such as JIS in Japan or ASTM in the U.S. Additionally, anodized finishes can enhance corrosion resistance, which is vital in humid environments.

4. Glass

Key Properties:

Glass is a non-porous material that offers excellent visibility and aesthetic appeal. It can withstand temperatures up to 500°C, depending on the type of glass used.

Pros & Cons:

Glass provides a premium look and is highly resistant to chemical corrosion. However, it is fragile and can break easily, posing risks in high-traffic areas.

Impact on Application:

Glass is often used for front panels and display cases in vending machines, enhancing visibility and customer engagement. Its non-porous nature ensures hygiene, as it does not harbor bacteria.

Specific Considerations for International Buyers:

Buyers should ensure that the glass used complies with safety standards, such as tempered or laminated glass requirements, especially in regions with stringent safety regulations.

Summary Table

| Material | Typical Use Case for automatic food vending machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel (e.g., AISI 304) | Structural components, food contact areas | Excellent corrosion resistance, durable | Higher cost, complex manufacturing | High |

| Polycarbonate | Transparent panels, display cases | Lightweight, cost-effective | Scratches easily, less durable than metals | Medium |

| Aluminum | Structural frames, non-food contact areas | Lightweight, easy to machine | Prone to denting, less strong than stainless | Low |

| Glass | Front panels, display cases | Premium look, hygienic | Fragile, risk of breakage | Medium |

This analysis provides a comprehensive overview of the materials suitable for automatic food vending machines, offering actionable insights for international B2B buyers in various regions.

In-depth Look: Manufacturing Processes and Quality Assurance for automatic food vending machine

Manufacturing Processes for Automatic Food Vending Machines

The manufacturing of automatic food vending machines involves a series of well-defined stages, each critical to ensuring the final product meets the required performance and quality standards. Below, we detail the main stages of the manufacturing process, along with key techniques employed at each stage.

1. Material Preparation

Material Selection: The process begins with selecting appropriate materials that can withstand the rigors of outdoor and indoor environments. Common materials include stainless steel for the casing, tempered glass for display panels, and high-density polyethylene for internal components.

Pre-Treatment: Materials often undergo pre-treatment processes such as cleaning, coating, or galvanizing to enhance durability and resistance to corrosion. This step is crucial, especially for machines intended for outdoor use in varying climates.

2. Forming

Cutting and Shaping: Advanced machinery, such as CNC (Computer Numerical Control) machines, is utilized to cut and shape metal sheets into components like panels, frames, and brackets. Precision in this stage is vital to ensure all parts fit together seamlessly during assembly.

Molding: For plastic components, injection molding is commonly used. This technique allows for the mass production of complex shapes and designs, ensuring consistency in quality across all units.

3. Assembly

Sub-Assembly: Components are first assembled into sub-units. For example, the electronic control systems, refrigeration units, and payment systems are assembled independently before being integrated into the main machine.

Final Assembly: During this stage, sub-assemblies are brought together. Skilled technicians ensure that all mechanical and electrical components are correctly integrated, with careful attention to wiring and connectivity.

Integration of Software: The software that controls the vending machine’s operations is installed. This includes user interfaces, payment processing systems, and inventory management software, which require thorough testing before final deployment.

4. Finishing

Surface Treatment: After assembly, machines undergo surface treatments such as painting or powder coating. These treatments enhance aesthetics and provide additional protection against wear and environmental damage.

Quality Inspection: Before machines are packaged for shipment, they undergo a rigorous quality inspection to ensure they meet the specifications set during the design phase.

Quality Assurance

Quality assurance (QA) is paramount in the manufacturing of automatic food vending machines, as it directly impacts reliability, customer satisfaction, and compliance with international standards.

International Standards

ISO 9001: This widely recognized standard outlines the criteria for a quality management system. Manufacturers seeking ISO 9001 certification must demonstrate their ability to consistently provide products that meet customer and regulatory requirements.

CE Marking: For machines sold in Europe, CE marking indicates compliance with health, safety, and environmental protection standards. This certification is vital for market entry in EU countries.

API Standards: Depending on the machine’s functionality, adherence to specific American Petroleum Institute (API) standards may be necessary, particularly if the vending machines dispense products that fall under these regulations.

Quality Control Checkpoints

Incoming Quality Control (IQC): This initial checkpoint ensures that all incoming materials meet specified standards before they are used in production. This step helps identify potential issues early in the manufacturing process.

In-Process Quality Control (IPQC): Throughout the assembly process, IPQC measures are implemented to monitor the quality of components and assemblies in real-time. This approach allows for immediate corrective actions if defects are identified.

Final Quality Control (FQC): Before dispatch, machines undergo comprehensive testing, including functionality tests, safety checks, and performance evaluations. Only units that pass these tests are approved for shipment.

Common Testing Methods

- Electrical Testing: Ensures that all electrical components function correctly and safely.

- Mechanical Testing: Assesses the durability and reliability of mechanical parts under operational conditions.

- User Interface Testing: Confirms that software and user interfaces operate smoothly and are user-friendly.

Verifying Supplier Quality Control

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial to ensure product reliability.

Supplier Audits

Conducting supplier audits is an effective way to assess their quality management practices. Audits should focus on production processes, quality control measures, and adherence to international standards.

Quality Reports

Requesting detailed quality reports from suppliers can provide insights into their manufacturing processes and quality assurance practices. These reports should include data on defect rates, corrective actions taken, and compliance with industry standards.

Third-Party Inspections

Engaging third-party inspection services can offer an unbiased assessment of the manufacturing process. These inspectors can verify that products meet the required specifications and standards before shipment.

Conclusion

Understanding the manufacturing processes and quality assurance practices behind automatic food vending machines is essential for B2B buyers. By focusing on material preparation, forming, assembly, and finishing, alongside robust quality control measures, buyers can ensure they procure reliable and high-quality vending machines. Implementing thorough verification processes will further mitigate risks and enhance confidence in supplier relationships, ultimately contributing to successful business operations.

Related Video: Parle-G Biscuits Manufacturing process – Food Factory Tour- Modern Food factory, Mega Factory II

Comprehensive Cost and Pricing Analysis for automatic food vending machine Sourcing

Cost Structure for Automatic Food Vending Machines

Understanding the cost structure of automatic food vending machines is essential for B2B buyers. The primary cost components include:

-

Materials: This encompasses the costs of raw materials such as metal, plastic, electronics, and components like payment systems and refrigeration units. Quality materials directly impact the durability and performance of the machines.

-

Labor: Labor costs involve the wages paid to workers for manufacturing and assembling the machines. In regions with higher labor costs, such as parts of Europe, this can significantly affect overall pricing.

-

Manufacturing Overhead: These are indirect costs associated with production, including utilities, rent, and equipment maintenance. Efficient production processes can help minimize overhead costs.

-

Tooling: This refers to the costs incurred in creating and maintaining the tools necessary for manufacturing. Custom designs may require specialized tooling, which can increase initial costs.

-

Quality Control (QC): Ensuring that machines meet quality standards incurs costs related to inspections, testing, and certifications. High-quality standards often justify higher prices in the marketplace.

-

Logistics: This includes transportation costs for shipping the machines from the manufacturer to the buyer. Factors such as distance, shipping method, and customs duties can all influence logistics costs.

-

Margin: Suppliers typically add a profit margin on top of their costs, which can vary significantly depending on market conditions and competition.

Price Influencers

Several factors influence the pricing of automatic food vending machines:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often attract discounts, making it essential for buyers to assess their needs accurately.

-

Specifications/Customization: Customized machines with specific features or branding will generally cost more. Buyers should weigh the benefits of customization against the added costs.

-

Materials: The choice of materials affects both cost and quality. Higher-quality materials may lead to a more expensive machine but can reduce maintenance costs and extend lifespan.

-

Quality/Certifications: Machines that meet international quality standards or certifications can command higher prices. Buyers should consider the long-term benefits of investing in certified products.

-

Supplier Factors: The reputation, reliability, and location of suppliers can influence pricing. Established suppliers with good track records may charge premium prices but often deliver better service.

-

Incoterms: Understanding shipping terms can help buyers manage costs effectively. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who is responsible for costs at various stages of shipping.

Buyer Tips

International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should consider the following strategies:

-

Negotiation: Engage in active negotiation with suppliers to secure better pricing. Understanding the cost structure can empower buyers to negotiate effectively.

-

Cost-Efficiency: Look beyond initial purchase price. Consider the Total Cost of Ownership (TCO), which includes maintenance, energy consumption, and potential downtime costs.

-

Pricing Nuances: Be aware that prices can fluctuate based on market demand, currency exchange rates, and geopolitical factors. It’s advisable to monitor these aspects continuously.

-

Supplier Diversity: Explore multiple suppliers to compare costs and offerings. This can lead to better deals and a deeper understanding of market pricing.

-

Local Partnerships: In regions like Africa and South America, forming partnerships with local distributors can help mitigate logistics costs and provide better service.

Disclaimer

Prices for automatic food vending machines can vary widely based on the factors discussed. Buyers are encouraged to conduct thorough market research and obtain multiple quotes to ensure they are getting the best value for their investment.

Spotlight on Potential automatic food vending machine Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘automatic food vending machine’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for automatic food vending machine

In the competitive landscape of automatic food vending machines, understanding essential technical properties and trade terminology is crucial for international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe. This knowledge not only facilitates informed purchasing decisions but also enhances negotiation capabilities and supplier relationship management.

Key Technical Properties

-

Material Grade

– The material grade refers to the quality and type of materials used in the construction of the vending machine, such as stainless steel or high-grade plastic. High-quality materials ensure durability and resistance to wear, which is essential for machines exposed to various environmental conditions, particularly in outdoor settings. -

Temperature Control Range

– This specification indicates the machine’s ability to maintain optimal temperatures for food storage. A wider temperature control range (e.g., -5°C to 75°C) allows for greater versatility in product offerings, catering to diverse consumer preferences. For B2B buyers, this is vital for maximizing the range of items that can be sold, thus increasing potential revenue. -

Power Consumption

– Measured in watts, power consumption is a critical factor influencing operational costs. Machines with lower energy usage not only reduce electricity bills but also align with sustainability goals. Buyers should consider energy-efficient models, especially in regions where energy costs are high or where sustainability is a priority. -

User Interface and Payment System

– The user interface encompasses the machine’s digital display and controls, while the payment system includes options for cash, credit/debit cards, and mobile payments. A user-friendly interface enhances customer experience, and a versatile payment system can attract a wider range of consumers, increasing sales opportunities. -

Capacity and Dimensions

– The capacity refers to the number of items the machine can hold, while dimensions dictate the space required for installation. Understanding these factors helps buyers select machines that fit their operational needs and available locations, avoiding costly installation errors. -

Maintenance Requirements

– This specification outlines the ease and frequency of maintenance tasks. Machines designed for easy access to components for cleaning and repairs can significantly reduce downtime and operational disruptions, which is critical for maintaining consistent service levels.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is essential for buyers seeking custom solutions or specific features in vending machines. -

MOQ (Minimum Order Quantity)

– This term defines the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps buyers manage inventory costs and plan purchases effectively, especially when entering new markets. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers requesting pricing for specific products or services. It is a vital tool for buyers to compare prices, negotiate terms, and ensure competitive sourcing of vending machines. -

Incoterms (International Commercial Terms)

– A set of predefined international rules that clarify the responsibilities of buyers and sellers regarding shipping and delivery. Familiarity with Incoterms helps buyers understand shipping costs and risks, ensuring smoother international transactions. -

Lead Time

– This term refers to the amount of time between placing an order and receiving the product. Understanding lead times is critical for inventory management, as it affects how quickly buyers can respond to market demands. -

Warranty and Support Terms

– Warranty terms outline the conditions under which the manufacturer will repair or replace defective products. Knowing these terms is essential for buyers to assess the long-term viability of their investment in vending machines.

By grasping these technical properties and trade terms, international B2B buyers can make more informed decisions, negotiate effectively, and ultimately enhance their operational efficiency in the vending machine market.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the automatic food vending machine Sector

Market Overview & Key Trends

The automatic food vending machine sector is experiencing significant transformation, driven by several global factors. Increasing urbanization, a growing demand for convenience, and the shift towards contactless payment solutions are key drivers propelling market growth. In regions like Africa, South America, the Middle East, and Europe, buyers are witnessing the adoption of advanced technologies such as IoT, which enables real-time inventory management and enhances user engagement through interactive interfaces.

Emerging trends in sourcing reflect a move towards smart vending solutions that integrate AI and machine learning for personalized customer experiences. For instance, machines that adapt their offerings based on customer preferences or seasonal trends are becoming more prevalent. Additionally, the introduction of cloud-based platforms for machine monitoring and analytics is gaining traction, allowing for better operational efficiency and reduced downtime.

International B2B buyers must also navigate the complexities of regional market dynamics. In Africa, for example, while there is a burgeoning demand for vending solutions, buyers must contend with infrastructure challenges and varying regulatory environments. Conversely, in Europe, stricter health and safety regulations are shaping product offerings, emphasizing the need for compliance in sourcing decisions. Understanding these regional nuances is crucial for successful market entry and sustained competitive advantage.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a cornerstone of strategic sourcing in the automatic food vending machine sector. Environmental concerns around waste generation and energy consumption are prompting buyers to seek solutions that minimize ecological footprints. One significant impact area is the packaging of food products sold through vending machines. B2B buyers are increasingly prioritizing suppliers that use biodegradable or recyclable materials, reflecting a commitment to reducing plastic waste.

Moreover, the importance of ethical supply chains cannot be overstated. Sourcing from vendors who adhere to fair labor practices and sustainable farming methods enhances brand reputation and consumer trust. Certifications such as Fair Trade, Rainforest Alliance, and organic labels are becoming essential for B2B buyers looking to align their procurement strategies with sustainability goals.

Incorporating ‘green’ certifications and materials not only fulfills corporate social responsibility objectives but also caters to an increasingly environmentally-conscious consumer base. As the market evolves, buyers must stay informed about the sustainability practices of their suppliers and consider these factors in their sourcing decisions to remain competitive.

Brief Evolution/History

The evolution of the automatic food vending machine sector can be traced back to the early 1880s, when the first coin-operated machines dispensed simple products like postcards and cigarettes. Over the decades, the technology has advanced significantly, transitioning from basic mechanical devices to sophisticated digital systems capable of offering a wide variety of food and beverages.

The late 20th century saw the introduction of refrigerated vending machines, expanding the range of consumables available to consumers. As consumer preferences shifted towards healthier options, manufacturers began to innovate, incorporating fresh food items and healthier snacks into their offerings. Today, the sector is on the cusp of a technological revolution, with advancements in AI, IoT, and sustainability shaping its future trajectory. For B2B buyers, understanding this evolution is essential for identifying future opportunities and aligning sourcing strategies with market demands.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of automatic food vending machine

-

What should I consider when vetting suppliers for automatic food vending machines?

When vetting suppliers, focus on their industry experience, customer reviews, and the quality of their products. Request references from previous clients, and check if they have a solid track record in delivering machines that meet international standards. Additionally, verify their certifications (such as ISO) to ensure compliance with safety and quality regulations. It’s also wise to conduct a site visit if possible, or utilize third-party inspection services to assess their manufacturing capabilities firsthand. -

Can I customize automatic food vending machines to fit my business needs?

Yes, many suppliers offer customization options for automatic food vending machines. You can tailor features such as machine size, product selection, branding, and payment systems to align with your target market’s preferences. Ensure to discuss your specific requirements early in the negotiation process, as customization may affect lead times and costs. Always request a prototype or design mock-up before finalizing your order to confirm that the specifications meet your expectations. -

What are the typical minimum order quantities (MOQ) and lead times for vending machines?

Minimum order quantities vary by supplier and can range from one machine to several dozen, depending on the manufacturer’s production capacity. Lead times generally range from 4 to 12 weeks, influenced by factors such as customization, order size, and shipping logistics. It’s advisable to confirm MOQs and lead times during initial discussions to avoid unexpected delays. For urgent needs, inquire about expedited shipping options or ready-to-ship models. -

What payment methods are commonly accepted in international transactions?

Most suppliers accept various payment methods, including wire transfers, letters of credit, and online payment platforms. It’s crucial to negotiate favorable payment terms, such as a percentage upfront and the balance upon delivery or after installation. Be cautious with suppliers requesting full payment in advance, as this can increase the risk of fraud. Additionally, consider using escrow services for larger transactions to safeguard your funds until the machines are delivered and meet your specifications. -

What quality assurance measures should I look for in a vending machine supplier?

Ensure that the supplier has a robust quality assurance (QA) process in place, including regular testing and inspections throughout the manufacturing process. Request details on their QA certifications and any third-party testing they conduct. Inquire about warranty terms and after-sales support, as these reflect the supplier’s confidence in their product quality. It’s also beneficial to ask for samples or trial machines to evaluate performance before committing to larger orders. -

How can I handle logistics and shipping for my vending machine orders?

Logistics can be complex, especially with international shipping. Discuss shipping options with your supplier, including whether they handle logistics or if you’ll need to arrange it independently. Consider factors such as shipping costs, import duties, and insurance. Choose a reliable freight forwarder experienced in handling machinery to ensure timely and safe delivery. Additionally, confirm that the supplier provides clear shipping documentation, including customs paperwork, to avoid delays at the border. -

What should I do in case of disputes with a supplier?

In the event of a dispute, it’s essential to address the issue promptly and professionally. Start by reviewing your contract and any correspondence related to the transaction. Communicate your concerns directly with the supplier to seek a resolution. If informal discussions do not resolve the matter, consider mediation or arbitration, as specified in your contract. Maintaining thorough documentation of all communications and agreements will be crucial if legal action becomes necessary.

Illustrative Image (Source: Google Search)

- What certifications should I look for when sourcing vending machines?

When sourcing automatic food vending machines, look for certifications that ensure product safety and quality. Key certifications include CE (European Conformity) for compliance with EU regulations, UL (Underwriters Laboratories) for safety standards, and ISO 9001 for quality management systems. Additionally, food safety certifications like HACCP (Hazard Analysis Critical Control Point) are essential if the machines dispense food products. Verifying these certifications can help ensure that the machines meet local regulations and industry standards in your target market.

Strategic Sourcing Conclusion and Outlook for automatic food vending machine

In conclusion, the strategic sourcing of automatic food vending machines presents a unique opportunity for international B2B buyers from diverse regions, including Africa, South America, the Middle East, and Europe. By leveraging strategic sourcing practices, businesses can optimize their procurement processes, ensuring cost-effectiveness while enhancing service delivery. It is essential to consider factors such as supplier reliability, technological advancements, and local market preferences to make informed purchasing decisions.

Moreover, as consumer demand for convenience and quality continues to rise, investing in modern vending solutions can provide a competitive edge. Buyers should explore partnerships with manufacturers that offer customizable and scalable vending solutions tailored to their specific market needs.

Illustrative Image (Source: Google Search)

As we look to the future, the growth potential in this sector is substantial. Companies that proactively engage in strategic sourcing will not only streamline their operations but also position themselves as leaders in the evolving landscape of automated food services. Now is the time for B2B buyers to act—embrace innovation, foster strategic partnerships, and invest in vending technology that meets the demands of tomorrow’s consumers.