Is Vending Machine a Good Business? Key Insights for B2B

Guide to Is Vending Machine A Good Business

- Introduction: Navigating the Global Market for is vending machine a good business

- Understanding is vending machine a good business Types and Variations

- Key Industrial Applications of is vending machine a good business

- Strategic Material Selection Guide for is vending machine a good business

- In-depth Look: Manufacturing Processes and Quality Assurance for is vending machine a good business

- Comprehensive Cost and Pricing Analysis for is vending machine a good business Sourcing

- Spotlight on Potential is vending machine a good business Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for is vending machine a good business

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the is vending machine a good business Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of is vending machine a good business

- Strategic Sourcing Conclusion and Outlook for is vending machine a good business

Introduction: Navigating the Global Market for is vending machine a good business

In today’s fast-paced global economy, the vending machine business stands out as a compelling opportunity for international B2B buyers. With the ability to provide convenience and instant access to products, vending machines have evolved from traditional snack dispensers to sophisticated retail solutions catering to diverse consumer needs. This guide delves into the critical factors determining whether investing in vending machines is a viable business strategy for stakeholders in Africa, South America, the Middle East, and Europe.

Understanding the nuances of the vending machine market is paramount. This comprehensive resource covers various aspects, including the types of vending machines available, essential materials used in their manufacturing, and quality control measures that ensure reliability. Buyers will gain insights into reputable suppliers and manufacturers, enabling them to make informed sourcing decisions. Additionally, the guide addresses cost considerations and market trends, helping stakeholders assess the potential return on investment.

By equipping B2B buyers with knowledge about frequently asked questions and key industry insights, this guide empowers them to navigate the complexities of the vending machine sector confidently. Whether you are a seasoned entrepreneur or a newcomer exploring business opportunities, this resource serves as a valuable tool in making strategic decisions that align with your market objectives and growth aspirations.

Understanding is vending machine a good business Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Snack Vending | Offers a variety of snacks and beverages | Offices, schools, public areas | Pros: Low overhead, easy to stock; Cons: High competition, limited product range. |

| Healthy Vending | Focuses on nutritious snacks and beverages | Gyms, hospitals, schools | Pros: Meets rising health trends; Cons: Higher cost of healthier options. |

| Specialty Vending | Targets niche markets (e.g., organic, local) | Farmers’ markets, events | Pros: Unique offerings attract specific customers; Cons: Requires careful location selection. |

| Automated Retail Kiosks | Technology-driven with smart payment options | Airports, shopping malls | Pros: 24/7 operation, reduced labor costs; Cons: High initial investment, tech maintenance. |

| Micro Markets | Combines vending with a self-service market setup | Office buildings, warehouses | Pros: Greater product variety, fresh options; Cons: Requires management and inventory oversight. |

Traditional Snack Vending

Traditional snack vending machines are the most common type, providing a variety of snacks and beverages such as chips, candy bars, and sodas. They are typically placed in high-traffic areas like offices and schools. When considering purchasing these machines, buyers should focus on the product mix and location, as competition can be stiff. While they have low operational costs, the limited product range might not meet diverse consumer preferences.

Healthy Vending

Healthy vending machines cater to the increasing demand for nutritious snacks and beverages. They are often found in gyms, hospitals, and schools, targeting health-conscious consumers. Buyers should evaluate the sourcing of products, as healthier options can be more expensive. The advantage of aligning with health trends can enhance brand reputation, although the higher price point may limit customer uptake in some markets.

Specialty Vending

Specialty vending machines focus on niche products, such as organic, locally sourced, or gourmet items. These machines are ideal for farmers’ markets or events where unique offerings can attract specific customer segments. Buyers should consider the location carefully, as success depends on the target audience’s willingness to pay for premium items. While they can stand out in the market, the need for a tailored product selection and marketing strategy can increase complexity.

Automated Retail Kiosks

Automated retail kiosks are advanced vending solutions that incorporate technology for smart payments and inventory management. Commonly found in airports and shopping malls, these machines operate 24/7, significantly reducing labor costs. Buyers must weigh the high initial investment against the potential for increased sales volume. However, the reliance on technology means ongoing maintenance and updates are crucial for smooth operations.

Micro Markets

Micro markets blend vending with a self-service market concept, offering a wider variety of fresh food and beverages in a retail-like setting. These are typically installed in office buildings and warehouses, providing employees with convenient access to meals and snacks. Buyers should be prepared for the operational management and inventory oversight required to maintain product freshness. The ability to offer a broader selection can lead to higher customer satisfaction and increased sales.

Related Video: How To Start A Vending Machine Business Step-By-Step (With $0)

Key Industrial Applications of is vending machine a good business

| Industry/Sector | Specific Application of is vending machine a good business | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Medical supplies vending machines | Immediate access to essential items, reduced wait times | Compliance with health regulations, reliability of supply |

| Education | Snack and beverage vending in schools | Enhances student satisfaction, promotes healthy options | Variety of products offered, payment flexibility |

| Corporate Offices | Office snack and beverage vending machines | Increases employee productivity, reduces downtime | Product variety, machine maintenance support |

| Hospitality | Vending machines for toiletries and snacks in hotels | Enhances guest experience, increases ancillary revenue | Quality of products, machine aesthetics and placement |

| Transportation Hubs | Vending machines at airports and train stations | Provides convenience for travelers, increases sales | High foot traffic analysis, product selection for travelers |

Healthcare

In the healthcare sector, vending machines for medical supplies can significantly improve efficiency. Hospitals and clinics can install vending machines stocked with essential items like gloves, masks, and sanitizers, providing immediate access for medical staff. This reduces wait times and ensures that crucial supplies are always available. International buyers should consider compliance with health regulations and the reliability of supply chains, especially in regions with logistical challenges.

Education

Vending machines in educational institutions serve a dual purpose: offering snacks and beverages while promoting healthy choices. By providing nutritious options, schools can enhance student satisfaction and well-being. This initiative encourages healthy eating habits among students and can be integrated into wellness programs. B2B buyers in this sector should focus on product variety and payment flexibility to accommodate diverse student needs and preferences.

Corporate Offices

In corporate environments, vending machines that offer snacks and beverages can enhance employee productivity. By reducing the need for employees to leave the premises for refreshments, companies can minimize downtime and maintain a continuous workflow. Additionally, a well-stocked vending machine can contribute to employee satisfaction and morale. Key considerations for sourcing include the variety of products offered and the availability of maintenance support to ensure machines are always operational.

Hospitality

In the hospitality industry, vending machines that dispense toiletries and snacks can significantly enhance the guest experience. Hotels can provide convenient access to essential items, ensuring that guests have what they need without having to leave the premises. This not only improves guest satisfaction but also generates additional revenue for the hotel. When sourcing, businesses should prioritize product quality and the aesthetic appeal of vending machines to complement the hotel environment.

Transportation Hubs

Vending machines located in airports and train stations cater to the needs of travelers seeking convenience. These machines can offer a variety of food and beverage options, providing a quick solution for passengers on the go. The high foot traffic in these locations presents a lucrative opportunity for vending machine operators. International buyers should analyze foot traffic patterns and select products that align with the preferences of travelers in their specific regions.

Related Video: How to Start a Vending Machine Business, Cost, Tips, How Much You Make

Strategic Material Selection Guide for is vending machine a good business

When considering the materials for vending machines, it is essential to analyze common materials used in their construction from a B2B perspective. The selection of materials impacts not only the performance and durability of the machines but also their compliance with international standards, which is crucial for buyers across various regions, including Africa, South America, the Middle East, and Europe.

Stainless Steel

Key Properties: Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand a range of temperatures. It is often used in environments where hygiene is paramount, such as food and beverage vending machines.

Pros & Cons: The main advantage of stainless steel is its durability and resistance to rust and staining, making it ideal for outdoor and high-moisture environments. However, it can be more expensive than other materials, and its manufacturing process can be complex, requiring specialized techniques.

Impact on Application: Stainless steel is compatible with a variety of media, including food and beverages, ensuring safety and compliance with health regulations. Its non-porous surface is easy to clean, which is a significant benefit for maintaining hygiene standards.

Specific Considerations for International Buyers: Buyers should ensure that the stainless steel used meets international standards such as ASTM A240 for stainless steel sheets and plates. Additionally, understanding local regulations regarding food safety is crucial, especially in regions like Europe, where compliance is strictly enforced.

Carbon Steel

Key Properties: Carbon steel is characterized by its high tensile strength and hardness. It is often used in structural components of vending machines.

Pros & Cons: Carbon steel is cost-effective and provides good mechanical properties, making it suitable for non-corrosive applications. However, it is susceptible to corrosion if not properly coated or treated, which can lead to a shorter lifespan in humid environments.

Impact on Application: While carbon steel can be used in vending machines, it is less suitable for those intended for outdoor use or in wet environments unless adequately protected. This limitation can affect its application in regions with high humidity or rainfall.

Specific Considerations for International Buyers: Buyers should consider protective coatings or treatments to enhance corrosion resistance. Compliance with standards such as ASTM A36 for carbon structural steel is also important for ensuring quality and safety.

Aluminum

Key Properties: Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity. It is often used in the frames and panels of vending machines.

Pros & Cons: The main advantage of aluminum is its lightweight nature, which makes transportation and installation easier. However, it may not be as strong as steel, and its cost can vary significantly based on alloy composition.

Impact on Application: Aluminum is suitable for a variety of applications, including those that require lightweight materials. It is also compatible with various media, making it a versatile choice for vending machines.

Specific Considerations for International Buyers: Buyers should look for aluminum that meets standards such as ASTM B221 for extruded aluminum alloys. Understanding local recycling regulations is also crucial, as aluminum is highly recyclable.

Polycarbonate

Key Properties: Polycarbonate is a durable thermoplastic known for its impact resistance and transparency. It is often used for the windows and doors of vending machines.

Pros & Cons: The key advantage of polycarbonate is its high impact resistance, making it ideal for high-traffic areas. However, it can be more prone to scratching and may require protective coatings to maintain clarity.

Impact on Application: Polycarbonate is suitable for applications requiring visibility, such as displaying products in vending machines. Its ability to withstand various weather conditions makes it a good choice for outdoor installations.

Specific Considerations for International Buyers: Buyers should ensure that the polycarbonate used complies with standards such as ASTM D576 for plastic materials. Awareness of UV resistance and potential degradation over time is also important, especially in sunny regions.

| Material | Typical Use Case for is vending machine a good business | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food and beverage vending machines | Excellent corrosion resistance | Higher cost, complex manufacturing | High |

| Carbon Steel | Structural components | Cost-effective, good strength | Susceptible to corrosion | Low |

| Aluminum | Frames and panels | Lightweight, good thermal conductivity | Lower strength compared to steel | Medium |

| Polycarbonate | Windows and doors | High impact resistance | Prone to scratching | Medium |

This strategic material selection guide provides insights into the various materials used in vending machines, highlighting their properties, advantages, disadvantages, and considerations for international buyers. Understanding these factors will enable B2B buyers to make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for is vending machine a good business

Manufacturing Processes for Vending Machines

The manufacturing of vending machines involves several critical stages, each contributing to the overall quality and functionality of the final product. Understanding these processes is essential for international B2B buyers seeking reliable suppliers.

1. Material Preparation

The first stage in the manufacturing process is material preparation. This involves sourcing high-quality materials such as steel, aluminum, and plastic. Buyers should look for suppliers that prioritize sustainable sourcing practices, as this can significantly impact the machine’s durability and environmental footprint. Additionally, suppliers should provide material certifications to guarantee compliance with international standards.

2. Forming

The forming stage includes processes such as cutting, bending, and stamping. Advanced techniques like CNC (Computer Numerical Control) machining are often employed to ensure precision in shaping components. This stage is crucial as it dictates the structural integrity of the vending machine. Buyers should inquire about the machinery used and the expertise of the workforce involved in this process.

3. Assembly

Once individual components are formed, they are assembled into the final product. This stage typically includes the integration of electrical systems, payment mechanisms, and refrigeration units. Automated assembly lines can enhance consistency and speed, but manual assembly may be required for complex parts. B2B buyers should verify the assembly methods used by potential suppliers to ensure they align with their quality expectations.

4. Finishing

Finishing processes such as painting, powder coating, and surface treatments are applied to improve aesthetics and protect against corrosion. The choice of finishing techniques can influence the machine’s longevity and maintenance requirements. Buyers should request information on the finishing processes, including the types of coatings used and their compliance with environmental regulations.

Quality Assurance in Vending Machine Manufacturing

Quality assurance (QA) is a critical aspect of the manufacturing process, ensuring that the final product meets specified standards and performs reliably. For international B2B buyers, understanding the QA protocols of potential suppliers is essential.

Illustrative Image (Source: Google Search)

International Standards

Adherence to international quality standards is vital for ensuring product reliability. Suppliers should comply with:

- ISO 9001: This standard focuses on quality management systems and is essential for any manufacturer aiming for international recognition.

- CE Marking: Particularly relevant for suppliers in Europe, CE marking indicates conformity with health, safety, and environmental protection standards.

- API Standards: For vending machines that dispense specific products (e.g., pharmaceuticals), compliance with API standards may be necessary.

Quality Control Checkpoints

To maintain quality throughout the manufacturing process, various quality control checkpoints should be implemented:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards before processing.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify defects early, reducing waste and rework.

- Final Quality Control (FQC): The final product is subjected to rigorous testing to ensure it meets all specifications before shipment.

Common Testing Methods

Testing methods can vary based on the machine’s complexity and intended use. Common methods include:

- Functional Testing: Ensuring all mechanical and electronic components operate as intended.

- Safety Testing: Assessing the machine for electrical safety, including compliance with local regulations.

- Durability Testing: Simulating long-term use to identify potential failure points.

Verifying Supplier Quality Control

B2B buyers should take proactive steps to verify the quality control measures of potential suppliers:

- Supplier Audits: Conducting on-site audits can provide insights into the manufacturing processes and quality control measures in place.

- Quality Assurance Reports: Requesting detailed QA reports can help assess the supplier’s commitment to quality.

- Third-Party Inspections: Engaging third-party inspection agencies to evaluate compliance with international standards can provide an additional layer of assurance.

QC and Certification Nuances for International Buyers

When sourcing vending machines internationally, buyers must navigate various certification and compliance nuances:

- Cultural and Regulatory Differences: Different regions may have specific regulations regarding safety and environmental impact. It is crucial to understand these differences when sourcing from Africa, South America, the Middle East, or Europe.

- Documentation Requirements: Ensure that suppliers provide all necessary documentation, including certificates of compliance, test reports, and material safety data sheets. This documentation is essential for customs clearance and regulatory compliance in the buyer’s country.

- Post-Purchase Support: Evaluate the supplier’s ability to provide post-purchase support, including warranty services and spare parts availability. A reliable supplier should offer clear terms regarding support and maintenance.

Conclusion

The manufacturing processes and quality assurance practices for vending machines are integral to the success of international B2B buyers. By understanding these processes and verifying supplier capabilities, buyers can make informed decisions that align with their business needs. Prioritizing quality, compliance, and supplier reliability will ultimately contribute to a successful vending machine venture in diverse markets.

Related Video: Business English Vocabulary : VV 47 – Manufacturing & Production Process (1) | English Vocabulary

Comprehensive Cost and Pricing Analysis for is vending machine a good business Sourcing

Understanding the cost structure and pricing dynamics of vending machines is crucial for international B2B buyers, especially those from Africa, South America, the Middle East, and Europe. This analysis will delve into the key cost components, price influencers, and actionable buyer tips to navigate this segment effectively.

Cost Components

-

Materials: The materials used in vending machines, including metals, plastics, and electronic components, significantly influence costs. Higher quality materials can lead to increased durability and functionality but may raise the initial purchase price.

-

Labor: Labor costs encompass the wages for skilled workers involved in manufacturing, assembly, and installation. In regions with higher labor costs, such as parts of Europe, this can significantly affect the overall pricing structure.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and administrative expenses. Efficient manufacturing processes can help minimize overhead costs, impacting the final price.

-

Tooling: The cost of tools and machinery necessary for producing vending machines can be substantial. Custom designs or features will increase tooling costs, which should be factored into the overall pricing.

-

Quality Control (QC): Implementing rigorous QC measures ensures product reliability and compliance with international standards. However, these practices add to the cost, which may be reflected in the pricing of high-quality vending machines.

Illustrative Image (Source: Google Search)

-

Logistics: Shipping and handling costs vary greatly depending on the destination. International shipping can be expensive, especially for bulky vending machines, and should be carefully evaluated by buyers.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure profitability. Understanding the expected margins within the vending machine industry can aid buyers in assessing the fairness of pricing.

Price Influencers

Several factors can affect the pricing of vending machines:

-

Volume/MOQ: Bulk orders can lead to discounts. Establishing a long-term relationship with suppliers may also yield better pricing based on higher volumes.

-

Specifications/Customization: Custom features or specifications can increase costs. Buyers should weigh the need for customization against potential price increases.

-

Materials: The choice of materials directly affects durability and cost. Sustainable or premium materials may enhance the machine’s appeal but also raise costs.

-

Quality/Certifications: Machines that meet international quality standards or certifications may command higher prices. However, these can be advantageous for marketability and compliance.

-

Supplier Factors: The supplier’s reputation, location, and operational efficiency can influence pricing. Established suppliers may offer better reliability but at a higher cost.

-

Incoterms: Understanding the terms of trade is vital. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) impact the total landed cost and should be negotiated clearly.

Buyer Tips

-

Negotiation: Engage in thorough negotiations with suppliers. Leverage your purchasing power, especially for large orders, to secure better pricing.

-

Cost-Efficiency: Assess the Total Cost of Ownership (TCO), which includes not only the initial purchase price but also maintenance, operational costs, and potential revenue generation over time.

-

Pricing Nuances: International buyers should be aware of currency fluctuations and local market conditions that can affect pricing. Understanding regional pricing norms can aid in negotiations.

-

Research and Comparison: Conduct extensive market research to compare prices and specifications across different suppliers and regions. This will empower buyers to make informed decisions.

In conclusion, while the vending machine business presents significant opportunities, understanding the comprehensive cost structure and pricing dynamics is essential for international B2B buyers. By considering these insights, buyers can make strategic decisions that align with their business objectives while optimizing their investment.

Spotlight on Potential is vending machine a good business Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘is vending machine a good business’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for is vending machine a good business

Key Technical Properties for Vending Machines

When considering vending machines as a business investment, understanding their technical specifications is crucial. Here are some essential properties that international B2B buyers should evaluate:

-

Material Grade: The quality of materials used in vending machine construction affects durability and maintenance. Common materials include stainless steel for the outer shell and high-grade plastics for internal components. Higher-grade materials resist rust and corrosion, which is particularly important in humid climates found in parts of Africa and South America.

-

Capacity and Size: Vending machines come in various sizes with differing product capacities. Buyers should assess how many products can be housed and the physical dimensions of the machine to ensure it fits the intended location. A larger capacity can lead to higher sales volume but may require more space and a higher initial investment.

-

Power Requirements: Understanding the energy consumption of vending machines is vital for operational cost estimation. Machines may vary in power needs, influencing electricity costs, especially in regions where energy prices are high. It’s important to consider energy-efficient models, which can reduce long-term operational costs.

-

Payment Systems: Modern vending machines offer multiple payment options, including cash, credit/debit cards, and mobile payments. Evaluating the payment systems is critical for customer convenience and can significantly impact sales. Machines that accept a wider range of payment methods are more likely to attract customers.

-

User Interface: The interface should be intuitive and accessible. Features such as touchscreens, multiple language options, and clear product display can enhance customer experience. A user-friendly interface can lead to increased sales and customer satisfaction.

-

Temperature Control: For machines that dispense perishable items, effective temperature control is essential. Ensuring that the machine maintains appropriate temperatures for food safety can prevent spoilage and enhance product quality, making it a key selling point.

Common Trade Terms in the Vending Machine Industry

Understanding industry jargon is essential for effective communication and negotiation in the vending machine market. Here are some key terms:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce components that are used in another company’s products. In the vending machine industry, OEMs may supply parts like payment systems or cooling units. Understanding OEM relationships can help buyers identify quality parts and negotiate better deals.

-

MOQ (Minimum Order Quantity): This indicates the smallest number of units that a supplier is willing to sell. Knowing the MOQ is important for budgeting and inventory planning, especially for buyers looking to enter new markets or test products with limited initial investment.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers to invite them to bid on specific products or services. It typically includes details about the quantity and specifications required. Buyers can use RFQs to compare pricing and terms among different vendors, ensuring they get the best deal.

-

Incoterms (International Commercial Terms): These are international standards for shipping and freight that define the responsibilities of buyers and sellers. Understanding Incoterms can help buyers manage logistics and clarify who is responsible for shipping costs, insurance, and risk during transportation.

-

Lead Time: This refers to the time taken from placing an order to the delivery of the product. In the vending machine business, understanding lead times is essential for planning inventory and ensuring timely availability of machines for new locations.

-

Warranty: A warranty is a guarantee from the manufacturer regarding the quality and longevity of the product. Knowing the warranty terms can help buyers understand their rights and the level of support they can expect post-purchase, which is crucial for maintaining operational efficiency.

By familiarizing themselves with these technical properties and trade terms, international B2B buyers can make informed decisions when investing in vending machines, ensuring they choose the right products for their markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the is vending machine a good business Sector

Market Overview & Key Trends

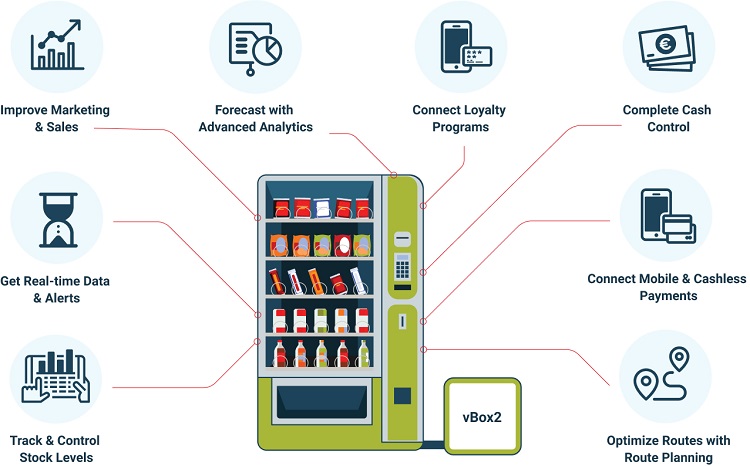

The vending machine industry is experiencing transformative changes driven by technological advancements and shifting consumer preferences. Globally, the market is projected to grow significantly, with innovations such as cashless payment systems, smart vending solutions, and IoT integration becoming standard. For B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, these trends present unique opportunities. The demand for healthy and convenient snack options is on the rise, leading to an increased presence of fresh food vending machines and organic product offerings.

Emerging markets are witnessing a rapid expansion of vending services, fueled by urbanization and the increasing pace of life. For instance, countries in Africa and South America are tapping into the vending business as a low-cost entry into retail. B2B buyers should also note the importance of data analytics in optimizing machine placement and inventory management, ensuring that popular products are readily available, thereby enhancing customer satisfaction and increasing sales.

Additionally, sustainability is becoming a key focus in the vending sector. Eco-friendly machines and biodegradable packaging are increasingly demanded by consumers and businesses alike. This trend aligns well with the global push towards sustainable practices, making it crucial for international buyers to prioritize suppliers who adhere to these values.

Sustainability & Ethical Sourcing in B2B

Sustainability in the vending machine industry is not just a trend; it has become a business imperative. The environmental impact of traditional vending operations can be significant, from energy consumption to waste generation. B2B buyers must consider suppliers who utilize energy-efficient machines and offer sustainable product options. For example, vending machines equipped with energy-saving technology can significantly reduce electricity usage, thereby decreasing the overall carbon footprint.

Moreover, ethical sourcing is increasingly important. Buyers should seek partnerships with manufacturers who prioritize responsible sourcing of materials and adhere to fair labor practices. Certifications such as Fair Trade, Rainforest Alliance, and organic labeling can serve as indicators of a supplier’s commitment to sustainability and ethical practices. By selecting partners who align with these values, B2B buyers can enhance their brand reputation and appeal to a growing consumer base that values sustainability.

The importance of transparent supply chains cannot be overstated. Buyers should demand visibility into the sourcing processes of their vendors to ensure compliance with environmental standards and ethical practices. This approach not only mitigates risks but also fosters trust and loyalty among consumers.

Brief Evolution/History

The vending machine industry has evolved significantly since its inception in the late 19th century. Initially, machines offered simple products like postcards and gum. Over the decades, technological advancements have transformed vending into a sophisticated retail channel. The introduction of electronic payment systems in the 1980s marked a pivotal moment, allowing for cashless transactions that have now become standard.

In the 21st century, the focus has shifted towards incorporating technology and sustainability into the vending experience. Smart vending machines that connect to the internet for real-time inventory management and consumer interaction are now commonplace. As consumer preferences continue to evolve, the vending industry is poised for further innovation, making it an attractive sector for international B2B buyers looking for growth opportunities.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of is vending machine a good business

-

What should I consider when vetting suppliers for vending machines?

When vetting suppliers, assess their reputation by checking reviews and testimonials from previous clients. Evaluate their experience in the vending machine industry, specifically in your target market. Request information on their production capacity, lead times, and after-sales support. Furthermore, verify if they comply with local regulations and standards relevant to your region, ensuring you are partnering with a reliable and compliant supplier. -

Can vending machines be customized to fit my business needs?

Yes, many suppliers offer customization options for vending machines. You can request modifications in size, design, product selection, and payment systems to align with your business model. Be sure to communicate your specific requirements clearly and ask for examples of previous custom projects they have completed. This will help you gauge their capability to meet your expectations. -

What are the typical minimum order quantities (MOQ) and lead times for vending machines?

MOQs for vending machines can vary significantly depending on the supplier and the type of machine. Generally, expect MOQs to range from 5 to 20 units for standard models. Lead times also differ, typically ranging from 4 to 12 weeks, depending on customization requirements and the supplier’s production schedule. Always confirm these details upfront to plan your procurement accordingly. -

What payment terms should I expect when sourcing vending machines internationally?

Payment terms can vary by supplier, but common practices include a deposit (usually 30-50%) upfront, with the balance due upon delivery or prior to shipment. For international transactions, consider using secure payment methods such as letters of credit or escrow services to mitigate risks. Discuss and agree on payment terms in advance to avoid misunderstandings later in the process. -

How can I ensure quality assurance and certifications for vending machines?

Request certifications and quality assurance documentation from your suppliers, such as ISO certification or compliance with CE and UL standards. Conduct a thorough inspection of the machines upon delivery to verify quality and functionality. If possible, consider arranging for third-party inspections or audits to ensure the machines meet your expectations and local regulations. -

What logistical considerations should I keep in mind when importing vending machines?

When importing vending machines, consider factors such as shipping methods, customs clearance, and local transportation. Determine the best shipping options (air vs. sea) based on cost and urgency. Ensure all necessary documentation is in order to avoid customs delays. Additionally, plan for the final delivery logistics to your location, including any installation requirements. -

How can I handle disputes with vending machine suppliers?

Establish clear terms in your contract regarding dispute resolution, including communication channels and timelines. If a dispute arises, maintain open communication with the supplier to resolve the issue amicably. If necessary, consider mediation or arbitration as alternative dispute resolution methods. Always document all communications and agreements related to the dispute for future reference. -

What are the common challenges when entering the vending machine business internationally?

Common challenges include navigating local regulations, understanding market preferences, and managing supply chain logistics. Additionally, cultural differences may affect product selection and marketing strategies. Conduct thorough market research to understand local consumer behavior and preferences. Building strong relationships with local suppliers and partners can also help mitigate these challenges and enhance your market entry strategy.

Strategic Sourcing Conclusion and Outlook for is vending machine a good business

In conclusion, the vending machine business presents a compelling opportunity for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. Key takeaways highlight the importance of strategic sourcing—from selecting the right suppliers to understanding local market dynamics. Investors must prioritize high-demand product offerings, ensure compliance with regional regulations, and leverage technology for efficient operations.

The adaptability of vending machines to cater to local tastes and preferences enhances their market viability. Moreover, emerging technologies, such as cashless payment systems and remote inventory management, are reshaping the vending landscape, offering significant competitive advantages.

As you consider entering this market, remember that thorough market research and strategic supplier partnerships are critical. These steps will not only mitigate risks but also maximize your return on investment.

We encourage B2B buyers to actively explore vending machine solutions that align with their business goals. By capitalizing on this growing sector, you can position your organization for sustained success in an increasingly automated world. Embrace the future of vending—your next venture awaits!