Your Ultimate Guide to Sourcing Carvana Vending Machine

Guide to Carvana Vending Machine

- Introduction: Navigating the Global Market for carvana vending machine

- Understanding carvana vending machine Types and Variations

- Key Industrial Applications of carvana vending machine

- Strategic Material Selection Guide for carvana vending machine

- In-depth Look: Manufacturing Processes and Quality Assurance for carvana vending machine

- Comprehensive Cost and Pricing Analysis for carvana vending machine Sourcing

- Spotlight on Potential carvana vending machine Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for carvana vending machine

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the carvana vending machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of carvana vending machine

- Strategic Sourcing Conclusion and Outlook for carvana vending machine

Introduction: Navigating the Global Market for carvana vending machine

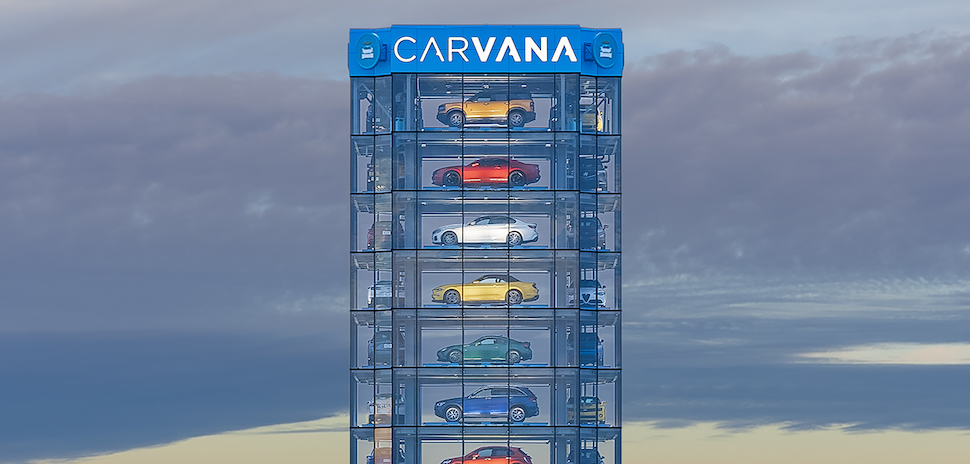

In the rapidly evolving landscape of automotive sales, Carvana’s innovative vending machines stand out as a symbol of modernity and efficiency. These automated structures not only streamline the vehicle purchasing process but also enhance the overall customer experience by integrating advanced technology with user-centric design. For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of Carvana’s vending machines is crucial for making informed sourcing decisions.

This comprehensive guide delves into the critical aspects of Carvana vending machines, covering various types, materials, manufacturing processes, quality control measures, and supplier insights. We will also explore cost considerations and market trends that influence the automotive vending landscape. In addition, frequently asked questions will be addressed to clarify common queries and concerns.

By equipping B2B buyers with actionable insights, this guide empowers them to navigate the complexities of sourcing Carvana vending machines effectively. Whether you’re looking to enhance your automotive sales strategy or explore innovative solutions for customer engagement, understanding the mechanics and market implications of these vending machines is essential. The knowledge gained here will enable buyers to leverage these advanced systems, ultimately driving growth and enhancing customer satisfaction in their respective markets.

Understanding carvana vending machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Vending Machine | Basic model with automated retrieval systems | Used car dealerships, rental agencies | Pros: Cost-effective, simple operation. Cons: Limited to standard inventory, less engagement. |

| Hybrid Vending Machine | Combines traditional sales with vending technology | Multi-brand dealerships | Pros: Versatile, offers both self-service and sales assistance. Cons: Higher setup costs, complex management. |

| Luxury Vending Machine | Designed for high-end vehicles with premium finishes | Luxury car dealerships | Pros: Attracts affluent buyers, enhances brand prestige. Cons: High investment, maintenance costs. |

| Mobile Vending Machine | Compact and transportable unit for various locations | Pop-up car sales, events | Pros: Flexible, can reach diverse markets. Cons: Limited inventory, potential logistical challenges. |

| Eco-Friendly Vending Machine | Utilizes sustainable materials and energy sources | Green car dealerships, eco-conscious brands | Pros: Appeals to environmentally aware consumers. Cons: Higher initial costs, niche market appeal. |

Standard Vending Machine

The standard vending machine is the foundational model utilized by many dealerships for selling used vehicles. It features automated retrieval systems that streamline the vehicle pickup process, making it efficient for buyers. This model is particularly suitable for businesses looking to minimize operational costs while providing a straightforward purchasing experience. However, B2B buyers should consider that its limited inventory and engagement features might not meet the needs of a more diverse customer base.

Hybrid Vending Machine

Hybrid vending machines integrate traditional sales approaches with advanced vending technology. These machines allow customers to browse a selection of vehicles while also providing access to sales staff for personalized service. This model is ideal for multi-brand dealerships aiming to enhance customer experience and drive sales. B2B buyers should weigh the higher setup costs against the potential for increased customer engagement and satisfaction.

Luxury Vending Machine

Luxury vending machines are tailored for high-end vehicles and are designed with premium finishes to attract affluent buyers. These machines provide an elevated purchasing experience, allowing customers to retrieve luxury cars in a visually impressive environment. Ideal for luxury car dealerships, this model enhances brand prestige. However, B2B buyers must consider the significant investment and ongoing maintenance costs associated with these high-end systems.

Mobile Vending Machine

Mobile vending machines are compact units that can be transported to various locations for pop-up car sales or events. This flexibility allows businesses to reach diverse markets and engage with potential customers in different regions. While they can be a cost-effective solution for expanding reach, B2B buyers should be aware of the limitations in inventory and potential logistical challenges that may arise from operating in multiple locations.

Eco-Friendly Vending Machine

Eco-friendly vending machines are designed with sustainable materials and energy-efficient technologies, appealing to environmentally conscious consumers. This model is particularly suitable for green car dealerships or brands focusing on sustainability. While they can enhance a brand’s image and attract a niche market, B2B buyers should consider the higher initial investment and the potential limitations in reaching a broader audience.

Related Video: Carvana: The Making of a Vending Machine

Key Industrial Applications of carvana vending machine

| Industry/Sector | Specific Application of Carvana Vending Machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Retail | Automated Vehicle Retrieval | Streamlined customer experience, reduced wait times | Technology compatibility, maintenance support |

| E-commerce | Direct-to-Consumer Vehicle Delivery | Enhanced customer engagement, unique brand experience | Location logistics, integration with online platforms |

| Logistics & Supply Chain | Efficient Inventory Management | Reduced overhead costs, improved inventory turnover | Space optimization, scalability of vending systems |

| Franchise Opportunities | Franchise Model for Car Sales | Low overhead, innovative customer acquisition | Training programs, local market adaptability |

| Technology Solutions | Integration with Smart City Initiatives | Contributes to urban mobility solutions, eco-friendly | Compliance with local regulations, technological support |

Automotive Retail

In the automotive retail sector, Carvana’s vending machines serve as a cutting-edge solution for automated vehicle retrieval. By allowing customers to collect their vehicles in a visually striking environment, businesses can significantly enhance customer satisfaction while reducing the traditional wait times associated with car purchases. For international buyers, especially in regions like Africa and South America, the ability to offer a unique and engaging buying experience can set a dealership apart in a competitive market. Key considerations include ensuring that the technology is compatible with local infrastructure and that adequate maintenance support is available.

E-commerce

Carvana’s vending machines represent a significant advancement in the direct-to-consumer vehicle delivery model. This application allows businesses to create a seamless online purchasing experience that culminates in an exciting vehicle pickup. By integrating the vending machine concept into their operations, companies can boost customer engagement and create a memorable brand experience. For B2B buyers in Europe and the Middle East, sourcing considerations include logistical aspects of machine placement and ensuring the vending system integrates smoothly with existing online platforms to facilitate transactions.

Logistics & Supply Chain

In logistics and supply chain management, Carvana’s vending machines streamline inventory management by automating vehicle retrieval and storage. This efficiency reduces overhead costs associated with traditional dealership operations and improves inventory turnover rates. For businesses in South America and Africa, where supply chain optimization is critical, adopting this technology can lead to significant cost savings and operational improvements. Buyers should consider the machine’s space optimization capabilities and its scalability to meet future growth needs.

Illustrative Image (Source: Google Search)

Franchise Opportunities

The franchise model for car sales utilizing Carvana’s vending machines offers a low-overhead business opportunity. This innovative approach allows franchisees to leverage advanced technology to attract customers while minimizing traditional dealership expenses. For potential franchise buyers in regions like Europe, understanding local market dynamics and ensuring adaptability to regional preferences are essential. Additionally, establishing robust training programs for staff can enhance the overall customer experience.

Technology Solutions

Integrating Carvana’s vending machines into smart city initiatives showcases their potential to contribute to urban mobility solutions. By offering eco-friendly vehicle retrieval options, businesses can align with global sustainability goals while enhancing their service offerings. For international B2B buyers, particularly in rapidly urbanizing regions, compliance with local regulations and access to technological support are vital to successfully implementing these systems within smart city frameworks.

Strategic Material Selection Guide for carvana vending machine

When selecting materials for Carvana’s innovative vending machines, it’s essential to consider the unique demands of the automotive retail environment. The materials used must not only withstand mechanical stresses but also offer durability and aesthetic appeal. Below, we analyze four common materials suitable for Carvana vending machines, focusing on their properties, advantages, disadvantages, and implications for international buyers.

1. Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand extreme temperatures. It typically has a temperature rating up to 1,000°F (537°C) and can endure significant pressure, making it suitable for various mechanical applications.

Pros & Cons:

The primary advantage of stainless steel is its durability and longevity, which reduces maintenance costs over time. However, it is more expensive than other materials like carbon steel, which can impact initial investment costs. Manufacturing complexity is moderate, as it requires specialized welding and finishing techniques.

Impact on Application:

Stainless steel is ideal for components exposed to the elements or high wear, such as structural supports and mechanical parts in the vending machines. It ensures that the machines maintain their integrity and appearance over time.

Considerations for International Buyers:

Buyers in regions like Europe and the Middle East should ensure compliance with local standards such as EN 10088 for stainless steel grades. The higher initial cost may be justified by the lower lifecycle costs in harsh environments.

2. Aluminum

Key Properties:

Aluminum is lightweight, corrosion-resistant, and has a good strength-to-weight ratio. It can typically handle temperatures up to 400°F (204°C) and is also resistant to many chemical environments.

Pros & Cons:

The lightweight nature of aluminum allows for easier installation and reduced shipping costs. However, it is less durable than stainless steel and may require protective coatings to prevent wear and corrosion in certain applications. Manufacturing processes for aluminum can be more complex due to the need for specialized techniques like anodizing.

Impact on Application:

Aluminum is well-suited for external panels and decorative elements of the vending machines, enhancing aesthetics while keeping weight down. Its corrosion resistance is particularly beneficial in coastal or humid environments.

Considerations for International Buyers:

Buyers should be aware of the relevant standards such as ASTM B221 for aluminum extrusions. In regions like Africa and South America, where cost sensitivity is higher, aluminum may offer a balance between performance and price.

3. Polycarbonate

Key Properties:

Polycarbonate is a high-impact, transparent thermoplastic known for its excellent optical clarity and UV resistance. It can withstand temperatures ranging from -40°F to 240°F (-40°C to 116°C).

Pros & Cons:

The primary advantage of polycarbonate is its lightweight nature and high impact resistance, making it ideal for safety applications. However, it can be prone to scratching and may not be as aesthetically pleasing as glass or metal finishes. Its manufacturing process is generally simpler and less costly than metals.

Impact on Application:

Polycarbonate is often used for protective covers or windows in vending machines, allowing visibility while providing safety. Its UV resistance helps maintain clarity over time.

Considerations for International Buyers:

Compliance with standards like ASTM D635 for flammability is crucial. In regions with high UV exposure, such as parts of Africa and South America, selecting high-quality polycarbonate is essential for long-term performance.

4. Glass

Key Properties:

Glass offers excellent transparency, aesthetic appeal, and is resistant to many chemicals. It can handle a range of temperatures but is more fragile than other materials.

Pros & Cons:

The key advantage of glass is its visual appeal, enhancing the customer experience by showcasing the vehicles inside the vending machine. However, its fragility poses a risk of breakage, and it may require more frequent maintenance. The manufacturing complexity can also lead to higher costs.

Impact on Application:

Glass is primarily used for the exterior of the vending machines, creating an inviting and modern look. Its transparency allows customers to view available vehicles, enhancing the overall experience.

Considerations for International Buyers:

Buyers should consider local building codes and safety standards, such as EN 12600 for impact testing. In regions with stringent safety regulations, tempered or laminated glass may be necessary to ensure compliance.

Summary Table

| Material | Typical Use Case for carvana vending machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural components, mechanical parts | High durability, corrosion resistance | Higher initial cost | High |

| Aluminum | External panels, decorative elements | Lightweight, good corrosion resistance | Less durable than stainless steel | Medium |

| Polycarbonate | Protective covers, windows | High impact resistance, lightweight | Prone to scratching | Low |

| Glass | Exterior façade, visibility | Aesthetic appeal, transparency | Fragile, higher maintenance | Medium |

This strategic material selection guide provides B2B buyers with critical insights into the materials used in Carvana vending machines, enabling informed decisions that align with regional standards and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for carvana vending machine

Carvana’s car vending machines represent a pinnacle of modern manufacturing and quality assurance, incorporating advanced technologies to facilitate a unique vehicle purchasing experience. For international B2B buyers, understanding the manufacturing processes and quality control (QC) measures behind these machines is crucial for making informed purchasing decisions. This section delves into the typical manufacturing processes, key techniques employed, and the stringent quality assurance standards that ensure reliability and safety.

Manufacturing Processes

1. Material Preparation

The first stage in the manufacturing of Carvana’s vending machines involves careful material selection and preparation. Key materials typically include:

- Structural Steel: Offers durability and strength.

- Glass Panels: Utilized for aesthetic appeal and transparency, allowing customers to view the vehicles.

- Mechanical Components: Including motors, sensors, and conveyor systems for the automated retrieval process.

These materials undergo rigorous inspections to ensure they meet specified standards before proceeding to the next stage.

2. Forming

Once the materials are prepared, the forming process begins. This involves shaping the structural components through techniques such as:

- CNC Machining: Precision cutting and shaping of metal parts to exact specifications.

- Glass Fabrication: Cutting and tempering glass panels to withstand environmental stresses and provide safety.

Effective forming techniques are crucial in ensuring that all components fit together seamlessly, which is vital for the operational integrity of the vending machine.

3. Assembly

The assembly process is where the individual components come together. This stage includes:

- Framework Construction: Assembling the structural frame that supports the machine.

- Mechanical Assembly: Installing motors, conveyors, and retrieval mechanisms.

- Electrical Wiring: Connecting sensors, control systems, and user interfaces.

A well-organized assembly line enhances efficiency and reduces the risk of errors, ensuring that each machine is built to high standards.

4. Finishing

The final stage of manufacturing involves finishing processes that enhance both functionality and aesthetics. This includes:

- Surface Treatment: Painting or coating metal parts to protect against corrosion and enhance appearance.

- Testing and Calibration: Each machine undergoes rigorous testing to ensure all mechanical and electronic systems function correctly.

Finishing not only improves the machine’s look but also its longevity and reliability in various environments.

Quality Assurance

International Standards

Quality assurance for Carvana’s vending machines adheres to several international standards, including:

- ISO 9001: This standard focuses on quality management systems and ensures that manufacturers maintain consistent quality in their products and services.

- CE Marking: Required for products sold within the European Economic Area, indicating compliance with health, safety, and environmental protection standards.

These certifications provide assurance to B2B buyers about the quality and safety of the vending machines.

Industry-Specific Standards

In addition to general international standards, there are also industry-specific certifications that may apply, such as:

- API Standards: For mechanical components, ensuring reliability and safety in operational conditions.

- UL Certification: For electrical components, guaranteeing safety and performance standards.

Understanding these certifications is essential for buyers, as they reflect the credibility and quality of the manufacturing processes.

QC Checkpoints

Quality control is integrated throughout the manufacturing process with multiple checkpoints:

- Incoming Quality Control (IQC): At this stage, raw materials and components are inspected to ensure they meet specified quality standards.

- In-Process Quality Control (IPQC): Ongoing checks during the manufacturing process to identify and rectify defects early.

- Final Quality Control (FQC): Comprehensive testing of the finished vending machines to ensure all systems operate correctly and meet quality specifications.

These checkpoints are critical in maintaining high standards and minimizing defects.

Common Testing Methods

Testing methods used in the quality assurance of vending machines include:

- Functional Testing: Ensuring that all mechanical and electronic systems work as intended.

- Load Testing: Assessing the machine’s ability to handle the weight of vehicles safely.

- Environmental Testing: Evaluating performance under various environmental conditions, such as temperature and humidity.

These tests help ensure that the machines are reliable and perform consistently in real-world conditions.

Verifying Supplier QC

For international B2B buyers, verifying the quality control measures of suppliers is crucial. Here are effective strategies:

- Conduct Audits: Regular audits of the manufacturing facility can provide insights into the supplier’s quality management practices.

- Request Quality Reports: Suppliers should provide documentation that outlines their quality control processes, test results, and certifications.

- Engage Third-Party Inspectors: Independent inspectors can evaluate the manufacturing processes and verify compliance with international standards.

These steps help buyers ensure they are partnering with reliable suppliers who prioritize quality.

QC and Certification Nuances for International Buyers

When dealing with international suppliers, B2B buyers should be aware of specific nuances:

- Regulatory Compliance: Different regions may have varying regulatory requirements. Buyers must ensure that machines comply with local laws in their respective markets, especially in Africa, South America, the Middle East, and Europe.

- Cultural Considerations: Understanding local practices and expectations in quality assurance can facilitate smoother transactions and enhance collaboration.

- Language Barriers: Clear communication regarding quality standards, expectations, and certifications is essential, particularly when dealing with suppliers from diverse linguistic backgrounds.

By being aware of these nuances, international buyers can better navigate the complexities of sourcing Carvana vending machines and ensure they meet their quality expectations.

In conclusion, the manufacturing processes and quality assurance measures for Carvana’s vending machines are designed to ensure reliability, safety, and customer satisfaction. For B2B buyers, understanding these aspects is essential for making informed purchasing decisions that align with their operational needs and standards.

Comprehensive Cost and Pricing Analysis for carvana vending machine Sourcing

Analyzing the cost structure and pricing dynamics of Carvana’s vending machines is crucial for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. Understanding the components that contribute to the total cost and the factors influencing pricing will enable buyers to make informed decisions and negotiate effectively.

Cost Components

-

Materials: The core materials for Carvana vending machines include high-strength glass, steel, and advanced automation components. The quality of these materials directly impacts both durability and operational efficiency. Buyers should consider sourcing from suppliers that offer materials certified for safety and sustainability.

-

Labor: Labor costs encompass not only the assembly and installation of the vending machines but also the ongoing maintenance. Skilled technicians are required for both initial setup and periodic servicing, which can be a significant cost factor, especially in regions with varying wage standards.

-

Manufacturing Overhead: This includes expenses related to facility operation, utilities, and administrative costs. Efficient manufacturing processes can reduce overhead, impacting the overall pricing structure. Buyers should inquire about the operational efficiencies of potential suppliers.

-

Tooling: Custom tooling may be necessary for specialized machine designs. This upfront investment can be substantial but is often amortized over larger production runs. Buyers should evaluate the tooling costs against their anticipated order volumes.

-

Quality Control (QC): Robust QC processes ensure that each machine meets safety and operational standards. This aspect is crucial for B2B buyers in regulated markets, as compliance can affect long-term operational viability. The costs associated with QC should be factored into the total cost of ownership.

-

Logistics: Transportation and shipping costs can vary significantly based on the machine’s size and weight, as well as the chosen shipping method. Buyers should consider the implications of Incoterms on their logistics costs, especially when importing machines from distant suppliers.

-

Margin: Suppliers will include a margin in their pricing to cover risks and ensure profitability. Understanding the typical margins within the industry can help buyers gauge whether the quoted prices are competitive.

Price Influencers

-

Volume/MOQ (Minimum Order Quantity): Larger orders can lead to reduced per-unit costs. Buyers should assess their demand to negotiate favorable terms with suppliers.

-

Specifications/Customization: Customized machines will incur additional costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials Quality/Certifications: Machines that meet higher quality standards or possess specific certifications may command a premium price. Buyers should weigh the benefits of these certifications against their budget constraints.

-

Supplier Factors: The supplier’s location, reputation, and production capacity can influence pricing. Building strong relationships with suppliers can lead to better pricing and terms.

-

Incoterms: Understanding the implications of different Incoterms is essential for managing shipping costs and risks. Buyers should negotiate terms that minimize their liability while ensuring timely delivery.

Buyer Tips

-

Negotiation: Engage in open discussions with suppliers about pricing structures. Leverage your knowledge of cost components to negotiate better terms.

-

Cost-Efficiency: Consider total cost of ownership rather than just initial purchase price. This includes maintenance, operational costs, and potential downtime.

-

Pricing Nuances: Be aware of regional pricing variations and market conditions. For instance, import tariffs and local regulations can significantly affect costs in Africa and South America.

-

Research and Due Diligence: Conduct thorough research on potential suppliers and their product offerings. This can provide leverage in negotiations and help in selecting a partner that aligns with your business goals.

Disclaimer

The prices and costs discussed herein are indicative and subject to change based on market conditions, supplier negotiations, and specific project requirements. Buyers should seek detailed quotes and conduct thorough market analysis before making procurement decisions.

Spotlight on Potential carvana vending machine Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘carvana vending machine’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for carvana vending machine

Key Technical Properties of Carvana Vending Machines

Understanding the technical specifications of Carvana vending machines is crucial for international B2B buyers. These specifications not only highlight the quality and efficiency of the machines but also influence procurement decisions and operational performance.

-

Material Grade

Carvana vending machines are predominantly constructed using high-strength steel and tempered glass. The material selection is pivotal for durability and security, ensuring that the machines withstand various environmental conditions while providing a transparent view of the vehicles inside. For buyers, understanding material grades helps assess the longevity and maintenance costs associated with these machines. -

Automated Retrieval System (ARS) Efficiency

The ARS is a central feature of Carvana vending machines, designed to retrieve vehicles quickly and safely. This system utilizes advanced robotics and algorithms to minimize the retrieval time, typically within a few minutes. For B2B buyers, knowing the efficiency ratings of the ARS can help in forecasting operational throughput and customer satisfaction levels. -

Size and Footprint

The dimensions of the vending machine are crucial for site selection and installation planning. Carvana machines vary in size, accommodating multiple vehicles in a compact space. Buyers must consider the footprint of the vending machine, ensuring it fits within their operational constraints and local zoning regulations. -

Power Consumption

The energy efficiency of these vending machines is a significant factor, especially for businesses in regions where energy costs are high. Carvana’s machines are designed to operate on standard electrical systems while minimizing power usage during idle periods. B2B buyers should evaluate the energy consumption specifications to calculate potential operational costs. -

User Interface Technology

The machines feature an intuitive user interface that facilitates a seamless customer experience. This includes touchscreen controls and integration with mobile applications. Understanding the technology behind the user interface can aid buyers in assessing the ease of use for customers and potential training requirements for staff. -

Safety and Compliance Standards

Compliance with safety standards is non-negotiable. Carvana’s vending machines are designed to meet international safety regulations, including fire safety and electrical standards. B2B buyers should prioritize machines that adhere to these standards to mitigate liability risks and ensure customer safety.

Common Trade Terms in the Automotive Vending Machine Industry

Familiarity with industry terminology is essential for effective communication and negotiation in B2B transactions involving Carvana vending machines.

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of vending machines, understanding OEM relationships can help buyers identify reliable suppliers and ensure product quality. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it affects budgeting and inventory management. Knowing the MOQ can aid in negotiating better terms with suppliers. -

RFQ (Request for Quotation)

An RFQ is a standard business process where a buyer requests pricing and terms from suppliers for specific products. For buyers of Carvana vending machines, issuing an RFQ allows them to compare offers and make informed purchasing decisions. -

Incoterms (International Commercial Terms)

These are pre-defined commercial terms published by the International Chamber of Commerce (ICC). They clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding Incoterms is vital for international buyers to manage logistics effectively. -

Lead Time

This term refers to the time it takes from placing an order to receiving the product. For buyers, knowing the lead time for Carvana vending machines helps in planning and aligning with market demands. -

Warranty and Support Terms

These refer to the commitments made by the manufacturer regarding the repair or replacement of products. Understanding warranty terms is crucial for B2B buyers to ensure they are protected against defects and can maintain their investment in vending machines.

By mastering these technical properties and trade terminologies, international B2B buyers can make informed decisions that enhance their operational efficiency and customer satisfaction in the automotive vending market.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the carvana vending machine Sector

Market Overview & Key Trends

The automotive retail sector is undergoing a transformative shift, with innovations like Carvana’s vending machines leading the charge. These automated car retrieval systems are not merely a novelty; they represent a significant evolution in consumer expectations and operational efficiency. Global drivers such as the increasing demand for contactless transactions, enhanced user experiences, and rapid urbanization are pushing businesses towards automation and digital solutions. For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding these trends is crucial.

Emerging technologies such as AI and IoT are reshaping sourcing strategies. Businesses are leveraging data analytics to optimize inventory management and streamline operations. The rise of e-commerce in the automotive sector is compelling companies to integrate online platforms with physical experiences, as seen in Carvana’s model. Moreover, sustainability is becoming a focal point in sourcing strategies, with buyers increasingly prioritizing vendors that adopt green practices.

Market dynamics also highlight the importance of local partnerships. For buyers in regions like Africa and South America, collaborating with local distributors can facilitate smoother logistics and better market penetration. In Europe, where regulatory frameworks are stringent, ensuring compliance with local laws while sourcing technologically advanced solutions is paramount. Overall, the car vending machine concept is paving the way for a more efficient, customer-centric automotive market.

Sustainability & Ethical Sourcing in B2B

As the automotive industry evolves, sustainability and ethical sourcing are no longer optional; they are essential. Carvana’s vending machines, while innovative, also present an opportunity for B2B buyers to consider the environmental impact of their operations. The production and deployment of these machines necessitate a thorough assessment of energy consumption, materials used, and waste management practices.

International buyers should prioritize suppliers who adhere to sustainable practices, such as utilizing recycled materials and minimizing carbon footprints in manufacturing. Certifications such as ISO 14001 for environmental management systems can serve as benchmarks for assessing potential partners. Moreover, engaging with vendors that focus on sustainable supply chains not only enhances brand reputation but also meets the growing consumer demand for responsible business practices.

The importance of transparency in the supply chain cannot be overstated. Buyers should seek suppliers who provide visibility into their sourcing processes, ensuring that all materials and components are ethically sourced. In regions where regulations around sustainability are tightening, aligning with compliant suppliers can also mitigate risks associated with non-compliance.

Brief Evolution/History

Carvana’s introduction of car vending machines marked a significant shift in the automotive retail landscape. Launched in 2013, this innovative concept redefined the vehicle purchasing experience, integrating technology with consumer engagement. The initial vending machines were designed to enhance convenience and streamline the car retrieval process, transforming a traditionally cumbersome experience into a memorable event. As the model gained popularity, Carvana expanded its footprint across the United States and began exploring international markets, showcasing how automation can revolutionize not just sales but also customer interaction in the automotive industry. This evolution highlights the ongoing trend towards digitalization and customer-centric solutions in B2B practices.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of carvana vending machine

-

What factors should I consider when vetting suppliers of Carvana vending machines?

When vetting suppliers, assess their manufacturing capabilities, experience in the automotive sector, and track record of delivering similar projects. Request client references and testimonials to gauge reliability. Ensure they comply with international standards and regulations relevant to your region. It’s also beneficial to evaluate their financial stability and after-sales support, as these factors can significantly impact your operational continuity and service quality. -

Can Carvana vending machines be customized for specific markets?

Yes, customization options are available for Carvana vending machines to cater to different market needs. This can include branding elements, language options, and payment systems tailored to local preferences. Discuss your specific requirements with potential suppliers to understand the extent of customization they can offer. Be mindful that extensive customization may affect lead times and costs, so clarify these aspects upfront. -

What are the typical lead times and minimum order quantities (MOQ) for Carvana vending machines?

Lead times can vary based on the complexity of the machine and the supplier’s capacity. Generally, expect a lead time ranging from 6 to 12 months from order placement to delivery. The MOQ often depends on the supplier; some may require a single unit while others might have higher minimums. Confirm these details during initial discussions to ensure they align with your business plans and timelines. -

What payment terms are common when purchasing Carvana vending machines?

Payment terms can vary significantly among suppliers. Common arrangements include a deposit upon order confirmation, followed by staggered payments linked to production milestones. Some suppliers may offer financing options or payment upon delivery. It’s crucial to negotiate terms that suit your cash flow and operational needs, and to document all agreements clearly to avoid future disputes. -

How can I ensure quality assurance and certifications for the vending machines?

To ensure quality, request detailed documentation of the supplier’s quality assurance processes and certifications. Look for ISO certifications or other relevant industry standards that validate the manufacturing quality. Additionally, consider arranging for third-party inspections during the production phase. This proactive approach can help mitigate risks related to product defects and ensure compliance with local regulations. -

What logistics considerations should I keep in mind when importing vending machines?

Logistics for importing vending machines involve several key factors, including shipping methods, customs clearance, and local transportation. Assess the supplier’s capability to handle international shipping, including packaging that protects the machines during transit. Engage with a reliable freight forwarder familiar with your destination country’s regulations to ensure smooth customs processes and timely delivery. -

What steps should I take if I encounter disputes with my vending machine supplier?

In the event of a dispute, first, attempt to resolve the issue directly with the supplier through open communication. If that fails, refer to the contract for dispute resolution clauses, which may include mediation or arbitration. Document all correspondence and agreements to support your position. If necessary, consider engaging legal counsel experienced in international trade to navigate complex situations effectively. -

Are there any specific regulations I should be aware of when operating Carvana vending machines in my region?

Yes, each region may have specific regulations regarding automated vehicle sales, consumer protection, and safety standards. Familiarize yourself with local laws governing automotive sales, including licensing, warranty requirements, and data protection laws. Consult with legal experts or trade associations in your area to ensure compliance, as this can prevent costly fines and operational disruptions.

Strategic Sourcing Conclusion and Outlook for carvana vending machine

The integration of Carvana’s innovative vending machine technology into the automotive purchasing landscape presents a transformative opportunity for international B2B buyers. By streamlining the vehicle acquisition process through automation and advanced engineering, Carvana not only enhances customer experience but also addresses operational inefficiencies common in traditional dealerships. Key takeaways for B2B buyers include:

- Enhanced Efficiency: Automated retrieval systems reduce wait times and improve service delivery, making it easier for businesses to manage vehicle inventory and customer interactions.

- Customer-Centric Design: The unique vending machine experience adds value to the customer journey, potentially increasing brand loyalty and repeat business.

- Market Adaptability: As Carvana expands its reach, understanding local market dynamics in regions like Africa, South America, the Middle East, and Europe can provide insights into consumer preferences and operational challenges.

In conclusion, strategic sourcing of Carvana’s vending machines can empower businesses to differentiate themselves in a competitive marketplace. As the automotive industry continues to evolve, investing in innovative solutions like Carvana’s vending machines will be crucial for staying ahead. International B2B buyers are encouraged to explore partnerships that leverage this technology, ensuring they are well-positioned for future growth and customer satisfaction.