Master Sourcing uconn Plan B Vending Machines for Optimal

Guide to Uconn Plan B Vending Machines

- Introduction: Navigating the Global Market for uconn plan b vending machines

- Understanding uconn plan b vending machines Types and Variations

- Key Industrial Applications of uconn plan b vending machines

- Strategic Material Selection Guide for uconn plan b vending machines

- In-depth Look: Manufacturing Processes and Quality Assurance for uconn plan b vending machines

- Comprehensive Cost and Pricing Analysis for uconn plan b vending machines Sourcing

- Spotlight on Potential uconn plan b vending machines Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for uconn plan b vending machines

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the uconn plan b vending machines Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of uconn plan b vending machines

- Strategic Sourcing Conclusion and Outlook for uconn plan b vending machines

Introduction: Navigating the Global Market for uconn plan b vending machines

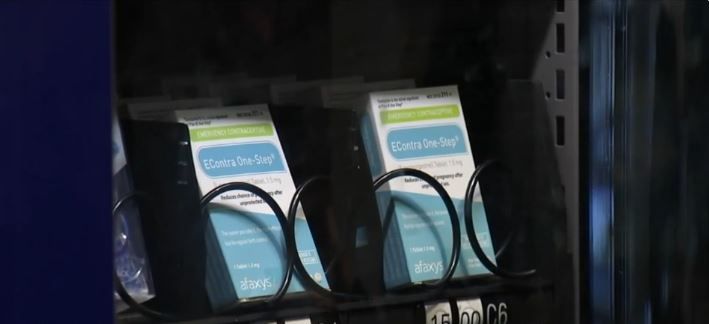

In today’s rapidly evolving global marketplace, uconn plan b vending machines represent a transformative solution in the distribution of essential health products. These machines provide a discreet, accessible, and efficient means for consumers to obtain emergency contraceptives, addressing critical health needs in various regions. With the rising demand for reproductive health solutions, understanding the nuances of this market is vital for international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, including key markets like Brazil and Mexico.

This comprehensive guide is designed to empower decision-makers by covering a wide array of topics relevant to sourcing uconn plan b vending machines. Buyers will find insights into different types of machines, the materials used in manufacturing, and the quality control measures that ensure product reliability. Additionally, the guide delves into supplier landscapes, cost considerations, and an analysis of current market trends.

By addressing frequently asked questions and providing actionable insights, this resource will equip international buyers with the knowledge necessary to make informed sourcing decisions. Whether you are looking to enhance product offerings in health services or expand into new markets, this guide serves as a crucial tool for navigating the complexities of the uconn plan b vending machine industry. Engage with this guide to unlock opportunities that not only meet consumer needs but also promote public health initiatives globally.

Understanding uconn plan b vending machines Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Vending Machines | Stocked with Plan B contraceptive pills | Universities, hospitals, clinics | Pros: Easy access for customers; Cons: Limited inventory management capabilities. |

| Smart Vending Machines | Equipped with digital interfaces and inventory tracking | Urban areas, corporate offices | Pros: Real-time inventory updates; Cons: Higher initial investment costs. |

| Mobile Vending Units | Portable units that can be relocated as needed | Events, festivals, temporary sites | Pros: Flexibility and mobility; Cons: May have limited stock due to size. |

| Customizable Vending Solutions | Tailored to specific client needs and branding | Retail stores, educational institutions | Pros: Enhanced brand visibility; Cons: Longer lead times for production. |

| Eco-Friendly Vending Machines | Use of sustainable materials and energy-efficient designs | Green initiatives, eco-conscious businesses | Pros: Appeals to environmentally aware consumers; Cons: Potentially higher operational costs. |

Traditional Vending Machines

Traditional vending machines serve as the most straightforward option for distributing Plan B contraceptive pills. These machines are typically stocked with a limited number of items and are placed in strategic locations such as universities, hospitals, and clinics. For B2B buyers, they offer a simple solution to meet the demand for emergency contraceptives without the need for extensive staffing. However, their limited inventory management capabilities can result in stockouts if not regularly monitored.

Smart Vending Machines

Smart vending machines integrate technology with vending operations, allowing for real-time inventory tracking and digital interfaces for user interaction. They are particularly suitable for urban areas and corporate offices where technology adoption is high. B2B buyers benefit from the data analytics these machines provide, enabling better inventory management and customer engagement. However, the higher initial costs can be a barrier for some organizations.

Mobile Vending Units

Mobile vending units are designed for flexibility and can be relocated to various sites, making them ideal for events, festivals, and temporary locations. Their portability allows businesses to respond to changing market demands effectively. For B2B buyers, these units represent an opportunity to reach customers in diverse settings, although the limited space may restrict the quantity of products that can be offered at any given time.

Customizable Vending Solutions

These vending machines can be tailored to meet specific client needs, including branding and product selection. This customization makes them a valuable option for retail stores and educational institutions aiming to enhance their brand visibility and customer experience. While they offer significant advantages in marketing and customer engagement, buyers should be prepared for longer lead times due to the customization process.

Eco-Friendly Vending Machines

Eco-friendly vending machines are designed using sustainable materials and energy-efficient technologies, appealing to businesses focused on green initiatives. They are particularly relevant for organizations looking to align with environmentally conscious consumers. B2B buyers can leverage these machines to enhance their corporate social responsibility profiles. However, potential higher operational costs may deter some companies from adopting this option.

Related Video: CS 198-126: Lecture 12 – Diffusion Models

Key Industrial Applications of uconn plan b vending machines

| Industry/Sector | Specific Application of uconn plan b vending machines | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Dispensing emergency contraceptives | Increases accessibility to reproductive health options | Compliance with health regulations, user privacy |

| Education | Providing student health services | Supports student well-being and reduces stigma | Stock management, partnership with health providers |

| Hospitality | Offering convenience items in hotels | Enhances guest experience and satisfaction | Inventory control, payment system integration |

| Retail | Vending for personal care products | Expands product range and increases impulse purchases | Product variety, machine placement strategy |

| Corporate Offices | Distributing wellness products | Promotes employee health and productivity | Customization options, service and maintenance support |

Healthcare

In the healthcare sector, uconn plan b vending machines are utilized to dispense emergency contraceptives, providing a critical service to women in need. This application addresses the issue of accessibility, particularly in regions where reproductive health services may be limited. International buyers should consider compliance with local health regulations and ensure that user privacy is maintained, as these factors are essential in building trust with customers.

Education

Within educational institutions, these vending machines can serve as a discreet option for students to access health-related products. By offering emergency contraceptives and other personal care items, schools can foster an environment that supports student well-being and reduces stigma associated with obtaining such products. Buyers in this sector should focus on stock management and consider partnerships with health providers to ensure a reliable supply.

Hospitality

In the hospitality industry, uconn plan b vending machines can enhance guest experiences by providing easy access to personal care products and emergency contraceptives. This convenience can significantly improve guest satisfaction, particularly among younger travelers who value accessibility. B2B buyers should prioritize inventory control and explore options for integrating payment systems to streamline transactions and improve operational efficiency.

Retail

Retailers can leverage uconn plan b vending machines to expand their product offerings, particularly in the personal care sector. By making emergency contraceptives readily available, businesses can cater to impulse purchases and meet consumer demand for convenience. When sourcing these machines, it is crucial to consider product variety and the strategic placement of vending machines within stores to maximize visibility and sales.

Corporate Offices

In corporate environments, these vending machines can distribute wellness products, promoting employee health and productivity. By providing access to emergency contraceptives and other health-related items, companies can demonstrate a commitment to employee well-being. Buyers should explore customization options to tailor the vending machines to their specific workplace needs, as well as ensure that service and maintenance support is readily available to keep operations running smoothly.

Related Video: What are all the Laboratory Apparatus and their uses?

Strategic Material Selection Guide for uconn plan b vending machines

When selecting materials for uconn plan b vending machines, it’s crucial to consider the properties and performance characteristics of various materials. The following analysis focuses on four common materials used in these machines, providing insights into their advantages, disadvantages, and suitability for international markets.

1. Stainless Steel (e.g., 304/316)

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand a wide range of temperatures. Grades 304 and 316 are particularly favored for their durability and resistance to oxidation and pitting.

Pros & Cons:

Stainless steel offers exceptional durability and a long lifespan, making it ideal for high-traffic environments. However, it can be more expensive than other materials and may require specialized manufacturing techniques, increasing production complexity.

Impact on Application:

Stainless steel is compatible with various media, including food and beverages, making it suitable for vending machines. Its non-reactive nature ensures that the quality of the products remains intact.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM A240 for stainless steel. In regions like Europe and the Middle East, preferences for food-grade materials can influence purchasing decisions.

2. Aluminum

Key Properties:

Aluminum is lightweight, has good corrosion resistance, and can be easily machined. It also has a favorable strength-to-weight ratio, making it suitable for portable applications.

Pros & Cons:

The primary advantage of aluminum is its low weight, which can reduce shipping costs. However, it is less durable than stainless steel and may not withstand heavy impacts or extreme temperatures as effectively.

Impact on Application:

Aluminum is ideal for applications where weight savings are critical, but it may not be suitable for environments with harsh chemicals or extreme temperatures.

Considerations for International Buyers:

Buyers should be aware of the relevant standards, such as ASTM B221 for aluminum extrusions. In markets like South America, where cost sensitivity is high, aluminum may be a preferred option despite its limitations in durability.

3. Carbon Steel (e.g., A36)

Key Properties:

Carbon steel is known for its high strength and toughness. It is generally less expensive than stainless steel and aluminum, making it a cost-effective choice for many applications.

Pros & Cons:

While carbon steel is strong and durable, it is prone to corrosion if not properly protected. This necessitates additional coatings or treatments, which can increase overall costs and complexity.

Impact on Application:

Carbon steel is suitable for structural components but may not be ideal for direct contact with food or beverages due to corrosion concerns.

Considerations for International Buyers:

Compliance with standards such as ASTM A36 is important. Buyers in Africa may find carbon steel appealing due to its lower cost, but they must also consider the implications of corrosion in humid environments.

4. Polycarbonate

Key Properties:

Polycarbonate is a high-performance thermoplastic known for its impact resistance and clarity. It can withstand a wide range of temperatures and is often used in applications requiring transparency.

Pros & Cons:

The key advantage of polycarbonate is its lightweight nature and ability to resist shattering, making it ideal for safety applications. However, it may not be as durable as metals in high-stress situations and can be susceptible to scratching.

Impact on Application:

Polycarbonate is particularly useful for display panels or protective covers in vending machines, allowing visibility while ensuring safety.

Considerations for International Buyers:

Buyers should verify compliance with standards like ISO 9001 for quality management systems. In regions like Europe, where safety regulations are stringent, polycarbonate may be favored for its safety features.

Summary Table

| Material | Typical Use Case for uconn plan b vending machines | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel (e.g., 304/316) | Structural components, external casing | Excellent corrosion resistance | Higher cost, complex manufacturing | High |

| Aluminum | Lightweight structural parts, external casing | Low weight, cost-effective | Less durable under heavy impact | Medium |

| Carbon Steel (e.g., A36) | Structural components, internal frames | High strength, cost-effective | Prone to corrosion without protection | Low |

| Polycarbonate | Display panels, protective covers | Lightweight, impact-resistant | Less durable than metals, scratches easily | Medium |

This guide provides a comprehensive overview of material options for uconn plan b vending machines, helping international B2B buyers make informed decisions based on performance, cost, and regional preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for uconn plan b vending machines

Manufacturing Processes for UConn Plan B Vending Machines

The manufacturing of UConn Plan B vending machines involves several critical stages, each designed to ensure the final product meets high standards of functionality, reliability, and safety. Understanding these processes is crucial for B2B buyers, especially those sourcing from diverse international markets.

Main Stages of Manufacturing

-

Material Preparation

– Raw Materials: The primary materials used in the construction of vending machines include steel, aluminum, plastic, and electronic components. Sourcing high-quality materials is essential for durability and performance.

– Material Treatment: This may involve processes such as cutting, bending, and coating to prepare the materials for assembly. Surface treatments, like powder coating, enhance resistance to corrosion and wear. -

Forming

– Fabrication: This stage involves shaping the prepared materials into the machine’s components. Techniques such as laser cutting and CNC machining are common, allowing for precise dimensions and complex designs.

– Welding and Joining: Parts are then joined using welding, riveting, or adhesive bonding, ensuring structural integrity. Automated welding systems are often employed to enhance efficiency and consistency. -

Assembly

– Component Integration: During assembly, various components—such as the dispensing mechanism, electronic controls, and user interface—are integrated. This requires skilled labor and often involves a combination of manual and automated assembly processes.

– Quality Checks: Each assembly line typically has checkpoints where components are tested for fit and function before proceeding to the next stage. -

Finishing

– Surface Treatment: Final finishes may include painting, plating, or applying protective coatings, which not only enhance aesthetic appeal but also provide additional protection against environmental factors.

– Final Assembly: The machine is fully assembled, including the installation of software systems and testing of electronic components. This stage ensures that everything functions as intended.

Quality Assurance in Manufacturing

Quality assurance (QA) is an integral part of the manufacturing process for UConn Plan B vending machines, ensuring that the final product adheres to both international and industry-specific standards.

Relevant International Standards

- ISO 9001: This standard outlines the criteria for a quality management system and is applicable to any organization, regardless of its size or industry. Compliance with ISO 9001 ensures that manufacturers consistently provide products that meet customer and regulatory requirements.

- CE Marking: For products sold in the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards. This is particularly relevant for electronic components within vending machines.

- API Certification: In some cases, especially for machines designed to dispense pharmaceuticals, adherence to the American Petroleum Institute (API) standards may be necessary to ensure safety and efficacy.

Quality Control Checkpoints

Quality control (QC) is monitored at various stages throughout the manufacturing process:

- Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials and components upon arrival to ensure they meet specified standards before they enter production.

- In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to verify that processes are being followed correctly and that quality standards are maintained.

- Final Quality Control (FQC): Before shipment, the finished machines undergo comprehensive testing to ensure they function correctly and meet all specifications. This may include performance tests, safety checks, and user interface evaluations.

Common Testing Methods

- Functional Testing: Ensures that the vending machine operates as intended under various conditions.

- Durability Testing: Simulates long-term use to assess the machine’s reliability and lifespan.

- Compliance Testing: Verifies that the machine meets all regulatory requirements for the markets it will serve.

Verifying Supplier Quality Control

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is vital to ensure product reliability and compliance with local regulations. Here are key strategies:

- Supplier Audits: Conducting regular audits of suppliers can help assess their adherence to quality standards and manufacturing processes. This can be done through on-site visits or third-party assessments.

- Quality Reports: Requesting detailed quality assurance reports from suppliers can provide insights into their QC processes, testing results, and compliance with relevant standards.

- Third-Party Inspections: Engaging independent inspectors to evaluate the manufacturing process and quality control measures can provide an unbiased assessment of the supplier’s capabilities.

QC and Certification Nuances for International Buyers

International buyers should be aware of several nuances regarding quality control and certification when sourcing UConn Plan B vending machines:

- Regional Regulations: Different regions have specific regulations that may affect machine design and functionality. Understanding these can help buyers avoid compliance issues.

- Cultural Considerations: Quality expectations may vary by region; therefore, clear communication regarding standards and expectations is crucial.

- Language Barriers: Ensure that all documentation, including quality reports and certifications, is available in the buyer’s preferred language to avoid misunderstandings.

By comprehensively understanding the manufacturing processes and quality assurance measures for UConn Plan B vending machines, international B2B buyers can make informed decisions and foster successful partnerships with suppliers.

Related Video: Business English Vocabulary : VV 47 – Manufacturing & Production Process (1) | English Vocabulary

Comprehensive Cost and Pricing Analysis for uconn plan b vending machines Sourcing

Cost Structure of UConn Plan B Vending Machines

When considering the procurement of UConn Plan B vending machines, it is essential to analyze the cost components involved. The primary cost structure includes:

-

Materials: The cost of raw materials such as metal, plastic, and electronic components can vary significantly based on quality and supplier. Opting for high-quality materials ensures durability but may increase initial costs.

-

Labor: Labor costs encompass both direct and indirect labor involved in manufacturing. Factors such as the location of the manufacturing facility and local wage rates can influence these costs. Outsourcing production to countries with lower labor costs may be an option, but it can impact quality and delivery times.

-

Manufacturing Overhead: This includes utilities, rent, and administrative expenses associated with the production facility. Efficient management of overhead can lead to reduced costs, enhancing overall profitability.

-

Tooling: Depending on the complexity of the vending machines, tooling costs for molds and dies can be substantial. These costs are often amortized over production runs, making it vital to consider the volume of machines ordered.

-

Quality Control (QC): Implementing rigorous QC measures ensures that the machines meet industry standards. While this may add to the upfront costs, it mitigates the risk of defects and subsequent warranty claims.

-

Logistics: Transportation costs from the manufacturing site to the buyer’s location can be significant. Factors such as shipping distance, mode of transport, and customs duties must be taken into account.

-

Margin: Suppliers typically mark up prices to ensure profitability. Understanding the expected margin can help in negotiations.

Price Influencers

Several factors influence the pricing of UConn Plan B vending machines:

-

Volume/MOQ (Minimum Order Quantity): Higher volumes often lead to lower per-unit costs. Buyers should evaluate their needs to determine if they can meet the MOQ to benefit from better pricing.

-

Specifications/Customization: Custom features or specifications can increase costs. Buyers should clearly define their requirements and understand how they impact pricing.

-

Materials: The choice of materials directly affects both the cost and quality of the machines. Opting for premium materials may enhance durability but will also increase costs.

-

Quality/Certifications: Machines that meet specific certifications (e.g., ISO standards) may come at a premium. Buyers should assess whether these certifications are necessary for their market.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge more but offer better quality assurance and customer service.

-

Incoterms: Understanding Incoterms is crucial for international buyers. These terms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, affecting the overall cost structure.

Buyer Tips

To navigate the procurement process effectively, international B2B buyers should consider the following tips:

-

Negotiation: Engage suppliers in discussions about pricing and terms. Leverage your order volume to negotiate better rates.

-

Cost-Efficiency: Assess the total cost of ownership, including maintenance and operational costs, rather than just the purchase price. A lower upfront cost may lead to higher long-term expenses.

-

Pricing Nuances: Be aware of regional pricing trends. For instance, buyers in Africa and South America might face different logistics costs compared to those in Europe due to varying infrastructure and tariffs.

-

Customization Considerations: If customization is necessary, ensure that you understand how it impacts both cost and delivery timelines. Custom features can lead to delays if not planned appropriately.

-

Research and Due Diligence: Conduct thorough research on potential suppliers, examining their track record, product quality, and customer feedback to make informed decisions.

Disclaimer: Prices can vary significantly based on market conditions, currency fluctuations, and other external factors. Buyers should seek updated quotes from suppliers for accurate pricing.

Spotlight on Potential uconn plan b vending machines Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘uconn plan b vending machines’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for uconn plan b vending machines

Understanding the essential technical properties and trade terminology related to UConn Plan B vending machines is crucial for international B2B buyers. This knowledge not only aids in making informed purchasing decisions but also enhances negotiation capabilities and supply chain efficiency. Below, we outline the key specifications and industry terms relevant to these vending machines.

Key Technical Properties

-

Material Grade

– Definition: This refers to the quality and type of materials used in the construction of the vending machine, such as stainless steel for durability and corrosion resistance.

– Importance: High-grade materials ensure longevity and reliability, minimizing maintenance costs and enhancing customer satisfaction. -

Power Consumption

– Definition: The amount of electrical power the vending machine requires to operate effectively.

– Importance: Understanding power consumption is vital for evaluating operational costs and ensuring compliance with local energy regulations. Efficient machines can lead to significant savings over time. -

Capacity

– Definition: This indicates the number of items the vending machine can hold, usually specified in terms of slots or total weight.

– Importance: Knowing the capacity helps businesses match the machine to their expected sales volume and customer footfall, optimizing inventory management. -

Dimensions and Weight

– Definition: The physical measurements (height, width, depth) and weight of the vending machine.

– Importance: Proper dimensions are essential for space planning, especially in high-traffic areas. Weight considerations can influence shipping costs and installation logistics. -

Temperature Control Range

– Definition: The range of temperatures that the vending machine can maintain, which is critical for products requiring refrigeration.

– Importance: Ensuring the right temperature range is crucial for product safety and quality, particularly for perishable items. -

User Interface Technology

– Definition: The type of interface (touchscreen, keypad) used for customer interaction.

– Importance: An intuitive user interface can enhance customer experience, reduce transaction times, and minimize errors, leading to increased sales.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Significance: Understanding OEM relationships can help buyers identify quality standards and potential customization options for vending machines. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Significance: Knowing the MOQ helps buyers plan their purchases effectively, ensuring they meet supplier requirements without overcommitting resources. -

RFQ (Request for Quotation)

– Definition: A document issued by a buyer to solicit price offers from suppliers for specific products or services.

– Significance: An RFQ is essential for comparing prices and terms from different vendors, allowing for informed decision-making.

Illustrative Image (Source: Google Search)

-

Incoterms (International Commercial Terms)

– Definition: A set of predefined commercial terms published by the International Chamber of Commerce, defining the responsibilities of sellers and buyers in international transactions.

– Significance: Familiarity with Incoterms helps buyers understand shipping responsibilities, risks, and costs, facilitating smoother international trade. -

Lead Time

– Definition: The time taken from placing an order to the delivery of the product.

– Significance: Understanding lead times is crucial for inventory management and planning, particularly in markets with fluctuating demand. -

Warranty

– Definition: A guarantee provided by the manufacturer regarding the condition of the product and the promise to repair or replace it if necessary.

– Significance: A solid warranty can provide peace of mind for buyers, ensuring support and service for potential issues that may arise post-purchase.

By grasping these technical properties and trade terms, international B2B buyers can navigate the complexities of acquiring UConn Plan B vending machines more effectively, ensuring better investment and operational outcomes.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the uconn plan b vending machines Sector

Market Overview & Key Trends

The market for UConn Plan B vending machines is influenced by several global drivers, including the rising demand for accessible healthcare solutions and increased awareness of reproductive rights. As urban populations grow and the need for discreet access to contraceptive options becomes paramount, B2B buyers from regions like Africa, South America, the Middle East, and Europe are presented with unique opportunities.

Emerging trends in technology and sourcing include the integration of digital payment systems and mobile app connectivity, which enhance user experience and streamline operations. For international buyers, understanding local regulations regarding healthcare products is critical, as compliance can vary significantly by region. Furthermore, the growing acceptance of telehealth and e-commerce platforms is reshaping how these machines are marketed and sold, making them more attractive to potential partners.

Supply chain dynamics are also shifting, with a focus on direct sourcing from manufacturers to reduce costs and improve product availability. Buyers are increasingly seeking partnerships with manufacturers that offer customization options, enabling them to tailor their offerings to local preferences and needs. This adaptability can be a key differentiator in competitive markets.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a cornerstone of business practices in the vending machine sector. The environmental impact of manufacturing and operating UConn Plan B vending machines necessitates a focus on sustainable practices. This includes the use of eco-friendly materials, energy-efficient technologies, and waste reduction strategies.

Ethical sourcing is equally important, as buyers increasingly prioritize suppliers who adhere to fair labor practices and transparent supply chains. Certifications such as ISO 14001 (Environmental Management) and Fair Trade can provide assurance to B2B buyers about the sustainability and ethical standards of their sourcing partners.

Moreover, utilizing ‘green’ certifications for materials, such as recycled plastics and biodegradable components, can not only enhance a company’s reputation but also appeal to environmentally conscious consumers. As buyers from diverse regions engage in this market, they should actively seek suppliers committed to sustainability, as this can significantly impact brand loyalty and customer trust.

Brief Evolution/History

The evolution of vending machines for contraceptive access can be traced back to the late 20th century when the need for discreet and convenient healthcare solutions became apparent. Initially, these machines were limited to urban centers in developed countries, but over time, they have expanded to meet the needs of diverse populations globally.

The introduction of Plan B vending machines represents a significant shift towards enhancing reproductive health access, particularly in areas where traditional healthcare services may be limited. As technology advances, these machines are now equipped with features such as touch screens and mobile payment options, making them more user-friendly. This evolution reflects a growing recognition of the importance of reproductive rights and the need for accessible healthcare solutions in various cultural contexts.

In summary, international B2B buyers in the UConn Plan B vending machine sector must navigate a landscape characterized by technological advancements, sustainability imperatives, and evolving consumer expectations. By leveraging these insights, they can make informed decisions that not only enhance their market positioning but also contribute positively to global health outcomes.

Related Video: Chapter 9: International Trade

Frequently Asked Questions (FAQs) for B2B Buyers of uconn plan b vending machines

-

What should I consider when vetting suppliers for UConn Plan B vending machines?

When vetting suppliers, prioritize their industry experience, customer reviews, and certifications. Check their production capacity and reliability in meeting deadlines. It’s also advisable to request references from other international buyers, especially those from your region. Establish clear communication to gauge responsiveness and support for any post-purchase issues. This will help ensure that you partner with a supplier capable of fulfilling your specific needs in terms of quality and compliance. -

Can I customize UConn Plan B vending machines to fit my market needs?

Yes, many manufacturers offer customization options for UConn Plan B vending machines. You can request features such as branding, size adjustments, and specific product offerings that cater to your local market preferences. Discuss your requirements early in the negotiation process to ensure that the customization aligns with your operational goals and regulatory requirements in your region. -

What is the minimum order quantity (MOQ) and typical lead time for UConn Plan B vending machines?

The MOQ for UConn Plan B vending machines typically ranges from 10 to 50 units, depending on the supplier. Lead times can vary significantly based on the supplier’s production schedule and your location, often ranging from 4 to 12 weeks. To avoid delays, confirm the lead time during your initial discussions and consider placing orders well in advance of your expected launch date. -

What payment methods are generally accepted for international orders?

Most suppliers accept a variety of payment methods, including wire transfers, letters of credit, and secure online payment systems. Ensure to clarify payment terms upfront, including any required deposits and payment schedules. Be cautious of suppliers requesting full payment upfront, and consider using escrow services for additional security, especially with high-value transactions. -

How can I ensure the quality of UConn Plan B vending machines?

To ensure quality, request detailed product specifications, certifications, and quality assurance processes from your supplier. It’s beneficial to conduct a pre-shipment inspection or third-party audit to verify that the machines meet your standards. Additionally, inquire about warranty terms and after-sales support, as these factors contribute significantly to overall satisfaction with the purchase.

Illustrative Image (Source: Google Search)

-

What certifications should I look for when sourcing UConn Plan B vending machines?

Look for certifications such as ISO 9001 for quality management systems, CE marking for compliance with European standards, and any local certifications required in your region. These certifications indicate that the supplier adheres to international safety and quality standards, which is crucial for maintaining compliance in your market. -

What logistics considerations should I keep in mind when importing vending machines?

Logistics is critical when importing UConn Plan B vending machines. Consider shipping methods (air vs. sea), customs clearance processes, and local regulations regarding import duties and taxes. Work with a logistics partner who has experience in your target markets to navigate these complexities effectively. Additionally, ensure that the supplier is willing to cooperate in providing necessary documentation for smooth customs processing. -

How should I handle disputes with my supplier?

To manage disputes effectively, establish clear contractual terms that outline responsibilities, quality expectations, and conflict resolution mechanisms. Maintain open communication with your supplier to address issues promptly. If disputes arise, consider mediation as a first step before escalating to legal action. Having a mutually agreed-upon process in place can save time and resources in resolving conflicts.

Strategic Sourcing Conclusion and Outlook for uconn plan b vending machines

In conclusion, strategic sourcing for UConn Plan B vending machines presents significant opportunities for international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe. By leveraging a comprehensive sourcing strategy, organizations can ensure not only the availability of essential health products but also enhance their operational efficiency and customer satisfaction.

Key takeaways include the importance of understanding regional market dynamics, building strong supplier relationships, and utilizing data-driven decision-making processes. These elements are crucial for optimizing supply chains and achieving cost-effective procurement solutions.

As the demand for accessible reproductive health solutions continues to grow, investing in innovative vending machine solutions can position your business as a leader in this vital market. We encourage international B2B buyers to explore partnerships with manufacturers and distributors who prioritize quality and compliance, ensuring that the products meet local regulations and cultural sensitivities.

Embrace the future of health product accessibility by prioritizing strategic sourcing today—your commitment will not only benefit your business but also contribute positively to community health outcomes across diverse regions.