Master Alcohol Vending Machines: A Strategic Guide for B2B

Guide to Alcohol Vending Machines

- Introduction: Navigating the Global Market for alcohol vending machines

- Understanding alcohol vending machines Types and Variations

- Key Industrial Applications of alcohol vending machines

- Strategic Material Selection Guide for alcohol vending machines

- In-depth Look: Manufacturing Processes and Quality Assurance for alcohol vending machines

- Comprehensive Cost and Pricing Analysis for alcohol vending machines Sourcing

- Spotlight on Potential alcohol vending machines Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for alcohol vending machines

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the alcohol vending machines Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of alcohol vending machines

- Strategic Sourcing Conclusion and Outlook for alcohol vending machines

Introduction: Navigating the Global Market for alcohol vending machines

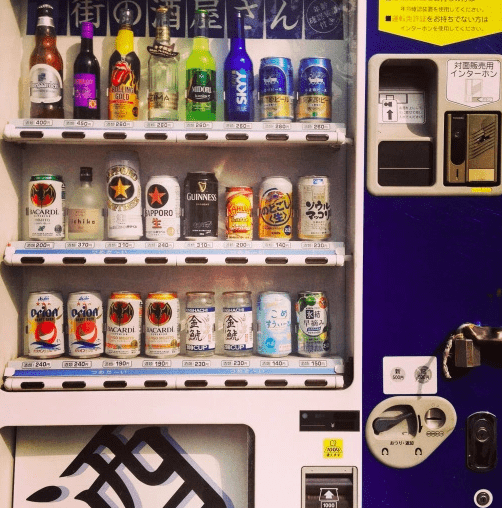

Alcohol vending machines represent a transformative opportunity in the global beverage market, combining convenience with a unique consumer experience. As international B2B buyers from Africa, South America, the Middle East, and Europe seek innovative solutions to meet evolving consumer demands, these machines offer a compelling avenue to enhance service delivery and drive profitability. With the rise of automated retail, alcohol vending machines cater to a demographic increasingly inclined towards self-service options, making them an essential addition to bars, restaurants, and entertainment venues.

This guide provides a comprehensive overview of the alcohol vending machine landscape, covering various types, materials, manufacturing processes, quality control measures, and key suppliers. It also delves into cost considerations and market trends, equipping buyers with the insights needed to make informed sourcing decisions. By addressing frequently asked questions, this resource aims to demystify the complexities surrounding alcohol vending machines, empowering stakeholders to navigate this burgeoning market confidently.

For B2B buyers in regions like Germany and Brazil, understanding the nuances of alcohol vending machines is crucial for capitalizing on market opportunities and enhancing customer satisfaction. This guide serves as a strategic tool, enabling businesses to leverage the advantages of automated beverage dispensing while ensuring compliance with local regulations and consumer preferences. Embrace the future of retail with confidence and clarity, as we explore the potential of alcohol vending machines in today’s dynamic market.

Understanding alcohol vending machines Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Alcohol Vending Machine | Standard vending machine design, manually stocked | Bars, clubs, and restaurants | Pros: Easy to operate; Cons: Limited inventory and slower sales turnover. |

| Smart Alcohol Vending Machine | Digital interfaces, cashless payment options | Events, festivals, and busy venues | Pros: Increased sales through convenience; Cons: Higher initial investment. |

| Temperature-Controlled Vending Machine | Maintains optimal temperatures for various beverages | Hotels, resorts, and gourmet shops | Pros: Preserves product quality; Cons: Requires regular maintenance. |

| Customizable Alcohol Vending Machine | Modular design allowing for product variation | Corporate events and private parties | Pros: Tailored offerings for specific demographics; Cons: Longer lead times for customization. |

| Mobile Alcohol Vending Unit | Portable design for easy relocation | Outdoor events, concerts, and festivals | Pros: Flexibility in location; Cons: May face regulatory challenges. |

Traditional Alcohol Vending Machine

Traditional alcohol vending machines are the most recognizable type, featuring a straightforward design that allows for manual stocking of various alcoholic beverages. They are commonly used in bars, clubs, and restaurants, providing a quick service option for customers. When considering a purchase, B2B buyers should evaluate the machine’s capacity, ease of use, and maintenance requirements. While these machines are easy to operate, they often have limited inventory options and may lead to slower sales turnover compared to more advanced models.

Smart Alcohol Vending Machine

Smart alcohol vending machines incorporate digital interfaces and cashless payment options, making them suitable for high-traffic locations such as events and festivals. These machines enhance customer experience by allowing for quick transactions and easier inventory management. B2B buyers should consider the upfront costs versus potential sales increases due to convenience. While they can significantly boost sales, the higher initial investment and the need for reliable internet connectivity may deter some buyers.

Temperature-Controlled Vending Machine

Temperature-controlled vending machines are designed to keep alcoholic beverages at optimal temperatures, ensuring quality and freshness. Ideal for hotels, resorts, and gourmet shops, these machines attract customers looking for premium products. When purchasing, businesses should consider the machine’s energy efficiency and maintenance needs. Although they preserve product quality effectively, these machines often require regular maintenance to ensure temperature consistency.

Customizable Alcohol Vending Machine

Customizable alcohol vending machines offer a modular design that allows businesses to tailor their product offerings according to specific demographics or events. This flexibility makes them particularly appealing for corporate events and private parties, where unique beverage selections can enhance the experience. B2B buyers should weigh the advantages of tailored offerings against the longer lead times associated with customization. While they provide a unique selling proposition, the customization process can be time-consuming.

Mobile Alcohol Vending Unit

Mobile alcohol vending units are portable and designed for easy relocation, making them perfect for outdoor events, concerts, and festivals. These units allow businesses to reach diverse audiences and adapt to various locations. Buyers should consider the regulatory challenges that may arise, as alcohol sales regulations can vary significantly by location. While the flexibility in location is a significant advantage, navigating local laws can present a hurdle for prospective buyers.

Related Video: Alcohol Vending Machine from Automatic Vending Specialists

Key Industrial Applications of alcohol vending machines

| Industry/Sector | Specific Application of Alcohol Vending Machines | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Hotel mini-bars | Increased guest convenience, enhanced service experience | Compliance with local regulations, payment system integration |

| Entertainment Venues | Bars and nightclubs | Streamlined sales process, reduced staffing costs | Size and capacity of machines, product selection options |

| Retail | Supermarkets and convenience stores | 24/7 sales capability, expanded product range | Temperature control features, security measures |

| Events and Festivals | Outdoor festivals and concerts | Quick service for high-demand situations, cashless transactions | Portability, ease of setup, power requirements |

| Corporate Offices | Employee lounges and break rooms | Boosted employee morale, convenient access to refreshments | Customization options, branding opportunities |

Hospitality

In hotels, alcohol vending machines can serve as mini-bars, providing guests with easy access to beverages without requiring staff intervention. This enhances the guest experience by offering convenience and variety while also minimizing labor costs for the hotel. Buyers in this sector must ensure that the machines comply with local alcohol laws and integrate seamlessly with existing payment systems to facilitate smooth transactions.

Entertainment Venues

Bars and nightclubs can utilize alcohol vending machines to streamline the sales process, particularly during peak hours. These machines can alleviate the burden on staff, allowing them to focus on customer service rather than drink preparation. For international buyers, factors such as machine capacity, product selection, and payment options (including cashless solutions) are critical to ensure a seamless operation.

Retail

Supermarkets and convenience stores can benefit from alcohol vending machines by offering 24/7 sales capabilities. This not only caters to customer demand at any hour but also expands the product range available in-store. Buyers should consider features like temperature control to ensure product quality and security measures to prevent theft, which are especially important in regions with higher rates of retail crime.

Events and Festivals

Outdoor festivals and concerts present unique opportunities for alcohol vending machines, which can provide quick service during high-demand situations. These machines can facilitate cashless transactions, speeding up the purchasing process and enhancing customer satisfaction. Buyers should focus on the portability of the machines, ease of setup, and power requirements to ensure they can be deployed efficiently in various locations.

Corporate Offices

In corporate settings, alcohol vending machines can be installed in employee lounges and break rooms to boost morale and provide convenient access to refreshments. This can enhance workplace culture and employee satisfaction. For B2B buyers in this sector, customization options and branding opportunities can help align the machines with the company’s image, while also ensuring compliance with workplace regulations regarding alcohol consumption.

Related Video: Kooler Ice Vending Machines – IM600XL vs. IM1000

Strategic Material Selection Guide for alcohol vending machines

When selecting materials for alcohol vending machines, several factors must be taken into account, including durability, cost, compliance with international standards, and specific application requirements. Below is an analysis of four common materials used in the construction of alcohol vending machines, focusing on their key properties, advantages and disadvantages, and considerations for international B2B buyers.

Stainless Steel

Key Properties: Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand a wide range of temperatures. It typically has a temperature rating of up to 800°C and can handle pressures of up to 1000 psi, depending on the grade.

Pros & Cons: The primary advantage of stainless steel is its durability and resistance to rust and corrosion, making it suitable for environments where moisture is prevalent. However, it is relatively expensive compared to other materials and can be more complex to manufacture due to its hardness.

Impact on Application: Stainless steel is highly compatible with alcoholic beverages, ensuring that there is no leaching of harmful substances. It is also easy to clean, which is crucial for maintaining hygiene standards in vending machines.

Considerations for International Buyers: Buyers in regions like Europe and the Middle East should ensure compliance with standards such as ASTM A240 or DIN 17440. In Africa and South America, local regulations regarding food safety and material standards must also be considered.

Aluminum

Key Properties: Aluminum is lightweight, has good corrosion resistance, and can withstand temperatures up to 400°C. Its pressure rating varies widely based on the alloy used.

Pros & Cons: The key advantage of aluminum is its lightweight nature, which reduces shipping costs and makes installation easier. However, it is less durable than stainless steel and can be prone to denting and scratching.

Impact on Application: Aluminum is suitable for low to moderate alcohol content beverages but may not be ideal for high-proof spirits due to its susceptibility to corrosion over time.

Considerations for International Buyers: Compliance with standards such as ASTM B221 is essential. Buyers should also consider local preferences for materials, as aluminum may be favored in regions where weight is a concern, such as in mobile vending applications.

Glass

Key Properties: Glass is non-reactive, can withstand temperatures up to 300°C, and is generally resistant to corrosion from alcohol.

Pros & Cons: Glass provides an aesthetically pleasing appearance and allows for visibility of the products inside the vending machine. However, it is fragile and can break easily, posing safety risks. Additionally, glass is heavier than other materials, which can increase shipping costs.

Impact on Application: Glass is ideal for displaying alcoholic beverages, enhancing customer appeal. However, its fragility limits its use in high-traffic areas or environments where it may be subjected to impacts.

Considerations for International Buyers: Buyers should ensure compliance with safety standards like ASTM C1036 for glass used in vending machines. In regions with high foot traffic, such as parts of Europe, reinforced glass may be preferred to enhance safety.

Polycarbonate

Key Properties: Polycarbonate is a durable plastic that can withstand temperatures from -40°C to 120°C and has excellent impact resistance.

Pros & Cons: The main advantage of polycarbonate is its lightweight and shatter-resistant properties, making it a safer alternative to glass. However, it may not be as aesthetically pleasing and can scratch easily, affecting visibility.

Impact on Application: Polycarbonate is suitable for housing components of vending machines and can be used for transparent panels. It is compatible with most alcoholic beverages but may not be suitable for long-term exposure to high-proof spirits.

Considerations for International Buyers: Buyers should check for compliance with standards such as ASTM D6677. In regions like Africa and South America, where durability and safety are paramount, polycarbonate may be a preferred choice for its impact resistance.

Summary Table

| Material | Typical Use Case for alcohol vending machines | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural components, exterior panels | Excellent corrosion resistance, durable | Higher cost, complex manufacturing | High |

| Aluminum | Lightweight structures, internal components | Lightweight, cost-effective | Less durable, prone to denting | Medium |

| Glass | Display panels, product visibility | Aesthetic appeal, non-reactive | Fragile, heavier shipping | Medium |

| Polycarbonate | Housing components, transparent panels | Shatter-resistant, lightweight | Scratches easily, less aesthetic | Low |

This analysis provides a comprehensive overview of the materials commonly used in alcohol vending machines, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for alcohol vending machines

Manufacturing Processes for Alcohol Vending Machines

The manufacturing of alcohol vending machines involves several critical stages, ensuring that the final product meets both functionality and regulatory standards. Understanding these processes can help B2B buyers make informed decisions when selecting suppliers.

Illustrative Image (Source: Google Search)

Material Preparation

The first stage in the manufacturing process is material preparation. This involves sourcing high-quality materials, such as:

- Metal Components: Steel or aluminum for structural integrity.

- Plastic Parts: High-grade plastics for housing and internal components.

- Electronic Components: Circuit boards, sensors, and payment systems.

Suppliers should demonstrate a commitment to sustainability by sourcing materials responsibly. Buyers can inquire about the suppliers’ material certifications to ensure compliance with international standards.

Forming

Once materials are prepared, the forming stage begins. Key techniques used in this phase include:

- CNC Machining: Precision cutting of metal parts to create the machine’s frame and compartments.

- Injection Molding: Forming plastic components for the user interface and other non-structural parts.

- Sheet Metal Fabrication: Bending and shaping metal sheets into required forms.

These techniques ensure that components are produced with high precision, which is essential for the smooth operation of the vending machines.

Assembly

The assembly stage is where all components come together. This process typically involves:

- Sub-assembly: Grouping related components, such as electronic systems and mechanical parts, for easier integration.

- Main Assembly: Combining sub-assemblies into the final product, including fitting the control panel, refrigeration units, and dispensing mechanisms.

During assembly, manufacturers often implement Lean Manufacturing Principles to reduce waste and optimize efficiency. B2B buyers should look for suppliers who can demonstrate efficient assembly processes, which can indicate a commitment to quality and timely delivery.

Finishing

The final stage involves finishing processes that enhance both aesthetics and functionality:

- Surface Treatment: Coating metal parts to prevent corrosion and improve appearance.

- Quality Control Checks: Inspecting for defects and ensuring all components function correctly.

Finishing not only ensures a polished look but also contributes to the longevity of the machines, an essential consideration for B2B buyers.

Quality Assurance

Quality assurance (QA) is vital in the manufacturing of alcohol vending machines, ensuring that products meet both customer expectations and regulatory requirements.

International Standards

B2B buyers should familiarize themselves with relevant international quality standards, including:

- ISO 9001: A global standard for quality management systems, ensuring that suppliers consistently meet customer and regulatory requirements.

- CE Marking: Indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

In addition, industry-specific certifications, such as those from the American National Standards Institute (ANSI) and American Petroleum Institute (API), may be relevant depending on the markets served.

Quality Control Checkpoints

The QA process typically involves several checkpoints:

- Incoming Quality Control (IQC): Inspection of raw materials and components upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing checks during the manufacturing process to identify defects early and maintain quality.

- Final Quality Control (FQC): Comprehensive testing of the finished product to verify functionality, safety, and compliance with standards.

Common Testing Methods

Testing methods for alcohol vending machines may include:

- Functional Testing: Ensuring that all mechanical and electronic components operate correctly.

- Safety Testing: Assessing the machine’s electrical safety and compliance with local regulations.

- Durability Testing: Simulating real-world usage to evaluate the machine’s performance over time.

B2B buyers should request detailed reports on these tests to verify that the supplier adheres to rigorous quality assurance practices.

Verifying Supplier Quality Control

To ensure that suppliers maintain high quality standards, B2B buyers can take several steps:

- Conduct Audits: Regularly auditing suppliers can provide insights into their manufacturing processes and quality control measures.

- Request Quality Reports: Suppliers should be able to provide documentation of their quality control processes and test results.

- Third-Party Inspections: Engaging independent inspectors can add another layer of verification, ensuring that suppliers meet international standards.

QC and Certification Nuances for International Buyers

For international buyers, especially from regions like Africa, South America, the Middle East, and Europe, it is crucial to understand the nuances of quality certification:

- Regulatory Differences: Each region may have specific regulations regarding alcohol vending machines. Buyers should ensure that suppliers are compliant with local laws.

- Cultural Considerations: Understanding cultural attitudes towards alcohol consumption can influence machine design and functionality, making it essential for suppliers to be aware of regional preferences.

- Logistical Challenges: Buyers should consider the logistics of importing machines, including customs regulations and potential tariffs that may affect the cost and delivery timeline.

By thoroughly understanding the manufacturing processes and quality assurance measures, B2B buyers can make informed decisions that lead to successful partnerships and high-quality products in the alcohol vending machine sector.

Comprehensive Cost and Pricing Analysis for alcohol vending machines Sourcing

In sourcing alcohol vending machines, understanding the comprehensive cost structure and pricing dynamics is essential for international B2B buyers. The costs associated with these machines can be broken down into several key components, while various price influencers can significantly affect the final pricing.

Illustrative Image (Source: Google Search)

Cost Components

-

Materials: The primary cost driver includes the materials used in the construction of the vending machines. High-quality metals, plastics, and electronic components are essential for durability and functionality. Sourcing sustainable materials can also impact costs positively in certain markets.

-

Labor: Labor costs vary significantly by region. For example, labor costs in Europe, particularly in Germany, tend to be higher than in South America or Africa. It’s crucial to consider the skill level required for assembly and maintenance when evaluating labor costs.

-

Manufacturing Overhead: This includes costs related to utilities, rent, and other operational expenses incurred during the manufacturing process. Efficient manufacturing processes can help reduce overhead, thus lowering overall costs.

-

Tooling: Custom tooling for unique designs or specifications can be a significant upfront cost. Buyers should evaluate whether standard machines suffice or if customization is necessary, which can influence pricing.

-

Quality Control (QC): Implementing rigorous QC processes ensures that the machines meet international safety and quality standards, which can increase costs but ultimately leads to higher customer satisfaction and reduced returns.

-

Logistics: Shipping and handling costs must be factored in, especially for international orders. The choice of shipping method, distance, and destination can significantly influence logistics expenses.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure profitability. Understanding the supplier’s cost structure can aid in negotiations.

Price Influencers

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to discounts, so buyers should assess their needs carefully to optimize their purchasing strategy.

-

Specifications/Customization: Custom features or specific branding can lead to increased costs. Buyers should weigh the benefits of customization against potential price increases.

-

Materials and Quality/Certifications: Higher-quality materials and certifications (like ISO) can enhance the machine’s value but also raise the price. Buyers should consider the trade-off between initial costs and long-term reliability.

-

Supplier Factors: Supplier reputation, reliability, and service levels can impact pricing. Establishing a strong relationship with suppliers can lead to better terms and conditions.

-

Incoterms: Understanding shipping terms (like FOB, CIF) is crucial. These terms define the responsibilities of buyers and sellers in shipping, impacting overall costs and risk exposure.

Buyer Tips

-

Negotiation: Leverage volume purchases and long-term contracts to negotiate better pricing. Don’t hesitate to ask for discounts or improved payment terms.

-

Cost-Efficiency: Look beyond initial costs and consider the Total Cost of Ownership (TCO), which includes maintenance, energy consumption, and potential downtime.

-

Pricing Nuances: Be aware of regional pricing differences. For example, machines sourced from Europe may carry higher prices due to labor and regulatory standards compared to those sourced from Africa or South America.

-

Market Trends: Stay informed about market trends and technological advancements in vending machines, as these can influence pricing and availability.

Disclaimer

The prices mentioned herein are indicative and can fluctuate based on various factors, including market demand, economic conditions, and specific supplier negotiations. It is advisable for buyers to conduct thorough market research and obtain multiple quotes before making purchasing decisions.

Spotlight on Potential alcohol vending machines Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘alcohol vending machines’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for alcohol vending machines

Key Technical Properties of Alcohol Vending Machines

Understanding the technical specifications of alcohol vending machines is crucial for B2B buyers seeking to make informed purchasing decisions. Here are some critical specifications to consider:

-

Material Grade

The material used in the construction of the vending machine affects durability and compliance with health standards. Common materials include stainless steel and high-grade plastic. Stainless steel is preferred for its resistance to corrosion and ease of cleaning, which is vital for maintaining hygiene in alcohol dispensing. -

Temperature Control Range

Alcohol vending machines must maintain specific temperature ranges to ensure product quality. The ideal range for storing alcoholic beverages is typically between 2°C to 10°C (36°F to 50°F). Effective temperature control systems are essential for preventing spoilage and ensuring customer satisfaction. -

Power Consumption

Energy efficiency is a significant consideration for B2B buyers. Machines with lower power consumption reduce operational costs and are more environmentally friendly. Look for machines that are ENERGY STAR certified or have similar energy efficiency ratings.

-

Capacity and Size

The capacity of the vending machine, measured in terms of the number of bottles or cans it can hold, is vital for determining its suitability for various business environments. Smaller machines may be suitable for bars or restaurants, while larger models are better suited for high-traffic areas like nightclubs or events. -

Payment Systems

Modern alcohol vending machines often include multiple payment options, such as credit/debit cards, mobile payments, and cash. The integration of contactless payment technology can enhance user experience and increase sales. -

Security Features

Given the nature of the products, security is a paramount concern. Features such as reinforced locks, anti-tampering mechanisms, and surveillance cameras can deter theft and ensure compliance with local regulations regarding the sale of alcohol.

Common Trade Terminology

Familiarity with industry jargon can greatly enhance communication between buyers and suppliers. Here are some key terms to understand:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. For buyers, working with OEMs can lead to better customization options and quality assurance. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers to manage inventory costs and ensure they meet supplier requirements. -

RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing and other details for a specific quantity of goods. This process allows buyers to compare prices and terms from multiple suppliers. -

Incoterms (International Commercial Terms)

These are standardized international trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Knowledge of Incoterms can help buyers negotiate better shipping terms and avoid unexpected costs. -

Lead Time

This term refers to the time it takes from placing an order to receiving the goods. Understanding lead time is crucial for inventory management and ensuring that products are available when needed. -

Warranty and Service Agreements

Warranties provide buyers with protection against defects and malfunctions, while service agreements outline the terms for maintenance and repair. These are vital for ensuring the longevity and performance of vending machines.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions, leading to better procurement outcomes and enhanced operational efficiency.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the alcohol vending machines Sector

Market Overview & Key Trends

The global alcohol vending machine market is experiencing significant growth driven by changing consumer preferences, technological advancements, and the increasing demand for convenience. As urbanization continues to rise in regions such as Africa and South America, there is a growing appetite for innovative retail solutions. International B2B buyers are particularly focused on machines that integrate smart technology, allowing for cashless transactions and real-time inventory management. This trend aligns with the digital transformation across various sectors, enhancing customer experiences and operational efficiencies.

Emerging markets in Africa and South America are witnessing a surge in the adoption of alcohol vending machines, particularly in urban areas where traditional retail outlets may be less accessible. In Europe, especially in Germany, vending machines are increasingly being equipped with advanced age verification systems, leveraging biometric technology to ensure compliance with legal regulations. This focus on regulatory adherence is crucial for B2B buyers looking to expand their operations in diverse markets.

Additionally, the rise of e-commerce and mobile apps is influencing sourcing strategies. Companies are now prioritizing suppliers that can provide integrated solutions, combining hardware and software for seamless operations. The market is also seeing increased competition, with manufacturers innovating to differentiate their offerings through unique designs and enhanced user interfaces. B2B buyers must stay informed about these dynamics to make strategic sourcing decisions that align with market trends.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a pivotal consideration in the alcohol vending machine sector, as environmental impacts increasingly influence purchasing decisions. B2B buyers are urged to assess the carbon footprint of their suppliers, focusing on those who prioritize eco-friendly practices. This includes the use of recyclable materials in machine construction and energy-efficient technologies that minimize operational energy consumption.

The importance of ethical supply chains cannot be overstated, particularly in regions where labor practices may vary significantly. Buyers should seek vendors who are transparent about their sourcing processes and who adhere to fair labor standards. Certifications such as Fair Trade and ISO 14001 can serve as indicators of a supplier’s commitment to sustainability and ethical practices.

Moreover, the demand for ‘green’ certifications is on the rise. Buyers should consider suppliers who utilize sustainable materials, such as recycled plastics or responsibly sourced metals, in their products. This not only enhances brand reputation but also meets the growing consumer demand for environmentally responsible options. By prioritizing sustainability and ethical sourcing, B2B buyers can contribute positively to the industry while also appealing to a more conscientious customer base.

Brief Evolution/History

The concept of vending machines dates back to ancient times, but the introduction of alcohol vending machines is a relatively recent phenomenon. Initially, these machines were rudimentary, offering limited selections and requiring manual cash transactions. Over the past two decades, however, technological advancements have transformed the landscape significantly.

Today’s alcohol vending machines are equipped with sophisticated features, including touchscreens, cashless payment options, and automated age verification systems. This evolution reflects broader trends in consumer behavior, as shoppers increasingly seek convenience and enhanced experiences. For B2B buyers, understanding this historical context is essential, as it informs current sourcing strategies and highlights the importance of innovation in the competitive marketplace.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of alcohol vending machines

-

How can I effectively vet suppliers of alcohol vending machines?

When vetting suppliers, prioritize their industry experience, reputation, and certifications. Request client references and case studies to gauge their reliability. Check for compliance with local regulations, particularly around alcohol sales. Utilize platforms like Alibaba or Global Sources for reviews, and consider visiting the supplier’s facility if feasible. Establish direct communication to discuss terms, ensuring transparency in their business practices and product quality. -

Can I customize my alcohol vending machines to fit my brand?

Most suppliers offer customization options, including branding, machine colors, and product selections. Discuss your specific requirements early in negotiations. Be clear about design elements, such as logos or user interfaces, and inquire about any additional costs associated with customization. Ensure that the supplier has the capability to meet your design specifications without compromising quality or functionality. -

What are typical minimum order quantities (MOQs) and lead times for alcohol vending machines?

MOQs can vary significantly based on the supplier and the complexity of the machine. Standard orders might start at 10-50 units, while custom designs may require higher quantities. Lead times often range from 4-12 weeks, depending on production schedules and customization levels. Always confirm these details upfront to align with your business needs and planning. -

What payment terms should I expect when sourcing alcohol vending machines?

Payment terms typically include a deposit (20-50%) upon order confirmation, with the balance due before shipment. Some suppliers may offer payment plans or financing options, especially for larger orders. It’s advisable to use secure payment methods, such as letters of credit or escrow services, to mitigate risks. Clarify all payment details to avoid misunderstandings and ensure a smooth transaction. -

What quality assurance certifications should I look for in suppliers?

Suppliers should ideally possess ISO 9001 certification, which indicates a commitment to quality management systems. Additionally, check for compliance with local safety standards, such as CE marking in Europe or UL certification in the U.S. Request documentation that validates their quality assurance processes and guarantees that their machines meet international safety and operational standards. -

How will logistics and shipping be handled for my alcohol vending machines?

Discuss logistics options with your supplier, including shipping methods and costs. Confirm whether they handle shipping or if you need to arrange a freight forwarder. Consider the implications of import duties and taxes in your country, as these can significantly affect total costs. Ensure that the supplier provides proper documentation for customs clearance to avoid delays. -

What steps should I take if I encounter a dispute with my supplier?

To address disputes, first, communicate directly with your supplier to resolve the issue amicably. Document all communications and agreements. If unresolved, refer to your contract for dispute resolution clauses, which may include mediation or arbitration processes. Engaging a legal professional familiar with international trade can provide guidance on the best course of action. -

Are there specific regulations I should be aware of when selling alcohol through vending machines?

Yes, regulations vary widely by country and region. In many places, you’ll need licenses for alcohol sales, which may involve local government approvals. Research the legal requirements in your target market, including age restrictions and operational hours for vending machines. Compliance is crucial to avoid fines or operational shutdowns, so consider consulting with legal experts in the beverage industry.

Strategic Sourcing Conclusion and Outlook for alcohol vending machines

As the market for alcohol vending machines continues to evolve, international B2B buyers from Africa, South America, the Middle East, and Europe must prioritize strategic sourcing to capitalize on emerging opportunities. By leveraging data-driven insights and understanding regional regulations, businesses can make informed decisions that enhance their competitive edge.

Key takeaways include the importance of supplier partnerships, the need for robust compliance with local laws, and the value of customizable features that cater to diverse consumer preferences. Investing in high-quality machines that incorporate technology for secure transactions and user-friendly interfaces will not only streamline operations but also improve customer experience.

Looking forward, the alcohol vending machine sector is poised for growth, driven by changing consumer habits and technological advancements. B2B buyers should proactively explore innovative solutions and consider collaborations that align with their strategic goals. Embrace this opportunity to redefine distribution channels and drive profitability in your market. As you navigate this dynamic landscape, remember that informed sourcing decisions will be pivotal in unlocking the full potential of alcohol vending machines.