Unlock Profits with Hot Food Vending Machines: Your

Guide to Hot Food Vending Machine

- Introduction: Navigating the Global Market for hot food vending machine

- Understanding hot food vending machine Types and Variations

- Key Industrial Applications of hot food vending machine

- Strategic Material Selection Guide for hot food vending machine

- In-depth Look: Manufacturing Processes and Quality Assurance for hot food vending machine

- Comprehensive Cost and Pricing Analysis for hot food vending machine Sourcing

- Spotlight on Potential hot food vending machine Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for hot food vending machine

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the hot food vending machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of hot food vending machine

- Strategic Sourcing Conclusion and Outlook for hot food vending machine

Introduction: Navigating the Global Market for hot food vending machine

In an increasingly fast-paced world, the demand for convenient meal solutions is surging, making hot food vending machines a pivotal innovation in the food service sector. These machines not only cater to busy lifestyles but also provide a lucrative opportunity for international B2B buyers looking to enhance their offerings and meet consumer needs in diverse markets. From bustling urban centers in Europe to emerging economies in Africa and South America, hot food vending machines present a flexible and efficient solution to satisfy a growing appetite for accessible, quality meals.

This comprehensive guide delves into the multifaceted landscape of hot food vending machines, equipping international buyers with the knowledge needed to navigate this dynamic market. We explore various types of machines, the materials used in their construction, and the manufacturing and quality control processes that ensure reliability and safety. Additionally, we provide insights into suppliers, cost considerations, and an overview of the global market trends influencing purchasing decisions today.

By addressing common FAQs and offering actionable insights, this guide empowers B2B buyers from regions such as Africa, South America, the Middle East, and Europe—specifically countries like the UAE and Germany—to make informed sourcing decisions. Whether you are looking to expand your existing vending solutions or venture into this innovative market for the first time, understanding these key components will be essential to your success.

Understanding hot food vending machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Microwave Vending Machine | Equipped with microwave technology for heating | Offices, universities, hospitals | Pros: Fast heating, versatile menu. Cons: Requires regular maintenance and potential power supply issues. |

| Heated Display Vending Machine | Offers visible, ready-to-eat meals in a heated environment | Airports, shopping malls, convenience stores | Pros: Attracts customers with visual appeal. Cons: Limited menu items, higher energy consumption. |

| Combo Vending Machine | Combines hot and cold food options in one unit | Corporate cafeterias, schools | Pros: Diverse offerings, maximizes space. Cons: Complexity in inventory management. |

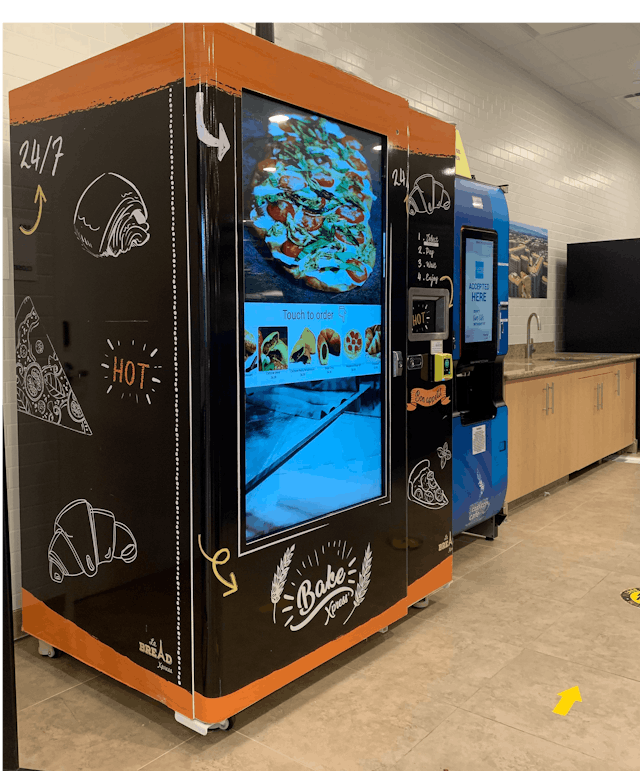

| Pizza Vending Machine | Specialized for pizza, often with self-service features | Entertainment venues, parks | Pros: Unique product offering, high customer interest. Cons: Limited to specific food types, may have longer prep times. |

| Gourmet Hot Food Vending Machine | Focuses on high-quality, chef-prepared meals | Business districts, upscale locations | Pros: Premium product appeal, attracts discerning customers. Cons: Higher initial investment, niche market. |

Microwave Vending Machine

Microwave vending machines utilize microwave technology to heat pre-packaged meals, making them suitable for environments like offices, universities, and hospitals where quick meal options are essential. Buyers should consider the power requirements and ensure sufficient electrical infrastructure is in place. Regular maintenance is crucial to prevent breakdowns and ensure food safety.

Heated Display Vending Machine

These machines keep ready-to-eat meals warm and visible, making them ideal for high-traffic areas like airports and shopping malls. The visual appeal of the food can significantly increase sales. However, buyers must assess the machine’s energy consumption and the need for regular replenishment of stock to maintain freshness.

Combo Vending Machine

Combo vending machines offer both hot and cold food options, catering to diverse consumer preferences. They are particularly beneficial in corporate cafeterias and schools where varied meal options are desired. Buyers should evaluate the complexity of inventory management and ensure they have the capacity to handle both types of food efficiently.

Pizza Vending Machine

Designed specifically for pizza, these machines often allow customers to customize their orders and wait for a fresh pizza to be prepared. They are well-suited for entertainment venues and parks, where quick service is essential. However, buyers should be aware that the machine’s focus on a single product type can limit its versatility.

Gourmet Hot Food Vending Machine

These machines offer high-quality, chef-prepared meals, targeting business districts and upscale locations where consumers are willing to pay a premium for gourmet options. While this can attract a discerning clientele, the higher initial investment and niche market focus require careful consideration of the target demographic and location.

Related Video: TCN hot food vending machine

Key Industrial Applications of hot food vending machine

| Industry/Sector | Specific Application of Hot Food Vending Machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Corporate Offices | Employee break rooms | Enhances employee satisfaction and productivity | Machine size, variety of food options, payment systems |

| Healthcare Facilities | Patient and staff meal distribution | Provides quick access to nutritious meals | Compliance with health regulations, hygiene standards |

| Educational Institutions | Campus dining solutions | Offers convenient meal options for students | Customization for dietary needs, energy efficiency |

| Transportation Hubs | Train and bus stations | Serves travelers with quick meal solutions | Durability for high traffic, remote monitoring capabilities |

| Manufacturing Plants | On-site meal provision for workers | Increases workforce morale and reduces downtime | Robustness, ease of use, and maintenance support |

Corporate Offices

Hot food vending machines are increasingly being installed in corporate offices to provide employees with immediate access to meals during breaks. This application directly addresses the need for convenient food options, thereby enhancing employee satisfaction and productivity. International buyers should consider the machine’s size and the variety of food options available, as well as the payment systems that cater to diverse workforce preferences, including cashless payments.

Healthcare Facilities

In healthcare settings, hot food vending machines serve a crucial role in meal distribution for both patients and staff. They provide quick access to nutritious meals, which is essential for maintaining health standards. Buyers in this sector must prioritize compliance with health regulations and hygiene standards, ensuring that the machines are designed for easy cleaning and maintenance while offering a range of healthy meal options.

Illustrative Image (Source: Google Search)

Educational Institutions

Educational institutions, such as universities and colleges, utilize hot food vending machines to offer students convenient meal solutions on campus. These machines help accommodate busy schedules and diverse dietary needs. B2B buyers should focus on customization options for dietary restrictions, such as vegetarian or gluten-free meals, as well as the energy efficiency of the machines to align with sustainability goals.

Transportation Hubs

Hot food vending machines are increasingly found in transportation hubs like train and bus stations, where they provide travelers with quick meal solutions. This application addresses the high demand for food options in high-traffic areas. Buyers should consider the durability of the machines to withstand constant use and the need for remote monitoring capabilities to ensure consistent operation and product availability.

Manufacturing Plants

In manufacturing plants, hot food vending machines serve as an on-site meal provision for workers, reducing downtime and increasing morale. This application is particularly valuable in industries with long shifts, where access to nutritious meals is essential. When sourcing machines for this sector, buyers should evaluate the robustness of the equipment, ease of use, and availability of maintenance support to ensure seamless operation in a demanding environment.

Strategic Material Selection Guide for hot food vending machine

When selecting materials for hot food vending machines, it is crucial to consider the properties, advantages, and limitations of various materials. This section analyzes four common materials used in the construction of these machines, focusing on their performance characteristics, application impacts, and specific considerations for international B2B buyers, particularly in Africa, South America, the Middle East, and Europe.

Stainless Steel

Key Properties: Stainless steel is known for its excellent corrosion resistance, high-temperature tolerance, and durability. It can withstand a wide range of temperatures and pressures, making it suitable for hot food applications.

Pros & Cons: The primary advantages of stainless steel include its long lifespan, ease of cleaning, and aesthetic appeal. However, it can be more expensive than other materials and may require specialized manufacturing processes, which can increase costs.

Impact on Application: Stainless steel is compatible with various food types and does not impart flavors or odors, making it ideal for food contact surfaces. Its resistance to corrosion ensures that it maintains its integrity even in humid environments.

Considerations for International Buyers: Buyers should ensure compliance with international food safety standards, such as those set by the FDA or EFSA. In regions like the UAE and Germany, adherence to specific grades (e.g., AISI 304 or AISI 316) is essential for regulatory compliance.

Aluminum

Key Properties: Aluminum is lightweight and has good thermal conductivity, allowing for efficient heat distribution. It also offers decent corrosion resistance, especially when anodized.

Pros & Cons: The main advantages of aluminum include its low weight and cost-effectiveness. However, it is less durable than stainless steel and can be prone to denting and scratching, which may affect its appearance over time.

Impact on Application: Aluminum is suitable for applications where weight is a concern, such as portable vending machines. However, it may not be ideal for high-temperature environments without proper coatings to prevent warping or degradation.

Considerations for International Buyers: In markets like South America and Africa, where cost is a significant factor, aluminum can be an attractive option. Buyers should be aware of local regulations regarding food contact materials and ensure that the aluminum used is food-grade.

Polycarbonate

Key Properties: Polycarbonate is a strong, transparent thermoplastic known for its impact resistance and ability to withstand high temperatures. It is often used for viewing panels and protective covers in vending machines.

Pros & Cons: The advantages of polycarbonate include its lightweight nature and excellent visibility for food displays. However, it can be susceptible to scratching and may degrade under prolonged exposure to UV light unless treated.

Impact on Application: Polycarbonate is commonly used for components that require visibility and protection from environmental factors. Its ability to withstand heat makes it suitable for certain internal parts of vending machines.

Considerations for International Buyers: Buyers in regions with high UV exposure, such as the Middle East, should consider UV-stabilized grades of polycarbonate. Compliance with local safety standards regarding plastics is also crucial.

Mild Steel

Key Properties: Mild steel is a versatile material known for its strength and affordability. However, it has limited corrosion resistance and is generally not recommended for direct food contact without protective coatings.

Pros & Cons: The key advantage of mild steel is its low cost and ease of manufacturing. However, its susceptibility to rust and corrosion makes it less suitable for hot food applications without proper treatment.

Impact on Application: Mild steel can be used for structural components of vending machines that do not come into direct contact with food. Its strength makes it suitable for frames and supports.

Considerations for International Buyers: Buyers should be cautious about using mild steel in food applications and ensure that any coatings used comply with local regulations. In Europe, adherence to standards like DIN EN 10025 is essential for structural integrity.

| Material | Typical Use Case for hot food vending machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food contact surfaces and structural components | Excellent corrosion resistance | Higher cost compared to other materials | High |

| Aluminum | Portable vending machines and heat exchangers | Lightweight and cost-effective | Less durable, prone to dents | Medium |

| Polycarbonate | Viewing panels and protective covers | High impact resistance and visibility | Susceptible to scratching and UV degradation | Medium |

| Mild Steel | Structural components (non-food contact) | Cost-effective and strong | Limited corrosion resistance | Low |

This strategic material selection guide provides B2B buyers with essential insights into the materials used in hot food vending machines, enabling informed decisions that align with performance requirements and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for hot food vending machine

The manufacturing process of hot food vending machines is intricate and requires a blend of advanced technology and meticulous craftsmanship. Understanding these processes can significantly empower B2B buyers, especially those from diverse regions like Africa, South America, the Middle East, and Europe. Here’s a comprehensive look at the key stages of manufacturing and the quality assurance measures that ensure these machines meet international standards.

Manufacturing Processes

1. Material Preparation

The first step in manufacturing hot food vending machines involves selecting high-quality materials. Common materials include stainless steel for durability and hygiene, tempered glass for visibility, and various polymers for insulation and electrical components.

- Sourcing: Buyers should prioritize suppliers that use locally sourced or sustainable materials to reduce shipping costs and environmental impact.

- Pre-Processing: Materials undergo cutting, shaping, and treatment to enhance their properties. Techniques such as laser cutting or CNC machining are often employed for precision.

2. Forming

This stage involves transforming raw materials into the machine’s components.

- Techniques: Common forming methods include stamping, bending, and welding. For instance, the chassis is often welded from steel sheets to provide a robust structure.

- Automation: Many manufacturers use automated processes for consistency and efficiency. Buyers should inquire about the level of automation in the production line, as this can impact lead times and costs.

3. Assembly

The assembly process is critical for ensuring that all components fit and function together seamlessly.

- Integration: Components such as heating elements, control panels, and vending mechanisms are assembled. Care is taken to ensure electrical components are safely integrated to prevent hazards.

- Workforce Skill: The skill level of assembly workers can greatly influence the machine’s quality. Buyers should assess whether the manufacturer provides adequate training and employs experienced technicians.

4. Finishing

The final stage includes painting, coating, and applying any necessary branding.

- Quality Coatings: High-quality finishes, such as powder coating, are essential for durability and aesthetics. Buyers should ask about the types of finishes used and their resistance to wear and corrosion.

- Customization: Many manufacturers offer customization options. Buyers should consider whether they want unique branding or features tailored to local markets.

Quality Assurance

International Standards

Quality assurance is paramount in the manufacturing of hot food vending machines, ensuring safety, reliability, and performance. Key international standards include:

- ISO 9001: This standard focuses on quality management systems. Manufacturers certified under ISO 9001 have demonstrated their ability to consistently provide products that meet customer and regulatory requirements.

- CE Marking: In Europe, CE marking indicates compliance with health, safety, and environmental protection standards. This is essential for machines intended for the European market.

Industry-Specific Standards

Certain regions and industries may have additional requirements:

- API Standards: For machines used in sensitive environments, adherence to American Petroleum Institute standards may be necessary, especially for equipment that interacts with food products.

- Local Regulations: Buyers in Africa and South America should be aware of local certifications, which may differ from international standards.

Quality Control Checkpoints

Quality control (QC) is integral at various stages of the manufacturing process:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps catch defects early.

- Final Quality Control (FQC): The finished product undergoes rigorous testing to ensure it meets all specifications before shipping.

Common Testing Methods

Testing methods can include:

- Functional Testing: Ensuring all components work correctly, including heating and vending functions.

- Safety Testing: Evaluating electrical safety, thermal stability, and compliance with relevant safety standards.

- Durability Testing: Assessing how the machine withstands wear and tear under typical operating conditions.

Verifying Supplier Quality Control

For B2B buyers, verifying a supplier’s quality assurance processes is crucial for ensuring product reliability. Consider the following methods:

- Supplier Audits: Conducting on-site audits can provide insight into the manufacturer’s processes and adherence to quality standards. Buyers should establish a clear audit protocol and checklist.

- Quality Reports: Request regular quality reports that outline QC measures, testing results, and compliance with international standards.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the manufacturing processes and final products.

QC/Certifications Nuances for International Buyers

When sourcing hot food vending machines, international buyers must navigate various certification landscapes:

- Documentation: Ensure all certificates are up-to-date and valid. This includes international standards as well as local certifications.

- Cultural Considerations: In regions like Africa and the Middle East, understanding local business practices and relationships can enhance negotiations and supplier reliability.

- Regulatory Changes: Stay informed about changes in regulations that may affect quality standards or certifications in your target market.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance measures for hot food vending machines equips B2B buyers with the knowledge necessary to make informed purchasing decisions. By focusing on quality, compliance, and supplier verification, buyers can ensure they invest in reliable and efficient machines that meet their operational needs.

Related Video: Parle-G Biscuits Manufacturing process – Food Factory Tour- Modern Food factory, Mega Factory II

Comprehensive Cost and Pricing Analysis for hot food vending machine Sourcing

Understanding the Cost Structure of Hot Food Vending Machines

When sourcing hot food vending machines, it is crucial for international B2B buyers to grasp the various cost components that contribute to the overall price. The primary cost elements include:

-

Materials: The choice of materials significantly impacts the manufacturing cost. Stainless steel is often preferred for its durability and hygiene, but it can be more expensive than other materials. Buyers should assess the trade-off between cost and quality.

-

Labor: Labor costs vary by region. For example, manufacturing in countries with lower wage standards may reduce costs, but it is essential to consider the skill level and training of the workforce to ensure high-quality production.

-

Manufacturing Overhead: This includes costs related to utilities, rent, and other operational expenses incurred during production. Overhead can vary widely based on the manufacturer’s location and efficiency.

-

Tooling: The cost of molds and specialized equipment for production can be significant, especially for customized designs. Buyers should inquire about these costs upfront.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability and safety, which can incur additional costs. However, these costs are often justified by reducing the risk of defects and enhancing customer satisfaction.

-

Logistics: Shipping and handling costs must be factored into the total price. These costs can vary based on the destination, shipping method, and any applicable tariffs or taxes.

-

Margin: Suppliers will include a profit margin in their pricing. Understanding typical margins in the industry can help buyers negotiate better deals.

Factors Influencing Pricing

Several elements can influence the pricing of hot food vending machines, including:

-

Volume/MOQ: Suppliers often offer better pricing for larger orders. Understanding the minimum order quantities can help buyers secure more favorable rates.

-

Specifications/Customization: Custom features or specifications may increase costs. Buyers should evaluate whether these customizations are necessary or if standard models will suffice.

-

Materials and Quality Certifications: Higher quality materials and certifications (e.g., ISO, CE) can lead to higher costs. Buyers should balance the need for certifications against budget constraints.

-

Supplier Factors: The supplier’s reputation, location, and production capabilities play a significant role in pricing. Conducting thorough due diligence can help identify reliable partners.

-

Incoterms: The agreed-upon Incoterms (International Commercial Terms) can affect the total cost of ownership, influencing who bears shipping costs, insurance, and risk during transit.

Buyer Tips for Cost-Efficiency

For B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, the following strategies can enhance cost-efficiency:

-

Negotiation: Engage in open discussions with suppliers to negotiate pricing. Highlighting potential long-term partnerships can incentivize suppliers to offer better terms.

-

Total Cost of Ownership (TCO): Consider not just the purchase price but the total cost of ownership, which includes maintenance, operational costs, and potential downtime. A lower initial price may lead to higher long-term costs.

-

Pricing Nuances: Be aware of regional pricing differences. For instance, prices may fluctuate due to local demand and supply conditions. Understanding these nuances can aid in better budgeting.

-

Leverage Local Suppliers: Local suppliers may offer advantages in terms of logistics and reduced shipping costs. Additionally, they may have a better understanding of local market needs.

Disclaimer on Indicative Prices

Prices for hot food vending machines can vary significantly based on the factors outlined above. It is advisable for buyers to obtain multiple quotes and conduct thorough market research to ensure they are making informed purchasing decisions. Always consider the latest market trends and engage with suppliers for the most accurate pricing information.

Spotlight on Potential hot food vending machine Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘hot food vending machine’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for hot food vending machine

Key Technical Properties of Hot Food Vending Machines

When evaluating hot food vending machines, several critical technical properties should be considered to ensure optimal performance, durability, and compliance with international standards. Understanding these specifications will enable B2B buyers to make informed purchasing decisions.

-

Material Grade

– The materials used in the construction of vending machines significantly impact their longevity and functionality. Stainless steel is commonly preferred for its resistance to corrosion and ease of cleaning, making it ideal for food applications. Buyers should look for machines constructed with high-grade materials to ensure hygiene and durability, particularly in regions with varying climates. -

Temperature Control Range

– Effective temperature control is crucial for maintaining food quality and safety. Hot food vending machines typically feature adjustable temperature settings, often ranging from 60°C to 85°C. This flexibility allows operators to cater to different food types and customer preferences. Buyers should ensure that the machines provide precise temperature controls to avoid food spoilage or safety issues. -

Power Consumption

– Energy efficiency is increasingly important in the global market. Hot food vending machines should have specifications indicating their power consumption in watts. Machines with lower energy usage will not only reduce operational costs but also appeal to environmentally conscious consumers. B2B buyers should seek energy-efficient models that comply with local energy regulations. -

Capacity and Dimensions

– The capacity of a vending machine is determined by its size and the number of food items it can hold. Buyers need to consider their target market and location when selecting the dimensions of the machine. For example, urban areas may require compact models that fit in limited spaces, while larger machines may be suitable for high-traffic locations. Assessing capacity helps optimize product offerings and sales potential. -

User Interface and Payment Systems

– The user interface should be intuitive and accessible to enhance customer experience. Additionally, modern vending machines often incorporate various payment systems, including cash, credit/debit cards, and mobile payments. B2B buyers should ensure that the machines offer multiple payment options to cater to diverse customer preferences and maximize sales.

Common Trade Terminology

Understanding industry jargon is essential for navigating the procurement process effectively. Here are some key terms that international B2B buyers should be familiar with:

-

OEM (Original Equipment Manufacturer)

– An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of hot food vending machines, buyers may engage with OEMs to source specific components or entire machines tailored to their requirements. -

MOQ (Minimum Order Quantity)

– MOQ denotes the smallest number of units a supplier is willing to sell. This term is vital for buyers to understand as it impacts inventory management and cost efficiency. Buyers should negotiate MOQs that align with their sales forecasts and operational needs. -

RFQ (Request for Quotation)

– An RFQ is a formal document used to solicit price quotes from suppliers for specific products or services. For hot food vending machines, submitting an RFQ enables buyers to compare prices, specifications, and delivery terms across different manufacturers, facilitating better purchasing decisions. -

Incoterms (International Commercial Terms)

– Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce that define the responsibilities of sellers and buyers in international transactions. Familiarity with Incoterms helps buyers understand shipping responsibilities, risk allocation, and cost implications when sourcing machines from different countries. -

Warranty and Service Agreement

– A warranty provides assurance regarding the quality and performance of the vending machine, while a service agreement outlines the terms of maintenance and support. Buyers should prioritize machines with robust warranty options and clear service agreements to mitigate risks associated with equipment malfunction.

By understanding these technical properties and trade terms, international B2B buyers can navigate the hot food vending machine market more effectively, ensuring they select the right equipment for their operational needs and customer demands.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the hot food vending machine Sector

Market Overview & Key Trends

The hot food vending machine sector is experiencing transformative growth driven by several global factors. Increasing urbanization and a busy lifestyle have led to higher demand for convenient meal options. Particularly in regions like Africa and South America, where food accessibility can be a challenge, hot food vending machines provide an innovative solution. In Europe and the Middle East, the trend is fueled by a growing focus on workplace efficiency and employee satisfaction, prompting companies to invest in modern vending solutions.

Emerging B2B technology trends include the integration of IoT (Internet of Things) capabilities, which allow for real-time inventory management and predictive maintenance, reducing downtime and enhancing user experience. Additionally, contactless payment systems are becoming the norm, appealing to a tech-savvy consumer base. These advancements not only streamline operations but also attract a broader clientele.

International B2B buyers should be aware of regional market dynamics. In the UAE, for instance, there is a strong push towards high-tech solutions that cater to both local tastes and international cuisine preferences. In Germany, sustainability and energy efficiency are paramount, making it essential for suppliers to demonstrate compliance with EU regulations. Understanding these nuances can help buyers make informed sourcing decisions that align with their target market’s needs.

Sustainability & Ethical Sourcing in B2B

As the demand for hot food vending machines rises, so does the importance of sustainability and ethical sourcing. Environmental concerns are at the forefront of consumer preferences, particularly in regions like Europe, where regulatory frameworks are stringent. B2B buyers must prioritize suppliers that utilize sustainable materials and energy-efficient technologies to minimize their environmental impact.

Ethical supply chains are critical in ensuring that sourcing practices do not exploit labor or harm the environment. Buyers should look for certifications such as Fair Trade and ISO 14001, which indicate a commitment to sustainable practices. Additionally, sourcing ingredients from local suppliers can significantly reduce carbon footprints while supporting local economies.

Green certifications and eco-friendly materials, such as biodegradable packaging and energy-efficient components, are not only beneficial for the planet but also enhance brand reputation. Buyers who emphasize these factors in their procurement processes can attract environmentally conscious consumers and gain a competitive edge in the market.

Brief Evolution/History

The hot food vending machine sector has evolved significantly over the past few decades. Originally limited to snacks and cold beverages, advancements in technology have enabled these machines to offer a diverse range of hot meals, from gourmet options to traditional ethnic cuisines. The introduction of refrigeration, microwaving, and self-heating technologies has expanded the possibilities, allowing for the preservation of taste and quality.

In the early 2000s, the focus was primarily on convenience; however, recent years have seen a shift towards healthier and more sustainable options, reflecting changing consumer preferences. This evolution highlights the need for B2B buyers to stay abreast of market trends and technological advancements, ensuring that their offerings meet the demands of today’s health-conscious and environmentally aware consumers.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of hot food vending machine

-

What should I consider when vetting suppliers for hot food vending machines?

When vetting suppliers, focus on their industry experience, reputation, and client testimonials. Verify their manufacturing capabilities and technology standards. It’s crucial to assess their compliance with international quality standards, particularly if you are importing to regions with stringent regulations. Additionally, consider conducting background checks to ensure they have a track record of reliability in delivery and customer service. -

Can I customize hot food vending machines to suit local tastes?

Yes, many manufacturers offer customization options for hot food vending machines. You can specify the types of food to be offered, machine design, and branding elements. When negotiating with suppliers, clearly communicate your requirements and ask for examples of previous custom projects. This ensures that the final product aligns with local consumer preferences and enhances market acceptance. -

What are the typical minimum order quantities (MOQs) and lead times for hot food vending machines?

MOQs can vary significantly between suppliers, often depending on the complexity of the machine and customization requirements. Generally, you might expect MOQs ranging from 5 to 50 units. Lead times can also differ based on the supplier’s location and manufacturing schedule, typically ranging from 4 to 12 weeks. Always confirm these details during initial discussions to plan your procurement strategy effectively. -

What payment methods are commonly accepted, and how can I protect my investment?

Most suppliers accept a variety of payment methods, including bank transfers, letters of credit, and online payment platforms. To protect your investment, consider negotiating terms that include partial payments upfront and the remainder upon delivery or successful installation. Always use secure payment methods and, if applicable, ensure there are clear contracts outlining the terms of sale, including warranties and return policies. -

What quality assurance certifications should I look for in hot food vending machines?

Look for certifications such as ISO 9001 for quality management systems and CE marking for compliance with European safety standards. Additionally, check for food safety certifications like HACCP (Hazard Analysis and Critical Control Points) to ensure the machines meet health regulations. Request documentation of these certifications from suppliers to verify compliance before finalizing your purchase. -

How should I approach logistics for importing hot food vending machines?

Logistics can be complex when importing hot food vending machines, especially across international borders. Engage a freight forwarder experienced in handling machinery to manage shipping, customs clearance, and delivery logistics. Discuss shipping options, insurance, and potential tariffs with your supplier, and ensure they provide the necessary documentation for smooth customs processing. -

What steps can I take to resolve disputes with suppliers?

To resolve disputes effectively, first, try to communicate directly with the supplier to reach an amicable solution. If this fails, refer to the contract terms that outline dispute resolution procedures, such as mediation or arbitration. Keeping a detailed record of all correspondence and agreements can support your case. Additionally, consider involving a local legal advisor familiar with international trade laws to guide you through the process. -

How can I ensure ongoing support and maintenance for my hot food vending machines?

When sourcing hot food vending machines, inquire about the supplier’s after-sales support and maintenance services. A good supplier should offer training for your staff, a warranty period, and readily available spare parts. Establish clear terms regarding service agreements, response times for maintenance requests, and the availability of technical support to ensure your machines remain operational and efficient.

Strategic Sourcing Conclusion and Outlook for hot food vending machine

In conclusion, the strategic sourcing of hot food vending machines presents a multitude of opportunities for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. As urbanization continues to rise and consumer preferences shift towards convenience and quality, investing in advanced vending solutions can significantly enhance service offerings.

Key Takeaways:

– Market Trends: Stay informed about evolving consumer demands for diverse, healthy food options, which can guide procurement decisions.

– Supplier Relationships: Cultivating strong partnerships with reliable suppliers ensures access to innovative technologies and competitive pricing.

– Regulatory Considerations: Understanding local regulations and compliance requirements is crucial for successful implementation and operation.

By prioritizing strategic sourcing, businesses can not only optimize their supply chains but also enhance customer satisfaction and brand loyalty. Looking ahead, the hot food vending machine market is poised for growth, driven by technological advancements and changing consumer behavior.

Now is the time for international buyers to explore partnerships and investments in this dynamic sector. Embrace the future of food service and capitalize on the potential that hot food vending machines offer to meet the demands of modern consumers.

Illustrative Image (Source: Google Search)