Your Ultimate Guide to Sourcing Healthy You Vending Machines

Guide to Healthy You Vending Machines

- Introduction: Navigating the Global Market for healthy you vending machines

- Understanding healthy you vending machines Types and Variations

- Key Industrial Applications of healthy you vending machines

- Strategic Material Selection Guide for healthy you vending machines

- In-depth Look: Manufacturing Processes and Quality Assurance for healthy you vending machines

- Comprehensive Cost and Pricing Analysis for healthy you vending machines Sourcing

- Spotlight on Potential healthy you vending machines Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for healthy you vending machines

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the healthy you vending machines Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of healthy you vending machines

- Strategic Sourcing Conclusion and Outlook for healthy you vending machines

Introduction: Navigating the Global Market for healthy you vending machines

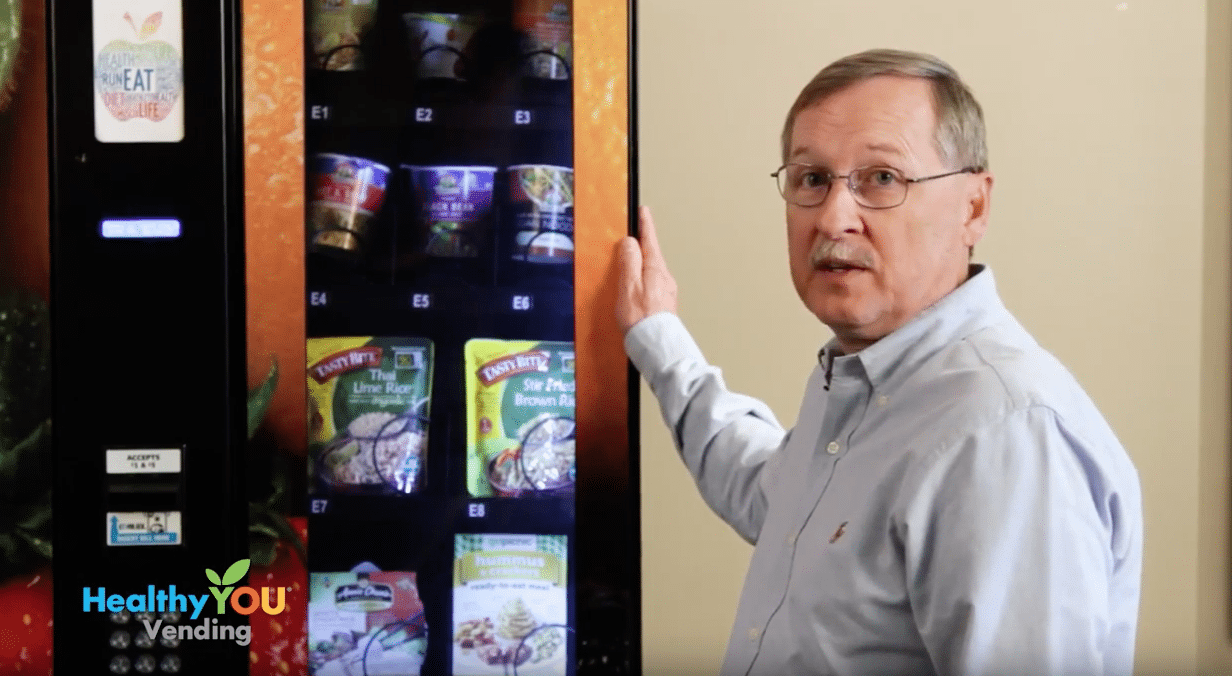

In today’s fast-paced world, the demand for healthier snack options is surging, making Healthy You Vending Machines a strategic investment for businesses aiming to meet consumer needs while capitalizing on market trends. These innovative machines not only provide convenient access to nutritious food choices but also cater to a growing health-conscious demographic across diverse regions, including Africa, South America, the Middle East, and Europe. As the global emphasis on wellness intensifies, incorporating healthy vending solutions into your offerings can set your business apart in competitive markets.

This comprehensive guide serves as an essential resource for international B2B buyers, detailing everything from the types of healthy vending machines available to the materials used in their construction, manufacturing quality control standards, and supplier options. We delve into cost considerations, market insights, and frequently asked questions to ensure you are equipped with the knowledge necessary for informed sourcing decisions.

Understanding the nuances of this burgeoning sector is crucial for success. By exploring the various aspects of Healthy You Vending Machines, this guide empowers you to make strategic choices that align with your business goals, enhance customer satisfaction, and ultimately drive profitability. Whether you’re based in the bustling cities of Europe or the emerging markets of Africa, the insights provided will help you navigate the global landscape effectively, ensuring your investment leads to sustainable growth and success.

Understanding healthy you vending machines Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fresh Food Vending Machines | Refrigerated units offering salads, wraps, and fruits | Gyms, offices, schools | Pros: Healthy options attract health-conscious consumers. Cons: Requires regular restocking and maintenance. |

| Snack & Beverage Machines | Combines healthy snacks and drinks like nuts, juices | Corporate environments, events | Pros: Versatile offerings cater to diverse preferences. Cons: Limited space for variety compared to dedicated machines. |

| Smoothie & Juice Machines | Automated blending machines for fresh smoothies | Gyms, health clubs, cafes | Pros: High demand for fresh beverages; unique selling point. Cons: Higher initial investment and maintenance costs. |

| Nutritional Supplements Machines | Dispenses protein powders, bars, and vitamins | Fitness centers, universities | Pros: Appeals to fitness enthusiasts; niche market. Cons: Requires education on product benefits for effective sales. |

| Meal Replacement Vending | Offers pre-packaged meal options for on-the-go eating | Airports, hospitals, schools | Pros: Convenient for busy consumers; promotes healthy eating. Cons: Perception of being less fresh compared to other options. |

Fresh Food Vending Machines

Fresh food vending machines are designed to offer a variety of nutritious, ready-to-eat meals, such as salads, wraps, and fruits. These machines typically include refrigeration to ensure food safety and quality. Ideal for locations like gyms, offices, and schools, they cater to health-conscious consumers seeking convenient meal options. B2B buyers should consider the need for regular restocking and maintenance, as these machines require consistent supply to meet demand.

Snack & Beverage Machines

These machines combine healthy snacks, such as mixed nuts and granola bars, with beverages like natural juices and flavored water. They are versatile and can fit into various business settings, including corporate offices and event venues. Buyers benefit from the ability to cater to diverse consumer preferences, but they should be aware of the limited space for product variety, which may affect sales potential.

Smoothie & Juice Machines

Automated smoothie and juice machines are increasingly popular in health-focused environments such as gyms and cafes. They provide fresh, blended beverages that appeal to consumers looking for quick, nutritious options. B2B buyers should note that while these machines can attract a loyal customer base, they often require a higher initial investment and ongoing maintenance to ensure consistent operation.

Nutritional Supplements Machines

These machines specialize in dispensing nutritional supplements, including protein powders, energy bars, and vitamins. They are particularly suited for fitness centers and universities, where health and wellness are prioritized. B2B buyers should focus on educating consumers about the benefits of these products to drive sales, while also considering the niche market appeal that may limit broader consumer reach.

Meal Replacement Vending

Meal replacement vending machines provide pre-packaged meals designed for convenience and nutrition. They are well-suited for high-traffic areas such as airports, hospitals, and schools, where consumers seek quick yet healthy eating options. While these machines promote healthy eating habits, buyers should consider the perception of meal quality compared to fresh alternatives, which may influence consumer choices.

Related Video: What are the Different Types of Vending Machines? | Healthy YOU Vending

Key Industrial Applications of healthy you vending machines

| Industry/Sector | Specific Application of healthy you vending machines | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Corporate Offices | Healthy snack and beverage options for employees | Boosts employee productivity and morale | Sourcing local suppliers for fresh, nutritious products |

| Educational Institutions | Providing nutritious snacks for students | Supports health initiatives and improves student focus | Aligning with dietary guidelines and sourcing healthy options |

| Fitness Centers | Onsite healthy meal replacements and snacks | Enhances member satisfaction and retention | Ensuring product variety to cater to diverse dietary needs |

| Healthcare Facilities | Convenient access to healthy snacks for staff and visitors | Promotes wellness and reduces unhealthy eating habits | Compliance with health regulations and sourcing organic options |

| Hospitality Industry | Offering healthy snacks in hotels and resorts | Attracts health-conscious guests and enhances customer experience | Sourcing premium products that align with brand image |

Corporate Offices

In corporate environments, healthy you vending machines serve as a convenient solution for providing nutritious snacks and beverages to employees. By replacing traditional vending options with healthier choices, businesses can enhance employee productivity and morale. This application is particularly relevant in regions like Europe, where workplace wellness is prioritized. International buyers should consider sourcing local suppliers to ensure freshness and cater to regional tastes, which can vary significantly across cultures.

Educational Institutions

Healthy you vending machines can play a vital role in educational settings by offering nutritious snacks to students. This not only aligns with health initiatives aimed at combating childhood obesity but also helps improve student focus and performance. For international buyers in Africa and South America, it’s essential to align product offerings with local dietary guidelines and preferences, ensuring that options are appealing and culturally appropriate. Establishing relationships with suppliers who understand these nuances can enhance the effectiveness of these machines in schools.

Fitness Centers

Fitness centers benefit greatly from healthy you vending machines by providing members with convenient access to meal replacements and snacks that support their health goals. This application helps to improve member satisfaction and retention by aligning with their lifestyle choices. For buyers in the Middle East, where fitness culture is rapidly growing, sourcing a diverse range of products that cater to various dietary needs—such as vegan, gluten-free, and high-protein options—is crucial for success.

Healthcare Facilities

In healthcare settings, healthy you vending machines offer staff and visitors convenient access to nutritious snacks, promoting overall wellness and reducing unhealthy eating habits. This is particularly important in hospitals and clinics, where there is a growing emphasis on preventative health measures. Buyers in Europe should focus on sourcing organic and locally-produced options to comply with health regulations and meet the expectations of health-conscious consumers.

Hospitality Industry

The hospitality sector can leverage healthy you vending machines to cater to health-conscious guests in hotels and resorts. By offering a selection of nutritious snacks, establishments can enhance the overall guest experience and attract a demographic that prioritizes wellness. For international buyers, sourcing premium products that align with the brand’s image is vital, as it reflects the quality and values of the hospitality business. Understanding regional preferences and trends can help tailor the product mix effectively.

Strategic Material Selection Guide for healthy you vending machines

When selecting materials for healthy vending machines, it is crucial to consider properties that directly influence product performance, durability, and safety. Below is an analysis of four common materials used in the construction of healthy vending machines, focusing on their key properties, advantages, disadvantages, and specific considerations for international B2B buyers.

Illustrative Image (Source: Google Search)

Stainless Steel

Key Properties: Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand high temperatures. It typically has a temperature rating of up to 800°F (427°C) and can handle various pressures depending on the grade.

Pros & Cons: The primary advantage of stainless steel is its durability and resistance to rust and stains, making it ideal for environments where hygiene is paramount, such as food vending. However, it can be more expensive than other materials and may require specialized manufacturing processes.

Impact on Application: Stainless steel is compatible with a wide range of media, including various food products and beverages. Its non-porous surface helps maintain product integrity and cleanliness.

Considerations for International Buyers: Compliance with standards such as ASTM A240 for stainless steel is essential. Buyers in regions like Europe and Australia may also need to consider local regulations regarding food safety and material certifications.

Aluminum

Key Properties: Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity. It can withstand temperatures up to 400°F (204°C) and is often used in components requiring lower weight.

Pros & Cons: The main advantage of aluminum is its low weight, which reduces shipping costs and makes installation easier. However, it is less durable than stainless steel and can be prone to dents and scratches.

Impact on Application: Aluminum is suitable for non-corrosive products and can be used in structural components of vending machines. Its thermal properties are beneficial for maintaining optimal temperatures for perishable items.

Considerations for International Buyers: Buyers should ensure compliance with standards like ASTM B221 for aluminum. In regions such as Africa and South America, where environmental conditions may vary, selecting the right alloy is crucial for performance.

Polycarbonate

Key Properties: Polycarbonate is a strong, impact-resistant plastic that can withstand temperatures ranging from -40°F to 240°F (-40°C to 116°C). It also offers good UV resistance.

Pros & Cons: The key advantage of polycarbonate is its lightweight nature and high impact resistance, making it ideal for transparent panels in vending machines. However, it is less heat-resistant than metals and may not be suitable for high-temperature applications.

Impact on Application: Polycarbonate is often used for windows and doors of vending machines, providing visibility while protecting the contents. It is compatible with various products, including snacks and beverages.

Considerations for International Buyers: Compliance with standards such as ASTM D3935 is necessary. Buyers in the Middle East should consider UV resistance due to high sunlight exposure, while European buyers may look for REACH compliance regarding chemical safety.

Glass

Key Properties: Glass is a rigid material that offers excellent clarity and is resistant to chemical corrosion. It can handle temperatures up to 300°F (149°C) but is fragile compared to other materials.

Pros & Cons: The primary advantage of glass is its aesthetic appeal and the ability to showcase products effectively. However, its fragility makes it less suitable for high-traffic environments, and it can be more expensive to replace.

Impact on Application: Glass is typically used for display panels in vending machines, allowing customers to see the products clearly. It is compatible with most food and beverage items but requires careful handling.

Considerations for International Buyers: Buyers must consider local safety standards, such as EN 12150 for tempered glass in Europe. In regions like South America, where breakage might be more common, ensuring robust installation is critical.

Summary Table

| Material | Typical Use Case for healthy you vending machines | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural components, food storage | Excellent durability and corrosion resistance | Higher cost, requires specialized manufacturing | High |

| Aluminum | Structural components, lightweight applications | Lightweight, reduces shipping costs | Less durable, prone to dents | Medium |

| Polycarbonate | Transparent panels, product visibility | Impact-resistant, lightweight | Less heat-resistant | Medium |

| Glass | Display panels for product visibility | Aesthetic appeal, excellent clarity | Fragile, higher replacement costs | High |

This strategic material selection guide provides actionable insights for international B2B buyers, ensuring that they can make informed decisions when sourcing materials for healthy vending machines. Each material’s properties and considerations are tailored to meet diverse regional needs and compliance standards, enhancing operational success in various markets.

In-depth Look: Manufacturing Processes and Quality Assurance for healthy you vending machines

Manufacturing healthy vending machines involves a series of precise processes and stringent quality assurance measures. For international B2B buyers, understanding these stages not only ensures the procurement of high-quality machines but also guarantees compliance with various regulatory standards across different markets. Below, we explore the manufacturing processes, quality control checkpoints, and verification strategies crucial for buyers from Africa, South America, the Middle East, and Europe.

Manufacturing Process Stages

1. Material Preparation

The manufacturing process begins with the selection and preparation of raw materials. This phase involves:

- Material Selection: Choosing high-grade materials that ensure durability and safety. Common materials include stainless steel for the exterior, which resists corrosion, and food-safe plastics for internal components.

- Material Inspection: Conducting quality checks on incoming materials to ensure they meet specified standards and specifications.

- Cutting and Shaping: Using advanced machinery to cut and shape materials according to design specifications. Techniques such as laser cutting and CNC machining are commonly employed for precision.

2. Forming

In this stage, the prepared materials are transformed into the desired shapes and forms:

- Bending and Forming: Techniques like stamping and hydroforming are utilized to create the machine’s body and panels.

- Welding and Joining: Automated welding processes ensure strong joints, particularly in areas subjected to stress. This is critical for maintaining structural integrity.

3. Assembly

Once the components are formed, they are assembled into the final product:

- Component Assembly: This includes the installation of electronic components, refrigeration units, and payment systems. Each component must be carefully integrated to ensure functionality.

- Testing During Assembly: Inline quality checks (IPQC) are performed to verify that each assembly step meets quality standards, reducing the likelihood of defects.

4. Finishing

The final stage involves polishing and preparing the machine for distribution:

- Surface Treatment: Techniques such as powder coating or painting are used to enhance aesthetics and protect against wear and tear.

- Final Inspection: A thorough examination of the completed machine is conducted to ensure all components function correctly and meet safety standards.

Quality Assurance Measures

Quality assurance is vital in the manufacturing of healthy vending machines, as it directly impacts user safety and product reliability. Below are key standards and checkpoints:

Relevant International Standards

- ISO 9001: This standard outlines the criteria for a quality management system, ensuring that organizations consistently meet customer and regulatory requirements.

- CE Marking: Particularly important for the European market, CE marking indicates conformity with health, safety, and environmental protection standards.

- API Standards: For machines that include advanced technology, adherence to API standards ensures operational reliability and safety.

Quality Control Checkpoints

- Incoming Quality Control (IQC): At this stage, raw materials are inspected upon arrival to ensure they meet the required specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process allows for immediate corrections of any deviations from quality standards.

- Final Quality Control (FQC): A comprehensive examination of the finished product ensures that it meets all operational and safety requirements before shipment.

Common Testing Methods

- Functional Testing: Assessing the operational capabilities of the vending machine, including user interface responsiveness and product dispensing mechanisms.

- Electrical Safety Testing: Ensuring that all electrical components comply with safety regulations to prevent hazards.

- Environmental Testing: Evaluating the machine’s performance under various environmental conditions, such as temperature and humidity.

Verification Strategies for B2B Buyers

For international buyers, verifying the quality assurance processes of suppliers is essential. Here are strategies to ensure compliance:

Supplier Audits

Conducting audits of potential suppliers can provide insights into their manufacturing processes and quality control measures. Key areas to assess include:

- Production Facilities: Inspect the cleanliness, organization, and technological advancements in the manufacturing facility.

- Quality Management Systems: Review the supplier’s quality management practices and adherence to international standards.

Quality Assurance Reports

Requesting detailed quality assurance reports from suppliers can help verify their compliance with industry standards. Important elements to review include:

- Inspection Records: Documentation of quality checks performed at various stages of production.

- Test Results: Results from functional and safety testing that confirm the machine’s reliability.

Third-Party Inspections

Engaging third-party inspectors can offer an unbiased assessment of the manufacturing processes and quality control systems. This is particularly valuable for buyers unfamiliar with local compliance standards.

Navigating Certification Nuances

B2B buyers, especially those from diverse regions, must be aware of the nuances in certification requirements. For example:

- Africa: Compliance may vary significantly by country; therefore, understanding local regulations is crucial.

- South America: There may be a focus on environmental certifications, reflecting regional priorities for sustainable practices.

- Middle East: Many countries have specific standards for food safety and machinery, requiring thorough documentation.

- Europe (e.g., Italy): Emphasis on CE marking and compliance with EU directives can complicate importation processes for vending machines.

Conclusion

Understanding the manufacturing processes and quality assurance measures for healthy vending machines is critical for international B2B buyers. By focusing on material selection, assembly techniques, and quality control checkpoints, buyers can ensure they procure reliable, safe, and high-quality machines. Additionally, leveraging verification strategies like supplier audits and third-party inspections can further enhance the procurement process, leading to successful business outcomes in the competitive vending market.

Related Video: Made in China 2.0: Top 10 Factory Processes You Must See

Comprehensive Cost and Pricing Analysis for healthy you vending machines Sourcing

When sourcing healthy vending machines, understanding the comprehensive cost structure and pricing strategy is crucial for B2B buyers, especially those operating in diverse markets like Africa, South America, the Middle East, and Europe. The cost components and price influencers play a significant role in shaping the overall investment and profitability of vending machine operations.

Cost Components

-

Materials: The cost of materials is one of the largest components in the pricing of healthy vending machines. This includes the machine’s chassis, electronic components, and refrigeration systems. Opting for high-quality, sustainable materials may increase upfront costs but can enhance durability and attract eco-conscious consumers.

-

Labor: Labor costs encompass the wages paid to workers involved in manufacturing, assembling, and maintaining the machines. In regions with higher labor costs, this can significantly affect pricing. Conversely, outsourcing manufacturing to countries with lower labor costs can offer savings but may impact quality control.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, rent, and administrative expenses. Buyers should inquire about how these costs are calculated and whether they are variable or fixed.

-

Tooling: Customization of vending machines often requires specific tooling, which can be a significant upfront investment. Customization options can lead to higher costs, but they may be necessary to meet local market demands or branding requirements.

-

Quality Control (QC): Implementing rigorous quality control processes ensures that machines meet safety and performance standards. While this incurs additional costs, it is vital for maintaining brand reputation and customer satisfaction.

-

Logistics: Transportation and shipping costs vary depending on the geographical location of both the supplier and the buyer. Understanding Incoterms is essential, as they dictate who is responsible for shipping costs and risks.

-

Margin: The profit margin expected by the manufacturer or supplier will influence the final price. Buyers should be aware of standard margins in the industry to ensure they are getting a fair deal.

Price Influencers

Several factors can influence the pricing of healthy vending machines:

-

Volume/MOQ (Minimum Order Quantity): Purchasing in larger quantities typically reduces the per-unit cost, making it crucial for buyers to assess their demand accurately.

-

Specifications and Customization: Unique features or specifications can increase costs. Buyers should weigh the benefits of customization against the potential price increase.

-

Material Quality and Certifications: Machines built with certified materials or those that meet specific industry standards may command higher prices, reflecting their quality and reliability.

-

Supplier Factors: The reputation, reliability, and negotiation flexibility of suppliers can significantly influence pricing. Building strong relationships with suppliers may yield better terms.

Buyer Tips

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

-

Negotiation: Always negotiate pricing and terms with suppliers. Leverage competitive offers and establish long-term relationships to secure better deals.

-

Total Cost of Ownership (TCO): Evaluate the total cost, including maintenance, operational expenses, and potential downtime. This approach helps in understanding the long-term financial implications of the investment.

-

Pricing Nuances: Be aware of regional pricing differences due to currency fluctuations, import taxes, and tariffs. Understanding these nuances will help in making informed purchasing decisions.

-

Local Market Research: Conduct thorough research on local consumer preferences and trends. This knowledge can guide product selection and machine placement, ultimately affecting profitability.

Disclaimer

Prices for healthy vending machines can vary widely based on the factors outlined above. Buyers should request detailed quotes and consider all cost components before making purchasing decisions to ensure a sound investment.

Spotlight on Potential healthy you vending machines Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘healthy you vending machines’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for healthy you vending machines

Critical Technical Properties of Healthy You Vending Machines

When sourcing healthy vending machines, understanding their technical specifications is crucial for making informed purchasing decisions. Below are some of the key properties to consider:

-

Material Grade

– This refers to the quality of materials used in the construction of the vending machines, typically stainless steel or high-grade plastics. The choice of material affects the machine’s durability, corrosion resistance, and overall lifespan. For B2B buyers, investing in high-grade materials ensures lower maintenance costs and longer operational periods. -

Temperature Control Range

– Healthy vending machines often require precise temperature controls to maintain the quality of perishable items. A typical range might be between 0°C to 4°C for refrigerated items. Understanding this specification is vital for ensuring that products such as salads and dairy remain fresh, thus reducing waste and enhancing customer satisfaction. -

Power Consumption

– This property indicates how much energy the machine requires to operate. Machines with lower power consumption can significantly reduce operational costs, making them more appealing to businesses focused on sustainability and cost-efficiency. It’s essential to evaluate energy efficiency ratings when selecting machines for long-term profitability. -

Capacity

– The capacity of a vending machine refers to how many items it can hold. This is typically measured in terms of the number of product slots available. Selecting a machine with the right capacity is crucial for meeting demand without overstocking, which can lead to waste. B2B buyers should analyze expected foot traffic and sales volume to determine the appropriate size. -

User Interface

– The interface includes the display and payment systems, which should be user-friendly and accessible. Features like touchscreens or mobile payment options can enhance the customer experience and increase sales. B2B buyers should prioritize machines that offer seamless interaction, as this can differentiate their offerings in competitive markets. -

Warranty and Support

– This encompasses the manufacturer’s warranty and the availability of technical support. A robust warranty can protect your investment against defects and operational issues. It’s important for B2B buyers to consider the terms of service and support options to ensure minimal downtime and efficient troubleshooting.

Common Trade Terminology

Navigating the vending machine industry requires familiarity with specific jargon. Here are some essential terms that international B2B buyers should understand:

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. In vending, an OEM could provide the machine components or entire machines. Understanding OEM relationships is crucial for securing quality products and reliable supply chains. -

MOQ (Minimum Order Quantity)

– MOQ indicates the smallest number of units a supplier is willing to sell. For B2B buyers, knowing the MOQ is essential for budgeting and inventory management. It helps determine how much product to purchase without overextending financial resources. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers to request pricing information for specific products or services. This is a critical step in the procurement process, enabling buyers to compare offers and negotiate better terms, ensuring they get the best value. -

Incoterms (International Commercial Terms)

– Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps B2B buyers understand shipping costs, risks, and logistics responsibilities. -

Lead Time

– This refers to the time it takes from placing an order to receiving the goods. Understanding lead times is vital for inventory management and planning, especially in fast-paced markets. Effective management of lead times can help businesses maintain stock levels and meet customer demand without delays. -

SKU (Stock Keeping Unit)

– An SKU is a unique identifier for each distinct product and service that can be purchased. In vending operations, SKUs help in tracking inventory and sales. For B2B buyers, a well-organized SKU system ensures efficient inventory management and better sales analysis.

By grasping these technical properties and trade terminologies, international B2B buyers can make informed decisions that enhance their vending machine operations and profitability.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the healthy you vending machines Sector

Global drivers are reshaping the landscape of the healthy vending machine sector. An increasing emphasis on health and wellness has led consumers to seek nutritious options, driving demand for healthy vending machines across various markets. This trend is particularly pronounced in urban areas in Africa, South America, the Middle East, and Europe, where busy lifestyles necessitate convenient access to healthier food choices.

Emerging technologies are playing a pivotal role in transforming vending operations. For instance, IoT-enabled machines are providing real-time inventory management and sales data, enabling operators to optimize product offerings based on consumer preferences. Furthermore, cashless payment systems, including mobile wallets and contactless cards, are enhancing the user experience and increasing transaction speeds. International B2B buyers should prioritize partnerships with suppliers that offer advanced technology solutions to stay competitive.

As the market continues to evolve, buyers must remain agile in adapting to changing consumer preferences. The rise of plant-based and organic products is reshaping product assortments, necessitating a close alignment with suppliers who can provide trending and high-demand items. Additionally, sustainability concerns are pushing buyers to consider the environmental impact of their product sourcing strategies.

Sustainability & Ethical Sourcing in B2B

The importance of sustainability in the vending machine sector cannot be overstated. As consumers increasingly prioritize eco-friendly options, international buyers must integrate sustainable practices into their operations. This includes selecting products that are not only healthy but also produced through environmentally responsible methods.

Ethical sourcing plays a critical role in this endeavor. Establishing relationships with suppliers who adhere to fair trade practices and prioritize animal welfare ensures that the products offered in vending machines meet ethical standards. Additionally, buyers should consider sourcing from companies that utilize biodegradable packaging or recyclable materials to minimize environmental impact.

Certifications such as Organic, Fair Trade, and Rainforest Alliance can serve as valuable indicators of a supplier’s commitment to sustainability. By aligning with certified suppliers, B2B buyers can enhance their brand reputation and appeal to a growing segment of environmentally conscious consumers.

Brief Evolution/History

The concept of vending machines dates back to ancient times, but the healthy vending machine niche has gained traction over the past few decades. Initially dominated by traditional snack options, the sector began to evolve in response to rising health awareness in the late 20th century. The introduction of healthier snacks and beverages has transformed vending machines into viable alternatives for nutritious on-the-go options.

Today, the healthy vending machine market is characterized by innovation and adaptability, with operators increasingly focusing on technology and sustainability. This evolution presents a unique opportunity for B2B buyers to tap into a growing market that not only meets consumer demand but also supports global health and environmental goals.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of healthy you vending machines

-

What should I consider when vetting suppliers for healthy vending machines?

When vetting suppliers, prioritize their experience in the vending machine industry, particularly with healthy product offerings. Request references and check their reputation in international markets. Evaluate their compliance with local regulations and quality standards relevant to your region. Additionally, assess their financial stability to ensure they can fulfill orders consistently. Finally, consider their communication practices; a responsive supplier will facilitate smoother transactions and problem resolution. -

Can I customize the products in my healthy vending machines?

Yes, many suppliers offer customization options for healthy vending machines. You can tailor the product selection to meet the preferences of your target market, whether that’s organic snacks, gluten-free options, or protein-rich items. Discuss your specific needs with potential suppliers and ask about their flexibility in product sourcing. Be prepared to provide market research data to support your choices, as this can enhance your partnership and product offering. -

What are the typical minimum order quantities (MOQ) and lead times?

Minimum order quantities can vary significantly by supplier and product type, typically ranging from 50 to 500 units for vending machines. Lead times for delivery may also differ based on the supplier’s location and production capacity, often taking between 4 to 12 weeks. It’s crucial to confirm these details upfront to align your inventory strategy with customer demand and avoid stock shortages. -

How do I ensure quality assurance and certifications for my vending machines?

Request documentation from suppliers regarding their quality assurance processes and any relevant certifications, such as ISO or local health regulations. Ask for third-party test results for the products you intend to stock to verify their nutritional claims. Establish a protocol for regular quality checks and audits of the machines and products to maintain high standards and compliance with health regulations in your region. -

What logistics considerations should I be aware of when importing vending machines?

Logistics for importing vending machines can be complex, involving customs clearance, shipping methods, and delivery timelines. Ensure your supplier has experience with international shipping and can provide a clear outline of the costs involved, including tariffs and taxes. Partnering with a reputable freight forwarder can simplify the process, ensuring timely and safe delivery while navigating the regulations of your importing country. -

How can I handle disputes with suppliers effectively?

Establish clear terms and conditions in your purchase agreement that outline responsibilities, liabilities, and dispute resolution procedures. Open lines of communication are essential; address issues promptly and constructively. If disputes arise, consider mediation or arbitration as less confrontational alternatives to litigation. Document all communications and agreements to support your position should formal proceedings be necessary. -

What payment methods are typically accepted, and are there any risks involved?

Most suppliers accept various payment methods, including bank transfers, credit cards, and letters of credit. Each method carries its own risks; for instance, bank transfers may lack recourse if a supplier defaults. Research the financial practices of your supplier and consider escrow services for large transactions. Establishing trust and a good rapport with your supplier can also mitigate financial risks. -

Are there specific regulations I need to comply with when operating healthy vending machines in my region?

Yes, regulations vary by country and region, often covering health and safety standards, nutritional labeling, and product sourcing. It is essential to familiarize yourself with local laws governing vending operations and food safety. Collaborating with a legal expert or local business consultant can provide insights into compliance requirements, ensuring your vending machines meet all necessary guidelines and operate without legal complications.

Strategic Sourcing Conclusion and Outlook for healthy you vending machines

As you navigate the landscape of healthy vending machines, the importance of strategic sourcing cannot be overstated. By aligning your product offerings with consumer preferences, particularly in health-conscious markets, you can enhance customer satisfaction and drive profitability. Establishing solid relationships with reliable wholesale suppliers is crucial; they not only provide access to trending products but also ensure consistent inventory levels, which is vital for maintaining operational efficiency.

Moreover, understanding your target demographic—whether in bustling urban centers of Europe, emerging markets in Africa, or health-focused communities in South America and the Middle East—will empower you to tailor your product selection effectively. Focus on local tastes and preferences to differentiate your vending machines from competitors.

Looking ahead, the potential for growth in the healthy vending sector is significant. As global demand for convenient, nutritious options rises, now is the time for international B2B buyers to invest in this thriving market. Embrace innovative sourcing strategies and foster strong supplier partnerships to capitalize on this opportunity. Take the next step today—explore new suppliers, refine your inventory, and position your vending business for success in the dynamic landscape of healthy options.

Illustrative Image (Source: Google Search)