Your Ultimate Guide to Sourcing Dixie Narco Vending Machine

Guide to Dixie Narco Vending Machine Parts

- Introduction: Navigating the Global Market for dixie narco vending machine parts

- Understanding dixie narco vending machine parts Types and Variations

- Key Industrial Applications of dixie narco vending machine parts

- Strategic Material Selection Guide for dixie narco vending machine parts

- In-depth Look: Manufacturing Processes and Quality Assurance for dixie narco vending machine parts

- Comprehensive Cost and Pricing Analysis for dixie narco vending machine parts Sourcing

- Spotlight on Potential dixie narco vending machine parts Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for dixie narco vending machine parts

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the dixie narco vending machine parts Sector

- Market Overview & Key Trends

- Sustainability & Ethical Sourcing in B2B

- Brief Evolution/History

- Frequently Asked Questions (FAQs) for B2B Buyers of dixie narco vending machine parts

- Strategic Sourcing Conclusion and Outlook for dixie narco vending machine parts

Introduction: Navigating the Global Market for dixie narco vending machine parts

In today’s fast-paced global marketplace, sourcing quality parts for Dixie Narco vending machines is crucial for businesses looking to optimize their operations and enhance customer satisfaction. These machines are not just points of sale; they represent a significant investment in automation and service delivery. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe (including Nigeria and Brazil) navigate this landscape, understanding the intricacies of vending machine parts becomes essential for maintaining competitive advantage.

This guide offers a comprehensive overview of the Dixie Narco vending machine parts market, covering various aspects such as types of parts available, materials used, manufacturing processes, and quality control measures. We delve into the profiles of reputable suppliers and provide insights into cost structures, enabling buyers to make informed decisions. Additionally, we address frequently asked questions, ensuring that you have the knowledge needed to navigate potential challenges.

Armed with this information, B2B buyers can streamline their sourcing processes, minimize downtime, and ultimately enhance their service offerings. By understanding the market dynamics and supplier landscape, you can ensure that your vending machines are equipped with the best components, driving efficiency and profitability in your operations. This guide is designed to empower you with the insights necessary to make strategic sourcing decisions that align with your business goals.

Understanding dixie narco vending machine parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Coin Mechanisms | Accepts various coins, often adjustable | Vending machines for snacks & drinks | Reliable, easy to replace; may require frequent maintenance for jams. |

| Bill Validators | Accepts paper currency, often multi-denominational | High-end vending machines | Increases sales potential; can be costly to replace and repair. |

| Control Boards | Centralized unit managing machine operations | All types of vending machines | Enables advanced features; can be complex to troubleshoot. |

| Product Dispensing Units | Mechanisms that dispense items upon selection | Snack, beverage, and merchandise machines | Efficient item delivery; may jam or misalign, requiring regular checks. |

| Shelving & Trays | Configurable storage for products | Custom vending solutions | Maximizes space and product visibility; customization may increase costs. |

Coin Mechanisms

Coin mechanisms are vital components of Dixie Narco vending machines, designed to accept a variety of coins. They often feature adjustable settings to accommodate different currencies, making them suitable for international markets. When purchasing, B2B buyers should consider the reliability of the mechanism and the ease of maintenance, as jammed coins can lead to customer dissatisfaction and lost sales. Regular maintenance is essential to ensure optimal performance.

Bill Validators

Bill validators are sophisticated devices that allow vending machines to accept paper currency. These components are crucial for high-end vending operations, especially in markets where cash transactions dominate. While they can significantly increase sales potential by accommodating larger purchases, buyers must be aware of the higher costs associated with their installation and repair. Ensuring compatibility with various currency denominations is also a critical purchasing factor.

Control Boards

Control boards serve as the brain of the vending machine, managing all operational aspects, including payment processing and inventory tracking. They are essential for modern vending machines that incorporate advanced features such as touch screens and remote monitoring. Buyers should evaluate the complexity of the control board, as troubleshooting issues can require specialized knowledge. Additionally, the longevity and compatibility of the control board with other parts are vital considerations.

Product Dispensing Units

These units are responsible for delivering products to customers after selection. They are designed for efficiency and speed, ensuring that items are dispensed without delay. While they enhance the user experience, they can sometimes jam or misalign, necessitating regular checks and maintenance. B2B buyers should assess the durability of the dispensing unit and its ease of integration into existing machines.

Shelving & Trays

Shelving and trays are essential for organizing products within vending machines. They can be customized to fit various product sizes, maximizing space and visibility. For B2B buyers, the ability to customize shelving can lead to increased sales, as well-organized products are more appealing to consumers. However, customization may come with increased costs, so buyers should weigh the benefits against their budget constraints.

Related Video: Dixie Narco 501E & 276E Vending Machine – How To Adjust The Vend Motor For Different Drink Sizes

Key Industrial Applications of dixie narco vending machine parts

| Industry/Sector | Specific Application of dixie narco vending machine parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Beverage and snack dispensing | Increased sales volume and customer satisfaction | Compatibility with local products, reliable supply chain |

| Hospitality | In-room vending solutions for hotels | Enhanced guest experience, reduced staff workload | Durability in high-use environments, aesthetic design |

| Transportation | Vending services at airports and train stations | Convenience for travelers, additional revenue stream | Compliance with safety regulations, ease of maintenance |

| Education | Vending machines in schools and universities | Improved access to snacks and drinks for students | Health regulations compliance, payment options availability |

| Healthcare | Vending solutions for hospitals and clinics | Quick access to refreshments for patients and staff | Hygiene standards, product variety for dietary needs |

In the Retail sector, Dixie Narco vending machine parts are essential for beverage and snack dispensing applications. These machines can significantly increase sales volume, especially in high-traffic areas. International buyers should ensure compatibility with local products and establish a reliable supply chain to avoid stockouts, which can negatively impact customer satisfaction.

Within the Hospitality industry, vending machines equipped with Dixie Narco parts provide in-room solutions for hotels. This application enhances the guest experience by offering a convenient way to access snacks and beverages without requiring staff intervention. Buyers must consider the durability of the parts to withstand high usage and the aesthetic design to match hotel interiors.

In the Transportation sector, vending machines are increasingly deployed at airports and train stations. These machines provide a convenient service for travelers, helping to generate additional revenue streams for transportation hubs. Buyers should prioritize sourcing parts that comply with safety regulations and ensure ease of maintenance to minimize downtime.

The Education sector benefits from vending machines installed in schools and universities. These machines improve access to snacks and drinks for students, promoting healthier eating habits. Buyers need to consider compliance with health regulations and the availability of diverse payment options to cater to a varied student population.

Finally, in Healthcare, vending solutions equipped with Dixie Narco parts serve hospitals and clinics, allowing quick access to refreshments for both patients and staff. This application is vital for maintaining energy levels during long shifts or recovery periods. Buyers in this sector must focus on hygiene standards and ensure that product variety meets dietary needs to enhance patient and staff satisfaction.

Related Video: Dixie-Narco Vending Machine R12 refrigerant recharge To 12a Alternative IT WORKS!

Strategic Material Selection Guide for dixie narco vending machine parts

When selecting materials for Dixie Narco vending machine parts, it is crucial to consider the specific properties, advantages, and limitations of common materials used in their manufacturing. This analysis will focus on four prevalent materials: Stainless Steel, Plastic (Polycarbonate), Aluminum, and Carbon Steel. Each material has distinct characteristics that can impact performance, durability, and overall cost-effectiveness.

Stainless Steel

Key Properties: Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand extreme temperatures. It typically has a temperature rating of up to 800°F (427°C) and can handle high-pressure applications.

Pros & Cons: The primary advantage of stainless steel is its durability and longevity, making it ideal for components exposed to moisture or corrosive environments. However, it is more expensive than other materials and can be challenging to machine, which may increase manufacturing complexity.

Impact on Application: Stainless steel is particularly suitable for parts that interact with various beverages and food products, ensuring hygiene and safety. Its resistance to corrosion makes it an excellent choice for vending machines in humid climates.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM A240 for stainless steel. It’s also vital to consider local regulations regarding food safety and material certifications.

Plastic (Polycarbonate)

Key Properties: Polycarbonate is a lightweight, impact-resistant thermoplastic that can withstand temperatures up to 250°F (121°C). It offers good clarity and is often used in transparent applications.

Pros & Cons: The main advantage of polycarbonate is its low cost and ease of manufacturing, allowing for complex shapes and designs. However, it is less durable than metals and can be susceptible to scratching and UV degradation.

Impact on Application: Polycarbonate is ideal for components such as display windows and push buttons where visibility and impact resistance are crucial. However, it may not be suitable for parts exposed to high temperatures or heavy loads.

Considerations for International Buyers: Buyers should verify that the polycarbonate used complies with relevant standards, such as ISO 11607 for packaging materials. Additionally, understanding local recycling regulations is important for sustainability.

Aluminum

Key Properties: Aluminum is lightweight, corrosion-resistant, and has a good strength-to-weight ratio. It can withstand temperatures up to 400°F (204°C) and is often used in structural applications.

Pros & Cons: One of the key advantages of aluminum is its excellent machinability and lower cost compared to stainless steel. However, it is less durable under extreme conditions and may not be suitable for high-pressure applications.

Impact on Application: Aluminum is commonly used for structural components and frames in vending machines. Its lightweight nature aids in reducing shipping costs and ease of installation.

Considerations for International Buyers: Compliance with standards such as ASTM B221 for aluminum alloys is essential. Buyers should also consider the local availability of aluminum, as sourcing can vary significantly by region.

Carbon Steel

Key Properties: Carbon steel is known for its high tensile strength and durability, with a temperature rating of up to 600°F (316°C). It is less corrosion-resistant than stainless steel but can be treated for improved performance.

Pros & Cons: The primary advantage of carbon steel is its cost-effectiveness and strength, making it suitable for heavy-duty components. However, it is prone to rusting and requires protective coatings to enhance its lifespan.

Impact on Application: Carbon steel is often used for structural components that do not come into contact with moisture or corrosive substances. Its strength makes it suitable for load-bearing parts.

Considerations for International Buyers: Buyers should ensure that carbon steel components meet standards such as ASTM A36. Additionally, understanding local environmental regulations regarding coatings and finishes is critical.

Summary Table

| Material | Typical Use Case for dixie narco vending machine parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Components exposed to moisture and food products | Excellent corrosion resistance | Higher cost and machining complexity | High |

| Plastic (Polycarbonate) | Display windows and push buttons | Low cost and easy to manufacture | Less durable and UV susceptible | Low |

| Aluminum | Structural components and frames | Lightweight and good machinability | Less durable under extreme conditions | Medium |

| Carbon Steel | Heavy-duty structural components | Cost-effective and strong | Prone to rust without protective coatings | Low |

This guide provides international B2B buyers with essential insights into material selection for Dixie Narco vending machine parts, ensuring informed decisions that align with regional standards and application requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for dixie narco vending machine parts

The manufacturing of Dixie Narco vending machine parts involves several critical stages, each integral to ensuring the final product meets quality and performance standards. Understanding these processes can help international B2B buyers make informed purchasing decisions.

Manufacturing Process Overview

-

Material Preparation

– Selection of Raw Materials: The process begins with the selection of high-quality raw materials, typically including metals (such as steel and aluminum), plastics, and electronic components. Suppliers must ensure that materials meet industry specifications to enhance durability and functionality.

– Material Testing: Before production, raw materials undergo rigorous testing for strength, resistance to wear, and compatibility with other components. This step ensures that only materials that meet the required standards are used in production. -

Forming

– Machining and Fabrication: The prepared materials are cut, shaped, and assembled using various techniques such as CNC machining, stamping, and injection molding. Precision in this stage is crucial as it determines the fit and function of each part.

– Welding and Joining: For metal components, welding techniques like MIG (Metal Inert Gas) or TIG (Tungsten Inert Gas) are employed to join parts securely. This ensures structural integrity and longevity of the vending machines. -

Assembly

– Component Integration: Parts are assembled in a systematic manner, often following a predefined layout to facilitate efficiency. This includes integrating electrical components, display units, and mechanical systems.

– Automation: Many manufacturers utilize automated assembly lines to enhance consistency and reduce human error. Robotics can be employed for tasks such as part placement and fastening. -

Finishing

– Surface Treatment: After assembly, parts undergo finishing processes such as powder coating or anodizing. These treatments not only enhance aesthetics but also provide protection against corrosion and wear.

– Final Inspection: Completed assemblies are subjected to a final inspection to ensure they meet design specifications and quality standards before being packaged for shipment.

Quality Assurance Protocols

Quality assurance is a critical aspect of the manufacturing process, particularly in industries where safety and reliability are paramount. Here are the key elements relevant to Dixie Narco vending machine parts:

-

International Standards

– ISO 9001: This international standard specifies requirements for a quality management system (QMS). Manufacturers should be certified to ISO 9001 to ensure they consistently produce products that meet customer and regulatory requirements.

– CE Marking: For companies exporting to Europe, CE marking indicates compliance with EU safety, health, and environmental protection standards. It is essential for ensuring that the vending machine parts can be legally sold in European markets. -

Industry-Specific Standards

– API Standards: If parts are used in environments where they may be exposed to harsh conditions, compliance with American Petroleum Institute (API) standards may be necessary, particularly for components that interact with fluids. -

Quality Control Checkpoints

– Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival to ensure they meet specified standards. Any non-conforming materials are rejected.

– In-Process Quality Control (IPQC): During the manufacturing process, regular checks are performed to monitor production quality. This includes measuring dimensions, checking assembly accuracy, and assessing any potential defects.

– Final Quality Control (FQC): This final inspection involves a thorough evaluation of the completed parts to ensure they meet all specifications and are free from defects. Testing may include functional tests, stress tests, and visual inspections. -

Common Testing Methods

– Functional Testing: Ensures that the vending machine parts perform as intended under operational conditions.

– Durability Testing: Simulates long-term use to identify potential weaknesses in materials or design.

Verifying Supplier Quality Control

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, ensuring supplier quality is paramount. Here are actionable insights:

-

Supplier Audits: Conducting audits of potential suppliers can provide insight into their manufacturing processes and quality control systems. Buyers should request to see documentation of their quality management certifications, including ISO 9001 and CE markings.

-

Quality Reports: Request regular quality reports that detail the results of IQC, IPQC, and FQC. This transparency can help build trust and ensure that quality standards are consistently met.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the manufacturing processes and product quality. This is especially beneficial when dealing with suppliers in different geographical regions, where local standards may vary.

-

Understanding QC/CERT Nuances: International buyers should be aware of the specific quality certifications and standards applicable in their regions. For instance, while CE marking is crucial in Europe, other regions may have different regulatory requirements. Familiarizing oneself with these nuances can prevent compliance issues and enhance market entry strategies.

Conclusion

A thorough understanding of the manufacturing processes and quality assurance protocols for Dixie Narco vending machine parts is essential for international B2B buyers. By focusing on supplier quality, adhering to international standards, and implementing rigorous verification methods, buyers can ensure they procure reliable and durable products that meet their operational needs. This proactive approach will ultimately lead to improved customer satisfaction and business success.

Related Video: How a soda machine works – Dixie Narco vending machine

Comprehensive Cost and Pricing Analysis for dixie narco vending machine parts Sourcing

When sourcing Dixie Narco vending machine parts, understanding the comprehensive cost structure and pricing nuances is crucial for international B2B buyers. Here’s an in-depth analysis of the cost components and pricing factors that can influence your purchasing decisions.

Cost Components

-

Materials: The primary cost driver in manufacturing vending machine parts is the raw materials used. These can include metals, plastics, and electronic components. Prices can fluctuate based on global demand and supply, so it’s essential to consider sourcing materials from reliable suppliers who can provide consistent quality.

-

Labor: Labor costs can vary significantly depending on the region of production. Countries with lower labor costs may offer more competitive pricing, but it’s vital to balance this with the quality of workmanship. Skilled labor may command higher wages but can lead to better product quality and fewer defects.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and indirect labor. Efficient manufacturing processes can help reduce overhead costs, which can be passed on to buyers in the form of lower prices.

-

Tooling: Custom tooling for specific parts can be a significant initial investment. However, when producing larger volumes, the cost per unit decreases as the tooling costs are amortized over more units. Always inquire about tooling costs and how they will affect pricing, especially if you have custom specifications.

-

Quality Control (QC): Implementing stringent QC processes ensures that parts meet specified standards. While this may increase initial costs, it can save money in the long run by reducing returns and replacements. Look for suppliers with certifications that demonstrate their commitment to quality.

-

Logistics: Shipping and handling costs can vary greatly depending on the origin of the parts and the destination. Factors such as shipping methods, distance, and customs duties should be factored into the total cost. Incoterms (International Commercial Terms) will also play a role in determining who is responsible for shipping costs and risks.

-

Margin: Suppliers will typically add a profit margin to their costs. Understanding the typical margins in the industry can help buyers negotiate better terms. Be aware that margins may be higher for specialty parts or low-volume orders.

Price Influencers

Several factors can influence the final price of vending machine parts:

-

Volume/MOQ: Higher order volumes typically lead to lower per-unit costs. Suppliers may offer discounts for bulk purchases, so consider your long-term needs when negotiating.

-

Specifications/Customization: Custom parts may incur additional costs for design and production. Be clear about your requirements upfront to avoid unexpected expenses.

-

Quality/Certifications: Parts that meet industry standards or come with specific certifications may be priced higher but can offer peace of mind regarding quality.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a track record of quality may charge more, but they can also minimize risks associated with poor-quality parts.

-

Incoterms: Understanding the agreed terms of delivery can help avoid additional costs. For instance, choosing DDP (Delivered Duty Paid) can simplify logistics but may come at a higher price.

Buyer Tips

-

Negotiation: Always be prepared to negotiate terms and pricing. Leverage multiple quotes from suppliers to establish a competitive edge.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes purchase price, maintenance, and operational costs. Sometimes, a higher upfront cost can lead to lower overall expenses.

-

Pricing Nuances: International buyers should account for currency fluctuations, tariffs, and local taxes when evaluating prices.

-

Research Suppliers: Investigate potential suppliers thoroughly. Look for reviews, industry reputation, and any certifications that can assure quality and reliability.

-

Plan for Contingencies: Always have a backup supplier to mitigate risks associated with production delays or quality issues.

Disclaimer

The prices mentioned herein are indicative and can vary based on market conditions, supplier negotiations, and specific order requirements. Always consult with suppliers for the most accurate and updated pricing information.

Spotlight on Potential dixie narco vending machine parts Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘dixie narco vending machine parts’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for dixie narco vending machine parts

When sourcing Dixie Narco vending machine parts, understanding essential technical properties and trade terminology is crucial for making informed purchasing decisions. Below, we outline key specifications and industry terms that will enhance your procurement strategy.

Key Technical Properties

- Material Grade

– Definition: This refers to the quality and type of materials used in manufacturing parts, such as plastic, metal, or rubber.

– Importance: Selecting the correct material grade is vital for durability and performance. Higher-grade materials can withstand environmental stressors, which is particularly important in regions with extreme weather conditions.

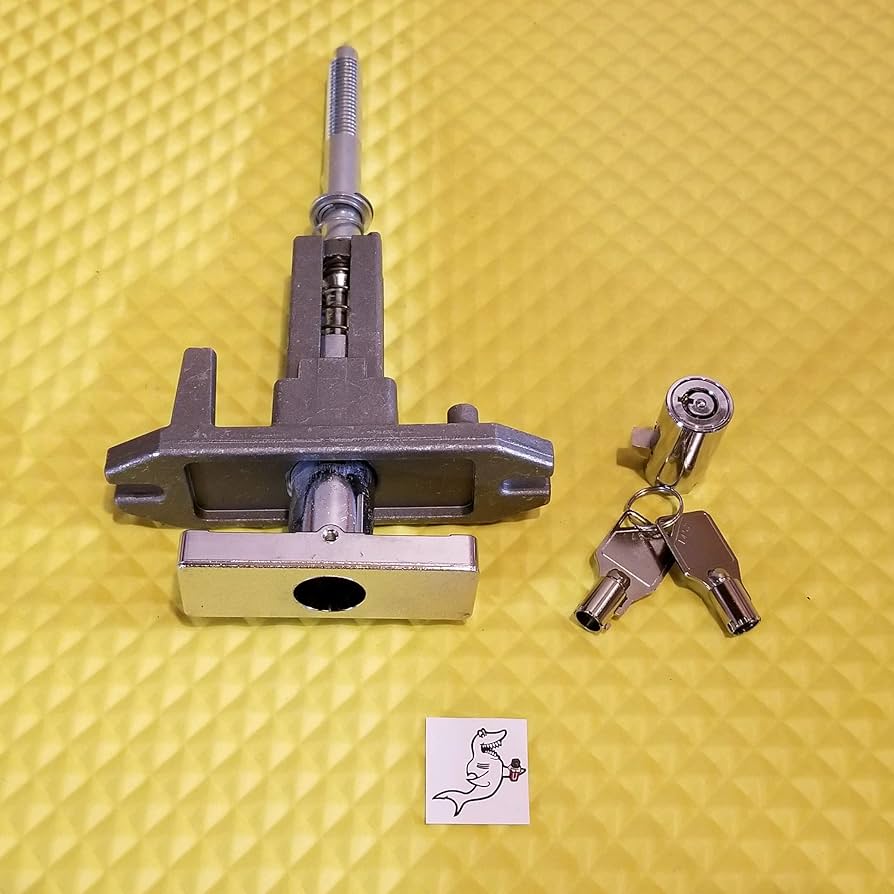

Illustrative Image (Source: Google Search)

-

Tolerance

– Definition: Tolerance indicates the permissible limit of variation in a part’s dimensions.

– Importance: Accurate tolerances ensure that parts fit correctly and function as intended. In vending machines, improper tolerances can lead to mechanical failures or jams, affecting customer satisfaction and operational efficiency. -

Voltage Rating

– Definition: This specification defines the maximum electrical voltage that components can safely handle.

– Importance: Matching voltage ratings to your local power supply is essential to avoid electrical failures. Understanding this property is critical for international buyers, as voltage standards differ by region. -

Compatibility

– Definition: This property assesses whether a part is designed to work seamlessly with existing vending machine models.

– Importance: Ensuring compatibility minimizes installation issues and reduces downtime. This is particularly relevant for businesses in Africa and South America, where part availability may vary. -

Finish

– Definition: The finish refers to the surface treatment of a part, which can affect aesthetics and functionality.

– Importance: A good finish can prevent corrosion and enhance the visual appeal of vending machines, making them more attractive to customers. This is particularly important in competitive markets. -

Load Capacity

– Definition: This indicates the maximum weight or volume of products that the vending machine part can support.

– Importance: Knowing the load capacity is critical for optimizing inventory and ensuring that machines operate effectively without risk of damage.

Common Trade Terms

-

OEM (Original Equipment Manufacturer)

– Definition: Refers to companies that produce parts that are used in the assembly of a vending machine.

– Usage: When sourcing parts, opting for OEM components can ensure higher reliability and compatibility, as these parts are designed specifically for the machine models. -

MOQ (Minimum Order Quantity)

– Definition: The smallest number of units that a supplier is willing to sell.

– Usage: Understanding MOQ is essential for budgeting and inventory management. Buyers should negotiate favorable terms that align with their purchase volume and storage capacity. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers to request pricing and terms for specific parts.

– Usage: An effective RFQ can streamline the procurement process, allowing buyers to compare prices and terms from multiple suppliers, facilitating better negotiation. -

Incoterms

– Definition: International commercial terms that define the responsibilities of buyers and sellers in international transactions.

– Usage: Familiarity with Incoterms helps in understanding shipping responsibilities, risk management, and cost allocation, which is crucial for international buyers, particularly in diverse markets like Africa and the Middle East. -

Lead Time

– Definition: The time taken from placing an order to receiving the goods.

– Usage: Knowing the lead time helps businesses plan their inventory and avoid stockouts. It is especially critical in regions where delays may occur due to logistics challenges. -

Warranty

– Definition: A guarantee from the manufacturer regarding the condition of the parts and their functionality over a specified period.

– Usage: Understanding warranty terms can protect buyers from defects and ensure that they receive quality products. This is particularly important for establishing long-term supplier relationships.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing Dixie Narco vending machine parts, ultimately leading to better operational efficiency and customer satisfaction.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the dixie narco vending machine parts Sector

Market Overview & Key Trends

The dixie narco vending machine parts sector is experiencing significant transformation driven by technological advancements and evolving consumer preferences. Globally, the demand for vending machines has surged, particularly in urban areas across Africa, South America, the Middle East, and Europe. Factors such as increased urbanization, a growing middle class, and the rise of cashless transactions are propelling this growth. International B2B buyers should note that the integration of IoT (Internet of Things) technology in vending machines is becoming a key trend, enhancing operational efficiency and providing real-time data analytics for inventory management.

Emerging trends also include the customization of vending machines to cater to local tastes and preferences, particularly in diverse markets like Nigeria and Brazil. Buyers should be aware of the shift towards more automated and user-friendly interfaces, which are crucial for attracting tech-savvy consumers. Additionally, the market is witnessing a rise in hybrid vending machines that offer a combination of traditional and modern payment methods, including mobile payments and cryptocurrencies, catering to a broader audience.

In terms of sourcing, there is a notable shift towards global supply chains that leverage both local and international suppliers. This shift not only reduces lead times but also enhances responsiveness to market changes. Buyers should consider suppliers that can provide integrated solutions, including parts, maintenance, and technical support, ensuring a comprehensive service offering.

Sustainability & Ethical Sourcing in B2B

The importance of sustainability in the dixie narco vending machine parts sector cannot be overstated. Environmental concerns are prompting B2B buyers to prioritize suppliers that demonstrate a commitment to sustainable practices. This includes using recyclable materials in the manufacturing of vending machine parts and implementing energy-efficient technologies that reduce the carbon footprint.

Ethical sourcing has become a critical factor for international buyers, particularly in markets where consumers are increasingly conscious of corporate social responsibility. Companies that can provide ‘green’ certifications and demonstrate compliance with environmental regulations are more likely to gain favor with discerning buyers. Furthermore, adopting a transparent supply chain can enhance brand reputation and foster trust among consumers.

Buyers should actively seek suppliers who utilize sustainable materials and offer products designed for longevity and repairability. This approach not only minimizes waste but also aligns with the global push towards a circular economy, where the focus is on reducing, reusing, and recycling materials.

Brief Evolution/History

The dixie narco vending machine parts sector has evolved significantly since its inception in the mid-20th century. Initially dominated by mechanical vending solutions, the industry has transitioned to more sophisticated electronic systems. This evolution has been marked by the introduction of digital payment systems and smart vending technologies, which have transformed consumer interactions with vending machines.

As global trends shift towards automation and sustainability, the sector continues to adapt, integrating innovative technologies and sustainable practices into its operations. This historical context is essential for B2B buyers, as it highlights the sector’s resilience and its capacity for ongoing transformation in response to market demands. Buyers should leverage this knowledge to make informed sourcing decisions that align with current trends and future innovations.

Related Video: Dixie Narco DN3800-4 Glass Front Vending Machine @East Las Vegas Community Center, Las Vegas, NV USA

Frequently Asked Questions (FAQs) for B2B Buyers of dixie narco vending machine parts

-

How can I effectively vet suppliers for Dixie Narco vending machine parts?

Vetting suppliers is crucial for ensuring quality and reliability. Start by checking for certifications relevant to the vending industry, such as ISO or CE markings. Request references from other international clients, particularly those in your region, to assess their experience. Additionally, consider visiting the supplier’s facility, if feasible, or utilizing third-party inspection services. Online reviews and industry forums can also provide insights into a supplier’s reputation. -

Are customization options available for vending machine parts?

Yes, many suppliers offer customization options for Dixie Narco vending machine parts to meet specific requirements. It’s essential to communicate your needs clearly, including dimensions, materials, and any specific features you require. Discussing customization during the initial negotiations can help avoid delays later. Be prepared to provide technical drawings or specifications, and inquire about additional costs associated with custom designs. -

What are the typical minimum order quantities (MOQ) and lead times?

Minimum order quantities can vary significantly among suppliers, typically ranging from 50 to 500 units, depending on the part and the supplier’s capabilities. Lead times also vary, often between 4 to 12 weeks, influenced by factors such as customization and shipping logistics. Always clarify these details during negotiations to ensure they align with your business needs and project timelines. -

What payment terms should I expect when sourcing from international suppliers?

Payment terms can vary widely; however, many suppliers may request a deposit of 30-50% upfront, with the balance due upon shipment or delivery. Consider using secure payment methods like letters of credit or escrow services to mitigate risk. Additionally, be aware of currency fluctuations and potential transaction fees that may affect the overall cost.

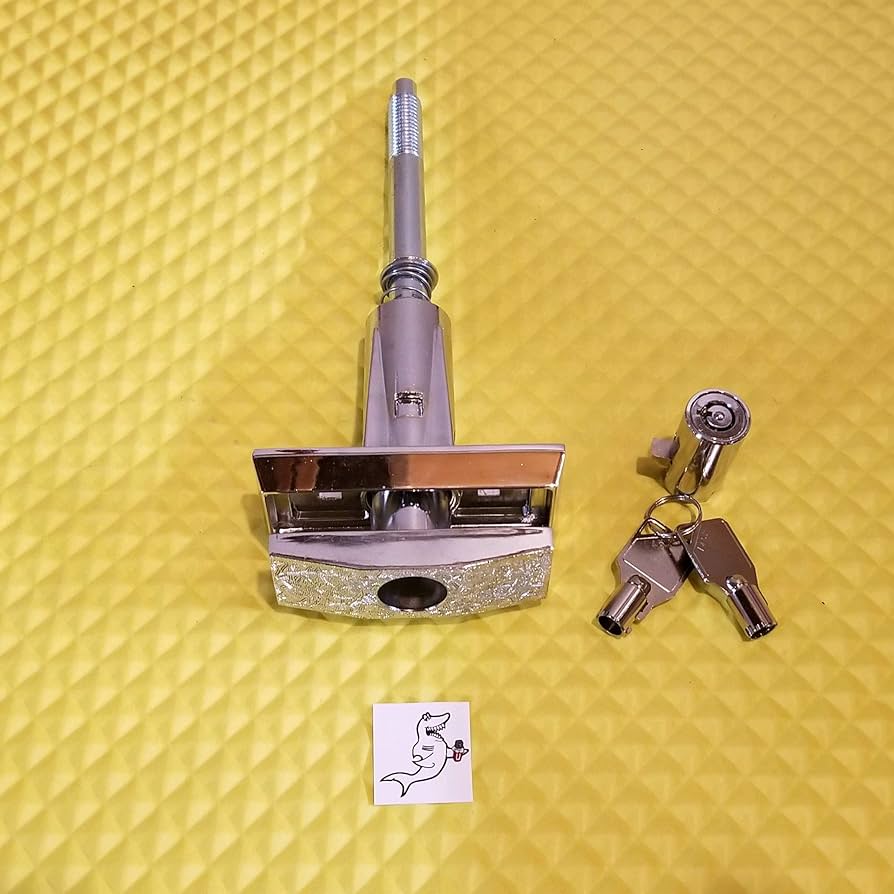

Illustrative Image (Source: Google Search)

-

How can I ensure quality assurance and certifications for parts?

Requesting quality assurance documentation is vital when sourcing vending machine parts. This includes certificates of conformity, inspection reports, and details on the manufacturing process. It’s advisable to ask suppliers about their quality control processes, including testing procedures for durability and functionality. Establishing clear quality standards in your contract can help enforce compliance. -

What logistics considerations should I keep in mind for international shipping?

Logistics play a significant role in international trade. Ensure that your supplier has experience with international shipping and understands the regulations applicable to your country. Discuss shipping methods (air vs. sea), insurance options, and customs clearance processes. It’s also wise to consider potential delays due to customs or geopolitical issues, and plan for contingencies in your supply chain. -

How can I handle disputes with international suppliers?

Disputes can arise from misunderstandings or unmet expectations. To mitigate this risk, establish clear contracts that outline terms, responsibilities, and dispute resolution processes. If a dispute occurs, begin with open communication to resolve the issue amicably. If necessary, consider mediation or arbitration as alternatives to litigation, especially in cross-border contexts, to save time and costs. -

What are the best practices for maintaining long-term relationships with suppliers?

Building long-term relationships with suppliers can lead to better pricing, priority service, and improved collaboration. Regular communication is key; keep them updated on your business needs and future projects. Providing feedback on product quality and service can help them understand your expectations. Additionally, consider engaging in joint development projects or exclusive agreements to strengthen the partnership and ensure mutual growth.

Strategic Sourcing Conclusion and Outlook for dixie narco vending machine parts

In conclusion, strategic sourcing for Dixie Narco vending machine parts is not just about acquiring components; it’s about building lasting partnerships that enhance operational efficiency and reduce costs. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should prioritize suppliers who offer quality assurance, timely delivery, and robust support services.

Key Takeaways:

- Quality Control: Ensure that parts meet industry standards to minimize downtime and maintenance costs.

- Supplier Relationships: Foster strong relationships with suppliers for better negotiation power and insights into market trends.

- Local vs. Global Sourcing: Consider the benefits of local sourcing to reduce lead times and support regional economies while balancing the advantages of global suppliers for specialized parts.

Looking ahead, the demand for vending machine parts is expected to grow, driven by advancements in technology and consumer preferences. This presents a unique opportunity for B2B buyers to leverage strategic sourcing as a competitive advantage. Engage with suppliers now to secure the best deals and innovations, ensuring your vending operations remain efficient and profitable in the evolving marketplace.