Unlock Profits with the Vendo 39 Coke Machine: A B2B

Guide to Vendo 39 Coke Machine

- Introduction: Navigating the Global Market for vendo 39 coke machine

- Understanding vendo 39 coke machine Types and Variations

- Key Industrial Applications of vendo 39 coke machine

- Strategic Material Selection Guide for vendo 39 coke machine

- In-depth Look: Manufacturing Processes and Quality Assurance for vendo 39 coke machine

- Comprehensive Cost and Pricing Analysis for vendo 39 coke machine Sourcing

- Spotlight on Potential vendo 39 coke machine Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for vendo 39 coke machine

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the vendo 39 coke machine Sector

- Market Overview & Key Trends

- Sustainability & Ethical Sourcing in B2B

- Brief Evolution/History

- Frequently Asked Questions (FAQs) for B2B Buyers of vendo 39 coke machine

- Strategic Sourcing Conclusion and Outlook for vendo 39 coke machine

Introduction: Navigating the Global Market for vendo 39 coke machine

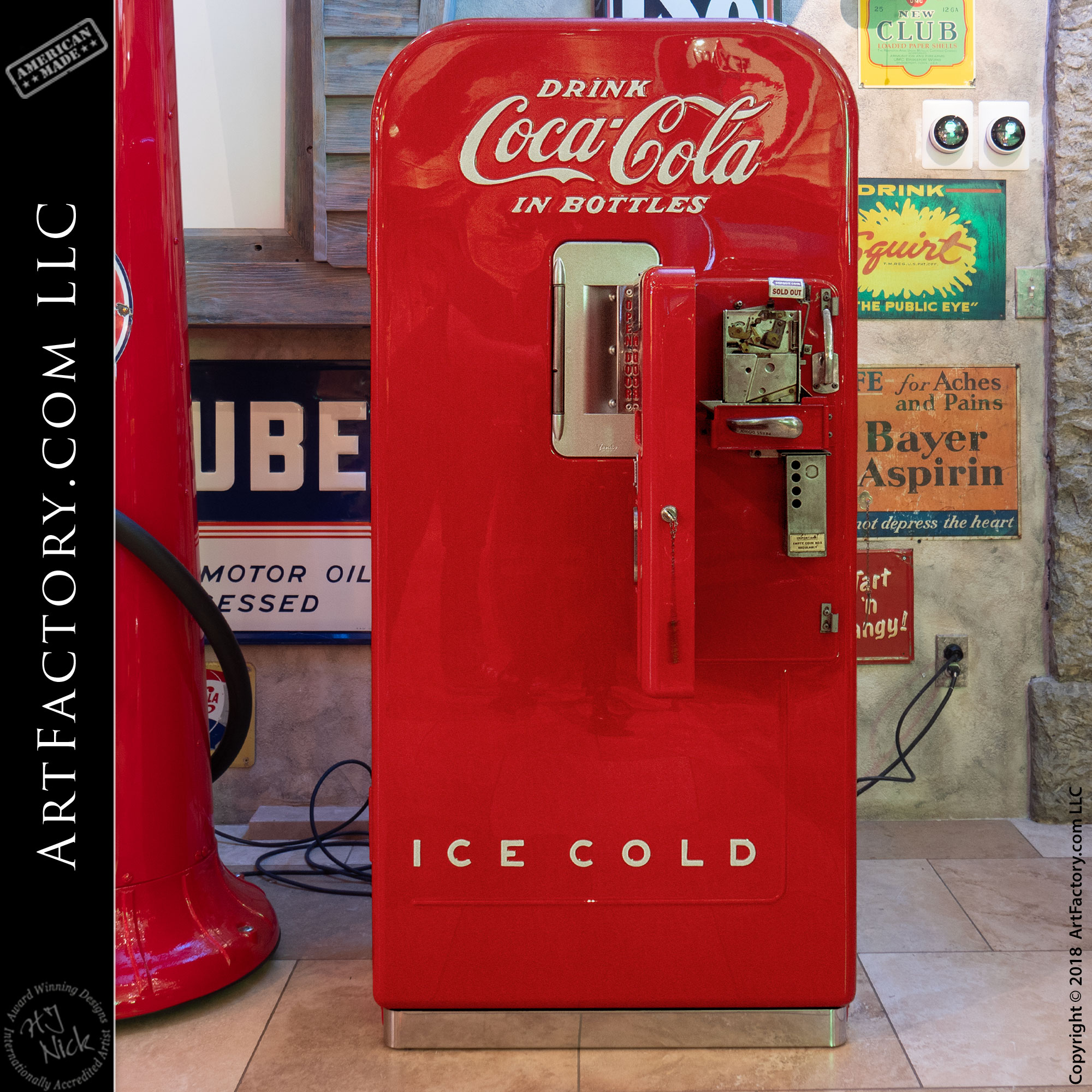

In today’s competitive market, the Vendo 39 Coke machine stands out as a pivotal asset for businesses aiming to enhance their beverage offerings. Renowned for its reliability and user-friendly interface, this vending machine not only delivers a diverse range of Coca-Cola products but also ensures a seamless customer experience. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the nuances of sourcing this machine is crucial.

This comprehensive guide delves into the essential aspects of the Vendo 39, covering various types and specifications, the materials used in its construction, and the manufacturing and quality control processes that underpin its durability. Additionally, we will explore reputable suppliers, provide insights into pricing structures, and analyze current market trends that could influence purchasing decisions.

By equipping buyers with detailed information and actionable insights, this guide empowers businesses to make informed sourcing decisions. Whether you are looking to expand your vending options or ensure a steady supply of popular beverages, understanding the intricacies of the Vendo 39 Coke machine will enable you to enhance your service offerings, improve customer satisfaction, and ultimately drive sales. Join us as we navigate the global market for the Vendo 39 and unlock the potential it holds for your business.

Understanding vendo 39 coke machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Vendo 39 Classic | Mechanical coin mechanism, glass front for product visibility | Offices, schools, and public spaces | Pros: Reliable, low maintenance; Cons: Limited payment options, slower service. |

| Vendo 39 Touchscreen | Digital touchscreen interface, customizable product selection | Retail environments, cafes, and gyms | Pros: User-friendly, modern interface; Cons: Higher initial cost, requires power. |

| Vendo 39 High Capacity | Increased storage for more products, often includes refrigeration | Large venues, stadiums, and events | Pros: Higher sales potential; Cons: Requires more space, higher upfront investment. |

| Vendo 39 Combo Machine | Dispenses both snacks and beverages, dual compartment design | Convenience stores, break rooms | Pros: Versatile offering; Cons: More complex maintenance, potential for cross-contamination. |

| Vendo 39 Eco-Friendly Model | Energy-efficient design, made from recyclable materials | Eco-conscious businesses, schools | Pros: Reduces carbon footprint; Cons: May have fewer features, higher initial cost. |

Vendo 39 Classic

The Vendo 39 Classic is a traditional vending machine featuring a mechanical coin mechanism and a glass front that enhances product visibility. It is ideal for environments such as offices, schools, and public spaces where reliability and ease of use are paramount. When considering this model, buyers should evaluate the balance between low maintenance needs and the limited payment options, which may deter some customers.

Vendo 39 Touchscreen

With a modern digital touchscreen interface, the Vendo 39 Touchscreen allows for customizable product selection, making it perfect for retail environments, cafes, and gyms. This machine enhances user experience through its intuitive design, attracting tech-savvy customers. However, buyers should weigh the higher initial costs and the requirement for a consistent power supply against the machine’s potential for increased sales.

Vendo 39 High Capacity

Designed for larger venues, the Vendo 39 High Capacity model offers increased storage for more products, often featuring refrigeration to keep beverages cool. This machine is particularly suited for stadiums, events, and other high-traffic areas where maximizing sales potential is crucial. However, businesses must consider the need for additional space and the higher upfront investment required for this model.

Vendo 39 Combo Machine

The Vendo 39 Combo Machine is a versatile solution that dispenses both snacks and beverages, making it ideal for convenience stores and break rooms. Its dual compartment design allows businesses to cater to a wider range of consumer preferences. While this model offers versatility, buyers should consider the complexities of maintenance and the risk of cross-contamination between food and drink products.

Vendo 39 Eco-Friendly Model

The Eco-Friendly Model of the Vendo 39 emphasizes sustainability with its energy-efficient design and use of recyclable materials. This machine appeals to eco-conscious businesses and schools looking to reduce their carbon footprint. While it promotes environmental responsibility, potential buyers should be aware that it may offer fewer features and a higher initial cost compared to traditional models, which could affect short-term profitability.

Related Video: 1951 Vendo 39 Coke Machine | Restoration Recap

Key Industrial Applications of vendo 39 coke machine

| Industry/Sector | Specific Application of vendo 39 coke machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Beverage dispensing in hotels and restaurants | Enhances guest experience with easy access to popular drinks | Reliability in high foot traffic environments, energy efficiency |

| Retail | Vending solutions in supermarkets and convenience stores | Increases sales through 24/7 availability of beverages | Size and placement for maximum visibility, payment system integration |

| Events and Venues | Refreshment stations for conferences and exhibitions | Provides instant refreshment options for attendees | Portability, capacity to handle large volumes, branding opportunities |

| Educational Institutions | Snack and beverage services in schools and colleges | Promotes student satisfaction and convenience | Compliance with health regulations, variety of beverage options |

| Transportation Hubs | Beverage vending in airports and train stations | Meets high demand for quick refreshments | Durability for high usage, payment flexibility, and compact design |

The hospitality sector benefits significantly from the vendo 39 coke machine by providing guests with easy access to beverages. This machine can be strategically placed in hotel lobbies, restaurants, and bars, enhancing the overall guest experience. For international buyers, especially in regions like Africa and the Middle East, it is crucial to consider the machine’s energy efficiency and reliability, particularly in areas with high foot traffic.

In the retail industry, the vendo 39 coke machine serves as an effective vending solution in supermarkets and convenience stores. Its 24/7 availability can drive sales, especially in urban areas where consumers seek quick beverage options. Buyers should focus on the machine’s size and visibility to ensure it captures customer attention, as well as its capability to integrate with modern payment systems to accommodate various customer preferences.

For events and venues, such as conferences and exhibitions, the vendo 39 coke machine provides a convenient refreshment station for attendees. This application is vital for maintaining attendee satisfaction during long events. Key considerations for buyers include the machine’s portability and capacity to handle high volumes, as well as the potential for branding opportunities to enhance event visibility.

In educational institutions, the vendo 39 coke machine can play a crucial role in providing snack and beverage services in schools and colleges. This not only promotes student satisfaction but also encourages healthy choices if paired with appropriate beverage options. International buyers need to ensure compliance with local health regulations and consider the variety of beverages offered to cater to diverse student preferences.

Lastly, in transportation hubs like airports and train stations, the vendo 39 coke machine meets the high demand for quick refreshments. Its design must accommodate durability for high usage and flexibility in payment options, ensuring that travelers can easily access beverages on the go. Buyers from Europe and South America should prioritize compact designs that fit within the often limited space of transportation facilities while still delivering a wide range of drink options.

Related Video: Vendo 39 Coca Cola Vending Machine (1949)

Strategic Material Selection Guide for vendo 39 coke machine

When selecting materials for the Vendo 39 Coke machine, it is essential to consider various factors that influence the machine’s performance, durability, and compliance with international standards. Below are analyses of four common materials used in the construction of vending machines, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

Stainless Steel

Key Properties: Stainless steel is known for its excellent corrosion resistance, high strength-to-weight ratio, and ability to withstand high temperatures and pressures. It typically has a temperature rating of up to 800°F (427°C) and is resistant to rust and staining.

Pros & Cons: The primary advantage of stainless steel is its durability and aesthetic appeal, making it suitable for high-traffic environments. However, it is more expensive than other materials and can be challenging to machine and weld, which may increase manufacturing complexity.

Impact on Application: Stainless steel is ideal for components exposed to moisture and varying temperatures, such as the exterior casing and internal structures of the vending machine. It is compatible with a wide range of media, including carbonated beverages.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM A240 for stainless steel. Additionally, variations in grades (e.g., 304 vs. 316) may affect corrosion resistance, especially in coastal regions.

Carbon Steel

Key Properties: Carbon steel offers good tensile strength and is suitable for applications where high strength is required. It generally has a temperature rating of up to 400°F (204°C) but is susceptible to corrosion without proper treatment.

Pros & Cons: This material is cost-effective and easy to fabricate, making it a popular choice for structural components. However, its susceptibility to rust can be a significant drawback, necessitating protective coatings or galvanization.

Impact on Application: Carbon steel is typically used for internal frames and supports within the vending machine. Its compatibility with non-corrosive fluids makes it suitable for internal components that do not come into direct contact with beverages.

Considerations for International Buyers: Compliance with standards like ASTM A36 is crucial. Buyers in humid or coastal regions should consider additional corrosion protection measures to prolong the material’s lifespan.

Aluminum

Key Properties: Aluminum is lightweight, corrosion-resistant, and has a lower melting point than steel, making it easier to work with. It can withstand temperatures up to 600°F (316°C) and is often anodized for enhanced durability.

Pros & Cons: The lightweight nature of aluminum allows for easy installation and reduced shipping costs. However, it may not provide the same strength as steel, which could limit its use in high-stress applications.

Impact on Application: Aluminum is often used for decorative panels and non-structural components of the vending machine. It is compatible with various media, including soft drinks, and its corrosion resistance is beneficial in high-humidity environments.

Considerations for International Buyers: Buyers should ensure that the aluminum used meets international standards such as ASTM B221. Anodization processes may vary by region, affecting the material’s surface properties.

Plastic Composites

Key Properties: Plastic composites are lightweight, resistant to corrosion, and can be molded into complex shapes. They typically have a lower temperature tolerance, around 180°F (82°C), but are versatile in design.

Pros & Cons: The primary advantage of plastic composites is their cost-effectiveness and ease of manufacturing. However, they may not offer the same strength and durability as metals, which can limit their application in high-stress environments.

Impact on Application: These materials are often used for internal components, such as trays and dispensers, where weight savings are essential. They are compatible with various beverages but may degrade over time with exposure to UV light.

Considerations for International Buyers: Compliance with safety standards such as FDA regulations for food contact materials is essential. Buyers should also consider the environmental impact and recyclability of plastic composites in their regions.

Summary Table

| Material | Typical Use Case for vendo 39 coke machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Exterior casing, internal structures | Excellent corrosion resistance | Higher cost, manufacturing complexity | High |

| Carbon Steel | Internal frames and supports | Cost-effective, good strength | Susceptible to corrosion | Low |

| Aluminum | Decorative panels, non-structural components | Lightweight, easy to work with | Lower strength compared to steel | Medium |

| Plastic Composites | Internal components like trays and dispensers | Cost-effective, versatile design | Limited strength, potential UV degradation | Low |

This guide provides a comprehensive overview of material options for the Vendo 39 Coke machine, helping international B2B buyers make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for vendo 39 coke machine

Manufacturing Processes for the Vendo 39 Coke Machine

The manufacturing of the Vendo 39 Coke machine involves a series of meticulous steps designed to ensure durability, functionality, and aesthetic appeal. Below is a breakdown of the main stages of manufacturing, along with key techniques utilized throughout the process.

1. Material Preparation

The first step in the manufacturing process is the preparation of materials. This typically involves:

- Selection of Materials: High-quality materials such as stainless steel for the exterior and durable plastics for internal components are selected to ensure longevity and resistance to corrosion.

- Cutting and Shaping: Sheets of metal and plastic are cut to specified dimensions using laser cutting or CNC machining techniques. This precision minimizes waste and ensures that components fit together seamlessly during assembly.

2. Forming

Forming is where the prepared materials are shaped into usable components. Key techniques include:

- Stamping: Metal parts are stamped into shape, which is ideal for creating the various panels and structural components of the vending machine.

- Injection Molding: Plastic parts, including buttons and internal compartments, are produced using injection molding. This method allows for complex shapes and high-volume production.

3. Assembly

Once the individual components are ready, the assembly process begins. This stage includes:

- Sub-Assembly: Different sections of the machine, such as the refrigeration unit and payment system, are assembled separately before being combined.

- Final Assembly: The sub-assemblies are brought together, where components like the cooling system, vending mechanism, and control panel are integrated. Automated assembly lines may be used to enhance efficiency and consistency.

4. Finishing

Finishing processes enhance the aesthetic quality and protect the machine from environmental factors. This includes:

- Coating and Painting: The exterior is often coated with a powder finish or painted to provide a visually appealing look and added protection against rust and wear.

- Quality Testing: Before final packaging, each machine undergoes thorough testing to ensure all components function correctly and meet design specifications.

Quality Assurance Standards

Quality assurance is critical in the production of vending machines, particularly for international markets. Adhering to recognized standards is essential for building trust with B2B buyers.

International Standards

- ISO 9001: This standard focuses on quality management systems and is widely recognized globally. Compliance indicates that the manufacturer has established processes to ensure consistent quality in their products.

- CE Marking: Required for products sold within the European Economic Area (EEA), CE marking ensures that the machine meets health, safety, and environmental protection standards.

- API Standards: While primarily associated with the petroleum and natural gas industries, API standards can apply to the manufacturing processes of vending machines that utilize similar mechanical systems.

Quality Control Checkpoints

Quality control is integrated at various stages of the manufacturing process to ensure that every unit meets the required standards:

- Incoming Quality Control (IQC): Raw materials and components are inspected upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Ongoing checks are performed during the assembly process to identify and rectify defects early.

- Final Quality Control (FQC): A comprehensive review is conducted after assembly and finishing, ensuring that the vending machine functions correctly and meets all specifications.

Common Testing Methods

To validate the quality of the Vendo 39 Coke machine, manufacturers employ several testing methods, including:

- Functional Testing: Ensures that all features, including payment processing and cooling systems, operate as intended.

- Durability Testing: Simulates long-term use to assess wear and tear, particularly on mechanical components.

- Safety Testing: Confirms compliance with electrical safety standards, especially for machines operating in public spaces.

Verifying Supplier Quality Control

For B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial to ensuring product reliability. Here are actionable steps:

- Supplier Audits: Conduct regular audits of the manufacturing facility to assess adherence to quality standards and practices.

- Request Quality Reports: Suppliers should provide documentation of their quality control processes, including testing results and compliance certifications.

- Third-Party Inspections: Engage independent inspection agencies to perform checks and validate quality claims made by the manufacturer.

Quality Control and Certification Nuances for International Buyers

B2B buyers from different regions may encounter unique challenges related to quality control and certification:

- Cultural Differences: Understanding local manufacturing practices and expectations is crucial. For example, European buyers may prioritize environmental sustainability, while buyers in Africa may focus on cost-effectiveness.

- Regulatory Compliance: Different regions have varying regulations regarding safety and quality. Buyers should be familiar with local standards and ensure that their suppliers comply.

- Communication Barriers: Language differences can lead to misunderstandings about quality requirements. Establishing clear communication channels is vital for successful partnerships.

By understanding these manufacturing processes and quality assurance practices, international B2B buyers can make informed decisions when sourcing the Vendo 39 Coke machine, ensuring they acquire reliable and high-quality products for their markets.

Related Video: Amazing coca cola manufacturing line – Inside the soft drink factory – Filling Machine

Comprehensive Cost and Pricing Analysis for vendo 39 coke machine Sourcing

In sourcing a Vendo 39 Coke machine, understanding the comprehensive cost structure and pricing is essential for international B2B buyers. This analysis will delve into the various cost components, price influencers, and provide actionable tips tailored for buyers from Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The primary materials include steel, plastic, and electronic components. The quality and sourcing of these materials can significantly affect the overall cost. For instance, opting for higher-grade steel can increase durability but also the cost.

-

Labor: Labor costs vary by region. In countries with a lower cost of living, labor may represent a smaller percentage of the total cost. However, skilled labor is essential for the assembly and quality control processes, which can add to labor costs in regions with higher wage expectations.

-

Manufacturing Overhead: This includes costs associated with the production facility, utilities, and administrative expenses. Efficient manufacturing processes can help minimize these overhead costs.

-

Tooling: Initial tooling for the production of Vendo 39 machines can be substantial, especially if customizations are required. Tooling costs are typically amortized over the production volume, making them a crucial factor in pricing.

-

Quality Control (QC): Rigorous QC processes ensure the machines meet international standards. This can include testing for reliability and safety, which adds to the upfront cost but is vital for long-term customer satisfaction.

-

Logistics: Transportation costs, including shipping and handling, can vary significantly based on the destination. Incoterms (International Commercial Terms) will influence who bears these costs and can affect the final price.

-

Margin: Suppliers typically apply a profit margin to cover their risks and operational costs. Understanding this margin can provide insights into pricing negotiations.

Price Influencers

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should assess their needs and negotiate based on expected demand.

-

Specifications/Customization: Custom features can increase costs. Buyers should clarify their specifications upfront to avoid unexpected price adjustments.

-

Materials: The choice of materials directly impacts the price. Buyers should balance cost with quality to ensure they receive a durable product.

-

Quality/Certifications: Machines that meet specific international standards may come at a premium but can provide assurance of quality and reliability, which is particularly important for long-term investments.

-

Supplier Factors: The supplier’s reputation, reliability, and past performance can influence pricing. Established suppliers may command higher prices due to their proven track record.

-

Incoterms: Understanding the shipping terms (such as FOB, CIF, etc.) is crucial as they dictate who pays for transport and insurance, affecting the total landed cost.

Buyer Tips

-

Negotiation: Leverage your position as a bulk buyer to negotiate better terms. Being informed about market prices and competitor offerings can strengthen your negotiating power.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes purchase price, operating costs, maintenance, and potential resale value. This broader perspective can lead to smarter purchasing decisions.

-

Pricing Nuances: Be aware of regional pricing differences. For instance, buyers in Europe may face different regulatory costs compared to those in Africa or South America. Understanding these nuances can aid in more effective budgeting.

-

Sourcing Strategy: Consider diversifying suppliers to mitigate risks associated with price fluctuations or supply chain disruptions. Establishing relationships with multiple suppliers can also provide leverage in negotiations.

Disclaimer

Prices for Vendo 39 Coke machines can fluctuate based on market conditions, supplier negotiations, and geopolitical factors. Always seek multiple quotes and conduct thorough due diligence before making purchasing decisions.

Spotlight on Potential vendo 39 coke machine Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘vendo 39 coke machine’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for vendo 39 coke machine

Key Technical Properties of the Vendo 39 Coke Machine

When considering the Vendo 39 Coke machine for your business needs, understanding its technical properties is essential. Below are critical specifications that influence performance, durability, and operational efficiency:

-

Material Grade: The Vendo 39 is typically constructed from high-grade stainless steel and robust plastics. The choice of materials is crucial for ensuring longevity and resistance to corrosion, especially in humid or outdoor environments. B2B buyers should prioritize machines made from these materials to reduce maintenance costs and extend service life.

-

Capacity: This vending machine generally has a capacity of around 39 beverage selections, accommodating various can sizes. Understanding capacity is vital for businesses with high foot traffic, as it ensures the machine meets consumer demand without frequent restocking.

-

Cooling Technology: The Vendo 39 utilizes an efficient refrigeration system that ensures drinks are kept at optimal temperatures. This is important for customer satisfaction, as temperature significantly affects beverage quality. For B2B buyers, investing in machines with advanced cooling technology can enhance sales and reduce energy consumption.

-

Power Consumption: Typically rated at around 115 volts, knowing the power requirements helps in planning electrical installations. Lower power consumption models can lead to substantial savings on energy bills, which is a critical factor for businesses looking to minimize operational costs.

-

Dimensions and Weight: With a standard height of approximately 72 inches and a weight of around 600 pounds, understanding the dimensions is essential for placement considerations in retail or commercial spaces. Ensuring the machine fits within designated areas while allowing for adequate space for maintenance is key for smooth operations.

-

User Interface: The Vendo 39 features a user-friendly interface with clear selection buttons and an intuitive layout. For B2B buyers, a well-designed interface can enhance the customer experience, leading to increased sales and customer satisfaction.

Common Trade Terminology

Familiarity with industry jargon is crucial for effective communication and negotiation in the B2B environment. Here are some key terms related to the procurement of the Vendo 39 Coke machine:

-

OEM (Original Equipment Manufacturer): This term refers to the company that manufactures the Vendo 39. Understanding OEM status can help buyers assess product quality and warranty support, as reputable OEMs often provide better service and reliability.

-

MOQ (Minimum Order Quantity): This is the smallest number of units a supplier is willing to sell. Knowing the MOQ is important for budgeting and inventory management, as it can influence purchasing decisions, particularly for smaller businesses.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers to request pricing for specific quantities of goods. B2B buyers should use RFQs to gather competitive pricing and terms from multiple suppliers, ensuring they make informed purchasing decisions.

-

Incoterms (International Commercial Terms): These are standardized terms used in international trade that define the responsibilities of buyers and sellers. Familiarity with Incoterms can prevent misunderstandings related to shipping, insurance, and delivery responsibilities, which is particularly important for international buyers from regions like Africa and South America.

-

Lead Time: This term refers to the time it takes from placing an order until it is delivered. Understanding lead times is critical for inventory planning, especially for businesses that rely on timely product availability to meet customer demands.

-

Warranty: A warranty is a guarantee provided by the manufacturer regarding the condition of the product and the terms of repair or replacement. Knowing the warranty details can protect your investment and ensure you have support in case of product failures.

By grasping these technical properties and trade terminologies, international B2B buyers can make informed decisions when investing in the Vendo 39 Coke machine, optimizing their operational efficiency and customer satisfaction.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the vendo 39 coke machine Sector

Market Overview & Key Trends

The global market for vending machines, particularly the Vendo 39 Coke Machine, is experiencing significant transformation driven by technological advancements and changing consumer preferences. Notably, the demand for contactless payment systems has surged, especially in regions like Africa and the Middle East, where mobile payment solutions are becoming increasingly popular. This trend is complemented by the rise of smart vending machines, which utilize IoT technology to monitor inventory levels, optimize supply chains, and enhance customer engagement through personalized marketing.

In Europe and South America, sustainability is becoming a key driver in purchasing decisions. Buyers are increasingly looking for machines that not only offer energy efficiency but also align with their corporate social responsibility goals. The emergence of digital vending solutions that integrate with e-commerce platforms is also noteworthy, allowing businesses to expand their reach and offer a seamless purchasing experience.

For international B2B buyers, understanding the local market dynamics is crucial. In Africa and South America, for example, the informal sector plays a significant role in vending operations, necessitating partnerships with local distributors who understand regional nuances. Furthermore, the demand for diverse product offerings—such as healthy snacks and beverages—reflects a broader trend towards wellness and health-conscious consumption.

Sustainability & Ethical Sourcing in B2B

Sustainability is not just a trend but a necessity in the vending machine sector. The environmental impact of manufacturing, operating, and disposing of vending machines is significant, making it essential for buyers to prioritize ethical sourcing and sustainable practices. This includes selecting suppliers who use recyclable materials and energy-efficient components in their machines.

Certifications such as ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) can serve as indicators of a supplier’s commitment to sustainability. Furthermore, incorporating green materials into the Vendo 39 machines, such as biodegradable plastics and low-energy refrigeration systems, can enhance marketability and meet the growing consumer demand for eco-friendly products.

Illustrative Image (Source: Google Search)

Buyers should also consider the entire lifecycle of the vending machine, including its end-of-life disposal. Collaborating with suppliers who have robust recycling programs can help mitigate the environmental footprint. By investing in sustainable vending solutions, businesses not only contribute to environmental preservation but also improve their brand image, appealing to a conscientious customer base.

Brief Evolution/History

The Vendo 39 Coke Machine has a storied history that reflects broader trends in the vending industry. Originally introduced in the mid-20th century, this model has evolved from simple mechanical machines to sophisticated, electronically controlled units. Early models were characterized by their straightforward operation and limited product offerings, primarily soft drinks.

Over the years, the Vendo 39 has adapted to technological advancements, incorporating features such as digital displays and cashless payment systems. This evolution highlights the vending industry’s shift towards automation and consumer-centric design, responding to the demands of a more connected and health-conscious consumer base. For B2B buyers, understanding this historical context can provide insights into the product’s reliability and longevity in various market conditions.

Related Video: 1955 Vendo 39 Coca-Cola Machine | Restoration Recap

Frequently Asked Questions (FAQs) for B2B Buyers of vendo 39 coke machine

-

What should I consider when vetting suppliers for the Vendo 39 Coke machine?

When vetting suppliers, prioritize those with a proven track record in international trade and experience with vending machines. Check their certifications, such as ISO and CE, which indicate adherence to quality and safety standards. Request references from previous clients, and consider conducting a site visit or virtual inspection to evaluate their manufacturing processes. Additionally, ensure they have reliable customer support and after-sales service in your region. -

Can the Vendo 39 Coke machine be customized to fit my business needs?

Yes, many suppliers offer customization options for the Vendo 39 Coke machine. This can include branding, color schemes, and specific configurations to accommodate different beverage selections. Discuss your requirements with potential suppliers early in the negotiation process to ensure they can meet your specifications. Customization may also affect lead times and costs, so clarify these details upfront. -

What are the typical minimum order quantities (MOQ) and lead times for the Vendo 39 Coke machine?

MOQs can vary significantly by supplier, but they typically range from 5 to 20 units for the Vendo 39 model. Lead times may also differ based on customization requests and the supplier’s production schedule, often ranging from 4 to 12 weeks. To avoid disruptions, plan your inventory needs well in advance and discuss lead times during initial conversations with suppliers. -

What payment terms should I expect when purchasing the Vendo 39 Coke machine?

Payment terms can vary, but many suppliers require a deposit (often 30-50%) upon order confirmation, with the balance due before shipment. Some may offer flexible financing options or letter of credit arrangements, particularly for larger orders. Always clarify payment methods accepted (e.g., bank transfer, PayPal) and ensure that the terms are documented in your purchase agreement to avoid misunderstandings. -

How can I ensure quality assurance and certifications for the Vendo 39 Coke machine?

Before placing an order, request documentation proving that the Vendo 39 meets international quality standards. Look for compliance certificates such as ISO 9001 for quality management and CE marking for safety in the European market. Additionally, consider asking for a sample or conducting a pre-shipment inspection to verify that the machines meet your specifications and quality expectations. -

What logistics considerations should I be aware of when importing the Vendo 39 Coke machine?

Logistics can be complex, so factor in shipping costs, customs duties, and potential tariffs when budgeting. Choose a reliable freight forwarder experienced in handling machinery to navigate the import process smoothly. Ensure that the supplier provides the necessary shipping documents and guarantees that the machines are packaged securely to prevent damage during transit. -

How should I handle disputes with suppliers of the Vendo 39 Coke machine?

To minimize disputes, ensure clear communication and well-documented agreements from the outset. In the event of a disagreement, attempt to resolve the issue amicably through direct negotiation. If this fails, refer to the terms outlined in your contract, which may specify mediation or arbitration processes. Always keep records of all communications and agreements to support your position if formal dispute resolution is necessary. -

What after-sales support can I expect after purchasing the Vendo 39 Coke machine?

After-sales support varies by supplier, but reputable companies typically offer warranty services, technical support, and access to spare parts. Inquire about the duration of the warranty and the specifics of what it covers. Additionally, check if the supplier provides training for your staff on machine operation and maintenance, as this can enhance performance and longevity of the vending machines.

Strategic Sourcing Conclusion and Outlook for vendo 39 coke machine

The Vendo 39 Coke machine represents a significant opportunity for international B2B buyers looking to enhance their vending solutions. Strategic sourcing plays a pivotal role in ensuring that businesses not only acquire high-quality machines but also benefit from favorable pricing, reliability, and after-sales support. Key takeaways include the importance of evaluating suppliers based on their reputation, product quality, and ability to provide local support.

Illustrative Image (Source: Google Search)

Moreover, understanding regional market dynamics in Africa, South America, the Middle East, and Europe can lead to more informed purchasing decisions. For instance, buyers should consider local regulations, consumer preferences, and logistical challenges when sourcing these machines.

As we look ahead, the demand for automated vending solutions is expected to grow, driven by trends in convenience and contactless transactions. B2B buyers are encouraged to leverage this momentum by exploring partnerships with reputable suppliers who can offer tailored solutions. Embrace this opportunity to invest in a Vendo 39 Coke machine that meets your operational needs and enhances customer satisfaction, positioning your business for future success.