Do You Need a License for Vending Machines? Essential

Guide to Do You Need A License For Vending Machines

- Introduction: Navigating the Global Market for do you need a license for vending machines

- Understanding do you need a license for vending machines Types and Variations

- Key Industrial Applications of do you need a license for vending machines

- Strategic Material Selection Guide for do you need a license for vending machines

- In-depth Look: Manufacturing Processes and Quality Assurance for do you need a license for vending machines

- Comprehensive Cost and Pricing Analysis for do you need a license for vending machines Sourcing

- Spotlight on Potential do you need a license for vending machines Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for do you need a license for vending machines

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the do you need a license for vending machines Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of do you need a license for vending machines

- Strategic Sourcing Conclusion and Outlook for do you need a license for vending machines

Introduction: Navigating the Global Market for do you need a license for vending machines

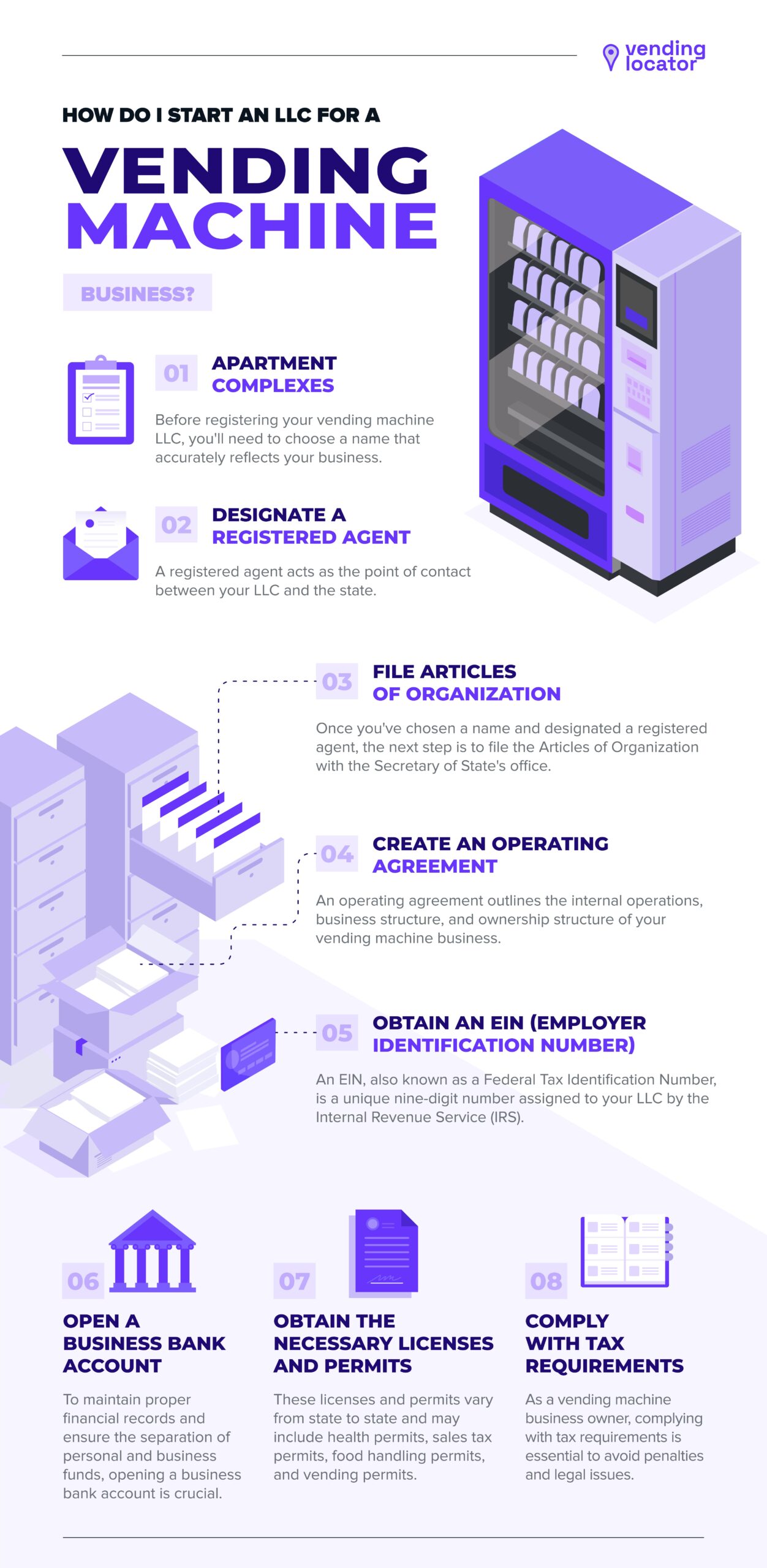

In the dynamic world of vending machines, understanding the licensing requirements is critical for international B2B buyers aiming to enter or expand in diverse markets. Licensing not only ensures compliance with local regulations but also safeguards your investment by mitigating legal risks. Whether you’re sourcing machines for placement in schools, offices, or public spaces, knowing if and how to obtain a license can significantly influence your operational strategy and profitability.

This comprehensive guide delves into the intricate landscape of vending machine licensing, covering essential aspects such as types of licenses, materials used, manufacturing and quality control standards, supplier options, and cost analysis. Additionally, we address common questions that arise during the licensing process, providing clarity and actionable insights for your sourcing decisions.

With a focus on international markets, particularly in Africa, South America, the Middle East, and Europe, this guide empowers B2B buyers to navigate the complexities of vending machine operations. By equipping you with the knowledge to make informed decisions, we facilitate smoother market entry and expansion, ensuring that your vending machine business is not only compliant but also positioned for success in a competitive landscape. Embrace this opportunity to enhance your understanding and streamline your operations in the global vending machine market.

Understanding do you need a license for vending machines Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Food and Beverage Vending | Offers snacks, drinks, and meals; often refrigerated | Offices, schools, hospitals | Pros: High demand, diverse offerings. Cons: Requires regular restocking and maintenance. |

| Specialized Vending Machines | Machines for specific products (e.g., electronics, cosmetics) | Retail stores, airports, events | Pros: Niche market appeal, less competition. Cons: Higher initial investment, limited customer base. |

| Bulk Vending Machines | Dispenses products in bulk (e.g., candy, toys) | Arcades, schools, parks | Pros: Low operational costs, simple maintenance. Cons: Lower profit margins per sale. |

| Smart Vending Machines | Equipped with technology for cashless payments and inventory tracking | Tech-savvy locations, universities | Pros: Enhanced user experience, real-time data analytics. Cons: Higher upfront costs, technology dependence. |

| Health and Wellness Vending | Focus on healthy snacks and drinks; often organic or local | Gyms, wellness centers, corporate offices | Pros: Growing market trend, aligns with health initiatives. Cons: Higher product costs, potential limited audience. |

Food and Beverage Vending

Food and beverage vending machines are the most common type, providing a variety of snacks, drinks, and meals. They are typically found in high-traffic areas such as offices, schools, and hospitals. For B2B buyers, these machines offer a reliable income stream due to the constant demand for quick and accessible food options. However, they require regular restocking and maintenance to ensure product freshness and quality, which can be a logistical challenge.

Specialized Vending Machines

Specialized vending machines cater to specific niches, offering products like electronics, beauty products, or even personal protective equipment. These machines are often placed in strategic locations such as airports or retail stores where the target demographic is likely to be present. While they can generate significant interest and sales, buyers should consider the higher initial investment and potentially limited customer base, which may affect profitability.

Bulk Vending Machines

Bulk vending machines provide products in larger quantities, such as candy or small toys, making them popular in arcades, schools, and parks. Their low operational costs and straightforward maintenance make them appealing to B2B buyers. However, the profit margins per sale can be lower compared to other vending options, requiring higher sales volumes to achieve desired returns.

Smart Vending Machines

Smart vending machines incorporate advanced technology, allowing for cashless payments, inventory tracking, and customer interaction through touch screens. They are particularly suited for tech-savvy locations like universities and urban centers. The initial costs may be higher due to the technology involved, but the benefits of real-time data analytics and enhanced user experience can lead to increased sales and customer loyalty.

Health and Wellness Vending

Health and wellness vending machines focus on providing nutritious snacks and beverages, often featuring organic or locally sourced products. They are increasingly popular in gyms, wellness centers, and corporate offices as businesses aim to promote healthier lifestyles. While this trend presents a lucrative opportunity, buyers must consider the higher product costs and potential limitations in audience reach, as not all consumers prioritize health-focused options.

Related Video: CS 198-126: Lecture 12 – Diffusion Models

Key Industrial Applications of do you need a license for vending machines

| Industry/Sector | Specific Application of do you need a license for vending machines | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Placement of vending machines in shopping malls | Increased foot traffic, additional revenue stream | Local regulations, target demographics |

| Healthcare | Vending machines in hospitals for snacks and medical supplies | Convenience for patients and staff, quick access | Compliance with health regulations, product selection |

| Education | Vending machines in schools and universities | Enhances student satisfaction, promotes healthy eating | Nutritional content, age-appropriate products |

| Hospitality | Vending machines in hotels for snacks and beverages | 24/7 service availability, guest convenience | Location strategy, product variety |

| Transportation | Vending machines in airports and train stations | Quick service for travelers, increased sales volume | High traffic analysis, payment system compatibility |

Retail

In the retail sector, vending machines are strategically placed in shopping malls to capitalize on foot traffic. These machines can offer a variety of products, from snacks to electronics, catering to diverse consumer needs. For international buyers, understanding local regulations regarding vending operations is crucial, as licensing requirements can vary significantly across regions. Additionally, targeting the right demographics with appropriate product offerings enhances the likelihood of success.

Healthcare

Vending machines in healthcare settings, such as hospitals, provide essential snacks and medical supplies for patients and staff. These machines not only offer convenience but also ensure that individuals have quick access to necessary items during critical times. For buyers in this sector, compliance with health regulations is paramount, necessitating a focus on product selection that meets safety and nutritional standards.

Education

In educational institutions, vending machines serve as a valuable resource for students, providing easy access to snacks and beverages. The presence of these machines can enhance student satisfaction and promote healthier eating habits when stocked with nutritious options. Buyers in this sector must consider the nutritional content of products offered, as well as age-appropriate selections to comply with educational health guidelines.

Hospitality

The hospitality industry benefits from vending machines by offering guests 24/7 access to snacks and beverages, enhancing overall guest experience. Hotels can strategically place these machines in high-traffic areas to maximize convenience and sales. For B2B buyers, developing a location strategy that considers guest flow and preferences, along with ensuring a diverse product variety, is essential for success in this application.

Transportation

Vending machines located in airports and train stations cater to travelers seeking quick service and refreshments. This application can significantly increase sales volume, especially during peak travel times. Buyers in the transportation sector should conduct high traffic analysis to determine optimal machine placement and ensure that payment systems are compatible with international currencies and contactless payment options, enhancing user experience.

Related Video: How to Start a Vending Machine Business, Cost, Tips, How Much You Make

Strategic Material Selection Guide for do you need a license for vending machines

When selecting materials for vending machines, especially for international markets, it is crucial to consider the properties, advantages, and limitations of each material. This analysis focuses on four common materials: stainless steel, aluminum, plastic, and carbon steel. Each material has unique characteristics that can significantly impact the performance and suitability of vending machines across different regions.

Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand high temperatures. It typically has a temperature rating up to 800°C and is resistant to various chemicals, making it ideal for food and beverage applications.

Pros & Cons:

The primary advantage of stainless steel is its durability and long lifespan, which reduces maintenance costs. However, it is relatively expensive compared to other materials, and its manufacturing process can be complex due to the need for specialized welding techniques.

Impact on Application:

Stainless steel is particularly well-suited for vending machines that dispense food and beverages, as it prevents contamination and is easy to clean. It is compatible with a wide range of media, including water, soft drinks, and snacks.

Considerations for International Buyers:

Buyers in regions like Europe and the Middle East often prefer stainless steel due to its hygienic properties and compliance with food safety standards (e.g., EN 10088). In Africa and South America, while the cost may be a concern, the long-term benefits often justify the initial investment.

Aluminum

Key Properties:

Aluminum is lightweight, corrosion-resistant, and has a good strength-to-weight ratio. It can withstand temperatures up to 600°C and is non-toxic, making it suitable for food applications.

Pros & Cons:

The lightweight nature of aluminum makes it easier to transport and install. However, it is less durable than stainless steel and can be prone to dents and scratches, which may affect its aesthetic appeal over time.

Impact on Application:

Aluminum is often used in vending machines that require mobility or frequent relocation. Its compatibility with various media is good, but it may not be suitable for highly acidic products due to potential corrosion.

Considerations for International Buyers:

In regions like South America and Africa, where cost efficiency is essential, aluminum can be a more affordable option. However, compliance with local standards (e.g., ASTM for materials) should be verified to ensure safety and reliability.

Plastic

Key Properties:

Plastic is lightweight, cost-effective, and resistant to corrosion. It can be molded into various shapes and sizes, making it versatile for different vending machine designs.

Pros & Cons:

The primary advantage of plastic is its low cost and ease of manufacturing. However, it may not be as durable as metals and can be susceptible to UV degradation and temperature extremes.

Impact on Application:

Plastic is commonly used for components like coin mechanisms and display panels. While it is suitable for non-food items, it may not be ideal for vending machines dispensing perishable goods.

Considerations for International Buyers:

In regions like Africa and the Middle East, where budget constraints are significant, plastic can be an attractive option. However, buyers should consider the environmental impact and potential regulations regarding plastic use in their respective countries.

Carbon Steel

Key Properties:

Carbon steel is known for its high strength and durability, with a temperature rating up to 400°C. However, it is susceptible to corrosion if not properly coated or treated.

Pros & Cons:

The cost-effectiveness of carbon steel makes it a popular choice for structural components. However, its susceptibility to rust and corrosion can lead to higher maintenance costs over time.

Impact on Application:

Carbon steel is often used in the structural framework of vending machines. It is compatible with various media but requires protective coatings to prevent corrosion, especially in humid environments.

Considerations for International Buyers:

Buyers from Europe may prefer carbon steel with protective coatings that comply with local standards (e.g., DIN). In contrast, buyers from South America and Africa should consider the long-term maintenance implications of using carbon steel in their vending machines.

Summary Table

| Material | Typical Use Case for do you need a license for vending machines | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food and beverage vending machines | Excellent durability and corrosion resistance | Higher cost and complex manufacturing | High |

| Aluminum | Mobile vending machines | Lightweight and cost-effective | Less durable, prone to dents and scratches | Medium |

| Plastic | Non-food vending machine components | Low cost and versatile | Less durable, susceptible to UV degradation | Low |

| Carbon Steel | Structural components of vending machines | Cost-effective and high strength | Susceptible to corrosion without treatment | Low |

This strategic material selection guide provides international B2B buyers with essential insights into material properties, advantages, and considerations for vending machine applications. Understanding these factors can aid in making informed purchasing decisions that align with regional standards and market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for do you need a license for vending machines

Manufacturing vending machines involves several critical processes that ensure the end product meets quality standards and operational requirements. Understanding these processes and the associated quality assurance measures is essential for B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. This section provides a comprehensive overview of typical manufacturing stages, quality control standards, and actionable insights for verifying supplier quality.

Manufacturing Processes

The manufacturing of vending machines can be divided into several key stages:

1. Material Preparation

This initial stage focuses on sourcing and preparing the raw materials required for vending machine production. Common materials include metals, plastics, glass, and electronic components. The selection of high-quality materials is crucial, as it directly impacts the machine’s durability and performance.

- Sourcing: Engage suppliers with a proven track record in providing quality materials. Ensure that they adhere to international standards, such as ISO certifications.

- Material Inspection: Conduct incoming quality control (IQC) checks to verify that the materials meet specified standards before production begins.

2. Forming

The forming process involves shaping the raw materials into the required components of the vending machine. This may include processes such as stamping, bending, and molding.

- Techniques: Techniques like CNC machining and injection molding are commonly used to achieve precision in component fabrication. These methods ensure that parts fit together seamlessly during assembly.

- Quality Checks: Implement in-process quality control (IPQC) measures to monitor the forming stage. Regular inspections can help catch defects early in the production process.

3. Assembly

Once the components are prepared, they are assembled into the final product. This stage requires skilled labor and meticulous attention to detail.

- Assembly Line Setup: Establish a streamlined assembly line to enhance efficiency. Each worker should be trained to follow standard operating procedures to minimize errors.

- Quality Assurance: Conduct functional tests during assembly to ensure that all components work together as intended. This includes electrical testing and mechanical checks.

4. Finishing

The finishing stage involves applying coatings, decals, and other aesthetic elements to the vending machine. This not only improves the machine’s appearance but also protects it from environmental factors.

- Techniques: Common finishing techniques include powder coating, painting, and screen printing. These methods should also meet environmental regulations relevant to the manufacturing location.

- Final Inspection: Before the machines are packaged for shipment, perform a final quality check (FQC) to ensure that the finished product meets all specifications and is free from defects.

Quality Assurance

Quality assurance in vending machine manufacturing is paramount to ensure reliability and customer satisfaction. Adherence to international and industry-specific standards is essential.

Relevant International Standards

- ISO 9001: This standard outlines requirements for a quality management system (QMS) and is applicable to any organization, regardless of size or industry. Certification can enhance supplier credibility.

- CE Marking: For suppliers in Europe, compliance with CE marking indicates that the product meets EU safety, health, and environmental protection requirements.

Industry-Specific Standards

- API Standards: The American Petroleum Institute (API) has standards relevant to the manufacturing of components that may be used in vending machines, especially those involving fuel or lubricants.

Quality Control Checkpoints

- Incoming Quality Control (IQC): Inspect materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Conduct checks during production to catch defects early.

- Final Quality Control (FQC): Perform comprehensive testing on the finished product to ensure it meets all operational standards.

Common Testing Methods

- Functional Testing: Verifies that all components operate as intended.

- Safety Testing: Ensures that the machine complies with safety standards, including electrical safety.

- Durability Testing: Assesses the machine’s ability to withstand wear and tear over time.

Verifying Supplier Quality

B2B buyers should take proactive steps to verify the quality assurance processes of potential suppliers:

1. Supplier Audits

Conducting audits of suppliers can provide insights into their manufacturing processes and quality control measures. Look for suppliers who welcome third-party audits and can demonstrate compliance with relevant standards.

2. Quality Reports

Request quality assurance reports from suppliers. These documents should detail their testing procedures, results, and any corrective actions taken in response to quality issues.

3. Third-Party Inspections

Engaging independent third-party inspection services can help validate the quality of the products before they are shipped. This is particularly important for international transactions where quality can vary significantly by region.

Illustrative Image (Source: Google Search)

QC/Cert Nuances for International Buyers

For international B2B buyers, understanding the nuances of quality control and certification can be challenging but is crucial for successful procurement:

- Regional Standards: Be aware of the local regulations and standards in your market. For instance, products sold in the EU must comply with CE marking, while those in the U.S. may need to meet specific safety standards.

- Documentation: Ensure that suppliers provide all necessary documentation related to compliance and certification. This will facilitate smoother customs clearance and regulatory approval.

By thoroughly understanding the manufacturing processes and quality assurance practices associated with vending machines, international B2B buyers can make informed decisions, ensuring they select suppliers who deliver high-quality products that meet their operational needs.

Related Video: Made in China 2.0: Top 10 Factory Processes You Must See

Comprehensive Cost and Pricing Analysis for do you need a license for vending machines Sourcing

When considering the procurement of vending machines, understanding the cost structure and pricing dynamics is essential for international B2B buyers. This analysis will delve into the components that contribute to the overall cost, the factors that influence pricing, and offer actionable insights for negotiation and cost efficiency.

Cost Components

-

Materials: The primary materials involved in vending machine production include metal, plastic, glass, and electronic components. The choice of materials can significantly affect the durability and aesthetics of the machines, which in turn influences pricing. Opting for high-quality materials may lead to higher upfront costs but can reduce long-term maintenance expenses.

-

Labor: Labor costs vary widely across regions. For buyers in Africa and South America, understanding local wage rates is crucial. Countries with lower labor costs may offer competitive pricing, but it is vital to assess the quality of workmanship to avoid costly repairs down the line.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, including utilities, rent, and administrative expenses. Efficient factories may pass savings on to buyers, making it beneficial to evaluate suppliers with streamlined operations.

-

Tooling: Customization of vending machines often requires specialized tooling, which can be a significant upfront cost. Buyers should weigh the need for unique designs against the potential for increased costs and longer lead times.

-

Quality Control (QC): Implementing stringent QC measures ensures product reliability but adds to the overall cost. Buyers should inquire about the QC processes of potential suppliers to gauge the impact on pricing.

-

Logistics: Shipping costs can vary based on the mode of transport, distance, and weight of the machines. Understanding Incoterms is critical for calculating total logistics costs, particularly for international transactions.

-

Margin: Supplier margins can differ based on market conditions and competition. Buyers should be aware that higher margins often correlate with better service and product support, which can justify the cost.

Price Influencers

Several factors can influence the pricing of vending machines:

-

Volume/MOQ: Purchasing in larger quantities often leads to discounts. Buyers should assess their needs and consider the benefits of bulk purchasing.

-

Specifications/Customization: Highly customized machines can incur additional costs. Buyers should determine the necessity of custom features versus standard models to optimize expenses.

-

Materials and Quality Certifications: Machines that comply with international quality standards may be priced higher but offer greater assurance of reliability and safety.

-

Supplier Factors: Established suppliers may command higher prices due to their reputation and reliability. However, emerging suppliers may provide competitive pricing with varying service levels.

-

Incoterms: Familiarity with shipping terms can greatly influence the final price. Buyers should clarify responsibilities for shipping costs and risks to avoid unexpected expenses.

Buyer Tips

-

Negotiation: Engage suppliers in transparent discussions about pricing. Understanding their cost structures can provide leverage in negotiations.

-

Cost-Efficiency: Conduct a thorough analysis of the Total Cost of Ownership (TCO), which includes not just purchase price but also maintenance, repair, and operational costs over the machine’s lifespan.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa and South America should consider currency fluctuations, local tariffs, and taxes that may affect overall costs. Establishing relationships with local suppliers can mitigate some of these risks.

-

Research and Due Diligence: Conducting market research on various suppliers can uncover competitive pricing and innovative solutions. Utilizing online platforms to compare offerings can save time and money.

Disclaimer

Prices and cost structures mentioned are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. Always consult with suppliers for the most accurate and updated pricing information.

Illustrative Image (Source: Google Search)

Spotlight on Potential do you need a license for vending machines Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘do you need a license for vending machines’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for do you need a license for vending machines

When considering the procurement of vending machines, international B2B buyers must familiarize themselves with essential technical properties and industry terminology. This knowledge not only aids in making informed purchasing decisions but also ensures compliance with local regulations and operational efficiency.

Critical Technical Properties

-

Material Grade

– Definition: The quality of materials used in vending machines, typically stainless steel or high-grade plastic.

– Importance: High-quality materials enhance durability and corrosion resistance, essential for machines exposed to various environmental conditions. Buyers should prioritize vendors who provide detailed material specifications to ensure longevity and reliability. -

Power Consumption

– Definition: The amount of electrical energy the vending machine requires to operate, often measured in watts.

– Importance: Understanding power consumption helps buyers estimate operational costs and ensure compatibility with local electrical standards. Machines with lower energy requirements can lead to significant cost savings over time. -

Capacity

– Definition: The maximum number of products a vending machine can hold, typically expressed in units or liters.

– Importance: Capacity affects the revenue potential of the machine. Buyers should assess product demand in their target locations to select machines with appropriate capacity, ensuring they are not under or overstocked. -

Temperature Range

– Definition: The operational temperature limits within which the vending machine can effectively maintain product integrity, particularly for refrigerated units.

– Importance: For machines dispensing perishable items, maintaining the correct temperature is crucial for food safety and compliance with health regulations. Buyers should ensure that machines meet local health standards. -

User Interface and Payment Options

– Definition: The technology used for user interaction, including touchscreen displays and various payment methods like cash, credit cards, and mobile payments.

– Importance: A user-friendly interface can enhance customer experience and increase sales. Additionally, offering multiple payment options caters to diverse consumer preferences, particularly in regions with varying payment habits.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships helps buyers identify reliable suppliers and gauge product quality, as OEMs often have established reputations for quality and reliability. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: MOQ can impact purchasing decisions, especially for small businesses or startups. Buyers must negotiate favorable terms to avoid excess inventory or unfulfilled orders. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers requesting pricing and terms for specific products or services.

– Importance: RFQs are essential for price comparison and ensuring transparency in supplier negotiations. Buyers should provide detailed specifications to receive accurate quotes. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined commercial terms published by the International Chamber of Commerce, defining responsibilities of buyers and sellers.

– Importance: Familiarity with Incoterms helps buyers understand shipping responsibilities, risk management, and cost allocation, which are critical for international transactions. -

Lead Time

– Definition: The time it takes from placing an order until it is delivered.

– Importance: Knowing the lead time is crucial for inventory planning and ensuring that vending machines are available when needed. Buyers should account for lead time in their operational strategies to minimize disruptions.

By understanding these technical properties and trade terms, international B2B buyers can navigate the complexities of vending machine procurement with greater confidence and efficiency. This knowledge not only aids in making informed decisions but also enhances strategic planning for market entry and growth.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the do you need a license for vending machines Sector

The vending machine sector is witnessing transformative changes driven by technological advancements and shifting consumer preferences. Globally, the demand for automated retail solutions has been spurred by the rising urbanization and the need for convenience in shopping. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must navigate a landscape characterized by rapid digitalization and evolving business models.

Market Overview & Key Trends

Key trends impacting the vending machine market include the integration of IoT (Internet of Things) technologies, which enable remote monitoring and management of machines, enhancing operational efficiency. Buyers are increasingly leaning towards smart vending solutions that utilize contactless payments and provide personalized product recommendations based on consumer data.

Emerging markets are also experiencing a surge in demand for vending machines that cater to local tastes, driven by regional culinary preferences. For instance, in South America, vending machines are adapting to include local snacks and beverages, while in Africa, there’s a growing interest in health-conscious options.

Moreover, the pandemic has accelerated the shift towards touchless technology, prompting businesses to seek machines that offer hygiene-focused features. Buyers should consider these factors when sourcing equipment, as aligning with technological trends can offer competitive advantages in diverse markets.

Sustainability & Ethical Sourcing in B2B

The environmental impact of vending machines is gaining significant attention, leading to an increased focus on sustainability within the sector. Buyers are urged to prioritize vendors who employ eco-friendly materials and practices in their manufacturing processes. This includes the use of recyclable materials for machine construction and energy-efficient components that reduce the carbon footprint.

Ethical supply chains are becoming a necessity, with consumers more aware of the sourcing practices behind the products they purchase. Vending machine operators are encouraged to seek certifications such as Fair Trade and other ‘green’ labels that signal commitment to ethical practices. By sourcing from suppliers who adhere to these standards, businesses can enhance their brand reputation and appeal to environmentally conscious consumers.

Investing in sustainable vending solutions not only addresses regulatory pressures but also opens up new market opportunities, particularly among younger, eco-aware demographics.

Brief Evolution/History

The vending machine industry has evolved significantly since its inception in the late 19th century. Originally designed to dispense simple items like postcards and chewing gum, the sector has diversified to offer a wide range of products, including fresh foods and electronics.

Technological advancements have propelled this evolution, particularly with the advent of cashless payment systems and smart technology integration. As consumers increasingly seek convenience and customization, the vending machine market continues to adapt, providing innovative solutions that meet modern consumer demands.

International B2B buyers must remain aware of these historical shifts to better understand current market dynamics and anticipate future trends in the vending machine sector.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of do you need a license for vending machines

-

What types of licenses are typically required for operating vending machines internationally?

Licensing requirements vary significantly by country and region. In general, you may need a business license, a food service license (if selling food items), and possibly a health department permit. For instance, in Europe, health and safety regulations are stringent, necessitating compliance with local food safety laws. In Africa and South America, the requirements may include local government permits. Always consult with local authorities or legal experts to ensure compliance with specific regulations. -

How can I vet potential suppliers for vending machines to ensure they comply with licensing regulations?

When vetting suppliers, request documentation of their licenses and certifications. Verify their compliance with local regulations by checking with relevant government bodies. Additionally, consider assessing their reputation through industry reviews, client testimonials, and case studies. Engaging a local legal advisor familiar with vending machine regulations can further ensure that your supplier meets all necessary standards. -

Can I customize vending machines to cater to local tastes, and how does this affect licensing?

Yes, customization is often essential for catering to local preferences. However, any changes made to the machine, especially those affecting food safety, may require additional licensing or permits. Ensure that your modifications comply with local health regulations. Engage your supplier early in the design process to understand how customization impacts licensing and operational approvals. -

What are the typical minimum order quantities (MOQs) and lead times for vending machines?

MOQs can vary widely depending on the supplier and the machine’s complexity. Generally, you might expect MOQs of 5-10 units for standard machines, while custom machines may have higher requirements. Lead times can range from 6 weeks to several months, especially for customized orders. Always clarify these details upfront to manage your inventory planning and operational timelines effectively. -

What payment terms should I expect when sourcing vending machines internationally?

Payment terms typically range from upfront payments to net 30-60 days after delivery. It’s common to see a deposit required before production, especially for custom orders. International transactions may also involve letters of credit or escrow services to mitigate risks. Negotiate clear terms that protect both parties and consider currency exchange rates when budgeting for your purchase.

-

How can I ensure quality assurance and certification compliance for vending machines?

To ensure quality assurance, request certifications from your supplier that demonstrate compliance with international safety and quality standards, such as ISO 9001. Implement a quality control process that includes pre-shipment inspections. If operating in regions with strict health regulations, ensure that machines meet local safety standards. Regular audits and supplier assessments can help maintain consistent quality. -

What logistics considerations should I be aware of when importing vending machines?

Importing vending machines involves understanding customs regulations, tariffs, and shipping logistics. Ensure that your supplier provides all necessary documentation, such as bills of lading and customs declarations. Collaborate with a logistics partner experienced in international shipping to navigate these complexities effectively. Also, factor in lead times for customs clearance to avoid delays in your operations. -

How should I handle disputes with suppliers regarding licenses or machine compliance?

Address disputes promptly by reviewing the terms outlined in your purchase agreement. Maintain clear communication with your supplier and document all interactions. If necessary, involve a mediator or legal professional to facilitate a resolution. Understanding local laws related to business disputes is crucial, as they can vary significantly between regions. Consider establishing a clear dispute resolution process in your contracts to streamline future issues.

Strategic Sourcing Conclusion and Outlook for do you need a license for vending machines

In conclusion, navigating the complex landscape of vending machine licensing is crucial for international B2B buyers looking to expand their operations across diverse markets. Key takeaways include understanding local regulations, which vary significantly between regions such as Africa, South America, the Middle East, and Europe. Buyers must prioritize strategic sourcing to identify reliable suppliers who can provide not only machines but also guidance on compliance and best practices in their respective markets.

Investing in local knowledge and partnerships can mitigate risks and enhance operational efficiency. Additionally, leveraging technology to monitor and manage vending operations can lead to increased profitability and customer satisfaction.

As you plan your entry or expansion into the vending machine market, consider these insights as a roadmap. Actively engage with local authorities and business networks to stay informed about licensing requirements and market trends. The future of vending machines is promising, and with the right strategies in place, your business can thrive in this dynamic industry. Embrace this opportunity to innovate and lead in your market.