Your Ultimate Guide to Sourcing Weed Vending Machine Prices

Guide to Weed Vending Machine Prices

- Introduction: Navigating the Global Market for weed vending machine prices

- Understanding weed vending machine prices Types and Variations

- Key Industrial Applications of weed vending machine prices

- Strategic Material Selection Guide for weed vending machine prices

- In-depth Look: Manufacturing Processes and Quality Assurance for weed vending machine prices

- Comprehensive Cost and Pricing Analysis for weed vending machine prices Sourcing

- Spotlight on Potential weed vending machine prices Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for weed vending machine prices

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the weed vending machine prices Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of weed vending machine prices

- Strategic Sourcing Conclusion and Outlook for weed vending machine prices

Introduction: Navigating the Global Market for weed vending machine prices

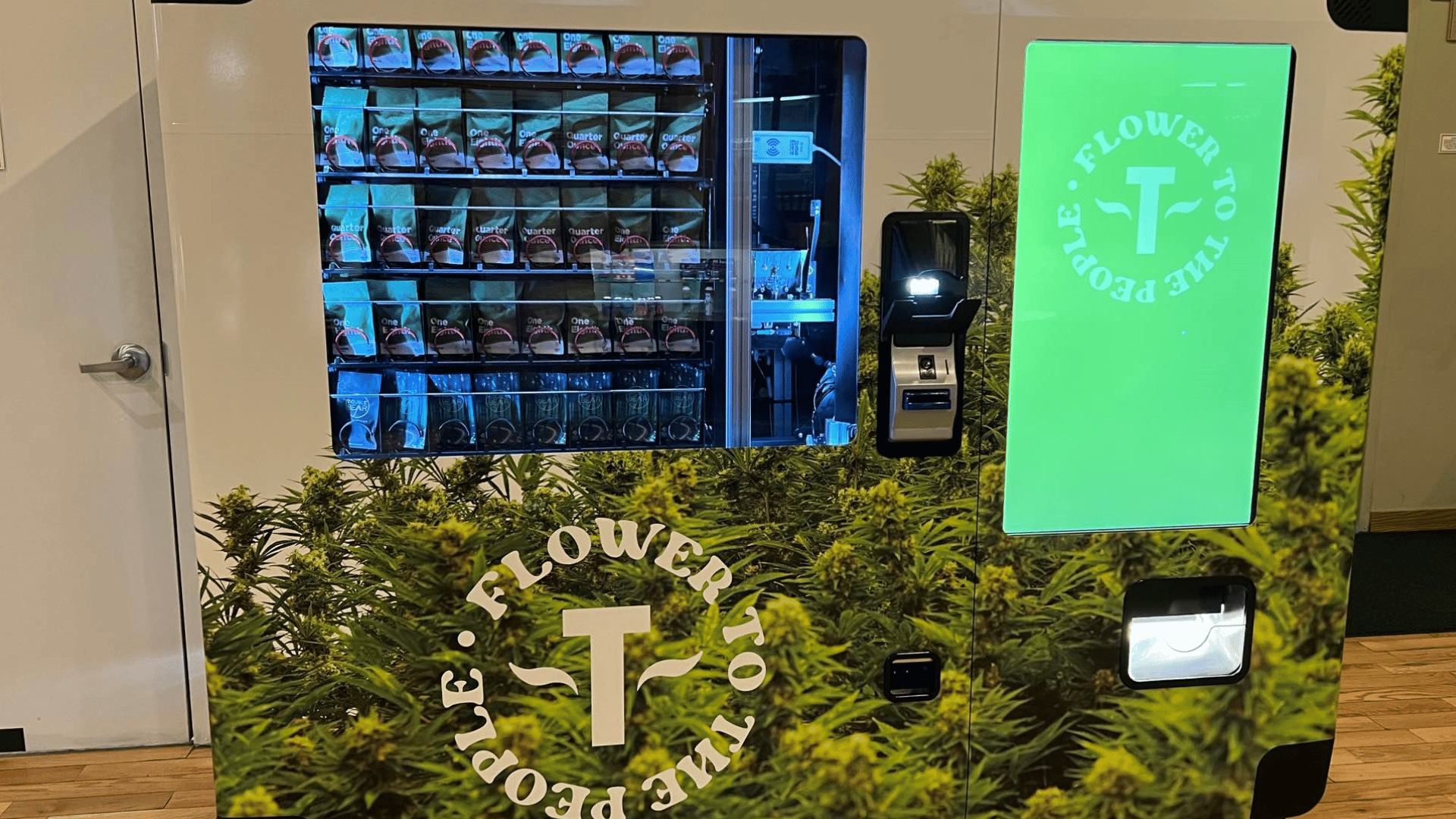

In the rapidly evolving cannabis industry, weed vending machines are emerging as a pivotal solution for businesses looking to capitalize on the growing demand for cannabis products. Understanding the prices of these machines is crucial for international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. As regulations surrounding cannabis continue to shift, investing in vending machines can provide a competitive edge, streamline distribution, and enhance customer accessibility.

This comprehensive guide delves into the multifaceted aspects of weed vending machine prices, offering insights into various types and materials used in manufacturing, as well as quality control processes that ensure reliability and compliance. It also examines the landscape of suppliers and the cost factors that influence pricing, providing an in-depth analysis of market trends and potential ROI.

By equipping B2B buyers with actionable insights and addressing common FAQs, this guide empowers businesses to make informed sourcing decisions. Whether you’re a distributor in Kenya or a retailer in Poland, understanding the nuances of weed vending machine pricing will enable you to navigate the global market effectively, ensuring that you invest wisely and maximize your business potential in this lucrative sector.

Understanding weed vending machine prices Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Vending Machines | Basic design, suitable for various products, including cannabis | Retail dispensaries, convenience stores | Pros: Cost-effective, easy to operate. Cons: Limited features, less secure. |

| Smart Vending Machines | Integrated technology for inventory tracking and sales data | High-end dispensaries, tech-savvy markets | Pros: Enhanced analytics, remote management. Cons: Higher initial investment. |

| Customized Vending Solutions | Tailored design to meet specific branding and product needs | Specialty cannabis brands, event marketing | Pros: Unique branding opportunities, tailored user experience. Cons: Longer lead time, higher costs. |

| Temperature-Controlled Machines | Maintains optimal conditions for sensitive products | Medical cannabis facilities, premium retailers | Pros: Preserves product quality, attracts premium clientele. Cons: More expensive, requires maintenance. |

| Contactless Payment Vending | Supports cashless transactions for enhanced safety | Urban areas, health-conscious markets | Pros: Increased safety, convenience for users. Cons: May require tech upgrades, potential transaction fees. |

Detailed Overview of Vending Machine Types

Standard Vending Machines are the most common type found in various retail environments. They typically feature a straightforward design that allows for easy stocking and operation. B2B buyers in regions like Africa or South America may find these machines appealing due to their lower upfront costs and simplicity. However, they offer limited security and features, which may not be suitable for high-value products like cannabis.

Smart Vending Machines incorporate advanced technology, allowing operators to monitor inventory levels and sales data remotely. This type is particularly advantageous for B2B buyers in Europe and the Middle East, where data-driven decision-making is emphasized. While the initial investment is higher, the long-term benefits of enhanced analytics and operational efficiency can justify the cost.

Customized Vending Solutions provide businesses with the opportunity to create a unique brand experience. These machines can be tailored to specific product lines or branding strategies, making them ideal for specialty cannabis brands and event marketing. However, buyers should consider the longer lead times and increased costs associated with customization.

Temperature-Controlled Machines are essential for preserving the quality of sensitive cannabis products. These machines regulate environmental conditions, making them suitable for medical cannabis facilities and premium retailers. While they ensure product integrity, the higher price point and maintenance requirements may deter some buyers.

Contactless Payment Vending has gained popularity, especially in urban areas where health and safety are paramount. These machines facilitate cashless transactions, enhancing convenience for users. B2B buyers should weigh the potential need for technological upgrades and transaction fees against the benefits of increased safety and consumer appeal.

Related Video: Machine Learning in 2024 – Beginner’s Course

Key Industrial Applications of weed vending machine prices

| Industry/Sector | Specific Application of weed vending machine prices | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Automated dispensary for cannabis products | Increased sales through 24/7 availability | Compliance with local regulations, machine reliability |

| Hospitality | On-site cannabis sales at hotels and events | Enhanced guest experience, additional revenue stream | Payment integration systems, machine capacity |

| Healthcare | Medical cannabis distribution in clinics | Streamlined patient access to prescribed products | Security features, user-friendly interface |

| Events & Festivals | Mobile weed vending for festivals | Convenience for attendees, increased foot traffic | Mobility of the unit, speed of transactions |

| Agriculture | Supply of cannabis-related equipment and products | Direct access to growers, improved product traceability | Quality assurance, vendor reliability |

Retail

In the retail sector, weed vending machines serve as automated dispensaries for cannabis products. These machines allow businesses to operate around the clock, significantly increasing sales potential. For international B2B buyers, especially in regions like Africa and South America, understanding local regulations is crucial to ensure compliance. Additionally, the reliability of the machines and their ability to handle various payment methods are key considerations for sourcing.

Hospitality

Hotels and event venues are increasingly adopting weed vending machines to provide guests with convenient access to cannabis products. This enhances the guest experience and creates an additional revenue stream for the business. For buyers in Europe, such as those in Poland, it’s essential to consider payment integration systems that accommodate various currencies and payment methods, ensuring a smooth transaction process for guests.

Healthcare

Medical cannabis vending machines in healthcare settings streamline the distribution of prescribed products, making it easier for patients to access their medications. This application addresses the need for secure, discreet, and efficient distribution channels. Buyers must prioritize security features and user-friendly interfaces to ensure patient safety and compliance with healthcare regulations, particularly in Middle Eastern countries where medical cannabis use is emerging.

Events & Festivals

Mobile weed vending machines at festivals provide a convenient solution for attendees looking to purchase cannabis products on-site. This application not only enhances the overall experience but also boosts foot traffic for vendors. For international buyers, the mobility of the unit and the speed of transactions are critical factors. Ensuring that the machines can handle high volumes of sales during peak times is essential for success in this fast-paced environment.

Agriculture

In the agriculture sector, weed vending machines can be utilized for the direct supply of cannabis-related equipment and products to growers. This ensures that growers have easy access to quality supplies, improving product traceability and operational efficiency. Buyers should focus on quality assurance and vendor reliability when sourcing these machines, particularly in markets where agricultural regulations are stringent, such as in parts of Europe and Africa.

Related Video: How To Make Passive Income From Vending Machine Business (Tips from The Vending Bizz)

Strategic Material Selection Guide for weed vending machine prices

When selecting materials for weed vending machines, international B2B buyers must consider various factors that directly impact performance, durability, and compliance with industry standards. Below is an analysis of four common materials used in the construction of these machines, focusing on their properties, advantages, disadvantages, and specific considerations for buyers in diverse regions such as Africa, South America, the Middle East, and Europe.

1. Stainless Steel

Key Properties: Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand high temperatures. It is often rated for various environmental conditions, making it suitable for outdoor installations.

Pros & Cons:

– Advantages: Durable and resistant to rust, stainless steel is easy to clean, which is essential for maintaining hygiene in vending machines that dispense consumables.

– Disadvantages: The initial cost is higher than other materials, and it can be challenging to machine, which may increase manufacturing complexity.

Impact on Application: Stainless steel is compatible with a wide range of media, including various cannabis products, ensuring that the integrity of the products remains intact.

Considerations for International Buyers: Compliance with local health and safety regulations is crucial. Buyers should also ensure that the stainless steel used meets international standards such as ASTM A240 for corrosion resistance.

2. Aluminum

Key Properties: Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity. It is often used in applications where weight is a critical factor.

Pros & Cons:

– Advantages: Its lightweight nature makes it easier to transport and install, reducing shipping costs. Additionally, aluminum can be anodized for enhanced corrosion resistance.

– Disadvantages: While it is strong, aluminum is generally less durable than stainless steel, especially in high-impact environments.

Impact on Application: Aluminum’s compatibility with various media is good, but it may not be suitable for high-temperature applications without special treatments.

Considerations for International Buyers: Buyers should be aware of the specific grades of aluminum used, as some may not meet the required strength or corrosion resistance for certain applications. Compliance with standards like ASTM B221 is also necessary.

3. Carbon Steel

Key Properties: Carbon steel is known for its high tensile strength and durability. It is often used in structural applications and can be treated for corrosion resistance.

Pros & Cons:

– Advantages: It is cost-effective and provides excellent strength, making it a popular choice for structural components of vending machines.

– Disadvantages: Susceptible to rust and corrosion if not properly coated or maintained, which can be a significant drawback in humid environments.

Impact on Application: Carbon steel is suitable for structural frames but may require additional coatings or treatments when in contact with consumables to prevent contamination.

Considerations for International Buyers: Buyers should ensure that the carbon steel used complies with local standards, such as DIN 17100 or JIS G3101, to guarantee quality and performance.

4. Polycarbonate

Key Properties: Polycarbonate is a high-performance plastic known for its impact resistance and clarity. It can withstand a wide range of temperatures and is often used for transparent components.

Pros & Cons:

– Advantages: Lightweight and shatter-resistant, polycarbonate is ideal for visibility in vending machines, allowing customers to see products clearly.

– Disadvantages: While it is durable, polycarbonate can be prone to scratching and may degrade under UV exposure unless treated.

Impact on Application: Polycarbonate is particularly suitable for display panels and protective covers, enhancing the user experience while maintaining product visibility.

Considerations for International Buyers: Compliance with safety standards for plastics, such as FDA regulations for food contact, is essential. Buyers should also consider UV protection treatments for outdoor installations.

Summary Table

| Material | Typical Use Case for weed vending machine prices | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural components and exterior panels | Excellent corrosion resistance | Higher initial cost | High |

| Aluminum | Lightweight frames and panels | Lightweight and easy to install | Less durable than stainless steel | Medium |

| Carbon Steel | Structural frames and supports | Cost-effective and strong | Susceptible to corrosion | Low |

| Polycarbonate | Display panels and protective covers | Impact-resistant and clear visibility | Prone to scratching and UV degradation | Medium |

This guide provides insights into material selection for weed vending machines, emphasizing the importance of durability, compliance, and cost-effectiveness for international B2B buyers. By carefully evaluating these materials, buyers can make informed decisions that align with their operational needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for weed vending machine prices

Manufacturing processes and quality assurance (QA) play crucial roles in determining the price and reliability of weed vending machines. For B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding these processes can significantly enhance their purchasing decisions. This section delves into the typical manufacturing stages, key quality assurance standards, and actionable insights for verifying supplier quality.

Manufacturing Processes

The manufacturing of weed vending machines generally comprises four main stages: material preparation, forming, assembly, and finishing. Each of these stages employs various techniques to ensure that the final product meets quality and functional standards.

1. Material Preparation

The initial stage involves sourcing and preparing materials. Common materials include:

- Metal Alloys: Often used for the machine casing due to their durability and resistance to corrosion.

- Plastics: For internal components and user interfaces, which require lightweight and flexible materials.

- Electronics: Essential components like circuit boards, payment systems, and sensors.

During this stage, materials are tested for quality, ensuring they meet specified standards before moving to the next phase. Buyers should inquire about the source of materials and whether they comply with international standards.

2. Forming

Forming is the process of shaping the prepared materials into components of the vending machine. Techniques used include:

- Laser Cutting: Ensures precise cuts for metal and plastic components, reducing waste.

- CNC Machining: Utilizes computer-controlled machines for high accuracy in forming parts.

- Injection Molding: Commonly used for creating plastic components, allowing for complex shapes and designs.

This stage is critical as the precision of formed parts directly influences the overall quality and performance of the vending machine.

3. Assembly

The assembly process brings together all the individual components into a functioning unit. This stage typically involves:

- Manual Assembly: Skilled workers assemble complex components, ensuring attention to detail.

- Automated Assembly Lines: For high-volume production, automated systems increase efficiency and consistency.

Quality control checkpoints during assembly, such as in-process inspections, help identify defects early, reducing rework and ensuring that the assembled machine meets specifications.

4. Finishing

Finishing processes enhance the appearance and durability of the weed vending machines. Techniques include:

- Powder Coating: Provides a durable finish that resists scratching and corrosion.

- Screen Printing: Used for branding and user interface designs.

- Final Assembly Testing: Each machine undergoes thorough testing to ensure all components function correctly before packaging.

This stage is vital for creating a positive user experience and ensuring the machine’s longevity.

Quality Assurance (QA)

Quality assurance in the manufacturing of weed vending machines involves adhering to various international and industry-specific standards. Understanding these standards is essential for B2B buyers to ensure product reliability.

International Standards

- ISO 9001: This standard ensures a quality management system (QMS) is in place, focusing on continuous improvement and customer satisfaction.

- CE Marking: A certification that indicates compliance with European health, safety, and environmental protection standards, essential for machines sold in Europe.

Industry-Specific Standards

- API Standards: If the vending machine dispenses consumables, compliance with API standards may be necessary to ensure safety and quality.

- Local Regulations: Buyers should be aware of any specific regulations that may apply in their region, such as health and safety guidelines.

QC Checkpoints

Quality control checkpoints are integral to ensuring that each machine meets quality standards. Key checkpoints include:

- Incoming Quality Control (IQC): Inspects raw materials and components upon arrival.

- In-Process Quality Control (IPQC): Conducts inspections at various assembly stages to ensure compliance with specifications.

- Final Quality Control (FQC): A thorough inspection of the completed machine to verify functionality and appearance before shipping.

Common Testing Methods

Testing methods for weed vending machines typically include:

- Functional Testing: Ensures all features work as intended, including payment systems and product dispensing.

- Durability Testing: Simulates real-world usage to assess the machine’s longevity and reliability.

- Electrical Safety Testing: Verifies that all electrical components meet safety standards.

Verifying Supplier Quality

B2B buyers can take several steps to verify the quality assurance processes of their suppliers:

- Supplier Audits: Conduct regular audits to assess compliance with quality standards and practices.

- Quality Reports: Request detailed reports on quality metrics, including defect rates and testing outcomes.

- Third-Party Inspections: Engage independent inspectors to evaluate the manufacturing process and product quality.

QC and Certification Nuances for International Buyers

International buyers should be aware of certain nuances regarding quality control and certification:

- Documentation: Ensure that suppliers provide all necessary certification documents, such as ISO and CE compliance, to facilitate customs clearance.

- Cultural Differences: Understand that quality standards may vary significantly between regions, necessitating clear communication of expectations.

- Supplier Reliability: Evaluate suppliers based on past performance, customer reviews, and their ability to meet delivery timelines.

Conclusion

For B2B buyers of weed vending machines, understanding the manufacturing processes and quality assurance practices is crucial for making informed purchasing decisions. By focusing on the stages of production, relevant quality standards, and verification methods, buyers can ensure they select reliable suppliers that meet their needs. Investing time in this due diligence not only safeguards their purchase but also enhances their operational efficiency in a growing market.

Related Video: The Production Planning Process

Comprehensive Cost and Pricing Analysis for weed vending machine prices Sourcing

When considering the sourcing of weed vending machines, B2B buyers must navigate a complex cost structure and pricing landscape. Understanding these components and their influencers is crucial for making informed purchasing decisions.

Cost Structure Components

-

Materials: The primary cost driver in manufacturing weed vending machines includes the components required for the machines themselves, such as metal casings, electronic parts, and software systems. High-quality materials can enhance durability and functionality, but they also increase costs.

-

Labor: Labor costs vary significantly based on the region of production. For buyers in Africa or South America, local labor costs may be lower, but this can impact quality if not managed properly. Conversely, European manufacturers may offer higher labor costs but often provide superior craftsmanship and compliance with stringent regulations.

-

Manufacturing Overhead: This includes utilities, rent, and operational expenses associated with running a production facility. Efficient manufacturing processes can help mitigate these costs, so buyers should inquire about a supplier’s operational efficiency.

-

Tooling: Initial tooling costs for custom designs can be significant. Buyers looking for bespoke machines may face higher upfront costs but should consider long-term benefits if the machines meet specific operational needs.

-

Quality Control (QC): Implementing quality assurance processes is essential to ensure that machines function as intended. Robust QC systems can add to the cost but are critical in preventing defects and ensuring compliance with safety standards.

-

Logistics: Shipping costs can vary widely depending on the distance and mode of transportation. For international buyers, understanding Incoterms (International Commercial Terms) is vital to anticipate who bears the cost and risk during transit.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure profitability. Buyers should understand the typical margins in the industry to negotiate effectively.

Price Influencers

-

Volume/MOQ (Minimum Order Quantity): Suppliers often provide discounts for larger orders. Buyers should assess their needs carefully to benefit from economies of scale without overcommitting.

-

Specifications/Customization: Custom features can significantly influence price. Buyers should weigh the benefits of customization against budget constraints.

-

Materials Quality and Certifications: Machines that meet specific industry certifications (e.g., CE, ISO) may cost more upfront but can lead to lower maintenance costs and enhanced resale value.

-

Supplier Factors: The reputation, reliability, and production capabilities of the supplier can affect pricing. Conducting due diligence on potential suppliers can yield better pricing and service.

-

Incoterms: Understanding the shipping terms agreed upon can influence the total cost. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) will determine who is responsible for costs at various points in the shipping process.

Buyer Tips

-

Negotiation: Develop a clear understanding of your requirements and leverage them during negotiations. Suppliers may be willing to adjust pricing based on long-term partnership potential.

-

Cost-Efficiency: Always consider the Total Cost of Ownership (TCO), which includes purchase price, maintenance, operation, and disposal costs. This perspective can help justify higher initial investments for better quality machines.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa and the Middle East should be aware of currency fluctuations and import tariffs that may affect final costs. Establishing contracts in stable currencies can mitigate some risks.

Disclaimer

Prices for weed vending machines can vary widely based on the factors outlined above. The figures mentioned are indicative and should be validated through direct engagement with suppliers to obtain accurate quotes tailored to specific requirements.

Spotlight on Potential weed vending machine prices Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘weed vending machine prices’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for weed vending machine prices

Key Technical Properties for Weed Vending Machines

When evaluating weed vending machines, international B2B buyers should focus on several critical technical properties that impact performance, durability, and compliance with local regulations. Understanding these specifications can aid in making informed purchasing decisions.

-

Material Grade

The material used in constructing the vending machine is crucial for its durability and resistance to environmental factors. Common materials include stainless steel and high-grade plastics. Stainless steel offers superior corrosion resistance, making it ideal for outdoor installations or humid environments. Buyers should verify material grades to ensure compliance with local health and safety standards. -

Size and Capacity

The dimensions and storage capacity of a vending machine influence its suitability for different environments. Machines designed for urban areas may be smaller and have a higher turnover rate, while those in more rural settings might prioritize larger storage for less frequent restocking. Knowing the expected foot traffic and product demand is essential for selecting the right size. -

Power Requirements

Understanding the power requirements, including voltage and energy consumption, is vital for installation. Some machines might require a dedicated circuit, while others can operate on standard outlets. This information impacts installation costs and should be clarified with suppliers. -

Temperature Control

Many cannabis products require specific temperature conditions for optimal preservation. Vending machines equipped with temperature control mechanisms help maintain product integrity. Buyers should assess the machine’s ability to regulate temperature and ensure it meets the requirements for the products being sold.

-

Security Features

Given the high-value nature of cannabis products, security is a paramount concern. Features such as biometric access, surveillance cameras, and anti-theft alarms should be considered. These elements not only protect inventory but also build customer trust. -

User Interface and Payment Systems

The ease of use and payment options available in a vending machine can significantly impact customer satisfaction. Machines that accept various payment methods, including credit cards, mobile payments, and cryptocurrencies, can appeal to a broader customer base. An intuitive user interface enhances the customer experience and reduces transaction times.

Essential Trade Terminology

Familiarity with industry-specific terminology is essential for B2B buyers to navigate the purchasing process effectively. Here are some key terms to understand:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. For buyers, working with OEMs can ensure that they receive high-quality components that meet specific standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQs is vital for budgeting and inventory management, especially for businesses looking to maintain a steady supply without overstocking. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers requesting pricing and terms for specific products. This process helps buyers compare costs and negotiate better deals, making it a crucial step in procurement. -

Incoterms (International Commercial Terms)

These are standardized trade terms used in international contracts to clarify the responsibilities of buyers and sellers. Understanding Incoterms helps buyers manage shipping costs, risk, and responsibilities during the transport of goods. -

Lead Time

This refers to the time it takes from placing an order to receiving the product. For buyers, understanding lead times is essential for planning inventory and ensuring timely delivery, especially in fast-moving markets. -

Warranty and Support Terms

These terms outline the manufacturer’s responsibility for product defects and the level of customer support offered. Buyers should carefully review warranty conditions to ensure they are adequately protected against potential issues.

By grasping these technical properties and trade terms, B2B buyers can enhance their purchasing strategies, ensuring they select the right weed vending machines for their markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the weed vending machine prices Sector

Market Overview & Key Trends

The global market for weed vending machines is experiencing notable growth, driven by an increasing acceptance of cannabis in various regions and the demand for more accessible purchasing options. In particular, international B2B buyers from Africa, South America, the Middle East, and Europe should be aware of several key trends shaping this sector.

-

Technological Advancements: Innovations such as cashless payment systems, biometric identification, and artificial intelligence are becoming standard in vending machines. These technologies enhance user experience and streamline operations, making them attractive for businesses looking to optimize sales.

-

Regulatory Changes: As countries liberalize cannabis laws, there is a corresponding rise in the number of licensed dispensaries. This expansion necessitates more vending machines to meet consumer demand, especially in urban areas where foot traffic is high.

Illustrative Image (Source: Google Search)

-

Customization and Branding: B2B buyers are increasingly seeking machines that can be customized to reflect their brand identity. This trend is particularly prominent in regions like Poland, where local businesses are striving to differentiate themselves in a competitive market.

-

Market Dynamics: The rise of e-commerce and delivery services is pushing vendors to explore hybrid models that integrate traditional retail with vending solutions. This approach allows businesses to cater to a wider audience while maintaining operational efficiency.

Overall, understanding these dynamics will empower B2B buyers to make informed sourcing decisions that align with market demands and technological advancements.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical consideration for businesses in the weed vending machine sector. The environmental impact of manufacturing and operating these machines can be significant, making it essential for companies to prioritize eco-friendly practices.

Illustrative Image (Source: Google Search)

-

Ethical Supply Chains: B2B buyers should seek suppliers who demonstrate a commitment to ethical sourcing. This includes ensuring that materials used in machines are sourced responsibly, minimizing waste, and adhering to fair labor practices.

-

Green Certifications: Look for suppliers that offer products with recognized environmental certifications, such as ISO 14001 or LEED certification. These certifications indicate a commitment to sustainability and can enhance your brand’s reputation among environmentally-conscious consumers.

-

Innovative Materials: Many manufacturers are now utilizing biodegradable or recyclable materials in their vending machines. By opting for these products, B2B buyers can reduce their carbon footprint and appeal to a growing segment of eco-minded consumers.

Ultimately, integrating sustainability into procurement strategies not only addresses regulatory pressures but also aligns with consumer preferences, fostering brand loyalty and long-term success.

Brief Evolution/History

The concept of vending machines has evolved significantly since their inception in the early 20th century, originally serving simple snacks and beverages. With the gradual legalization of cannabis across various regions, the introduction of weed vending machines marks a transformative phase in the industry.

Initially, these machines were deployed in limited markets, primarily in North America, where cannabis was legalized first. However, as acceptance grows globally, particularly in countries like South Africa and Germany, the market is expanding rapidly. This evolution reflects changing consumer attitudes towards cannabis and the need for innovative retail solutions that cater to both convenience and compliance. Understanding this historical context can provide B2B buyers with insights into future trends and opportunities within the sector.

Related Video: Global trade will never be the same again, says Christine Lagarde | Power & Politics

Frequently Asked Questions (FAQs) for B2B Buyers of weed vending machine prices

-

What factors influence the pricing of weed vending machines?

The price of weed vending machines can vary significantly based on several factors including machine size, technology (e.g., touchscreen vs. manual), capacity, and customization options. Additional features such as payment processing systems, security measures, and integrated inventory management can also affect the cost. International buyers should consider local regulations and market demand, as these can influence the pricing structure in different regions. -

How do I vet suppliers for weed vending machines?

Vetting suppliers involves checking their reputation, experience, and compliance with local regulations. Request references and client testimonials to gauge their reliability. It’s also essential to verify their certifications and quality assurance processes. Consider visiting their facilities if possible, or use third-party verification services to ensure they meet international standards. -

Can I customize my weed vending machine?

Yes, many suppliers offer customization options. Buyers can request modifications such as branding, size adjustments, or specific technology integrations. It’s advisable to communicate your needs clearly during the initial discussions to ensure the supplier can meet your specifications. Keep in mind that extensive customization may impact lead times and pricing. -

What are the typical minimum order quantities (MOQ) and lead times?

Minimum order quantities (MOQ) can vary by supplier, typically ranging from one machine for smaller manufacturers to larger quantities for mass production. Lead times also depend on customization levels and supplier capacity, often ranging from a few weeks to several months. Always confirm these details upfront to align your procurement timeline with your business needs. -

What payment methods are commonly accepted for international purchases?

Most suppliers accept various payment methods including bank transfers, letters of credit, and online payment platforms. It’s essential to discuss payment terms upfront to avoid any misunderstandings. Ensure that the payment method offers sufficient protection against fraud, especially for large transactions. Additionally, consider currency exchange rates and potential fees when making international payments. -

What quality assurance certifications should I look for?

Look for suppliers that hold certifications such as ISO 9001 for quality management and CE marking for compliance with European safety standards. Other relevant certifications may include UL for safety testing or specific local certifications based on your region’s regulations. These certifications indicate that the supplier adheres to industry standards, ensuring the reliability and safety of their products. -

How can I manage logistics and shipping for my order?

Collaborate with your supplier to determine the best logistics solutions for your order. Understand the shipping terms (Incoterms) and choose between options like FOB (Free on Board) or CIF (Cost, Insurance, and Freight). It’s also wise to work with a freight forwarder who specializes in international shipping to navigate customs and ensure timely delivery. -

What should I do in case of disputes with suppliers?

In the event of a dispute, first attempt to resolve the issue through direct communication with the supplier. If this fails, refer to the contract terms regarding dispute resolution, which may include mediation or arbitration. It’s advisable to keep detailed records of all communications and transactions to support your case. Additionally, consider engaging legal counsel experienced in international trade to navigate complex disputes.

Strategic Sourcing Conclusion and Outlook for weed vending machine prices

The landscape for weed vending machine prices is evolving rapidly, presenting both challenges and opportunities for international B2B buyers. Strategic sourcing is essential in navigating this dynamic market, allowing buyers to identify the best suppliers, negotiate favorable terms, and ensure quality compliance. By leveraging insights into market trends, buyers from Africa, South America, the Middle East, and Europe can make informed purchasing decisions that optimize their investment.

Key Takeaways:

– Market Research: Understanding regional regulations and market dynamics is critical for successful sourcing.

– Supplier Evaluation: Prioritize suppliers with proven track records and robust after-sales support.

– Cost Management: Explore bulk purchasing options and negotiate payment terms to improve cash flow.

Looking ahead, the demand for innovative solutions in the cannabis industry will continue to grow, making it imperative for B2B buyers to stay agile and proactive. Investing in high-quality vending machines not only enhances customer experience but also positions businesses for long-term success. As the market matures, now is the time to engage with suppliers and secure competitive pricing that aligns with your strategic goals. Embrace the future of cannabis retail with confidence and foresight.