Unlock Profits with Pizza Making Vending Machines: A B2B

Guide to Pizza Making Vending Machine

- Introduction: Navigating the Global Market for pizza making vending machine

- Understanding pizza making vending machine Types and Variations

- Key Industrial Applications of pizza making vending machine

- Strategic Material Selection Guide for pizza making vending machine

- In-depth Look: Manufacturing Processes and Quality Assurance for pizza making vending machine

- Comprehensive Cost and Pricing Analysis for pizza making vending machine Sourcing

- Spotlight on Potential pizza making vending machine Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for pizza making vending machine

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the pizza making vending machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of pizza making vending machine

- Strategic Sourcing Conclusion and Outlook for pizza making vending machine

Introduction: Navigating the Global Market for pizza making vending machine

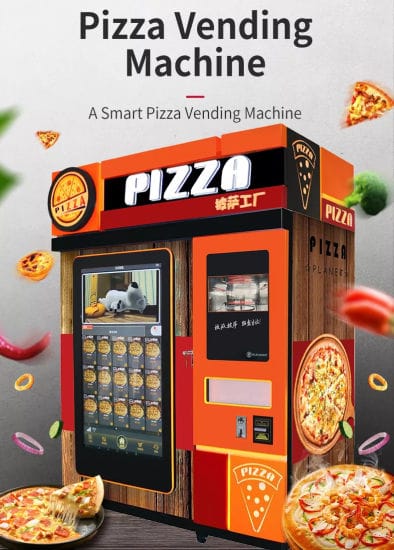

In the rapidly evolving landscape of the food and beverage industry, pizza making vending machines stand out as a revolutionary solution for on-demand dining. These machines not only cater to the increasing consumer demand for fast, convenient, and quality food options but also present a lucrative opportunity for international B2B buyers. With their ability to prepare and serve fresh pizzas within minutes, they redefine traditional dining experiences and offer a compelling business model for entrepreneurs across diverse markets.

Illustrative Image (Source: Google Search)

This guide aims to equip B2B buyers from regions such as Africa, South America, the Middle East, and Europe—particularly in emerging markets like Saudi Arabia and Kenya—with the knowledge necessary to navigate the complexities of sourcing pizza vending machines. We will explore the various types of machines, assess materials used, and delve into manufacturing and quality control standards that ensure product reliability. Additionally, we will provide insights into supplier options, cost considerations, and the current market landscape for pizza vending machines.

By addressing frequently asked questions and offering actionable insights, this comprehensive resource empowers buyers to make informed sourcing decisions. Whether you are looking to enhance your existing offerings or venture into a new market, understanding the intricacies of pizza making vending machines will be pivotal to your success. Embrace this opportunity to innovate and capitalize on a growing trend that caters to the modern consumer’s appetite for convenience and quality.

Understanding pizza making vending machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Pizza Vending Machine | Offers a selection of pre-prepared pizzas with customizable toppings | Fast-food outlets, shopping malls | Pros: Established technology, reliable. Cons: Limited customization options. |

| Automated Pizza Oven | Integrates cooking technology to prepare fresh pizzas on demand | Restaurants, food courts, convenience stores | Pros: Freshly made pizza, high quality. Cons: Higher initial investment and maintenance costs. |

| Mobile Pizza Vending Unit | Compact, portable units for events and festivals | Outdoor events, fairs, corporate gatherings | Pros: Flexibility and mobility, low operational costs. Cons: Limited capacity and menu. |

| Gourmet Pizza Vending Machine | Focuses on high-quality ingredients and artisanal recipes | Upscale locations, gourmet food markets | Pros: Attracts food enthusiasts, premium pricing potential. Cons: Higher ingredient costs and slower sales cycle. |

| Hybrid Pizza Vending Machine | Combines traditional vending with online ordering capabilities | Urban areas, tech-friendly environments | Pros: Enhanced customer engagement, diverse menu options. Cons: Requires tech-savvy customers, potential technical issues. |

Traditional Pizza Vending Machine

Traditional pizza vending machines are designed to dispense pre-prepared pizzas with limited customization options. They are widely used in fast-food outlets and shopping malls due to their reliability and established technology. Buyers should consider factors such as machine size, product variety, and ease of maintenance when investing in this type of machine, as these aspects directly impact customer satisfaction and operational efficiency.

Automated Pizza Oven

Automated pizza ovens represent a significant advancement in vending technology, offering freshly prepared pizzas made to order. These machines are ideal for restaurants, food courts, and convenience stores where quality is paramount. While they provide a superior product, buyers must weigh the higher initial investment and ongoing maintenance costs against the potential for increased sales and customer loyalty.

Mobile Pizza Vending Unit

Mobile pizza vending units are compact and portable, making them perfect for outdoor events, festivals, and corporate gatherings. These units typically have lower operational costs and can adapt to various locations, appealing to a diverse customer base. However, potential buyers should be mindful of the limited capacity and menu options, which may restrict profitability during peak demand periods.

Gourmet Pizza Vending Machine

Gourmet pizza vending machines focus on high-quality ingredients and artisanal recipes, targeting upscale locations and gourmet food markets. These machines can attract food enthusiasts willing to pay premium prices for unique offerings. Buyers need to consider the higher ingredient costs and potentially slower sales cycle, as well as the need for effective marketing strategies to reach their target audience.

Hybrid Pizza Vending Machine

Hybrid pizza vending machines integrate traditional vending with online ordering capabilities, appealing to tech-savvy consumers in urban areas. They allow for enhanced customer engagement and a diverse menu, which can lead to increased sales. However, buyers should be prepared for potential technical issues and the need for a customer base that is comfortable with technology, which may vary by region.

Related Video: Pizza Vending Machine

Key Industrial Applications of pizza making vending machine

| Industry/Sector | Specific Application of Pizza Making Vending Machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Hotel Lobbies | Provides guests with convenient dining options | Reliable supply of fresh ingredients, machine maintenance support |

| Corporate Offices | Break Rooms | Offers employees quick meal solutions | Bulk sourcing of popular pizza varieties, nutritional compliance |

| Public Transport | Train Stations | Serves travelers with fast, quality meals | Compliance with health regulations, efficient stocking logistics |

| Educational Institutions | College Campuses | Meets student demand for quick meals | Variety in menu options, affordability, local supplier partnerships |

| Retail | Shopping Malls | Attracts foot traffic and boosts sales | Trend analysis for popular flavors, seasonal menu adjustments |

Hospitality

In the hospitality sector, pizza making vending machines can be strategically placed in hotel lobbies to cater to guests seeking quick and satisfying meals. This solution addresses the challenge of providing food options during late hours, enhancing guest experience and satisfaction. For international B2B buyers, sourcing high-quality ingredients that meet local tastes and dietary restrictions is crucial, as is ensuring the vending machines can operate efficiently in various climates.

Corporate Offices

Corporate offices benefit from installing pizza vending machines in break rooms, offering employees a convenient meal option that saves time during busy workdays. This application helps solve the problem of limited dining choices nearby and encourages employee satisfaction. Buyers in this sector should consider sourcing popular pizza varieties that align with health trends, as well as establishing partnerships for regular ingredient replenishment to maintain freshness and quality.

Public Transport

Pizza vending machines in train stations provide travelers with quick access to hot meals, addressing the need for convenient dining options during commutes. This application solves the issue of limited food availability and enhances the overall travel experience. B2B buyers in this sector must ensure compliance with health regulations and focus on efficient logistics for stocking and maintaining the machines, especially in high-traffic areas.

Educational Institutions

Colleges and universities can leverage pizza vending machines on campuses to meet the demand for fast, affordable meals among students. This application addresses the challenge of providing nutritious food options in a setting where time is often limited. Buyers should focus on sourcing a variety of menu options that cater to different dietary preferences and establish local supplier partnerships to ensure cost-effectiveness and timely restocking.

Retail

In shopping malls, pizza making vending machines can attract foot traffic and increase sales by offering shoppers a quick meal option while they browse. This application meets the demand for fast food in a retail environment, enhancing the shopping experience. For international buyers, conducting trend analysis to identify popular flavors and seasonal menu adjustments will be essential for maximizing the appeal of the vending machine offerings.

Strategic Material Selection Guide for pizza making vending machine

Analyzing Common Materials for Pizza Making Vending Machines

When selecting materials for pizza-making vending machines, several factors come into play, including durability, cost, and performance under various conditions. Below, we analyze four common materials used in these machines, focusing on their properties, advantages, disadvantages, and considerations for international buyers.

Illustrative Image (Source: Google Search)

1. Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand high temperatures. It typically has a temperature rating of up to 800°C (1472°F) and is non-reactive, making it ideal for food applications.

Pros & Cons:

The primary advantage of stainless steel is its durability and ease of cleaning, which is crucial for food safety. However, it can be more expensive than other materials and may require specialized manufacturing processes.

Impact on Application:

Stainless steel is compatible with food products and can endure the high-temperature cooking processes involved in pizza preparation. Its non-reactive nature ensures that the flavor of the food remains unaltered.

Considerations for International Buyers:

Buyers must ensure compliance with food safety standards such as ASTM A240 for stainless steel. Additionally, local regulations in regions like Europe and the Middle East may dictate specific grades of stainless steel that are acceptable for food contact.

2. Aluminum

Key Properties:

Aluminum has a lower density and is lightweight, with good corrosion resistance and thermal conductivity. It can handle temperatures up to 400°C (752°F) and is often anodized for enhanced durability.

Pros & Cons:

Aluminum is cost-effective and easy to machine, making it suitable for complex designs. However, it is less durable than stainless steel and can warp under high heat if not properly treated.

Impact on Application:

Aluminum is suitable for components that require rapid heat transfer, such as pizza trays or cooking surfaces. Its lightweight nature aids in the overall design of vending machines, allowing for easier transportation and installation.

Considerations for International Buyers:

Compliance with standards such as ASTM B221 is essential. Buyers from regions like Africa and South America should also consider the availability of aluminum alloys that meet local quality standards.

3. High-Temperature Plastics

Key Properties:

High-temperature plastics, such as polyetheretherketone (PEEK), can withstand temperatures up to 260°C (500°F) and are resistant to various chemicals and moisture.

Pros & Cons:

These materials are lightweight and provide excellent insulation properties, which can enhance energy efficiency. However, they can be more expensive than traditional materials and may not be suitable for all structural components.

Impact on Application:

High-temperature plastics are ideal for non-structural components that require heat resistance, such as insulation panels or food contact surfaces. They help maintain the temperature of the pizza during cooking.

Considerations for International Buyers:

Buyers should verify compliance with food safety regulations and standards such as FDA approval for food contact materials. Additionally, sourcing high-temperature plastics may be more challenging in certain regions.

4. Carbon Steel

Key Properties:

Carbon steel is known for its high strength and durability, with a temperature rating of up to 600°C (1112°F). It is often coated to enhance corrosion resistance.

Pros & Cons:

This material is cost-effective and widely available, making it an attractive option for many manufacturers. However, it is susceptible to rust if not properly maintained, which can be a concern in humid environments.

Impact on Application:

Carbon steel can be used for structural components in vending machines, such as frames or supports. Its strength allows for robust designs that can withstand heavy usage.

Considerations for International Buyers:

Buyers must consider the environmental conditions of their regions, such as humidity levels in parts of Africa or the Middle East, which can affect the longevity of carbon steel products. Compliance with standards like ASTM A36 is also necessary.

Summary Table

| Material | Typical Use Case for pizza making vending machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Cooking chamber, exterior casing | Excellent corrosion resistance, durable | Higher cost, complex manufacturing | High |

| Aluminum | Pizza trays, cooking surfaces | Lightweight, cost-effective | Less durable, can warp under high heat | Med |

| High-Temperature Plastics | Insulation panels, non-structural components | Excellent heat resistance, lightweight | Higher cost, limited structural applications | High |

| Carbon Steel | Structural components, frames | Cost-effective, strong | Susceptible to rust, requires maintenance | Low |

This material selection guide provides a comprehensive overview for international B2B buyers, enabling informed decisions based on specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for pizza making vending machine

Manufacturing Processes for Pizza Making Vending Machines

The manufacturing process of pizza making vending machines is a complex endeavor that integrates various stages, each requiring precision and adherence to quality standards. For B2B buyers, understanding these stages can help in evaluating potential suppliers effectively.

Main Stages of Manufacturing

-

Material Preparation

– Raw Material Sourcing: High-quality components are essential for durability and performance. Key materials include stainless steel for structural integrity, high-grade plastics for the outer shell, and electronic components for control systems.

– Pre-processing: Materials undergo cleaning, cutting, and treatment to ensure they meet the specifications required for the assembly of the vending machine. -

Forming

– Sheet Metal Fabrication: Using techniques such as laser cutting, bending, and welding, manufacturers create the machine’s frame and casing. Advanced CNC (Computer Numerical Control) machines are often employed for precision.

– Component Molding: Plastic parts are typically produced through injection molding, allowing for complex shapes that are both lightweight and durable. -

Assembly

– Sub-Assembly: Key systems like the heating element, dispensing mechanism, and control interface are pre-assembled to streamline the final assembly process.

– Final Assembly: The machine is assembled as a whole, integrating all components. Quality assurance at this stage is critical, as it involves the assembly of intricate systems that must function seamlessly. -

Finishing

– Surface Treatment: The exterior is often coated or painted to enhance durability and aesthetics. Techniques like powder coating can provide a robust finish.

– Final Inspection: A thorough inspection is conducted to ensure that all components are correctly installed and that the machine meets design specifications.

Key Techniques in Manufacturing

- Automation and Robotics: Many manufacturers employ automated systems for tasks like assembly and packaging, which increases efficiency and reduces human error.

- Lean Manufacturing Principles: These principles are often applied to minimize waste and enhance productivity, ensuring cost-effectiveness in production.

- Modular Design: This allows for easier repairs and upgrades, which can be a significant selling point for B2B buyers looking for longevity in their investments.

Quality Assurance Protocols

Quality assurance is a critical aspect of the manufacturing process, ensuring that the final product meets both international standards and specific industry requirements.

Relevant International Standards

- ISO 9001: This standard focuses on quality management systems and is crucial for ensuring consistent quality in production.

- CE Marking: Required for products sold in the European Economic Area, this certification indicates compliance with health, safety, and environmental protection standards.

- API Standards: For components related to food safety and hygiene, adherence to American Petroleum Institute standards can be essential, particularly for parts that interact with food.

Quality Control Checkpoints

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified quality standards.

- In-Process Quality Control (IPQC): During manufacturing, periodic checks are made to assess the quality of the ongoing production process. This can include monitoring the assembly process and ensuring machinery is functioning correctly.

- Final Quality Control (FQC): Before the machines are packaged and shipped, a comprehensive inspection is conducted to verify functionality, safety, and compliance with standards.

Common Testing Methods

- Functional Testing: Each machine undergoes a series of tests to ensure that all systems (e.g., heating, dispensing) operate correctly.

- Safety Testing: This includes checks for electrical safety, fire hazards, and mechanical reliability.

- Hygiene Testing: Particularly critical for food-related machines, this ensures that all surfaces are safe and compliant with health regulations.

Verifying Supplier Quality Control

B2B buyers should adopt a proactive approach to verify the quality control practices of potential suppliers:

- Supplier Audits: Conducting on-site audits can provide insight into a supplier’s manufacturing processes and quality assurance protocols.

- Quality Reports: Requesting documentation on quality control practices, including results from IQC, IPQC, and FQC phases, helps buyers assess supplier reliability.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the manufacturing and quality assurance processes.

Quality Control and Certification Nuances for International Buyers

When sourcing pizza making vending machines, international buyers must be aware of specific certification and quality nuances:

- Regional Compliance: Different regions may have unique regulations and standards. For instance, compliance with the Gulf Standards Organization (GSO) for buyers in the Middle East, or adherence to the South African Bureau of Standards (SABS) in South Africa.

- Documentation and Traceability: Buyers should ensure that suppliers can provide documentation that traces the quality of materials and components back to their sources, which is crucial for compliance with local regulations.

- Cultural Sensitivities: Understanding local market preferences and regulatory environments is essential, especially in regions like Africa and South America, where regulations may differ significantly from those in Europe or North America.

Conclusion

For international B2B buyers, particularly those in diverse markets such as Africa, South America, the Middle East, and Europe, understanding the manufacturing processes and quality assurance protocols of pizza making vending machines is vital. By focusing on these elements, buyers can make informed decisions, ensuring that their investments in vending machines meet the highest standards of quality and reliability.

Related Video: Parle-G Biscuits Manufacturing process – Food Factory Tour- Modern Food factory, Mega Factory II

Comprehensive Cost and Pricing Analysis for pizza making vending machine Sourcing

In the competitive landscape of pizza vending machines, understanding the comprehensive cost structure and pricing dynamics is essential for international B2B buyers, especially those from Africa, South America, the Middle East, and Europe. This analysis will provide insights into the cost components involved, price influencers, and practical buyer tips to optimize sourcing decisions.

Cost Components

-

Materials: The primary materials for pizza vending machines include high-quality stainless steel, electronic components, and specialized cooking systems. The choice of materials impacts both durability and food safety, which are critical in maintaining product quality.

-

Labor: Labor costs encompass the workforce involved in manufacturing, assembly, and installation of the machines. In regions with lower labor costs, such as parts of Africa and South America, buyers may find opportunities for reduced prices, but this must be weighed against quality control.

-

Manufacturing Overhead: This includes costs related to factory operation, such as utilities, maintenance, and administrative expenses. Efficient manufacturing processes can lead to lower overhead costs, which can be beneficial for buyers looking to negotiate better pricing.

-

Tooling: Custom tooling for specific machine designs or features can significantly impact the overall cost. If a buyer requires bespoke modifications, they should prepare for higher tooling costs.

-

Quality Control (QC): Implementing stringent QC measures ensures that machines meet safety and operational standards. While this adds to costs, it is crucial for maintaining brand reputation and customer satisfaction.

-

Logistics: Shipping and handling costs vary greatly depending on the destination, with international shipping often incurring additional fees such as tariffs and customs duties. Understanding Incoterms is vital for clarifying responsibilities and costs during transport.

-

Margin: Suppliers typically apply a margin to cover their operating costs and profit. This can vary based on market demand and competition, impacting the final pricing for buyers.

Price Influencers

Several factors can influence the pricing of pizza vending machines:

-

Volume/MOQ (Minimum Order Quantity): Ordering in bulk can lead to significant discounts. Buyers should consider consolidating orders to meet MOQs for better pricing.

-

Specifications/Customization: Custom features or specifications can lead to increased costs. Buyers should evaluate whether these enhancements are essential for their target market.

-

Materials: The choice of materials directly impacts the pricing. Opting for high-quality, certified materials may raise upfront costs but can enhance durability and reduce long-term maintenance expenses.

-

Quality/Certifications: Machines that meet specific health and safety certifications may cost more initially but can offer better assurance of compliance with local regulations, especially in diverse markets.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge higher prices due to their proven track record, while newer entrants might offer competitive rates to gain market share.

-

Incoterms: The agreed-upon Incoterms can influence overall costs, as they define the responsibilities of buyers and sellers in terms of shipping, insurance, and tariffs.

Buyer Tips

-

Negotiate: Always engage in negotiations with suppliers. Understanding the cost components can provide leverage to secure better pricing or terms.

-

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes purchase price, maintenance, and operational costs over the machine’s lifespan. A higher initial investment may lead to lower long-term expenses.

- Consider Regional Variations: Be aware of pricing nuances across different regions. For example, supply chain dynamics may differ significantly between Europe and Africa, affecting availability and cost.

-

Request Samples: Before committing to a large order, request samples or prototypes to evaluate quality. This can prevent costly mistakes down the line.

-

Stay Informed: Keep abreast of market trends and shifts in supplier dynamics. Being informed can help in making timely decisions that capitalize on favorable market conditions.

Disclaimer

The prices discussed in this analysis are indicative and can vary based on numerous factors, including market conditions, supplier negotiations, and specific buyer requirements. It is recommended to conduct thorough market research and consult with multiple suppliers to obtain accurate pricing.

Spotlight on Potential pizza making vending machine Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘pizza making vending machine’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for pizza making vending machine

Key Technical Properties of Pizza Making Vending Machines

Understanding the essential technical properties of pizza making vending machines is crucial for B2B buyers aiming to invest in this innovative food service technology. Here are several key specifications that should be considered:

-

Material Grade

– Definition: Refers to the quality and type of materials used in the construction of the machine, typically stainless steel or food-grade plastics.

– Importance: High-quality materials ensure durability, hygiene, and compliance with food safety regulations. For buyers in regions with varying climates, such as Africa and the Middle East, selecting machines made from rust-resistant materials is vital to prolonging machine life. -

Temperature Control System

– Definition: A system that regulates the cooking temperature for preparing pizzas, often featuring adjustable settings.

– Importance: Precise temperature control is crucial for ensuring consistent cooking results and food safety. This is particularly important in diverse markets where consumer preferences for pizza doneness may vary. -

Production Capacity

– Definition: The number of pizzas that can be prepared and dispensed per hour.

– Importance: Understanding production capacity helps buyers gauge whether the machine can meet anticipated demand, especially in high-traffic locations. For instance, a machine with a higher output is essential in urban centers or during events. -

Power Consumption

– Definition: The amount of electricity the machine uses during operation, typically measured in kilowatts (kW).

– Importance: Power-efficient machines reduce operational costs, which is particularly relevant for buyers in regions with high electricity prices. Additionally, understanding power requirements is essential for ensuring compatibility with local electrical standards. -

User Interface

– Definition: The system through which customers interact with the machine, often featuring touchscreens or mobile app connectivity.

– Importance: A user-friendly interface enhances customer experience and can lead to increased sales. In markets where tech-savviness varies, intuitive design can significantly impact machine usage. -

Maintenance Accessibility

– Definition: The ease with which machine components can be accessed for cleaning and repairs.

– Importance: Machines that are easy to maintain ensure lower downtime and operational efficiency. This is particularly critical for international buyers who may face logistical challenges in obtaining parts or skilled technicians.

Common Trade Terminology

Familiarity with industry terminology is essential for effective communication and negotiation in the vending machine market. Here are some important terms:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts and equipment that may be marketed by another manufacturer.

– Relevance: Understanding OEM relationships is crucial for buyers seeking machines that can be customized or require specific parts, as it can affect warranty and service agreements. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Relevance: Knowing the MOQ helps buyers plan their initial orders effectively, ensuring they do not overcommit financially while still meeting supplier requirements. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers requesting pricing and terms for specific products or services.

– Relevance: An RFQ is a critical step in the procurement process, allowing buyers to compare prices and terms from multiple suppliers to make informed purchasing decisions. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined international rules that clarify the responsibilities of buyers and sellers in international transactions.

– Relevance: Understanding Incoterms helps buyers negotiate shipping and delivery terms effectively, minimizing risks associated with international logistics. -

Lead Time

– Definition: The total time taken from placing an order to delivery.

– Relevance: For B2B buyers, knowing the lead time is essential for planning inventory and ensuring that the machines are available when needed to meet consumer demand. -

Warranty and Service Agreements

– Definition: Contracts that outline the terms of repair and maintenance services provided by the manufacturer.

– Relevance: These agreements are vital for ensuring long-term support and minimizing operational disruptions, particularly in regions where service technicians may not be readily available.

By understanding these technical properties and trade terminologies, international B2B buyers can make informed decisions that align with their operational needs and market demands.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the pizza making vending machine Sector

Market Overview & Key Trends

The pizza making vending machine sector is experiencing a significant transformation driven by changing consumer preferences and technological advancements. Globally, there is an increasing demand for fast, convenient food options, particularly among younger demographics who favor quick-service solutions. This trend is particularly pronounced in urban areas across Africa, South America, the Middle East, and Europe, where busy lifestyles necessitate accessible meal options.

Emerging technologies such as AI and IoT are being integrated into vending machines, enhancing operational efficiency and customer experience. For instance, smart vending machines can analyze purchasing patterns to optimize inventory, ensuring that popular products are always available. Furthermore, contactless payment systems are becoming standard, catering to safety-conscious consumers post-pandemic.

For international B2B buyers, understanding these dynamics is crucial. Factors like location selection, machine design, and product variety must align with local market demands. For example, in regions like Saudi Arabia, vending machines offering halal-certified pizzas may have a competitive edge, while in Kenya, a focus on affordable pricing could drive sales. By leveraging data analytics and market insights, B2B buyers can make informed sourcing decisions that resonate with their target demographics.

Sustainability & Ethical Sourcing in B2B

As the pizza vending machine sector grows, sustainability and ethical sourcing are becoming increasingly critical. The environmental impact of food production and packaging is under scrutiny, pushing businesses to adopt greener practices. Buyers should prioritize suppliers who utilize sustainable materials and practices, such as biodegradable packaging and locally sourced ingredients, to minimize their carbon footprint.

Ethical supply chains are essential not only for compliance but also for brand reputation. Businesses that demonstrate a commitment to sustainability can enhance customer loyalty and attract eco-conscious consumers. Certifications such as Fair Trade, Rainforest Alliance, and organic labels can serve as benchmarks for ethical sourcing.

Moreover, integrating sustainability into the vending machine’s operations—like energy-efficient machines and waste reduction strategies—can significantly lower operational costs in the long run. For B2B buyers, investing in sustainable practices not only aligns with global trends but also positions their brand as a leader in corporate responsibility, appealing to a broader audience.

Brief Evolution/History

The concept of vending machines has evolved significantly since their inception in the late 19th century, primarily dispensing simple items like cigarettes and candy. The introduction of pizza vending machines in the early 2000s marked a pivotal shift, combining traditional fast-food concepts with automation.

These machines began by offering frozen pizzas, but advancements in technology have led to the development of machines capable of preparing fresh pizzas on-demand, revolutionizing the fast-food landscape. Today, the market is characterized by innovation, with companies continually enhancing machine functionality and user experience. For B2B buyers, this evolution underscores the importance of staying abreast of technological advancements and consumer preferences to remain competitive in a rapidly changing market.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of pizza making vending machine

-

How do I vet suppliers for pizza making vending machines?

Vetting suppliers is crucial for ensuring quality and reliability. Start by researching potential suppliers through industry directories and trade shows. Verify their business credentials, including registration and compliance with local regulations. Request references and check reviews from previous clients. It’s also advisable to ask for samples or visit their facilities if possible. Establishing clear communication is key; ensure they understand your specific needs and can meet them consistently. Finally, consider suppliers who offer after-sales support and warranty services. -

Can I customize the pizza making vending machine to suit my market needs?

Yes, many manufacturers offer customization options for their vending machines. This can include branding, size, and specific functionalities that cater to local tastes and preferences. When discussing customization, clearly outline your requirements and ensure the supplier has experience in delivering tailored solutions. Additionally, inquire about the lead times for custom orders and how they affect your overall procurement timeline. Remember that customization may involve additional costs, so factor this into your budget. -

What are the typical minimum order quantities (MOQs) and lead times for these machines?

Minimum order quantities can vary significantly based on the supplier and the model of the vending machine. Generally, MOQs can range from one machine to several units, especially for customized options. Lead times typically depend on the complexity of the order and the supplier’s production capacity, ranging from a few weeks to several months. Always clarify these details upfront to align your purchasing plan with your operational needs. Additionally, consider potential delays in shipping, especially for international orders. -

What payment terms should I expect when sourcing pizza making vending machines?

Payment terms can vary widely among suppliers. Common practices include a deposit upfront (often 30-50%) with the balance due before shipment or upon delivery. Some suppliers may offer financing options or extended payment plans, especially for larger orders. Always ensure that the payment terms are clearly outlined in the contract to avoid misunderstandings. Additionally, consider using secure payment methods that offer buyer protection, particularly for international transactions. -

What quality assurance (QA) certifications should I look for in pizza making vending machines?

When sourcing pizza making vending machines, look for quality assurance certifications relevant to your market. Common certifications include ISO 9001 for quality management systems, CE marking for compliance with European safety standards, and local health and safety certifications. These certifications indicate that the manufacturer adheres to industry standards and regulations, which is essential for ensuring product safety and reliability. Request documentation from suppliers to verify their certifications. -

How can I manage logistics and shipping when importing these machines?

Managing logistics effectively is critical when importing vending machines. Start by selecting a reliable freight forwarder experienced in handling machinery shipments. They can assist with customs clearance, documentation, and insurance. Understand the shipping terms (FOB, CIF, etc.) and ensure all costs, including duties and taxes, are factored into your budget. Additionally, consider the delivery method based on urgency and cost; air freight is faster but more expensive than sea freight. Always track your shipment to anticipate delivery timelines. -

What should I do if a dispute arises with the supplier?

In the event of a dispute, maintain open communication with your supplier to resolve issues amicably. Refer to your purchase agreement for terms regarding dispute resolution, which may include mediation or arbitration clauses. Document all communications and agreements to have a clear record. If the situation cannot be resolved directly, consider involving a third party or legal counsel, especially if significant financial investments are at stake. It’s crucial to act promptly to minimize disruptions to your business operations. -

What after-sales support can I expect from the suppliers?

After-sales support is a vital aspect of the purchasing process. Inquire about the warranty terms and conditions for the pizza making vending machines, as well as what is covered. Many suppliers offer technical support, maintenance services, and training for your staff on machine operation. Ensure you understand the process for obtaining spare parts and the expected response time for service requests. A supplier committed to after-sales support can significantly enhance the longevity and efficiency of your vending machines.

Strategic Sourcing Conclusion and Outlook for pizza making vending machine

As the market for pizza-making vending machines continues to expand globally, the importance of strategic sourcing cannot be overstated. By aligning product offerings with consumer preferences and ensuring a steady supply of high-quality ingredients, businesses can significantly enhance their profitability. Key takeaways for international B2B buyers include identifying reliable wholesale suppliers, understanding local market demands, and maintaining flexible sourcing strategies to adapt to evolving consumer trends.

Moreover, establishing strong relationships with suppliers will not only provide cost advantages but also ensure timely access to innovative products that can set your offerings apart in competitive markets. In regions such as Africa, South America, the Middle East, and Europe, where demand for convenient food options is on the rise, pizza vending machines present a unique opportunity to cater to diverse consumer bases.

Looking ahead, now is the time for B2B buyers to capitalize on this growing trend. By investing in pizza vending machines and refining sourcing strategies, businesses can position themselves as leaders in this innovative sector. Embrace the future of food service and explore the potential that pizza vending machines can bring to your portfolio.