Your Ultimate Guide to Sourcing Water Vending Machine

Guide to Water Vending Machine

- Introduction: Navigating the Global Market for water vending machine

- Understanding water vending machine Types and Variations

- Key Industrial Applications of water vending machine

- Strategic Material Selection Guide for water vending machine

- In-depth Look: Manufacturing Processes and Quality Assurance for water vending machine

- Comprehensive Cost and Pricing Analysis for water vending machine Sourcing

- Spotlight on Potential water vending machine Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for water vending machine

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the water vending machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of water vending machine

- Strategic Sourcing Conclusion and Outlook for water vending machine

Introduction: Navigating the Global Market for water vending machine

In today’s global market, the demand for clean and accessible drinking water has surged, making water vending machines an essential solution for both urban and rural communities. As international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding the nuances of this sector can empower you to make informed sourcing decisions that align with local needs and regulatory requirements. Water vending machines not only provide a sustainable alternative to bottled water but also address critical issues surrounding water quality and accessibility.

This comprehensive guide will delve into various aspects of the water vending machine industry, including types of machines, materials used in their construction, manufacturing and quality control processes, potential suppliers, and cost considerations. Additionally, we will explore market trends and insights to help you navigate regional differences and preferences.

By equipping yourself with this knowledge, you can strategically position your business to leverage opportunities in the growing water vending sector. From understanding the technical specifications of machines to evaluating supplier reliability, this guide serves as a valuable resource for maximizing your investment. Prepare to enhance your business portfolio while contributing positively to community health and sustainability through informed choices in the water vending machine market.

Understanding water vending machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Reverse Osmosis Vending Machine | Utilizes reverse osmosis filtration for high purity | Gyms, residential areas, health-conscious markets | Pros: High-quality water; effective contaminant removal. Cons: Higher initial cost; requires regular maintenance. |

| Filtered Water Vending Machine | Uses multi-stage filtration systems | Offices, public parks, schools | Pros: Lower cost than RO machines; simpler maintenance. Cons: May not remove all contaminants; water quality varies. |

| Bulk Water Vending Machine | Dispenses large volumes of water for refillable containers | Grocery stores, farmers’ markets, event venues | Pros: Cost-effective for consumers; promotes sustainability. Cons: Requires space for larger units; initial setup can be complex. |

| Ice and Water Vending Machine | Combines ice and water dispensing capabilities | Convenience stores, tourist areas, recreation centers | Pros: Diversifies offerings; attracts varied customer base. Cons: Higher operational costs; more complex maintenance. |

| Smart Water Vending Machine | Features cashless payment options and real-time monitoring | Urban areas, tech-savvy markets, transportation hubs | Pros: Enhanced user experience; data analytics for optimization. Cons: Higher initial investment; reliance on technology can cause issues. |

Reverse Osmosis Vending Machine

Reverse osmosis (RO) vending machines are designed to deliver high-quality purified water by forcing water through a semi-permeable membrane. This type is particularly suitable for health-focused B2B applications, such as gyms and residential areas where consumers prioritize water purity. When purchasing, businesses should consider the upfront costs, as well as the need for regular maintenance and filter replacement, which can impact long-term profitability.

Filtered Water Vending Machine

Filtered water vending machines typically employ multi-stage filtration systems to provide clean drinking water. These machines are ideal for locations like offices, public parks, and schools, where convenience is essential. Buyers should assess the filtration technology used, as water quality can vary significantly. While these machines are generally more affordable than RO models, they may not remove all contaminants, which is a critical consideration for health-conscious markets.

Bulk Water Vending Machine

Bulk water vending machines offer a practical solution for dispensing large quantities of water into refillable containers. This type is commonly found in grocery stores, farmers’ markets, and event venues, promoting sustainability by encouraging customers to reuse containers. When considering a bulk machine, businesses should evaluate the space requirements and the complexity of the initial setup. Additionally, understanding local regulations on bulk water dispensing is crucial to avoid compliance issues.

Ice and Water Vending Machine

Combining ice and water dispensing capabilities, ice and water vending machines cater to diverse customer needs in high-traffic areas like convenience stores and recreational centers. They are an attractive option for businesses looking to maximize revenue streams. However, potential buyers should be aware of the higher operational costs associated with these machines, as well as the increased complexity in maintenance and service.

Smart Water Vending Machine

Smart water vending machines are equipped with advanced technology, including cashless payment systems and real-time monitoring features. They are particularly effective in urban areas and tech-savvy markets, appealing to consumers who prefer convenience and innovation. B2B buyers should consider the higher initial investment and the reliance on technology, which may lead to operational challenges. However, the ability to collect data for optimization can significantly enhance business performance over time.

Related Video: water vending machine features and functions introduction

Key Industrial Applications of water vending machine

| Industry/Sector | Specific Application of Water Vending Machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Hotel Lobbies and Resorts | Enhances guest experience, promotes health and sustainability | Machine durability, water purification standards, payment options |

| Education | Schools and Universities | Provides accessible, safe drinking water for students | Compliance with health regulations, filtration technology, service support |

| Healthcare | Hospitals and Clinics | Ensures availability of clean water for patients and staff | Hygiene standards, regular maintenance, reliable water supply |

| Retail | Shopping Malls and Supermarkets | Increases customer satisfaction and foot traffic | Location analysis, machine capacity, payment systems |

| Construction | Construction Sites | Provides convenient hydration options for workers | Robustness of machines, water quality assurance, mobility requirements |

Hospitality

In the hospitality sector, water vending machines are strategically placed in hotel lobbies and resorts to provide guests with easy access to purified drinking water. This not only enhances the guest experience but also aligns with sustainability initiatives by reducing the reliance on single-use plastic bottles. For international buyers, it is essential to consider the durability of the machines, adherence to local water purification standards, and the variety of payment options available to accommodate diverse customer preferences.

Education

Water vending machines in schools and universities serve as vital hydration stations for students and faculty. They ensure that clean drinking water is readily available, promoting health and wellness in educational environments. Buyers from the education sector should prioritize compliance with local health regulations, the effectiveness of filtration technology, and the availability of reliable service support to maintain the machines in optimal condition.

Healthcare

In healthcare facilities like hospitals and clinics, water vending machines play a crucial role in providing safe drinking water for patients and staff. These machines help ensure that hydration needs are met efficiently, especially in high-traffic areas. When sourcing machines for this sector, it is vital to focus on hygiene standards, the frequency of regular maintenance, and the reliability of the water supply to meet the demands of a healthcare environment.

Retail

Shopping malls and supermarkets benefit from installing water vending machines by enhancing customer satisfaction and increasing foot traffic. These machines provide a convenient option for shoppers looking for hydration while reducing the environmental impact of plastic waste. Retail buyers should conduct thorough location analyses to identify high-traffic areas, evaluate the machine’s capacity to meet demand, and ensure the payment systems are user-friendly and diverse.

Construction

On construction sites, water vending machines offer a practical solution for providing workers with convenient access to clean drinking water. This is critical for maintaining hydration levels, particularly in hot climates or during intensive labor. Buyers in the construction industry should consider the robustness of the machines to withstand harsh conditions, the assurance of water quality, and the mobility of the units for easy relocation as projects progress.

Strategic Material Selection Guide for water vending machine

When selecting materials for water vending machines, it is crucial to consider properties that directly impact performance, durability, and compliance with international standards. Below is an analysis of four common materials used in the construction of water vending machines, focusing on their key properties, advantages and disadvantages, and specific considerations for international B2B buyers.

Stainless Steel

Key Properties: Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand a wide range of temperatures and pressures. It is often rated for high-pressure applications and can endure extreme environmental conditions.

Pros & Cons: The primary advantage of stainless steel is its durability and resistance to rust and corrosion, making it ideal for outdoor installations. However, it can be more expensive than other materials, and its manufacturing process is complex, which can increase lead times.

Impact on Application: Stainless steel is compatible with various water types, including potable water, and is easy to clean, ensuring hygiene standards are met. Its resistance to bacterial growth makes it a preferred choice in health-conscious markets.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure compliance with local health and safety standards. In Europe, adherence to standards such as EN 10088 for stainless steel is essential.

Polyethylene (PE)

Key Properties: Polyethylene is a lightweight, flexible plastic known for its chemical resistance and low moisture absorption. It has a high impact resistance and can operate effectively within a temperature range of -50°C to 80°C.

Pros & Cons: The main advantage of polyethylene is its low cost and ease of manufacturing, making it suitable for high-volume production. However, it is less durable than metals and may degrade under UV exposure unless treated.

Impact on Application: Polyethylene is suitable for water storage tanks and components that do not require high structural integrity. Its compatibility with various water types makes it a viable option for vending machines.

Considerations for International Buyers: Buyers should check for compliance with FDA and EU regulations regarding food-grade materials. In South America, local certifications may be necessary to ensure safety.

Aluminum

Key Properties: Aluminum is lightweight and has good corrosion resistance, particularly when anodized. It can withstand moderate temperatures and pressures, making it suitable for various applications.

Pros & Cons: The key advantage of aluminum is its lightweight nature, which simplifies installation and reduces shipping costs. However, it is less durable than stainless steel and can be prone to scratching and denting.

Impact on Application: Aluminum is often used in the construction of vending machine frames and panels. Its lightweight properties make it ideal for portable machines, but it may not be suitable for high-pressure water systems.

Considerations for International Buyers: In Europe, compliance with standards such as EN 573 for aluminum alloys is crucial. Buyers in Africa may need to consider local environmental factors that could affect aluminum’s longevity.

Glass-Reinforced Plastic (GRP)

Key Properties: Glass-reinforced plastic combines the lightweight characteristics of plastic with the strength of glass fibers. It is highly resistant to corrosion and can withstand a wide range of temperatures.

Pros & Cons: GRP offers excellent durability and resistance to environmental factors, making it suitable for outdoor applications. However, it can be more expensive than traditional plastics and may require specialized manufacturing processes.

Impact on Application: GRP is often used for water tanks and external casings of vending machines, providing a robust solution that maintains water quality. Its non-corrosive nature ensures longevity in various climates.

Considerations for International Buyers: Buyers should ensure that GRP materials comply with local regulations for water safety. In Europe, adherence to standards like ISO 9001 for quality management systems is important.

Summary Table

| Material | Typical Use Case for water vending machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Frame and internal components for durability | Excellent corrosion resistance | Higher cost and complex manufacturing | High |

| Polyethylene (PE) | Water storage tanks and components | Low cost and lightweight | Less durable and UV degradation potential | Low |

| Aluminum | Vending machine frames and panels | Lightweight and easy to install | Prone to scratching and denting | Medium |

| Glass-Reinforced Plastic (GRP) | External casings and tanks | Excellent durability and corrosion resistance | Higher cost and specialized manufacturing | Medium |

This strategic material selection guide provides a comprehensive overview for international B2B buyers, helping them make informed decisions based on performance, cost, and compliance with local standards.

In-depth Look: Manufacturing Processes and Quality Assurance for water vending machine

Manufacturing Processes for Water Vending Machines

Understanding the manufacturing processes of water vending machines is crucial for B2B buyers aiming to ensure quality and reliability in their purchases. The manufacturing journey typically involves several key stages, each integral to producing a high-quality product.

Main Stages of Manufacturing

-

Material Preparation

– Selection of Materials: The manufacturing process begins with the selection of appropriate materials. Stainless steel is commonly used for the machine’s exterior due to its durability and resistance to corrosion. Additionally, food-grade plastics are utilized for internal components to ensure safety and compliance with health regulations.

– Component Sourcing: Manufacturers procure components such as filtration systems, pumps, and electronic controls from certified suppliers to guarantee quality. -

Forming

– Metal Fabrication: This involves cutting, bending, and shaping metal sheets to create the structural framework of the vending machine. Techniques such as laser cutting and CNC machining are employed for precision.

– Molding of Plastics: For parts made from plastic, injection molding is typically used, ensuring uniformity and strength across components. -

Assembly

– Component Integration: In this stage, various components are assembled, including the water filtration system, dispensing unit, and payment processing hardware. Skilled technicians ensure that each part fits correctly and functions as intended.

– Wiring and Electronics: The machine’s electrical systems are installed, including sensors and control panels, which require careful handling to avoid damage. -

Finishing

– Surface Treatment: The machine undergoes surface treatments such as powder coating or painting to enhance aesthetics and protect against environmental factors.

– Quality Checks: Final inspections are conducted to ensure that the assembly meets all specifications and quality standards.

Quality Assurance Protocols

Quality assurance is a critical aspect of the manufacturing process for water vending machines. It ensures that products meet international standards and customer expectations.

Relevant International Standards

- ISO 9001: This standard focuses on quality management systems, ensuring that manufacturers consistently provide products that meet customer and regulatory requirements.

- CE Marking: For machines sold in Europe, CE marking indicates compliance with EU safety, health, and environmental protection standards.

- API Standards: The American Petroleum Institute standards may apply if the machine interacts with petroleum-based products or systems.

QC Checkpoints

-

Incoming Quality Control (IQC)

– At this stage, raw materials and components are inspected upon arrival at the manufacturing facility. This involves checking for compliance with specifications and conducting initial tests for functionality. -

In-Process Quality Control (IPQC)

– During the assembly process, regular inspections are carried out to monitor the quality of work and ensure that components are correctly integrated. This may involve testing individual parts or systems before final assembly. -

Final Quality Control (FQC)

– The final product is subjected to comprehensive testing, including functionality tests, leak tests, and safety evaluations. This step is crucial to verify that the machine operates as intended and meets all regulatory requirements.

Common Testing Methods

- Water Quality Testing: Testing for contaminants and ensuring the water purification system meets health standards.

- Operational Testing: Running the machine through its full cycle to ensure all systems function correctly, including payment processing and water dispensing.

- Durability Testing: Subjecting the machine to stress tests to evaluate its resilience under various conditions.

Verifying Supplier Quality Control

For B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is essential.

-

Supplier Audits

– Conduct on-site audits to assess the manufacturing facility’s capabilities, quality control processes, and adherence to international standards. This firsthand evaluation can provide valuable insights into the supplier’s operational integrity. -

Quality Reports

– Request detailed quality assurance reports from suppliers, including data on their compliance with ISO 9001, CE marking, and other relevant certifications. These documents should outline testing methods, results, and any corrective actions taken. -

Third-Party Inspections

– Engage third-party inspection services to conduct independent evaluations of the manufacturing processes and final products. These inspections can help confirm that the machines meet specified quality standards before shipment.

Quality Control Nuances for International Buyers

International buyers must be aware of certain nuances when dealing with quality control across different regions:

- Regulatory Variations: Different countries have varying regulations regarding water quality and vending machine operations. It is crucial to ensure that the supplier’s machines comply with local laws in the buyer’s region.

- Cultural Considerations: Understanding the market-specific preferences and standards can impact the quality expectations. For instance, buyers from Europe may prioritize energy efficiency, while those from Africa might focus on durability and maintenance ease.

- Supply Chain Reliability: The sourcing of materials and components can vary significantly by region. Buyers should assess the supplier’s supply chain to ensure consistent quality and timely delivery.

By thoroughly understanding the manufacturing processes and quality assurance protocols, international B2B buyers can make informed decisions when selecting water vending machines, ensuring they partner with reliable manufacturers that meet their specific needs and standards.

Related Video: Complete Bottled Water Production Line From A to Z

Comprehensive Cost and Pricing Analysis for water vending machine Sourcing

When sourcing water vending machines, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. This analysis will provide insights into the various cost components, pricing influencers, and actionable buyer tips to enhance decision-making.

Cost Components

-

Materials: The primary materials used in water vending machines include stainless steel for the machine casing, various plastics for components, and electronic parts for payment systems and controls. High-quality materials may increase upfront costs but can significantly enhance durability and longevity, reducing long-term expenses.

-

Labor: Labor costs encompass both direct labor involved in manufacturing the machines and indirect labor for assembly and quality assurance. These costs can vary significantly by region; for instance, labor costs in Europe may be higher than in certain African or South American countries.

-

Manufacturing Overhead: This includes costs associated with factory operations such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can minimize overhead, impacting the overall pricing of the vending machines.

-

Tooling: Initial tooling costs for custom designs or specialized features can add to the total cost. If a buyer requires specific customization, these costs should be factored into the budget early in the procurement process.

-

Quality Control (QC): Implementing robust QC measures ensures that each machine meets safety and performance standards. While this may increase initial costs, it helps prevent long-term issues that could arise from subpar equipment.

-

Logistics: Shipping and handling costs can vary based on the shipping terms (Incoterms) and the distance from the manufacturer to the buyer. International shipping may involve additional tariffs and taxes, impacting the final price.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary widely depending on market conditions and competition. Understanding the margin can provide leverage during negotiations.

Price Influencers

-

Volume/MOQ: Pricing often improves with larger order volumes due to economies of scale. Establishing minimum order quantities (MOQs) can also significantly affect unit costs.

-

Specifications/Customization: Customized machines tailored to specific regional needs may come at a premium. Buyers should weigh the benefits of customization against the added costs.

-

Materials and Quality Certifications: Machines certified for health and safety standards may command higher prices. Buyers should consider the importance of these certifications in their target market.

-

Supplier Factors: The reputation, experience, and support services of the supplier can influence pricing. Established suppliers may offer better warranties and post-sale support, justifying higher costs.

-

Incoterms: Understanding Incoterms is vital for international transactions. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect total landed costs and should be clearly negotiated in contracts.

Buyer Tips

-

Negotiation: Engage in thorough negotiations with suppliers to ensure competitive pricing. Use market research and comparable quotes to leverage negotiations.

-

Cost-Efficiency: Focus on the Total Cost of Ownership (TCO) rather than just the upfront price. Consider maintenance, operational costs, and potential downtime when evaluating suppliers.

-

Pricing Nuances: Be aware of regional pricing differences and currency fluctuations when sourcing internationally. Establish payment terms that mitigate risks associated with currency exchange.

-

Long-Term Partnerships: Developing strong relationships with suppliers can lead to better pricing and terms over time. Consider long-term contracts for stability in pricing and supply.

Disclaimer

Prices for water vending machines can vary significantly based on the factors mentioned above. This analysis provides indicative insights but does not reflect specific pricing. Buyers are encouraged to conduct thorough market research and seek multiple quotes to arrive at an accurate cost assessment for their needs.

Spotlight on Potential water vending machine Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘water vending machine’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for water vending machine

When considering the acquisition of a water vending machine, it is vital to understand both the technical specifications and the relevant industry terminology. This knowledge not only facilitates informed decision-making but also enhances communication with suppliers and manufacturers.

Critical Specifications of Water Vending Machines

-

Material Grade

The material grade refers to the quality and type of materials used in the construction of the vending machine, often stainless steel or high-grade plastic. Stainless steel is preferred for its durability, corrosion resistance, and ease of cleaning, which are crucial for maintaining hygiene in water vending operations. Understanding material grades helps buyers assess the longevity and maintenance requirements of the machines. -

Filtration System

A robust filtration system is essential for ensuring the quality of the water dispensed. Common systems include reverse osmosis and UV purification. Buyers should evaluate the filtration capabilities based on local water quality issues and regulatory standards, as this will directly impact customer satisfaction and compliance with health regulations. -

Capacity and Flow Rate

Capacity indicates the volume of water the machine can hold, while flow rate refers to how quickly water can be dispensed. These specifications are critical for determining how well the machine can meet customer demand, particularly in high-traffic areas. A machine with insufficient capacity may lead to customer dissatisfaction and lost sales opportunities.

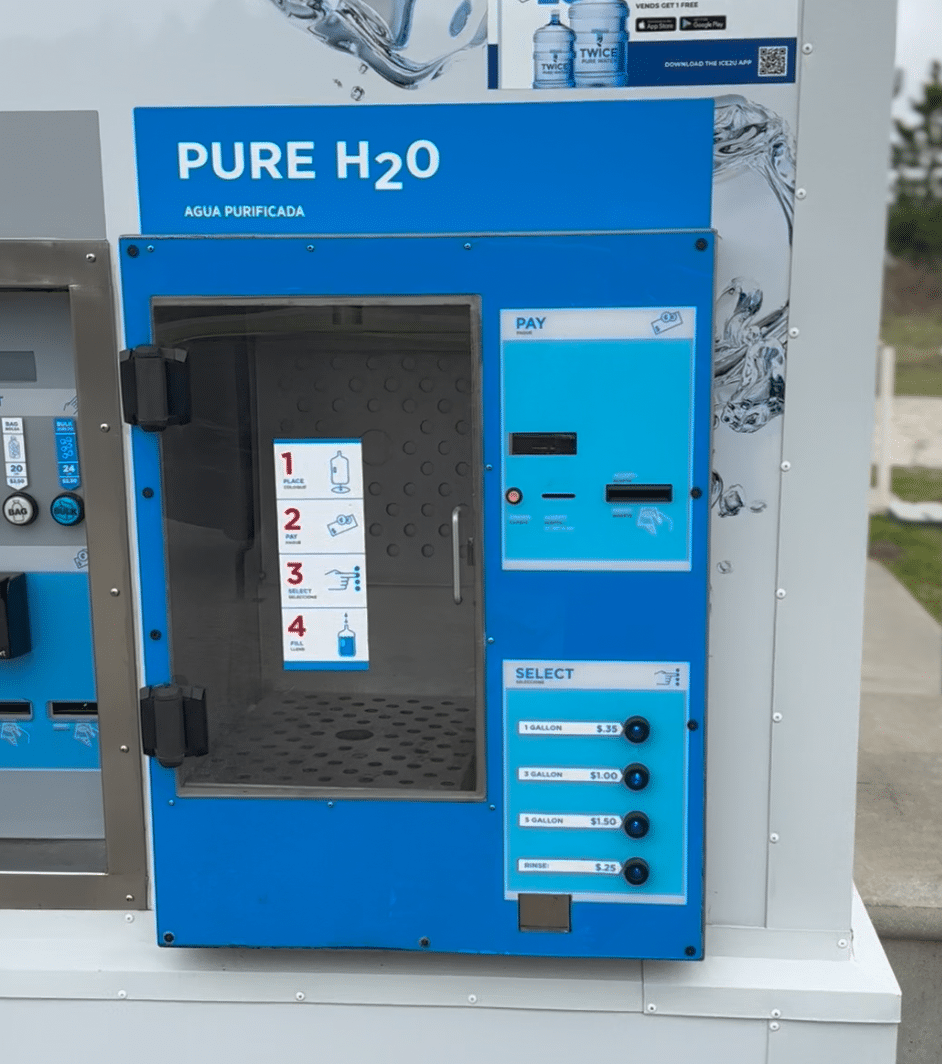

Illustrative Image (Source: Google Search)

-

Power Requirements

Understanding the power requirements of a vending machine is crucial for installation and operation. Machines may require different voltage and amperage levels, impacting the site selection and overall operational costs. Ensure that the chosen location can accommodate the machine’s electrical needs. -

Payment Options

Modern water vending machines often come equipped with various payment systems, including cash, credit/debit cards, and mobile payment options. The availability of multiple payment methods can significantly enhance user convenience and increase sales. Buyers should consider the technological compatibility and transaction fees associated with these systems. -

Maintenance Schedule

A clear maintenance schedule is essential for ensuring the ongoing functionality of the vending machine. Regular maintenance not only prolongs the machine’s lifespan but also guarantees consistent water quality. Buyers should inquire about the manufacturer’s recommended maintenance intervals and the availability of service contracts.

Common Trade Terms in the Water Vending Industry

- OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding this term is important for buyers looking to source machines or components, as it can influence pricing, warranty, and support options.

Illustrative Image (Source: Google Search)

-

MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a buyer must purchase to complete a transaction. This term is crucial for budgeting and inventory management, especially for companies looking to scale their operations quickly. Knowing the MOQ can help in negotiating better terms with suppliers. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and terms for specific products or services. For B2B buyers, issuing an RFQ is a strategic way to gather competitive pricing and service options from multiple vendors, facilitating better purchasing decisions. -

Incoterms

Incoterms (International Commercial Terms) are a series of pre-defined commercial terms published by the International Chamber of Commerce, which clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is vital for understanding shipping costs, risk management, and delivery obligations. -

Lead Time

Lead time refers to the time taken from placing an order until its delivery. This term is essential for project planning and inventory management, as longer lead times can impact the ability to meet customer demand and maintain sales. -

Warranty

A warranty is a guarantee provided by the manufacturer regarding the condition of the machine and the promise to repair or replace it if necessary. Understanding warranty terms is critical for risk management and budgeting for potential future expenses.

By grasping these technical specifications and trade terminologies, B2B buyers can make more informed decisions regarding their investment in water vending machines, ultimately leading to a successful business venture.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the water vending machine Sector

Market Overview & Key Trends

The water vending machine sector is experiencing significant growth, driven by increasing demand for clean, accessible drinking water and the rising awareness of water quality issues across global markets. In regions like Africa and South America, where access to potable water remains a challenge, water vending machines present a viable solution, providing affordable and convenient access to purified water. In contrast, European markets, particularly in the UK and Italy, are seeing a shift towards sustainable and eco-friendly water solutions, aligning with the broader trend of environmental consciousness among consumers.

Key technological advancements are shaping the industry, including the integration of cashless payment systems, mobile app connectivity for machine tracking, and IoT capabilities for real-time monitoring of water quality and inventory levels. These innovations not only enhance operational efficiency but also improve customer engagement, making it easier for B2B buyers to manage their vending machine networks effectively.

International B2B buyers must navigate varying regulatory landscapes, particularly concerning health and safety standards. For instance, in the Middle East, compliance with stringent local health regulations is crucial for market entry. Buyers should conduct comprehensive market research to identify local competitors and understand consumer behavior, ensuring their offerings align with market demands. Furthermore, the focus on customer-centric services, such as loyalty programs and promotions, can significantly enhance brand loyalty in this competitive landscape.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical factor in the water vending machine sector, driven by consumer preferences for environmentally responsible products. The environmental impact of water vending operations primarily revolves around energy consumption and waste management. By investing in energy-efficient machines and promoting refillable containers, companies can significantly reduce their carbon footprint.

Ethical sourcing is equally important. B2B buyers should prioritize suppliers that adhere to sustainable practices, such as using recycled materials for machine components and ensuring responsible water sourcing. Certifications like ISO 14001 for environmental management systems and other green certifications can serve as indicators of a supplier’s commitment to sustainability.

Moreover, engaging with local communities to ensure equitable access to water can enhance corporate social responsibility efforts. This not only fosters goodwill but can also create a loyal customer base that values ethical practices. Buyers must also consider the longevity and durability of the machines, as investing in high-quality equipment reduces waste and the need for frequent replacements.

Brief Evolution/History

The concept of water vending machines has evolved significantly since their inception in the late 1990s. Initially, these machines primarily dispensed bottled water, catering to consumers’ immediate needs. However, as awareness of environmental issues grew, the focus shifted towards providing purified water through vending systems that promote refillable containers.

Today, the market has matured, with advanced filtration technologies such as reverse osmosis becoming standard in many machines, ensuring high-quality water. The rise of digital payment solutions and remote monitoring capabilities has further transformed the landscape, allowing operators to streamline operations and enhance customer experiences. This evolution reflects broader trends in consumer preferences for convenience, quality, and sustainability, making water vending machines a relevant and essential component of modern urban infrastructure.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of water vending machine

-

What should I consider when vetting suppliers for water vending machines?

When vetting suppliers, prioritize their experience in the water vending industry and check their track record for reliability and quality. Request references from previous clients and verify their compliance with local and international health and safety regulations. Evaluate their customer support services, including technical assistance and warranty conditions. Additionally, assess their production capabilities to ensure they can meet your demand and customize machines according to your specifications. -

Can I customize the water vending machines to fit my market needs?

Yes, many manufacturers offer customization options. When discussing your requirements, consider factors like machine size, water filtration technology, payment systems (e.g., cash, card, mobile payments), and branding opportunities. Ensure that the supplier can accommodate specific features that cater to the preferences of your target market, such as language options or eco-friendly materials. It’s beneficial to request prototypes or samples to assess the modifications before full-scale production. -

What are the typical minimum order quantities (MOQ) and lead times for international orders?

MOQs can vary significantly between suppliers, typically ranging from 5 to 50 units, depending on the manufacturer’s capacity and your customization needs. Lead times for production and shipping can range from 4 to 12 weeks, influenced by factors such as order size, complexity, and shipping logistics. Always clarify these details upfront to plan your inventory and ensure timely availability in your target markets. -

What quality assurance certifications should I look for in water vending machines?

Look for certifications that demonstrate compliance with health and safety standards, such as ISO 9001 for quality management systems and NSF/ANSI certifications for water safety. Additionally, check for local certifications relevant to your region, which may include health department approvals. Confirm that the machines undergo rigorous testing for durability and performance, ensuring they meet your country’s regulatory requirements for vending equipment. -

How should I manage logistics when importing water vending machines?

Managing logistics involves coordinating with freight forwarders who specialize in international shipments. Ensure they are familiar with customs regulations in your country to prevent delays. Discuss shipping terms (e.g., FOB, CIF) and insurance coverage for your machines. Plan for potential tariffs and additional costs associated with importing goods, and maintain clear communication with your supplier about shipment tracking and expected delivery dates. -

What steps can I take to resolve disputes with suppliers?

To resolve disputes, first, approach the supplier directly to discuss the issue calmly and professionally. Document all communications and agreements to establish a clear timeline. If direct negotiation fails, consider mediation or arbitration as stipulated in your contract. It’s vital to have a legal framework in place for dispute resolution, including jurisdiction and applicable laws, especially when dealing with international suppliers. -

What payment options are typically available for purchasing water vending machines?

Payment options can include bank transfers, letters of credit, and payment platforms like PayPal or escrow services for added security. It’s advisable to negotiate terms that protect both parties, such as partial payments upfront and the remainder upon delivery. Ensure that all payment terms are clearly documented in your purchase agreement to avoid misunderstandings and safeguard your investment. -

How can I ensure ongoing maintenance and support for my water vending machines?

When sourcing your machines, inquire about the manufacturer’s support services, including warranty terms, maintenance schedules, and available training for your staff. Establish a service agreement that outlines the responsibilities of both parties regarding repairs and parts replacement. Regular maintenance checks are crucial to ensure the machines operate efficiently and comply with health standards, ultimately protecting your investment and ensuring customer satisfaction.

Strategic Sourcing Conclusion and Outlook for water vending machine

In the evolving landscape of the water vending machine industry, strategic sourcing stands as a critical pillar for success. By conducting thorough market research, identifying high-traffic locations, and establishing partnerships with reliable suppliers, international B2B buyers can position themselves advantageously. The emphasis on water quality and compliance with local regulations cannot be overstated, as these factors significantly impact customer trust and retention.

Moreover, leveraging innovative marketing strategies and maintaining operational efficiency will enhance profitability and foster long-term growth. As consumers increasingly prioritize access to clean, affordable water, the demand for water vending solutions will continue to rise, particularly in regions like Africa, South America, the Middle East, and Europe.

Looking ahead, the potential for expansion is substantial. B2B buyers are encouraged to explore diverse markets and adapt to local needs while embracing sustainability as a core business value. The time to invest in water vending machines is now—seize the opportunity to make a positive impact on communities while driving your business forward. Engage with industry experts and stay informed about emerging trends to maximize your strategic sourcing efforts.