Mastering Your Vending Machine Business Proposal for Global

Guide to Vending Machine Business Proposal

- Introduction: Navigating the Global Market for vending machine business proposal

- Understanding vending machine business proposal Types and Variations

- Key Industrial Applications of vending machine business proposal

- Strategic Material Selection Guide for vending machine business proposal

- In-depth Look: Manufacturing Processes and Quality Assurance for vending machine business proposal

- Comprehensive Cost and Pricing Analysis for vending machine business proposal Sourcing

- Spotlight on Potential vending machine business proposal Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for vending machine business proposal

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the vending machine business proposal Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of vending machine business proposal

- Strategic Sourcing Conclusion and Outlook for vending machine business proposal

Introduction: Navigating the Global Market for vending machine business proposal

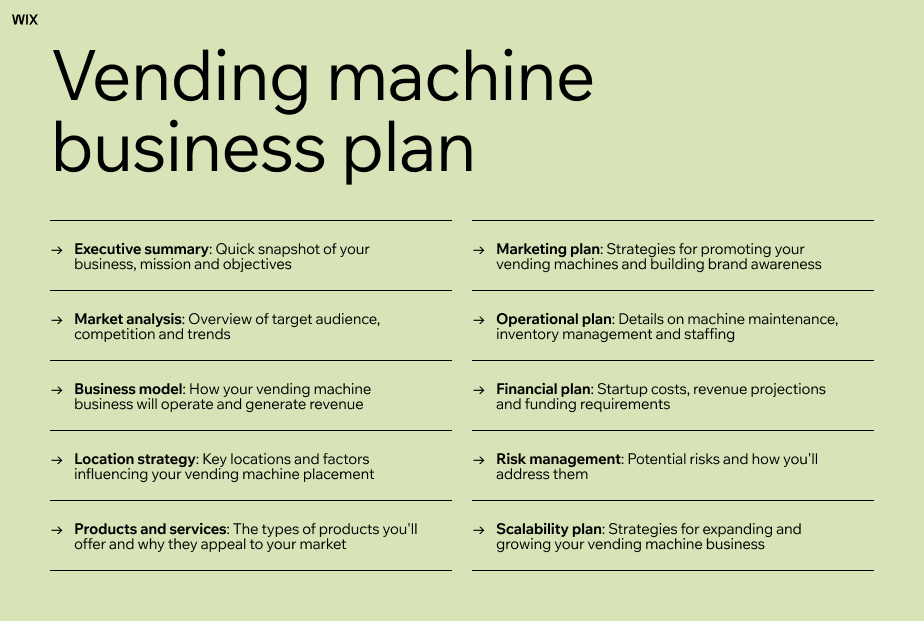

In the rapidly evolving landscape of international commerce, vending machines have emerged as a vital channel for convenience and accessibility. This guide serves as a comprehensive resource for B2B buyers seeking to navigate the complexities of vending machine business proposals. Understanding the nuances of these proposals is essential for making informed sourcing decisions, especially for buyers from diverse regions such as Africa, South America, the Middle East, and Europe, including countries like Argentina and Italy.

A well-structured vending machine business proposal not only outlines the operational framework but also details critical aspects such as types of machines, materials used, manufacturing processes, quality control measures, and supplier options. Furthermore, the guide offers insights into cost considerations and market trends, empowering buyers to optimize their investments and anticipate market dynamics.

By delving into frequently asked questions, this guide demystifies the vending machine procurement process, equipping international buyers with the knowledge necessary to identify reliable partners and make strategic decisions. Whether you are a seasoned entrepreneur or a newcomer to the vending sector, this resource is designed to enhance your understanding and facilitate successful business ventures in the global marketplace. Embrace the opportunity to leverage this guide as a tool for unlocking new possibilities in the vending machine business, ensuring you remain competitive and well-informed in this thriving industry.

Understanding vending machine business proposal Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Snack Vending | Dispenses packaged snacks and beverages | Offices, schools, malls | Pros: Low maintenance, familiar to users. Cons: Limited product range; may not attract health-conscious consumers. |

| Fresh Food Vending | Offers perishable items like salads, sandwiches, and fruits | Hospitals, universities, corporate offices | Pros: Appeals to health-conscious consumers; diverse offerings. Cons: Higher maintenance; requires refrigeration. |

| Specialty Coffee Vending | Provides high-quality coffee and related beverages | Coffee shops, office break rooms | Pros: High demand; premium pricing potential. Cons: Higher initial investment; requires regular supply management. |

| Automated Retail Kiosks | Multi-product vending with touchscreen interfaces | Retail environments, airports, malls | Pros: Engaging user experience; can sell a variety of products. Cons: Higher upfront costs; technical maintenance required. |

| Eco-Friendly Vending | Focuses on sustainable products and packaging | Eco-conscious businesses, universities | Pros: Attracts eco-friendly consumers; positive brand image. Cons: Often higher product costs; limited supplier options. |

Traditional Snack Vending

Traditional snack vending machines are the most common type, typically offering packaged snacks and beverages. These machines are suitable for various environments, including offices, schools, and shopping malls. When considering a purchase, B2B buyers should evaluate the machine’s capacity, product selection, and ease of restocking. While they require minimal maintenance and are familiar to consumers, their limited product range may not appeal to health-conscious customers.

Fresh Food Vending

Fresh food vending machines provide a selection of perishable items such as salads, sandwiches, and fruits. They are particularly suitable for locations like hospitals, universities, and corporate offices, where consumers seek healthier meal options. Key considerations for B2B buyers include the machine’s refrigeration capabilities and the frequency of product replenishment. Although they cater to a growing demand for healthy food, they entail higher maintenance costs and require careful inventory management to prevent spoilage.

Specialty Coffee Vending

Specialty coffee vending machines focus on high-quality coffee and related beverages, making them ideal for coffee shops and office break rooms. B2B buyers should assess the machine’s brewing capabilities and the variety of beverages offered. This type of vending can capitalize on the premium pricing potential associated with coffee, but it requires a higher initial investment and ongoing management of coffee supplies and maintenance.

Automated Retail Kiosks

Automated retail kiosks represent a modern evolution in vending, featuring touchscreen interfaces that allow for a broader range of products beyond traditional snacks. These machines are well-suited for retail environments, airports, and malls, where user engagement can drive sales. Buyers should consider the initial costs and the need for technical support. While they provide an engaging shopping experience and diverse product offerings, they also involve higher upfront investment and ongoing technical maintenance.

Eco-Friendly Vending

Eco-friendly vending machines prioritize sustainable products and packaging, appealing to environmentally conscious consumers. This type is particularly relevant for businesses and universities that want to promote sustainability. B2B buyers should evaluate the sourcing of products and the machine’s overall environmental impact. Although eco-friendly vending can enhance a brand’s image and attract a niche market, it often comes with higher product costs and a limited range of suppliers.

Related Video: How To Start A Vending Machine Business in 2025 (FREE COURSE)

Key Industrial Applications of vending machine business proposal

| Industry/Sector | Specific Application of vending machine business proposal | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food & Beverage | Snack and beverage vending machines | Increased convenience and sales in high-traffic areas | Machine reliability, payment options, product variety |

| Healthcare | Medicine and health product dispensers | Quick access to essential medications for patients | Compliance with regulations, secure payment systems |

| Education | Campus vending for snacks and supplies | Enhances student satisfaction and convenience | Energy efficiency, machine durability, product selection |

| Retail | Automated retail kiosks for small electronics | Reduces staffing costs and enhances customer experience | Compact design, inventory management, payment flexibility |

| Transportation | Vending solutions for airports and train stations | Improves passenger satisfaction and sales volume | Space optimization, product range, security features |

Food & Beverage

Vending machines in the food and beverage sector provide a quick and convenient way for consumers to access snacks and drinks. These machines can be strategically placed in high-traffic areas such as offices, schools, and public transportation hubs. For international B2B buyers, key considerations include ensuring product variety to cater to local tastes, machine reliability to minimize downtime, and flexible payment options to accommodate different customer preferences. Successful implementation can lead to increased sales and customer satisfaction.

Healthcare

In healthcare settings, vending machines can dispense essential medications and health products, ensuring quick access for patients and staff. This application is particularly beneficial in hospitals and clinics where time is critical. International buyers must consider compliance with health regulations, secure payment systems to protect sensitive patient information, and the ability to stock a variety of health-related items. By addressing these needs, healthcare facilities can enhance patient care and operational efficiency.

Education

Educational institutions can benefit from vending machines that provide snacks and essential supplies on campus. This not only enhances student satisfaction by offering convenient access to food and beverages but also supports their academic performance by catering to their needs. Buyers in this sector should focus on energy-efficient models that can handle high usage, durable machines that withstand daily wear and tear, and a diverse product selection that appeals to a wide range of students. Implementing these solutions can create a more engaging educational environment.

Retail

Automated retail kiosks in the retail sector allow businesses to sell small electronics and accessories without the need for a staffed store. This approach reduces staffing costs and provides customers with a unique shopping experience. B2B buyers should consider compact designs that fit in various retail spaces, effective inventory management systems to keep track of sales, and flexible payment methods to accommodate diverse consumer preferences. This application can drive sales while optimizing operational costs.

Transportation

Vending machines in transportation hubs, such as airports and train stations, significantly enhance passenger satisfaction by offering quick access to snacks, drinks, and travel essentials. For international B2B buyers, considerations include optimizing machine space to fit in often crowded environments, providing a wide range of products that cater to international travelers, and ensuring robust security features to protect against theft. By addressing these aspects, transportation facilities can improve the overall travel experience and increase sales.

Related Video: How to Write a Vending Machine Business Plan Proposal | Easy-to-Follow Steps

Strategic Material Selection Guide for vending machine business proposal

When selecting materials for vending machines, it is essential to consider properties that directly impact performance, durability, and cost. Below is an analysis of four common materials used in vending machine construction, focusing on their key properties, advantages, disadvantages, and specific considerations for international B2B buyers.

1. Stainless Steel

Key Properties:

Stainless steel is renowned for its excellent corrosion resistance, high strength, and ability to withstand high temperatures and pressures. It typically has a temperature rating of up to 800°C and can handle pressures exceeding 2000 psi, depending on the grade.

Pros & Cons:

Stainless steel is highly durable and resistant to rust and staining, making it suitable for environments where hygiene is critical. However, it can be more expensive than other materials, and its weight may complicate manufacturing and installation processes.

Impact on Application:

This material is ideal for vending machines that dispense food and beverages due to its hygienic properties. It is also compatible with a variety of media, including water and soft drinks.

Considerations for International Buyers:

Buyers from regions like Europe and the Middle East should ensure compliance with local health and safety standards. Common standards such as ASTM and EN should be referenced to guarantee quality.

2. Carbon Steel

Key Properties:

Carbon steel is known for its high tensile strength and toughness. It generally has a temperature rating of up to 500°C and can withstand moderate pressure levels.

Pros & Cons:

This material is cost-effective and readily available, making it a popular choice for structural components. However, it is prone to corrosion if not properly coated or treated, which can lead to maintenance issues over time.

Impact on Application:

Carbon steel is suitable for non-corrosive environments and can be used for the frame and structural elements of vending machines. Its compatibility with various media is limited compared to stainless steel.

Considerations for International Buyers:

In regions like Africa and South America, where humidity can be high, it is crucial to consider protective coatings to enhance durability. Compliance with local standards, such as JIS in Japan or ASTM in the U.S., is also important.

3. Aluminum

Key Properties:

Aluminum is lightweight, corrosion-resistant, and has a temperature rating of around 600°C. It is not as strong as stainless steel but offers good structural integrity for many applications.

Pros & Cons:

Its lightweight nature makes aluminum easy to work with and transport, reducing shipping costs. However, it is generally less durable than stainless steel and can be more susceptible to dents and scratches.

Impact on Application:

Aluminum is often used for the outer casing of vending machines, especially in environments where weight is a concern. It is compatible with a wide range of media, including snacks and beverages.

Considerations for International Buyers:

European buyers may prefer aluminum due to its recyclability and lower environmental impact. Compliance with EU regulations regarding materials and recycling should be considered.

4. Polycarbonate

Key Properties:

Polycarbonate is a durable thermoplastic known for its high impact resistance and transparency. It can withstand temperatures up to 120°C and offers good UV resistance.

Pros & Cons:

This material is lightweight and can be molded into complex shapes, making it suitable for custom designs. However, it is more expensive than other plastics and may degrade over time when exposed to UV light without proper treatment.

Impact on Application:

Polycarbonate is ideal for transparent panels on vending machines, allowing visibility of products. Its impact resistance makes it suitable for high-traffic areas.

Considerations for International Buyers:

Buyers in regions with high UV exposure, such as parts of Africa and South America, should ensure the material is treated for UV resistance. Familiarity with local plastic standards is also essential.

Summary Table

| Material | Typical Use Case for vending machine business proposal | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food and beverage dispensing machines | Excellent corrosion resistance | Higher cost, heavier weight | High |

| Carbon Steel | Structural components for vending machines | Cost-effective, high strength | Prone to corrosion without treatment | Low |

| Aluminum | Outer casing and structural elements | Lightweight, easy to work with | Less durable than stainless steel | Medium |

| Polycarbonate | Transparent panels for product visibility | High impact resistance, moldable | More expensive, UV degradation potential | Medium |

This guide provides essential insights into material selection for vending machines, helping international B2B buyers make informed decisions tailored to their specific market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for vending machine business proposal

Vending machines have evolved significantly, and understanding their manufacturing processes and quality assurance measures is crucial for B2B buyers looking to invest in this technology. This guide delves into the typical manufacturing stages, quality control measures, international standards, and how buyers can ensure their suppliers maintain high-quality standards.

Manufacturing Processes

The manufacturing of vending machines involves several key stages, each integral to producing a reliable and efficient product.

1. Material Preparation

The first stage involves sourcing and preparing the materials needed for the vending machines. Common materials include:

- Metal Components: Typically steel or aluminum for structural integrity.

- Plastic Parts: Used for buttons, display screens, and internal mechanisms.

- Electronic Components: Including microcontrollers, sensors, and payment systems.

Materials must be sourced from reputable suppliers to ensure quality. This stage may involve cutting, shaping, and treating materials to meet specific design requirements.

2. Forming

Once materials are prepared, the forming process begins. Techniques involved include:

- Stamping: Used for creating metal parts and panels.

- Injection Molding: Commonly used for producing plastic components.

- CNC Machining: Precision machining for intricate parts that require exact specifications.

Each technique must be performed with precision to ensure the parts fit together seamlessly during assembly.

3. Assembly

Assembly is a critical phase where all components come together. This process typically includes:

- Mechanical Assembly: Involves assembling the frame, doors, and internal mechanisms.

- Electronic Assembly: Installation of wiring, payment systems, and control boards.

- Quality Checks: Conducted throughout the assembly process to identify defects early.

Efficient assembly lines often employ lean manufacturing principles to minimize waste and optimize productivity.

4. Finishing

The finishing stage enhances the machine’s aesthetic and functional qualities. This may involve:

- Painting and Coating: To improve durability and appearance.

- Labeling: Ensuring user-friendly interfaces with clear instructions.

- Final Inspection: A thorough check to ensure all components function correctly.

This stage is essential for ensuring the product meets the buyer’s specifications and market expectations.

Quality Assurance (QA)

Quality assurance is crucial in the manufacturing of vending machines to guarantee reliability and customer satisfaction.

International Standards

B2B buyers should be familiar with relevant international standards that affect vending machine manufacturing, including:

- ISO 9001: A standard that outlines criteria for a quality management system, ensuring consistent quality in products and services.

- CE Marking: Indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

- API Standards: Relevant for machines that dispense food or beverages, ensuring hygiene and safety.

Understanding these standards helps buyers assess the credibility of suppliers.

QC Checkpoints

Quality control checkpoints are essential at various stages of the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): Inspecting raw materials and components upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Conducting checks during the manufacturing process to catch defects early.

- Final Quality Control (FQC): A comprehensive inspection of the finished product before shipment.

Implementing these checkpoints helps maintain high-quality standards throughout production.

Common Testing Methods

Testing methods play a significant role in verifying the quality of vending machines. Common methods include:

- Functional Testing: Ensuring all mechanical and electronic components work as intended.

- Durability Testing: Simulating prolonged use to assess the machine’s resilience.

- Safety Testing: Evaluating electrical safety and compliance with relevant regulations.

These tests help ensure that the vending machines are safe and reliable for end-users.

Verifying Supplier Quality Control

B2B buyers must take proactive steps to verify the quality control measures of potential suppliers. Here are actionable strategies:

Audits and Reports

- Conduct Supplier Audits: Regular audits can help assess the supplier’s quality management practices and adherence to international standards.

- Request Quality Reports: Suppliers should provide documentation of their quality control processes, including results from IQC, IPQC, and FQC.

Third-Party Inspections

Engaging third-party inspection agencies can offer an unbiased assessment of the supplier’s manufacturing and quality control processes. This step is particularly important for international buyers who may not have on-the-ground resources to conduct inspections themselves.

Illustrative Image (Source: Google Search)

QC and Certification Nuances for International Buyers

For buyers from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification is essential. Here are some considerations:

- Regional Standards: Be aware of local regulations and standards that may differ from international norms. For instance, certain countries may have specific requirements for electrical safety that must be met.

- Certification Validity: Verify that certifications are current and recognized in your target market. This may involve checking with relevant authorities or industry organizations.

- Cultural Sensitivity: Engage with suppliers who understand the cultural and logistical challenges that may arise in international trade, ensuring smoother transactions and better communication.

In conclusion, understanding the manufacturing processes and quality assurance protocols for vending machines is vital for B2B buyers. By focusing on material preparation, forming, assembly, and finishing, alongside rigorous quality control measures, buyers can ensure they partner with reliable suppliers that meet their standards.

Related Video: The Production Planning Process

Comprehensive Cost and Pricing Analysis for vending machine business proposal Sourcing

When entering the vending machine business, international B2B buyers must navigate a complex cost structure and pricing analysis to ensure profitability and sustainability. Understanding the various components involved in sourcing vending machines is crucial for making informed purchasing decisions.

Cost Components

-

Materials: The cost of materials typically constitutes the largest portion of the vending machine’s total cost. This includes the metal framework, electronic components, and the display unit. Buyers should consider the quality of materials used, as higher quality can lead to a longer lifespan and better performance.

-

Labor: Labor costs encompass wages for workers involved in the manufacturing and assembly processes. Depending on the region, labor costs can vary significantly. For example, labor might be cheaper in South America compared to Europe, impacting overall pricing.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, rent, and equipment depreciation. Understanding the overhead can help buyers gauge the pricing strategy of suppliers.

-

Tooling: Tooling costs are related to the equipment required for production. Custom tooling can be expensive but may be necessary for specialized vending machines. Buyers should weigh the benefits of customization against the associated costs.

-

Quality Control (QC): Implementing QC measures ensures that the machines meet safety and operational standards. While this adds to the cost, it can prevent future expenses related to repairs and warranty claims.

-

Logistics: Transportation and shipping costs can vary greatly depending on the distance and the chosen Incoterms. Buyers must factor in these costs when calculating the total expenditure.

-

Margin: Suppliers typically add a markup to cover their costs and generate profit. Understanding the margin can help buyers assess whether the price is competitive.

Price Influencers

Several factors can influence the pricing of vending machines:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes often lead to discounts, making it essential for buyers to negotiate bulk purchases.

-

Specifications/Customization: Custom features or specifications can significantly increase costs. Buyers should determine whether these customizations are necessary or if standard models suffice.

-

Materials: The choice of materials directly impacts the final price. Higher-grade materials may come at a premium but can enhance durability and aesthetics.

-

Quality/Certifications: Machines that meet specific certifications may command higher prices. Buyers should verify that the machines comply with local regulations and standards.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more due to their proven track record.

-

Incoterms: Understanding Incoterms is vital for international buyers. They define responsibilities for shipping, insurance, and tariffs, which can affect the total landed cost.

Buyer Tips

-

Negotiation: Engage in discussions with suppliers to negotiate better terms, especially regarding bulk purchases or long-term contracts.

-

Cost-Efficiency: Look beyond initial costs and consider the Total Cost of Ownership (TCO), which includes maintenance, operational expenses, and potential downtime.

-

Pricing Nuances: Be aware of regional pricing differences. For instance, the cost structure in Africa may differ significantly from Europe due to varying labor costs and material availability.

-

Market Research: Conduct thorough research on suppliers and market conditions to identify competitive pricing and potential cost-saving opportunities.

-

Flexibility: Be open to adjusting specifications based on budget constraints. Sometimes, opting for slightly less advanced features can yield significant cost savings.

Disclaimer

Prices can vary significantly based on numerous factors, including market fluctuations, supplier changes, and regional economic conditions. Buyers are encouraged to conduct their own due diligence and obtain multiple quotes to ensure they receive the best possible pricing.

Spotlight on Potential vending machine business proposal Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘vending machine business proposal’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for vending machine business proposal

Key Technical Properties for Vending Machines

When considering a vending machine business proposal, understanding the essential technical properties is crucial for making informed purchasing decisions. Here are some critical specifications that B2B buyers should evaluate:

-

Material Grade

The quality of materials used in the construction of vending machines directly impacts durability and maintenance costs. Common materials include stainless steel for the outer casing and tempered glass for the display. Higher-grade materials may incur a higher initial cost but can lead to lower long-term expenses due to reduced wear and tear. -

Temperature Control Range

This specification is vital for machines dispensing perishable items such as beverages or snacks. A suitable temperature control range ensures that products are stored at optimal temperatures, maintaining freshness and compliance with health regulations. Machines may feature adjustable thermostats for versatility in different climates. -

Power Consumption

Energy efficiency is increasingly important in global markets. Vending machines should have specifications indicating their power consumption, typically measured in watts. Machines with lower power consumption can reduce operational costs and appeal to eco-conscious consumers, aligning with sustainability goals. -

Payment System Compatibility

Modern vending machines often support multiple payment methods, including cash, credit/debit cards, and mobile payments. Compatibility with various payment systems ensures broader customer accessibility and can increase sales. Buyers should consider whether machines are equipped with contactless payment options, which are becoming increasingly popular. -

Size and Capacity

The dimensions and product capacity of a vending machine are essential for space management. Buyers should evaluate the available space at the intended location and ensure that the machine can accommodate the desired product variety without compromising accessibility. -

User Interface

A user-friendly interface enhances customer experience and can lead to increased sales. Features like touch screens, intuitive navigation, and multiple language options should be considered. A well-designed interface can also reduce the likelihood of customer errors during transactions.

Common Trade Terminology in Vending Machine Proposals

Understanding industry jargon is essential for effective communication and negotiations in the vending machine sector. Here are several key terms that B2B buyers should be familiar with:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce components or products that are sold under another company’s brand. In the vending machine industry, working with an OEM can ensure that the machines are built to specific standards and allow for customization. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest number of units that a supplier is willing to sell. Understanding MOQ is crucial for budgeting and inventory management, as it can influence the overall cost and feasibility of a vending machine business proposal. -

RFQ (Request for Quotation)

An RFQ is a document that a buyer submits to suppliers to request pricing and terms for a specific product or service. Utilizing RFQs allows buyers to compare offers and negotiate better deals, fostering competitive pricing. -

Incoterms (International Commercial Terms)

These are standardized terms used in international trade to clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is essential for international buyers to understand their obligations and rights. -

Lead Time

Lead time refers to the period between placing an order and receiving the goods. This is a critical factor for inventory planning and can affect operational efficiency. Buyers should clarify lead times in proposals to manage expectations. -

Warranty and Service Agreements

Warranties cover repairs or replacements for defects, while service agreements outline ongoing maintenance support. Understanding these terms helps buyers assess the long-term value and support associated with their vending machine investments.

By grasping these technical properties and trade terms, international B2B buyers can navigate vending machine proposals more effectively, ensuring they make informed, strategic decisions that align with their business objectives.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the vending machine business proposal Sector

Market Overview & Key Trends

The global vending machine market is experiencing significant transformation, driven by a blend of technological advancements and changing consumer behaviors. Digitalization is a major force, with smart vending machines equipped with IoT technology allowing for real-time inventory management and personalized consumer experiences. For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, understanding these trends is crucial.

Current sourcing trends indicate a shift towards automation and contactless payment options, particularly in response to the COVID-19 pandemic. The rise of cashless transactions has made it essential for vending machine suppliers to integrate mobile payment systems. Additionally, sustainability is becoming a key consideration; buyers are increasingly favoring vendors that prioritize eco-friendly practices. This includes using energy-efficient machines and sourcing products from sustainable suppliers.

Emerging markets in Africa and South America show promising growth, driven by urbanization and a growing middle class. In Europe, particularly in countries like Italy, there is a notable trend towards gourmet and healthy options in vending machines. This diversification not only appeals to health-conscious consumers but also enhances the brand image of businesses. Buyers must stay informed about these dynamics to effectively navigate sourcing and make strategic decisions that align with evolving market demands.

Sustainability & Ethical Sourcing in B2B

As global awareness of environmental issues rises, sustainability in the vending machine sector has become paramount. The environmental impact of vending machines, from energy consumption to waste generation, necessitates a proactive approach to sustainability. B2B buyers should prioritize suppliers who commit to using energy-efficient machines that minimize their carbon footprint.

Illustrative Image (Source: Google Search)

Furthermore, ethical sourcing is integral to establishing a responsible supply chain. This involves ensuring that all components, from the machines themselves to the snacks and beverages dispensed, are sourced from suppliers who adhere to ethical labor practices. Certifications like Fair Trade and organic labels are increasingly important for buyers seeking to enhance their corporate social responsibility (CSR) initiatives.

Investing in ‘green’ certifications and materials not only meets consumer demand for sustainable products but also positions businesses competitively in the market. By adopting these practices, companies can build a reputation that resonates with environmentally conscious consumers, thus driving sales and fostering loyalty.

Brief Evolution/History

The vending machine industry has evolved significantly since its inception in the late 19th century. Originally designed for dispensing simple items like cigarettes and postcards, machines have transitioned to incorporate advanced technology and a diverse range of products. The introduction of electronic payment systems and smart technology in the early 2000s marked a turning point, allowing for real-time data tracking and enhanced user experiences.

In recent years, the focus has shifted towards creating sustainable vending solutions. This evolution reflects a broader trend within the retail sector, where consumer preferences are increasingly aligned with environmental stewardship and ethical sourcing. For B2B buyers, recognizing this historical context is essential, as it highlights the importance of adapting to ongoing changes and consumer expectations in the vending machine market.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of vending machine business proposal

-

What should I consider when vetting suppliers for vending machines?

When vetting suppliers, prioritize their experience and reputation in the vending machine industry. Look for suppliers who have a proven track record with international clients, especially in your region. Verify their certifications, such as ISO standards, and request client testimonials. Additionally, assess their financial stability to ensure they can fulfill long-term commitments. A thorough background check can help mitigate risks associated with supplier reliability and product quality. -

Can I customize vending machines to suit my market needs?

Yes, many suppliers offer customization options for vending machines. You can tailor aspects such as machine size, design, product selection, and payment methods to better fit your target market’s preferences. Discuss your specific requirements with potential suppliers to understand their customization capabilities. Ensure that any custom features comply with local regulations and consumer preferences, as this can significantly impact sales performance. -

What are the typical minimum order quantities (MOQ) and lead times for vending machines?

MOQs can vary widely depending on the supplier and the complexity of the vending machines. Generally, expect an MOQ ranging from 5 to 50 units for standard models. Lead times typically range from 4 to 12 weeks, influenced by customization requests and the supplier’s production capacity. Always confirm these details upfront to ensure they align with your business timeline and inventory needs. -

What payment terms are common in international vending machine transactions?

Payment terms can vary significantly among suppliers. Common arrangements include advance payments, letters of credit, or payment upon delivery. For international transactions, consider using secure payment methods like escrow services to protect your investment. Discussing payment terms early in negotiations can help establish trust and ensure both parties are comfortable with the financial arrangements. -

How do I ensure quality assurance and certifications for vending machines?

To ensure quality assurance, request that suppliers provide relevant certifications, such as CE marking for Europe or ISO standards. Conduct factory audits if possible, or ask for samples to evaluate product quality firsthand. Additionally, inquire about the supplier’s quality control processes and warranty policies. Establishing a clear QA agreement can help safeguard your investment and ensure the machines meet your standards. -

What logistics considerations should I keep in mind when sourcing vending machines internationally?

Logistics are critical in international sourcing. Consider shipping methods, costs, and estimated delivery times when selecting a supplier. Ensure that the supplier has experience with customs regulations in your country to avoid delays. Additionally, evaluate the reliability of their logistics partners. It may be beneficial to work with a freight forwarder who understands the nuances of international shipping to streamline the process. -

How can I handle disputes with my vending machine supplier?

Disputes can arise over various issues, from product quality to delivery delays. To mitigate this risk, clearly define terms in your contract, including dispute resolution mechanisms like mediation or arbitration. Maintain open communication with your supplier to address issues promptly. If a dispute escalates, having documented evidence of correspondence and agreements can be invaluable in resolving the matter effectively. -

What are the key factors to consider regarding after-sales support for vending machines?

After-sales support is essential for the longevity of your vending machines. Ensure the supplier offers comprehensive support, including installation, maintenance, and troubleshooting services. Ask about warranty periods and the availability of spare parts. Additionally, consider their response time for service requests, as prompt support can minimize downtime and enhance customer satisfaction in your market.

Strategic Sourcing Conclusion and Outlook for vending machine business proposal

The vending machine industry presents a unique opportunity for international B2B buyers seeking to diversify their offerings and tap into emerging markets. Strategic sourcing plays a crucial role in this landscape, ensuring that businesses can access the right products at competitive prices while maintaining quality and sustainability. By partnering with reliable suppliers and leveraging local insights, companies can streamline their operations, reduce costs, and enhance their market presence.

As buyers from Africa, South America, the Middle East, and Europe evaluate their vending machine business proposals, it is essential to consider factors such as local consumer preferences, regulatory compliance, and logistical challenges. Engaging with local partners can provide valuable insights that drive successful product selection and deployment strategies.

Looking ahead, the demand for innovative vending solutions is expected to grow, driven by technological advancements and changing consumer behaviors. B2B buyers are encouraged to stay informed about industry trends and actively seek partnerships that foster long-term growth. By prioritizing strategic sourcing, businesses can position themselves for success in the evolving vending machine market and maximize their potential in diverse regions. Embrace this opportunity to lead the market by making informed, strategic decisions today.