Your Ultimate Guide to Sourcing Stamp Vending Machine Near

Guide to Stamp Vending Machine Near Me

- Introduction: Navigating the Global Market for stamp vending machine near me

- Understanding stamp vending machine near me Types and Variations

- Key Industrial Applications of stamp vending machine near me

- Strategic Material Selection Guide for stamp vending machine near me

- In-depth Look: Manufacturing Processes and Quality Assurance for stamp vending machine near me

- Comprehensive Cost and Pricing Analysis for stamp vending machine near me Sourcing

- Spotlight on Potential stamp vending machine near me Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for stamp vending machine near me

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the stamp vending machine near me Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of stamp vending machine near me

- Strategic Sourcing Conclusion and Outlook for stamp vending machine near me

Introduction: Navigating the Global Market for stamp vending machine near me

In today’s interconnected global marketplace, the demand for efficient and accessible postal solutions is more crucial than ever. Stamp vending machines play a pivotal role in facilitating seamless postal transactions, catering to a diverse range of businesses and consumers alike. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the intricacies of sourcing these machines is essential for enhancing operational efficiency and customer satisfaction.

This comprehensive guide delves into the multifaceted world of stamp vending machines, offering insights into various types, materials, manufacturing processes, and quality control measures. Buyers will gain a clear understanding of the market landscape, including key suppliers, pricing strategies, and potential cost-saving opportunities. Moreover, the guide addresses frequently asked questions, ensuring that buyers are well-equipped to make informed decisions.

By exploring the nuances of stamp vending machine sourcing, this guide empowers B2B buyers to navigate potential challenges and seize opportunities in their respective markets. Whether you are looking to enhance postal services in urban centers or remote locations, the knowledge and strategies outlined here will enable you to optimize your purchasing process and foster fruitful partnerships with manufacturers and suppliers. With the right insights, you can not only meet your business needs but also drive innovation in postal solutions across continents.

Understanding stamp vending machine near me Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standalone Stamp Vending Machine | Self-contained unit, often coin-operated, for purchasing stamps directly. | Retail environments, post offices | Pros: Easy to use, low maintenance. Cons: Limited stock, may require frequent refills. |

| Integrated POS Stamp Vending | Combines stamp vending with point-of-sale systems, allowing for electronic payments. | Supermarkets, convenience stores | Pros: Streamlined transactions, better inventory tracking. Cons: Higher initial investment, requires technical support. |

| Mobile Stamp Vending Kiosk | Portable units that can be relocated as needed, often used in events or temporary setups. | Trade shows, festivals | Pros: Flexibility in placement, attracts foot traffic. Cons: Vulnerable to theft, may require power supply. |

| Automated Stamp Dispenser | High-tech machines that dispense stamps based on user input, often touchscreen operated. | Corporate offices, shipping centers | Pros: Customizable options, reduces human error. Cons: Higher cost, technical issues can lead to downtime. |

| Digital Stamp Vending Solutions | Online platforms where stamps can be purchased digitally and printed at home. | E-commerce businesses, remote workers | Pros: Instant access, no physical inventory. Cons: Dependence on internet connectivity, less personal interaction. |

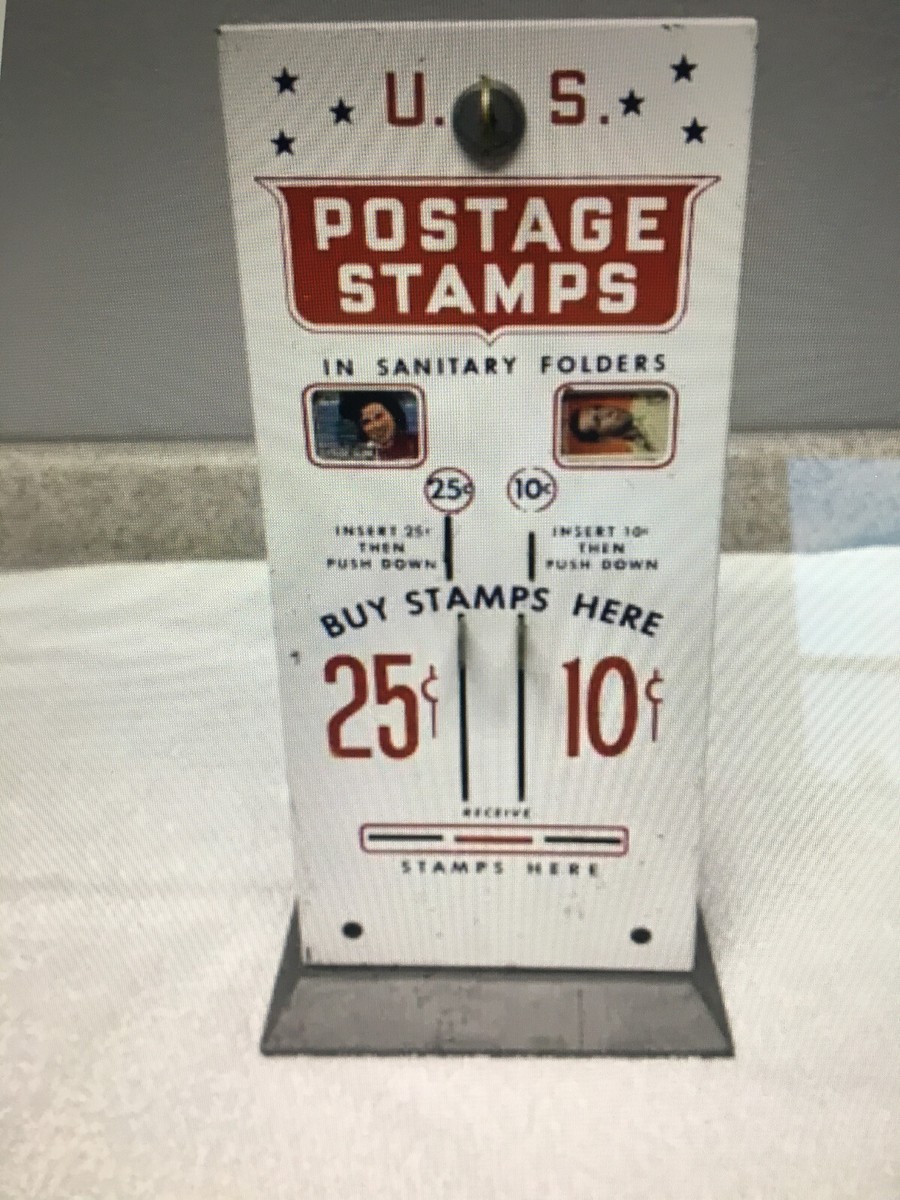

Standalone Stamp Vending Machine

Standalone stamp vending machines are typically found in retail environments and post offices. They are designed for easy operation, often accepting coins or bills to dispense stamps directly. These machines are ideal for businesses looking to provide quick access to postage without the need for staffing. However, their limited inventory means they may require frequent restocking, which can be a logistical challenge for high-traffic locations.

Integrated POS Stamp Vending

Integrated POS stamp vending machines combine the functionality of traditional stamp vending with point-of-sale systems. This allows businesses to accept electronic payments, streamlining the purchasing process for customers. They are particularly suitable for supermarkets and convenience stores where speed and efficiency are paramount. While the initial investment can be higher due to the technology involved, the benefits of improved inventory management and transaction tracking can offset these costs.

Mobile Stamp Vending Kiosk

Mobile stamp vending kiosks offer flexibility, allowing businesses to set up in various locations as needed. These units are particularly effective at events like trade shows and festivals, where foot traffic is high. The ability to attract customers in different environments is a significant advantage. However, mobile units may be more susceptible to theft and require a reliable power source, which can complicate logistics.

Automated Stamp Dispenser

Automated stamp dispensers are advanced machines that utilize touchscreen technology to allow users to select and purchase stamps. These units can be particularly beneficial in corporate offices and shipping centers, where accuracy and speed are essential. They help reduce human error and can be customized to meet specific business needs. However, the higher cost and potential for technical issues leading to downtime are critical considerations for buyers.

Digital Stamp Vending Solutions

Digital stamp vending solutions represent a modern approach to purchasing stamps, enabling customers to buy and print stamps online. This option is particularly advantageous for e-commerce businesses and remote workers who require quick access to postage without the need for physical inventory. While this model offers instant access and convenience, it also relies heavily on internet connectivity, which can be a drawback in areas with poor service.

Related Video: Pros And Cons Of Starting A Vending Machine Business

Key Industrial Applications of stamp vending machine near me

| Industry/Sector | Specific Application of stamp vending machine near me | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Postal Services | Automated stamp dispensing in post offices | Reduces waiting times, enhances customer experience | Reliability, ease of use, maintenance support |

| Retail | Stamp sales in convenience stores | Increases foot traffic, additional revenue stream | Size, payment options, integration with existing systems |

| Education | Stamp vending in universities for student services | Convenient access for students, promotes engagement | Security features, user-friendly interface, durability |

| Event Management | On-site stamp sales at exhibitions and fairs | Quick service, enhances participant experience | Portability, capacity to handle high demand |

| Government Services | Stamp vending for public services | Streamlines service delivery, reduces operational costs | Compliance with regulations, ease of replenishment |

Postal Services

In postal services, stamp vending machines are increasingly utilized to automate the dispensing of postage stamps. This application addresses issues of long queues and limited service hours, providing customers with 24/7 access to stamps. For international B2B buyers, reliability and ease of maintenance are critical; machines must be robust enough to handle varying climates and usage frequencies, particularly in regions such as Africa and South America, where service infrastructure may vary.

Retail

In the retail sector, convenience stores can benefit from installing stamp vending machines. This not only generates additional revenue but also attracts customers who may not have intended to purchase stamps. The machines can be programmed to accept various payment methods, which is essential for catering to diverse consumer preferences. Buyers should prioritize machines that integrate smoothly with existing point-of-sale systems and offer a user-friendly interface to enhance customer satisfaction.

Education

Universities and educational institutions can implement stamp vending machines to facilitate easy access to postage for students and staff. This application supports academic activities by allowing students to send documents and applications without hassle. Key considerations for buyers include security features to prevent theft, as well as durability to withstand frequent use. Additionally, machines should be designed for high traffic periods, ensuring they can handle demand during peak times, such as application deadlines.

Event Management

At events such as exhibitions and fairs, stamp vending machines can provide on-site stamp sales, significantly enhancing the participant experience. This application offers convenience, as attendees can easily purchase stamps without needing to leave the venue. For international buyers, portability and capacity to handle high demand are essential features. The ability to quickly replenish stock and maintain machine functionality in crowded environments is also a key consideration.

Government Services

Government offices can leverage stamp vending machines to streamline service delivery for public services. This application reduces operational costs and improves efficiency by allowing citizens to access stamps without waiting in line. When sourcing these machines, compliance with local regulations and ease of replenishment are vital. Machines should be designed to accommodate various payment methods, ensuring accessibility for all citizens, particularly in diverse economic environments found in regions like the Middle East and Europe.

Related Video: How to Start a Vending Machine Business, Cost, Tips, How Much You Make

Strategic Material Selection Guide for stamp vending machine near me

When selecting materials for stamp vending machines, international B2B buyers must consider various factors that influence performance, durability, and compliance with regional standards. Below is an analysis of four common materials used in the construction of stamp vending machines, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from diverse regions, including Africa, South America, the Middle East, and Europe.

1. Stainless Steel

Key Properties: Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand high temperatures. It typically has a temperature rating of up to 800°C and can handle pressures of up to 2000 psi, depending on the grade.

Pros & Cons: The primary advantage of stainless steel is its durability and longevity, making it ideal for outdoor applications where exposure to elements is a concern. However, it is more expensive than other materials and may require specialized manufacturing processes, which can increase costs.

Impact on Application: Stainless steel is suitable for environments where hygiene is critical, such as in public vending machines. It is compatible with various media, including water and corrosive fluids.

Considerations for International Buyers: Buyers should ensure compliance with local standards such as ASTM or DIN. In regions with high humidity, like parts of Africa and South America, selecting the right grade (e.g., 316 for marine environments) is crucial.

2. Carbon Steel

Key Properties: Carbon steel offers good strength and toughness, with a temperature rating typically around 400°C. It is also relatively easy to machine and weld.

Pros & Cons: Carbon steel is cost-effective and widely available, making it a popular choice for many applications. However, it is susceptible to corrosion if not properly coated or treated, which can limit its lifespan in outdoor settings.

Impact on Application: This material is generally suitable for internal components of vending machines that are not exposed to moisture or corrosive substances.

Considerations for International Buyers: Buyers should be aware of the need for protective coatings in humid regions. Compliance with local standards is essential, particularly in Europe, where specific grades must meet stringent regulations.

3. Aluminum

Key Properties: Aluminum is lightweight, with good corrosion resistance and a temperature rating of up to 200°C. It is also known for its excellent machinability and formability.

Pros & Cons: The main advantage of aluminum is its low weight, which can reduce shipping and installation costs. However, it is less durable than steel and may not withstand heavy impacts or high-pressure environments.

Impact on Application: Aluminum is suitable for components that require lightweight properties, such as housing or frames. It is compatible with various media but should be avoided in highly corrosive environments.

Considerations for International Buyers: Buyers should consider the local availability of aluminum and its grades. In Europe, aluminum standards like EN 485 must be adhered to, while buyers in Africa may need to evaluate local suppliers for quality assurance.

4. Plastic (Polycarbonate or ABS)

Key Properties: Plastics like polycarbonate and ABS offer good impact resistance and are lightweight. They typically have a temperature rating of around 80°C to 100°C.

Pros & Cons: The advantages of using plastics include their low cost and ease of molding into complex shapes. However, they may not be suitable for high-temperature applications and can degrade under UV exposure unless treated.

Impact on Application: Plastic components are often used in non-structural parts of vending machines, such as covers or internal trays. They are compatible with a range of media but should be selected carefully to avoid chemical incompatibility.

Considerations for International Buyers: Buyers should check for compliance with safety and environmental standards, especially in Europe, where regulations on plastic use are stringent. In regions like the Middle East, UV resistance is a critical factor due to high sun exposure.

Summary Table

| Material | Typical Use Case for stamp vending machine near me | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Outdoor components, frames, and internal parts | Excellent corrosion resistance | Higher cost, requires specialized manufacturing | High |

| Carbon Steel | Internal components, structural parts | Cost-effective, good strength | Susceptible to corrosion without protection | Low |

| Aluminum | Housing and lightweight frames | Lightweight, easy to machine | Less durable, not suitable for high impacts | Medium |

| Plastic (Polycarbonate or ABS) | Covers and non-structural components | Low cost, easy to mold | Limited temperature resistance, UV degradation | Low |

This guide provides actionable insights for international B2B buyers, enabling informed decisions when selecting materials for stamp vending machines tailored to their specific regional needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for stamp vending machine near me

The manufacturing processes and quality assurance protocols for stamp vending machines are essential for ensuring product reliability, safety, and compliance with international standards. This section provides an in-depth look into these processes, specifically tailored for international B2B buyers from Africa, South America, the Middle East, and Europe.

Manufacturing Processes

Manufacturing a stamp vending machine involves several critical stages, each requiring specialized techniques and materials. Understanding these stages can help buyers assess the capabilities of potential suppliers.

1. Material Preparation

The first stage involves selecting and preparing raw materials. Common materials include:

- Metal Components: Often made from steel or aluminum, these provide durability and structural integrity.

- Plastics: Used for housing and internal mechanisms, chosen for their lightweight and corrosion-resistant properties.

- Electronic Components: These include microcontrollers, sensors, and payment systems essential for the machine’s functionality.

During material preparation, quality checks ensure that materials meet specified standards for strength and durability. Buyers should inquire about suppliers’ sources and the quality certifications of these materials.

2. Forming

In the forming stage, raw materials are shaped into components through various techniques:

- Stamping: Metal sheets are cut and shaped using dies, a cost-effective method for high-volume production.

- Injection Molding: Plastics are melted and injected into molds, creating complex shapes with high precision.

- Machining: For components requiring tight tolerances, CNC machining is employed, allowing for intricate designs and accurate dimensions.

These techniques must align with international standards to ensure compatibility and safety in different markets.

3. Assembly

The assembly stage integrates all components into a final product. This process can be manual or automated, depending on the scale of production. Key steps include:

- Sub-Assembly: Grouping related components, such as electronic modules, before final assembly.

- Final Assembly: All sub-assemblies are combined, followed by the installation of software and testing interfaces.

Effective assembly processes should minimize errors and ensure consistent quality. B2B buyers should consider suppliers’ assembly capabilities, including workforce training and technology used.

4. Finishing

The finishing stage involves surface treatment and aesthetic enhancements, including:

- Painting or Coating: To protect against corrosion and improve appearance.

- Labeling: Ensuring compliance with local regulations regarding instructions and safety warnings.

Proper finishing is crucial for both functionality and market appeal. Buyers should verify the finishing techniques used and their compliance with environmental regulations.

Quality Assurance

Quality assurance (QA) is vital for maintaining high standards throughout the manufacturing process. International B2B buyers must understand the various QA measures that suppliers employ.

Relevant International Standards

Adhering to recognized quality standards is critical for manufacturers of stamp vending machines:

- ISO 9001: This standard outlines requirements for a quality management system, ensuring consistent product quality and customer satisfaction.

- CE Marking: Required for products sold within the European Economic Area, indicating compliance with health and safety standards.

- API Standards: For machines that may interface with payment systems or other electronic components, compliance with American Petroleum Institute (API) standards may be necessary.

Buyers should request documentation proving compliance with these standards, as it demonstrates a commitment to quality.

Quality Control Checkpoints

Quality control (QC) checkpoints are integral to the manufacturing process. These include:

- Incoming Quality Control (IQC): Assessing materials before production to ensure they meet specifications.

- In-Process Quality Control (IPQC): Monitoring production processes to detect and correct issues in real time.

- Final Quality Control (FQC): Conducting thorough inspections of finished products to confirm they meet all specifications and standards.

Implementing these checkpoints helps minimize defects and ensures that only high-quality products reach the market.

Common Testing Methods

Testing methods for stamp vending machines include:

- Functional Testing: Ensures all machine functions operate correctly, including payment acceptance and stamp dispensing.

- Durability Testing: Simulates long-term use to assess the machine’s resilience and reliability.

- Environmental Testing: Evaluates performance under various conditions, such as temperature fluctuations and humidity.

B2B buyers should inquire about the specific tests performed and the criteria for passing these tests.

Verifying Supplier Quality Control

Buyers must take proactive steps to verify the quality control measures of potential suppliers:

- Audits: Conducting regular audits of suppliers’ manufacturing facilities can reveal their adherence to quality standards.

- Quality Reports: Requesting detailed quality reports can provide insights into the suppliers’ QC processes and historical performance.

- Third-Party Inspections: Engaging third-party organizations to conduct inspections can add an extra layer of assurance regarding product quality.

QC and Certification Nuances for International Buyers

International buyers must be aware of regional differences in quality assurance and certification processes. Understanding local regulations and standards can help in selecting suppliers who are compliant with both international and local requirements.

- Cultural and Regulatory Considerations: Different regions may have unique expectations regarding product safety, environmental impact, and consumer rights. Buyers should familiarize themselves with these aspects to ensure compliance and avoid potential issues.

- Language Barriers: Ensure that documentation is available in the preferred language of the buyer to facilitate understanding and compliance.

By being informed about manufacturing processes and quality assurance protocols, B2B buyers can make educated decisions, ensuring they partner with reputable suppliers capable of delivering high-quality stamp vending machines.

Related Video: Glenroy’s Flexible Packaging Manufacturing Process

Comprehensive Cost and Pricing Analysis for stamp vending machine near me Sourcing

Understanding the Cost Structure for Stamp Vending Machines

When sourcing stamp vending machines, international B2B buyers need to grasp the intricate cost structure that comprises various components. This understanding is crucial for making informed purchasing decisions and ensuring cost efficiency.

Key Cost Components

-

Materials: The choice of materials significantly impacts the overall cost. High-quality metal or durable plastics may increase initial expenses but can lead to lower maintenance costs over time.

-

Labor: Labor costs vary by region. For example, manufacturers in Asia might offer lower labor rates compared to Europe or North America. Buyers should consider the total labor cost, including skilled and unskilled labor involved in assembly and quality control.

-

Manufacturing Overhead: This includes utilities, rent, and other operational costs. A transparent supplier will provide a breakdown of these costs, helping buyers understand the pricing structure.

-

Tooling: Depending on the complexity of the vending machine design, tooling costs can vary. Custom designs may require specialized tools, increasing the initial investment.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability but may add to costs. Buyers should evaluate whether the proposed QC measures align with their standards.

-

Logistics: Shipping costs, including freight charges, tariffs, and handling fees, can significantly affect the total cost. Understanding Incoterms is vital for clarifying who bears these costs and responsibilities.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure profitability. This margin can vary widely based on market demand, competition, and supplier relationships.

Influencers on Pricing

Several factors influence the pricing of stamp vending machines:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to reduced prices per unit due to economies of scale. Buyers should consider their demand forecasts when negotiating MOQs.

-

Specifications and Customization: Custom features or specifications can increase costs. Buyers should weigh the benefits of customization against potential price increases.

-

Material Quality and Certifications: Higher-quality materials and certifications (like ISO) may raise costs but can lead to better performance and reliability.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers with a track record may command higher prices due to perceived reliability and quality assurance.

-

Incoterms: Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is critical, as they dictate shipping responsibilities and can significantly impact total costs.

Tips for B2B Buyers

-

Negotiation: Effective negotiation strategies can yield better pricing. Engage suppliers in discussions about volume discounts, payment terms, and long-term contracts.

-

Cost-Efficiency: Always consider the Total Cost of Ownership (TCO), which includes initial costs, maintenance, and operational expenses over the product’s lifecycle. This approach helps in evaluating the true value of the investment.

-

Pricing Nuances: International buyers should be aware of regional pricing differences. Factors like local market demand, currency fluctuations, and import duties can influence costs.

-

Supplier Relationships: Building strong relationships with suppliers can lead to better pricing, preferential treatment, and access to innovative solutions.

-

Market Research: Conduct thorough market research to compare prices from multiple suppliers. This will provide leverage during negotiations and ensure competitive pricing.

Conclusion

Understanding the comprehensive cost structure and pricing influencers for stamp vending machines is essential for international B2B buyers. By considering these factors, buyers can negotiate effectively and make informed decisions that align with their operational needs and budget constraints. Always seek transparency from suppliers and maintain open communication to foster a mutually beneficial partnership.

Spotlight on Potential stamp vending machine near me Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘stamp vending machine near me’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for stamp vending machine near me

When considering the procurement of stamp vending machines, it is essential to understand the critical technical properties and relevant trade terminology that can significantly impact decision-making and operational efficiency. Below are key specifications and terms that every international B2B buyer should be familiar with.

Key Technical Properties

- Material Grade

The material grade of a stamp vending machine typically refers to the quality and type of materials used in its construction, such as stainless steel or high-grade plastics. High-quality materials ensure durability and resistance to wear and tear, which is crucial for machines placed in public areas. Selecting machines made from premium materials can reduce long-term maintenance costs and increase lifespan.

Illustrative Image (Source: Google Search)

-

Dimensions and Weight

Understanding the dimensions and weight of the vending machine is essential for logistical planning. These specifications dictate the space required for installation and the ease of transport. Machines that are too large may not fit in designated areas, while excessively heavy models could require special handling during transportation. -

Power Requirements

Stamp vending machines vary in their power requirements, typically operating on standard voltage systems (e.g., 110V or 220V). Knowing the power specifications is vital for ensuring compatibility with local electrical systems, which can prevent operational disruptions. Additionally, energy-efficient models can lower operating costs. -

User Interface and Accessibility

The design of the user interface affects customer interaction. Machines with touchscreens and multiple language options cater to a broader audience, enhancing customer experience and potentially increasing sales. Accessibility features, such as braille or audio prompts, can also expand usability for individuals with disabilities. -

Payment Acceptance

Modern stamp vending machines may accept various payment methods, including cash, credit/debit cards, and mobile payments. Understanding the payment acceptance capabilities is crucial for meeting customer preferences and ensuring smooth transactions. Machines that support multiple payment options can enhance user convenience and encourage sales. -

Service and Maintenance Support

Buyers should consider the availability of service and maintenance support from the manufacturer or supplier. A machine with robust support can minimize downtime and ensure quick repairs, which is essential for maintaining customer satisfaction and operational efficiency.

Common Trade Terms

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify reputable suppliers and ensure they are sourcing high-quality components for their machines. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers to understand, as it can affect their purchasing strategy. High MOQs may require larger upfront investments and inventory management considerations.

Illustrative Image (Source: Google Search)

-

RFQ (Request for Quotation)

An RFQ is a document used to solicit price offers from suppliers for specific products or services. Issuing an RFQ allows buyers to compare prices and terms from multiple vendors, enabling informed decision-making and potentially better pricing. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, particularly regarding shipping and delivery. Familiarity with these terms helps buyers understand their liabilities during transit, including shipping costs, insurance, and customs duties. -

Lead Time

Lead time refers to the duration from placing an order to the delivery of goods. Understanding lead times is essential for inventory management and operational planning, particularly for businesses that rely on timely access to vending machines. -

Warranty and Guarantee

Warranties and guarantees outline the terms under which a manufacturer will repair or replace defective products. Buyers should carefully review these terms to ensure they are protected against manufacturing defects and understand the duration of coverage.

By grasping these essential technical properties and trade terms, international B2B buyers can make well-informed decisions when sourcing stamp vending machines, ultimately enhancing their operational efficiency and customer satisfaction.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the stamp vending machine near me Sector

Market Overview & Key Trends

The stamp vending machine sector is experiencing transformative growth driven by a combination of technological advancements and changing consumer behaviors. Key global drivers include the increasing demand for automation in retail environments and the need for efficient, contactless payment solutions. In regions like Africa and South America, the adoption of mobile payment technologies is reshaping how consumers interact with vending machines, promoting a shift towards integrated solutions that offer both traditional and digital payment methods.

Emerging trends in B2B sourcing highlight the importance of connectivity and data analytics. Smart vending machines equipped with IoT capabilities are enabling operators to monitor inventory levels in real-time, reducing costs associated with stockouts and overstocking. Moreover, machine learning algorithms are being utilized to analyze consumer purchasing patterns, which assists businesses in optimizing product offerings and enhancing customer satisfaction.

For international buyers, particularly from Europe and the Middle East, understanding local market dynamics is crucial. Europe is seeing a push towards sustainability, prompting manufacturers to innovate with eco-friendly designs and materials. In contrast, buyers in the Middle East are focusing on robust machines that can withstand extreme climates, necessitating a thorough evaluation of machine durability and supplier reliability.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a non-negotiable aspect of procurement strategies in the stamp vending machine industry. The environmental impact of manufacturing processes and the materials used in machines is under scrutiny, leading to a demand for sustainable practices throughout the supply chain. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to reducing their carbon footprint through energy-efficient production methods and the use of recycled materials.

Ethical sourcing is also pivotal in enhancing brand reputation. Companies that engage in transparent supply chains and prioritize fair labor practices are more likely to attract conscientious consumers. Certifications such as ISO 14001 for environmental management and Fair Trade for labor standards are becoming essential benchmarks that buyers should consider when evaluating potential suppliers.

Incorporating sustainable practices not only aligns with consumer expectations but can also lead to cost savings in the long run. For instance, energy-efficient vending machines can significantly lower operational costs, while machines made from recyclable materials can reduce waste disposal fees.

Brief Evolution/History

The concept of vending machines dates back to ancient times, but the modern stamp vending machine emerged in the mid-20th century as a response to the growing need for convenience in postal services. Initially, these machines were manually operated, requiring cash payments and physical stamps. Over the years, advancements in technology have transformed these machines into sophisticated, automated systems capable of accepting various payment methods, including credit cards and mobile payments.

Today, stamp vending machines are not only integral to postal services but have also found applications in retail and tourism sectors, reflecting a broader trend towards multifunctional vending solutions. This evolution highlights the importance of adaptability and innovation in meeting the diverse needs of global consumers, particularly in emerging markets.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of stamp vending machine near me

-

What should I consider when vetting suppliers for stamp vending machines?

When vetting suppliers, focus on their industry experience, customer reviews, and certifications. Check their production capacity, quality control processes, and compliance with international standards. Ensure they have a robust supply chain and can provide references from previous clients, especially those in your region. Engage in direct communication to assess responsiveness and willingness to accommodate your specific needs. -

Can I customize the stamp vending machines to fit my business requirements?

Yes, many suppliers offer customization options for stamp vending machines. Discuss your specific requirements, such as size, design, branding, and functionality. Ensure that the supplier has experience with custom orders and can provide examples of previous projects. It’s also important to understand the associated costs and any implications for lead times. -

What are the typical minimum order quantities (MOQ) and lead times for stamp vending machines?

MOQs can vary significantly based on the supplier and the level of customization. Generally, expect MOQs to range from 10 to 50 units for standard models, while custom designs may require higher quantities. Lead times typically range from 4 to 12 weeks, depending on the complexity of the order and the supplier’s production capacity. Always confirm these details before placing an order to avoid unexpected delays. -

What payment terms are usually available for international orders?

Payment terms can vary widely among suppliers. Common arrangements include upfront payments, partial payments, or letters of credit. For international orders, consider using secure payment methods such as PayPal, bank transfers, or escrow services to mitigate risks. Ensure you clarify any currency conversion fees and the impact of international transaction regulations on your payment process. -

What quality assurance certifications should I look for?

Look for suppliers that hold relevant quality assurance certifications, such as ISO 9001 or CE certification for compliance with European standards. These certifications indicate that the supplier adheres to quality management principles and product safety standards. Additionally, inquire about their testing processes to ensure that the machines meet durability and performance benchmarks. -

How should I manage logistics for importing stamp vending machines?

Managing logistics involves understanding shipping methods, customs clearance, and delivery timelines. Choose a reliable freight forwarder experienced in handling machinery imports to ensure smooth transportation. Confirm the shipping costs, insurance options, and any duties or taxes applicable to your country. It’s essential to maintain open communication with the supplier throughout the shipping process to track the shipment. -

What steps should I take if there is a dispute with the supplier?

In the event of a dispute, first attempt to resolve the issue directly with the supplier through clear communication. Document all interactions and agreements. If direct negotiation fails, consult the contract terms regarding dispute resolution, which may include mediation or arbitration clauses. Consider involving a legal professional experienced in international trade to guide you through the process if necessary. -

How can I ensure the stamp vending machines meet my local regulations?

Before placing an order, research your local regulations regarding vending machines, including safety standards and operational permits. Request documentation from the supplier that proves compliance with relevant regulations in your region. Engaging with local authorities or trade associations can also provide guidance on regulatory requirements, ensuring that your machines are compliant upon arrival.

Strategic Sourcing Conclusion and Outlook for stamp vending machine near me

In the evolving landscape of international trade, strategic sourcing remains a crucial element for B2B buyers seeking reliable suppliers for stamp vending machines. By leveraging regional suppliers, buyers can reduce lead times, enhance supply chain resilience, and ensure compliance with local regulations. Understanding the specific needs of your market—whether in Africa, South America, the Middle East, or Europe—can significantly influence purchasing decisions.

Key takeaways for B2B buyers include:

- Local Market Insights: Engage with suppliers who possess a deep understanding of local market dynamics to tailor your offerings effectively.

- Cost Efficiency: Analyze the total cost of ownership, including maintenance and operational expenses, to maximize your investment in vending solutions.

- Technology Integration: Consider vendors who offer advanced technology features, such as digital payment options and real-time inventory tracking, to enhance user experience and operational efficiency.

Looking ahead, the demand for stamp vending machines is set to grow, driven by increased postal services and automation trends. International B2B buyers are encouraged to act now—evaluate potential suppliers, negotiate favorable terms, and invest in innovative solutions that align with future market needs. Embrace strategic sourcing to position your business for success in this competitive landscape.