Your Ultimate Guide to Sourcing Antique Candy Vending

Guide to Antique Candy Vending Machine

- Introduction: Navigating the Global Market for antique candy vending machine

- Understanding antique candy vending machine Types and Variations

- Key Industrial Applications of antique candy vending machine

- Strategic Material Selection Guide for antique candy vending machine

- In-depth Look: Manufacturing Processes and Quality Assurance for antique candy vending machine

- Comprehensive Cost and Pricing Analysis for antique candy vending machine Sourcing

- Spotlight on Potential antique candy vending machine Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for antique candy vending machine

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the antique candy vending machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of antique candy vending machine

- Strategic Sourcing Conclusion and Outlook for antique candy vending machine

Introduction: Navigating the Global Market for antique candy vending machine

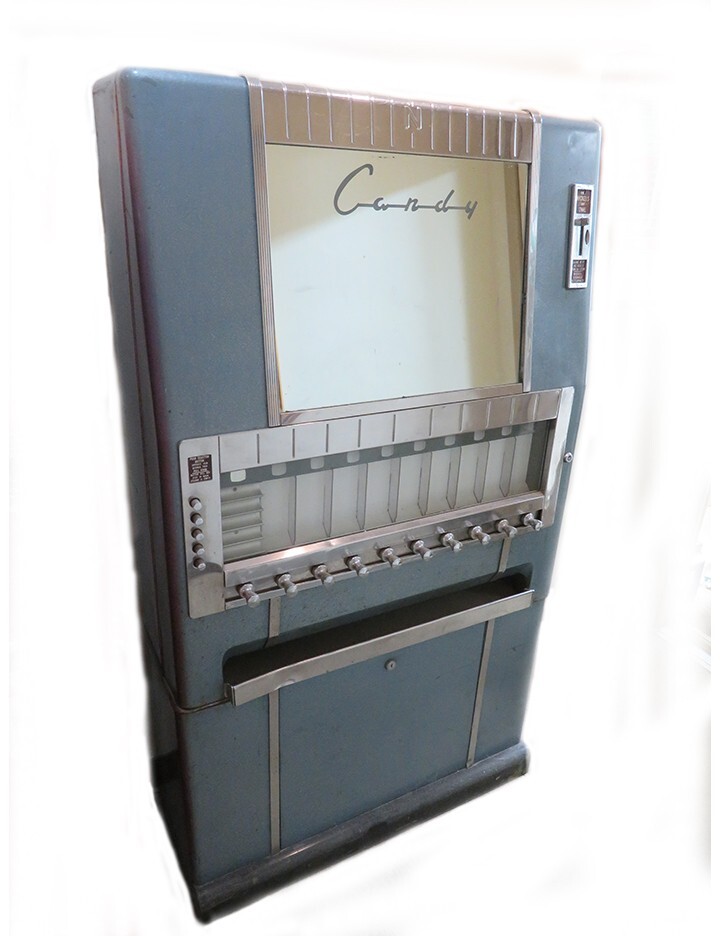

As the nostalgia for vintage aesthetics permeates modern consumer culture, the antique candy vending machine has emerged as a compelling investment for businesses looking to attract diverse clientele. These charming machines not only serve as unique decorative pieces but also offer a nostalgic experience that can enhance customer engagement in various settings, from cafes and restaurants to amusement parks and retail spaces. For international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of the antique candy vending machine market is crucial for informed purchasing decisions.

This comprehensive guide delves into the multifaceted world of antique candy vending machines. It covers essential topics such as the different types available, the materials used in their construction, and the manufacturing and quality control processes that ensure durability and functionality. Additionally, we provide insights into sourcing reliable suppliers, evaluating costs, and understanding market trends that can influence purchasing strategies.

Equipped with this knowledge, B2B buyers will be empowered to make confident decisions that align with their business goals. By navigating this guide, you will gain valuable insights that not only enhance your procurement strategies but also position your business to capitalize on the growing demand for vintage and unique consumer experiences.

Understanding antique candy vending machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Gumball Machines | Typically transparent, round, and operated by a simple mechanism | Retail stores, arcades, and amusement parks | Pros: High visibility, easy to operate; Cons: Limited product range. |

| Peanut Machines | Often metal, designed for dispensing peanuts or other similar snacks | Bars, pubs, and sporting events | Pros: Durable, nostalgic appeal; Cons: Limited to specific products. |

| Candy Carousel Machines | Multi-tiered design allowing for various types of candy | Shopping malls, fairs, and festivals | Pros: Attractively displays a range of products; Cons: Higher initial investment. |

| Novelty Vending Machines | Themed machines often featuring unique candy selections | Specialty shops and event venues | Pros: Engaging designs attract customers; Cons: Maintenance can be complex. |

| Classic Coin-Operated Machines | Vintage style with a mechanical coin mechanism | Collectors, antique shops | Pros: Unique aesthetic appeal; Cons: May require frequent repairs. |

Gumball Machines

Gumball machines are among the most recognizable types of antique candy vending machines. Their transparent design allows customers to see the colorful gumballs inside, making them visually appealing. These machines are commonly used in retail stores, arcades, and amusement parks, where foot traffic is high. For B2B buyers, the simplicity of operation and low maintenance make them an attractive option. However, their limited product range may not cater to all consumer preferences.

Peanut Machines

Peanut machines are typically constructed from metal and are designed to dispense peanuts or similar snacks. They are often found in bars, pubs, and during sporting events, where they serve as a nostalgic reminder of simpler times. For businesses, these machines offer durability and a classic aesthetic that can enhance the ambiance of a venue. However, their product offerings are restricted, which may limit their appeal in diverse consumer markets.

Candy Carousel Machines

These multi-tiered vending machines allow for a variety of candy types to be displayed and dispensed. Commonly seen in shopping malls, fairs, and festivals, candy carousel machines not only attract customers with their colorful displays but also maximize product visibility. For B2B buyers, the initial investment might be higher, but the potential for increased sales from a diverse product offering can justify the cost.

Novelty Vending Machines

Novelty vending machines often feature themed designs and unique candy selections, making them popular in specialty shops and event venues. Their engaging designs can attract customers and provide a memorable experience, which is essential for businesses looking to differentiate themselves in a competitive market. However, the complexity of maintenance and potential for niche market appeal can pose challenges for buyers.

Classic Coin-Operated Machines

These vintage machines embody a nostalgic charm that appeals to collectors and antique shops. They feature mechanical coin mechanisms and are often sought after for their unique aesthetic. While they can enhance the ambiance of a space, B2B buyers should consider that these machines may require more frequent repairs compared to modern alternatives. The appeal lies in their uniqueness, but potential buyers should be prepared for the upkeep involved.

Related Video: Machine Learning in 2024 – Beginner’s Course

Key Industrial Applications of antique candy vending machine

| Industry/Sector | Specific Application of antique candy vending machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Unique in-store display for specialty shops | Attracts customers, enhances shopping experience | Authenticity, condition, and maintenance requirements |

| Hospitality | Nostalgic decor in cafes and restaurants | Creates a themed atmosphere, encourages customer engagement | Space requirements, aesthetic compatibility, and product sourcing |

| Event Planning | Rental for themed parties or events | Offers a unique attraction, boosts event experience | Logistics for delivery, setup, and maintenance |

| Educational Institutions | Educational tool in museums or schools | Teaches history of vending machines and candy making | Safety regulations, educational value, and durability |

| Marketing & Promotions | Branded candy vending for promotional events | Increases brand visibility and customer interaction | Customization options, branding compatibility, and sourcing of products |

Antique candy vending machines serve as a unique marketing tool in the retail sector, especially for specialty shops and boutiques. These machines can be used as eye-catching displays that not only attract customers but also enhance their shopping experience. Buyers in this sector should consider the authenticity and condition of the machines, as well as maintenance requirements to ensure longevity and functionality.

In the hospitality industry, antique candy vending machines can be integrated into cafes and restaurants to create a nostalgic decor that resonates with customers. This thematic approach encourages customer engagement and can enhance the overall dining experience. When sourcing these machines, businesses should assess space requirements and aesthetic compatibility to ensure a seamless integration into their existing decor.

For event planning, renting antique candy vending machines for themed parties or events can be an excellent way to offer a unique attraction. These machines not only serve candy but also contribute to the event’s overall ambiance, making it memorable for attendees. Key considerations for international buyers include logistics for delivery and setup, as well as ongoing maintenance during the event.

In educational institutions, antique candy vending machines can be used as educational tools in museums or schools to teach students about the history of vending machines and candy making. This application provides a hands-on learning experience that can engage students in a fun way. Buyers should ensure compliance with safety regulations and assess the educational value and durability of the machines.

Finally, in marketing and promotions, businesses can utilize branded antique candy vending machines at promotional events to increase brand visibility and customer interaction. These machines can be customized to reflect the brand’s identity, making them a valuable asset during marketing campaigns. Buyers should explore customization options, branding compatibility, and the sourcing of candy products to maximize the impact of their promotional efforts.

Related Video: How to Make Candy Vending Machine at Home | DIY Candy Dispenser

Strategic Material Selection Guide for antique candy vending machine

When selecting materials for antique candy vending machines, it is crucial to consider the properties, advantages, disadvantages, and specific applications of various materials. This guide analyzes four common materials used in the construction of these machines, providing actionable insights for international B2B buyers.

1. Cast Iron

Key Properties:

Cast iron is known for its excellent strength and durability. It can withstand high temperatures and pressures, making it suitable for various environments. Additionally, it has good wear resistance, which is beneficial for moving parts in vending machines.

Pros & Cons:

The primary advantage of cast iron is its high strength-to-weight ratio, which allows for robust designs. However, it is prone to corrosion if not properly coated, which can lead to maintenance issues. The manufacturing complexity is moderate, as casting processes can be intricate and require skilled labor.

Impact on Application:

Cast iron is particularly compatible with environments where mechanical strength is paramount. However, its susceptibility to rust means that it may not be ideal for humid or wet conditions unless adequately treated.

Considerations for International Buyers:

Buyers should ensure compliance with local standards regarding metal coatings and treatments. In regions like Europe, adherence to ASTM or DIN standards is crucial for market acceptance.

2. Stainless Steel

Key Properties:

Stainless steel is highly resistant to corrosion and staining, making it an excellent choice for food-related applications. It can handle a wide range of temperatures and is easy to clean, which is vital for maintaining hygiene in vending machines.

Pros & Cons:

The key advantage of stainless steel is its longevity and low maintenance requirements. However, it tends to be more expensive than other materials, which can affect overall project budgets. The manufacturing process can also be complex, requiring specialized welding techniques.

Impact on Application:

Stainless steel is ideal for environments where food safety is a concern. Its compatibility with various media, including sugary substances, makes it a preferred choice for candy vending machines.

Considerations for International Buyers:

International buyers should verify compliance with food safety standards specific to their regions, such as FDA regulations in the U.S. or EU food safety directives. Understanding the grades of stainless steel (e.g., 304 vs. 316) is also essential for selecting the right material for specific applications.

3. Aluminum

Key Properties:

Aluminum is lightweight yet strong, with good corrosion resistance. It is also an excellent conductor of heat, which can be beneficial in applications where temperature control is necessary.

Pros & Cons:

The main advantage of aluminum is its lightweight nature, which reduces shipping costs and makes installation easier. However, it may not be as durable as cast iron or stainless steel in high-wear applications. The cost is generally moderate, but prices can vary based on alloy grades.

Impact on Application:

Aluminum is suitable for vending machines that require frequent relocation or those that need to be mounted on walls or other structures. However, it may not be suitable for environments with high mechanical wear.

Considerations for International Buyers:

Buyers should consider the specific alloy used, as different grades offer varying levels of strength and corrosion resistance. Compliance with local standards for aluminum products is also important, especially in regions with stringent regulations.

4. Glass

Key Properties:

Glass is often used for the display components of vending machines due to its transparency and aesthetic appeal. It is non-corrosive and can withstand various environmental conditions.

Pros & Cons:

The primary advantage of glass is its ability to showcase products effectively, enhancing consumer engagement. However, it is fragile and can break easily, posing a risk in high-traffic areas. The cost is typically higher than metal alternatives, especially for tempered or safety glass.

Impact on Application:

Glass is ideal for applications where visibility is critical, allowing customers to see the candy before making a purchase. However, its fragility limits its use in environments where impact resistance is necessary.

Considerations for International Buyers:

Buyers should ensure that the glass used meets safety standards relevant to their region, such as tempered glass requirements in Europe. Understanding local regulations regarding glass recycling and disposal is also essential.

Summary Table

| Material | Typical Use Case for antique candy vending machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cast Iron | Structural components, base support | High strength and durability | Prone to corrosion if uncoated | Low |

| Stainless Steel | Internal mechanisms, product display | Corrosion-resistant, hygienic | Higher cost, complex manufacturing | High |

| Aluminum | Lightweight frames, decorative elements | Lightweight, easy to handle | Less durable in high-wear applications | Medium |

| Glass | Display windows, product visibility | Excellent visibility | Fragile, higher cost | High |

This material selection guide aims to equip international B2B buyers with the insights needed to make informed decisions when sourcing materials for antique candy vending machines. Understanding the properties, advantages, and limitations of each material will facilitate better purchasing strategies tailored to specific market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for antique candy vending machine

Manufacturing Processes for Antique Candy Vending Machines

The manufacturing of antique candy vending machines is a multifaceted process that combines traditional craftsmanship with modern technology. This ensures that the final product not only meets aesthetic standards but also functions efficiently and reliably. Below is a detailed breakdown of the main stages involved in the manufacturing process, along with key techniques used throughout.

Illustrative Image (Source: Google Search)

1. Material Preparation

The initial stage involves selecting high-quality materials that reflect the vintage aesthetic while ensuring durability and functionality. Common materials include:

- Metal Alloys: Steel and aluminum are preferred for their strength and corrosion resistance.

- Glass: Often used for the display windows to showcase the candy inside, tempered glass is favored for its safety and durability.

- Wood: Some models incorporate wood for a classic look, typically sourced from sustainable forests.

Before production, materials undergo rigorous quality checks to ensure they meet specific standards, reducing waste and enhancing overall quality.

2. Forming

In this stage, raw materials are shaped into components using various techniques:

- Stamping and Die-Cutting: Metal parts are stamped into specific shapes using dies, ensuring precision and uniformity.

- Injection Molding: Plastic components, if any, are created using injection molding techniques, allowing for complex shapes and designs.

- Woodworking Techniques: For wooden parts, traditional woodworking methods such as carving and joining are employed, preserving the antique feel.

This phase is crucial for ensuring that all components fit together seamlessly during assembly.

3. Assembly

Once the individual components are prepared, the assembly process begins. Key aspects include:

- Manual Assembly: Skilled workers often hand-assemble parts, ensuring attention to detail and adherence to design specifications.

- Mechanical Assembly: Where applicable, machines may assist in the assembly process, especially for repetitive tasks, enhancing efficiency.

- Integration of Mechanisms: The internal vending mechanisms are carefully integrated into the structure, ensuring they operate smoothly.

Quality checks at this stage involve testing the alignment and fit of components to prevent issues in later stages.

4. Finishing

The finishing stage is where the antique candy vending machines truly come to life. Key techniques include:

- Painting and Coating: High-quality paints and coatings are applied, often in multiple layers, to achieve a durable and attractive finish. Antique finishes may involve patinas or distressed techniques to enhance the vintage look.

- Polishing and Buffing: Metal parts are polished to a shine, while glass components are cleaned to ensure clarity and presentation.

- Final Assembly of Decorative Elements: Any decorative features, such as logos or designs, are added during this phase, often using hand-painted techniques to maintain authenticity.

Quality Assurance in Manufacturing

Quality assurance is critical in the production of antique candy vending machines, ensuring that each unit meets international standards and customer expectations. Various quality control (QC) processes are employed throughout the manufacturing stages.

International Standards

B2B buyers should be aware of relevant international standards that impact manufacturing quality, including:

- ISO 9001: This standard outlines requirements for a quality management system (QMS). Compliance ensures that manufacturers maintain consistent quality and improve processes.

- CE Marking: Required for products sold in the European Economic Area, CE marking indicates conformity with health, safety, and environmental protection standards.

- API Certification: For components that may be used in specialized applications, API certification may be necessary, particularly in regions with stringent regulatory requirements.

Key QC Checkpoints

To maintain high-quality standards, manufacturers implement several QC checkpoints:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring is conducted during the manufacturing process to identify defects early and rectify them.

- Final Quality Control (FQC): Before shipping, finished products undergo a comprehensive inspection to ensure they meet quality standards and specifications.

Common Testing Methods

Manufacturers utilize a variety of testing methods to ensure product reliability and safety, including:

- Functional Testing: Verifying that vending mechanisms operate smoothly and dispense candy correctly.

- Durability Testing: Subjecting machines to various stress tests to ensure they can withstand regular use.

- Safety Testing: Ensuring that all components are safe for consumer use and comply with relevant safety regulations.

Verifying Supplier Quality Assurance

For B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying supplier quality assurance is essential. Here are actionable steps to ensure supplier compliance:

- Supplier Audits: Conduct regular audits of suppliers to assess their adherence to quality standards and manufacturing processes.

- Quality Reports: Request detailed quality reports that outline QC processes, testing results, and any corrective actions taken.

- Third-Party Inspections: Engage third-party inspection services to provide unbiased assessments of manufacturing practices and product quality.

Conclusion

Understanding the manufacturing processes and quality assurance protocols for antique candy vending machines is crucial for international B2B buyers. By focusing on material preparation, forming, assembly, and finishing, alongside rigorous quality control measures, buyers can ensure they select high-quality products that meet both aesthetic and functional requirements. Leveraging international standards and verifying supplier practices will further enhance the procurement process, ensuring that investments yield reliable and appealing vending solutions.

Related Video: Inside the Airheads Candy Factory

Comprehensive Cost and Pricing Analysis for antique candy vending machine Sourcing

When considering the sourcing of antique candy vending machines, understanding the cost structure and pricing dynamics is critical for international B2B buyers. This analysis will break down the various cost components involved in manufacturing these machines, the influencers on pricing, and offer strategic tips for negotiation and procurement.

Cost Components

-

Materials: The primary materials include metals (such as steel and aluminum), plastics, and glass. The quality and sourcing of these materials can significantly affect costs. For instance, locally sourced materials in Europe might differ in price from those imported to Africa or South America.

-

Labor: Labor costs vary widely depending on the country of manufacture. Regions with lower labor costs, such as parts of South America and Africa, may offer competitive pricing, but this can also impact the quality of craftsmanship. Understanding the local wage structures is essential for cost estimation.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and administrative expenses. High overhead can be indicative of advanced manufacturing processes or quality control measures, which may justify higher prices.

-

Tooling: Custom tooling for unique designs or features can add significant upfront costs. Buyers should assess whether the design specifications warrant these costs based on their target market.

-

Quality Control (QC): Rigorous QC processes ensure product reliability and compliance with international standards, which can add to the overall cost. Certifications such as ISO or CE can enhance the perceived value of the machines but may also increase production expenses.

-

Logistics: Shipping costs can vary based on distance, method (air vs. sea), and customs duties. For buyers in Africa or the Middle East, considering local distribution channels can reduce logistics costs.

-

Margin: Suppliers will typically mark up their costs to achieve a profit margin. Understanding industry standards for margins can help buyers gauge fair pricing.

Price Influencers

-

Volume/MOQ: Suppliers often offer better pricing for larger orders. Understanding the minimum order quantities (MOQs) can help in negotiating better deals, especially for buyers looking to stock multiple machines.

-

Specifications/Customization: Custom features may increase costs. Buyers should weigh the benefits of customization against potential price hikes.

-

Material Quality/Certifications: Higher quality materials and certifications can justify a premium price. Buyers should inquire about the standards adhered to by suppliers.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their proven track record.

-

Incoterms: Understanding the implications of various Incoterms (like FOB, CIF) is crucial as they determine who bears shipping costs and risks, impacting the total landed cost.

Buyer Tips

-

Negotiation: Always aim to negotiate not just price but also terms of payment, delivery schedules, and after-sales service. Building a good relationship with suppliers can lead to better terms.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes purchase price, maintenance, and operational costs over the machine’s lifespan. A lower initial price may lead to higher long-term costs if quality is compromised.

-

Pricing Nuances for International Buyers: Different regions have unique pricing dynamics due to local demand, currency fluctuations, and economic conditions. For instance, buyers from Turkey may face different challenges than those from Spain or Brazil.

In conclusion, while sourcing antique candy vending machines, B2B buyers should conduct thorough market research, understand cost components, and leverage negotiation strategies to secure the best possible outcomes. Keep in mind that prices can vary widely based on numerous factors, so it is advisable to request quotes and compare offers from multiple suppliers. Always consider a disclaimer regarding indicative prices, as market conditions and supplier capabilities can change rapidly.

Spotlight on Potential antique candy vending machine Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘antique candy vending machine’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for antique candy vending machine

When considering the procurement of antique candy vending machines, understanding the essential technical properties and trade terminology is crucial for making informed purchasing decisions. Below are key specifications and terms that will aid international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe.

Key Technical Properties

-

Material Grade

– Definition: The quality of the materials used in the construction of the vending machine, often specified in terms of stainless steel, aluminum, or plastic composites.

– Importance: Higher-grade materials ensure durability and resistance to corrosion, which is vital for machines placed in various environments. This can reduce maintenance costs and extend the machine’s lifespan. -

Capacity

– Definition: The number of candy compartments or the total weight the machine can hold.

– Importance: A larger capacity can lead to increased sales opportunities, particularly in high-traffic areas. Buyers must assess their target market to choose a machine that meets demand without requiring frequent restocking. -

Dimensions and Weight

– Definition: The physical size and weight of the machine.

– Importance: Knowing the dimensions is crucial for shipping and placement considerations. A heavier machine may provide stability but could also increase shipping costs. Buyers should consider their intended location and available space. -

Power Requirements

– Definition: The electrical specifications needed for operation, including voltage and amperage.

– Importance: Understanding power requirements ensures compatibility with local electrical systems, preventing potential operational issues. This is particularly important for international buyers who may face varying electrical standards. -

Temperature Control

– Definition: The ability of the machine to maintain specific temperature ranges for certain types of candies, especially if they are sensitive to heat.

– Importance: Machines with effective temperature control can preserve the quality of the product, ensuring customer satisfaction and reducing spoilage.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Explanation: A company that produces parts or equipment that may be marketed by another manufacturer.

– Relevance: Understanding OEM partnerships can help buyers secure high-quality machines that meet specific branding or functional requirements. -

MOQ (Minimum Order Quantity)

– Explanation: The smallest quantity of goods that a supplier is willing to sell.

– Relevance: Knowing the MOQ helps buyers plan their budgets and inventory needs. This is particularly important for smaller businesses or startups. -

RFQ (Request for Quotation)

– Explanation: A document issued by a buyer to solicit price quotes from suppliers.

– Relevance: An RFQ is essential for comparing costs from multiple vendors, ensuring buyers get the best price for the required specifications. -

Incoterms (International Commercial Terms)

– Explanation: A set of predefined international trade terms that clarify the responsibilities of buyers and sellers.

– Relevance: Familiarity with Incoterms helps buyers understand shipping responsibilities, costs, and risks associated with transportation, ensuring smoother transactions. -

Lead Time

– Explanation: The time between placing an order and receiving the product.

– Relevance: Understanding lead times is vital for inventory management and planning. It helps businesses avoid stockouts and meet customer demand promptly.

By familiarizing themselves with these technical properties and trade terms, international B2B buyers can make more informed decisions when purchasing antique candy vending machines, ultimately leading to better investment outcomes and operational success.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the antique candy vending machine Sector

Market Overview & Key Trends

The antique candy vending machine sector is experiencing a resurgence driven by nostalgia, the retro aesthetic, and a growing demand for unique consumer experiences. As urbanization continues to rise, particularly in Africa and South America, businesses are seeking innovative ways to attract customers. This trend is supported by technological advancements, such as cashless payment systems and mobile integrations, which enhance user convenience and engagement.

B2B buyers from regions like the Middle East and Europe are increasingly looking to source machines that offer not just traditional candy but also artisanal and local sweets, appealing to a more health-conscious and diverse customer base. Additionally, customization options are becoming a key factor in purchasing decisions, allowing businesses to tailor machines to their branding and consumer preferences.

Another emerging trend is the integration of smart technology into vending machines. Features such as inventory tracking, digital marketing capabilities, and real-time sales analytics are becoming essential for businesses looking to optimize operations and maximize ROI. For buyers in markets like Turkey and Spain, these technological innovations represent opportunities for differentiation and competitive advantage in the retail sector.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming increasingly important in the antique candy vending machine market. Businesses are expected to consider the environmental impact of their sourcing practices. This includes selecting materials that are recyclable, biodegradable, or sustainably sourced. Buyers should prioritize vendors who demonstrate a commitment to sustainability through certifications such as Forest Stewardship Council (FSC) for wood components or Fair Trade for sourced ingredients.

Moreover, ethical supply chains are essential for building brand reputation and consumer trust. As consumers become more environmentally conscious, they prefer brands that align with their values. This trend is particularly significant for international buyers, as they navigate varying regulations and consumer expectations across different regions.

Investing in ‘green’ materials and practices not only fulfills ethical obligations but can also lead to cost savings in the long term. For example, energy-efficient vending machines can reduce operational costs while appealing to environmentally conscious customers. Buyers should actively seek out partnerships with suppliers who are transparent about their sustainability practices and can provide documentation of their environmental impact.

Brief Evolution/History

The antique candy vending machine traces its roots back to the late 19th century, where it was primarily used in train stations and public spaces to dispense small confections. Initially, these machines were simple mechanical devices, but as technology evolved, so did the designs and functionalities. The introduction of electric vending machines in the mid-20th century marked a significant shift, allowing for more complex operations and a wider variety of products.

In recent years, a revival of interest in vintage and retro designs has led to a resurgence of antique-style machines, blending nostalgia with modern technology. This evolution reflects changing consumer preferences and the importance of unique, engaging retail experiences, making antique candy vending machines a lucrative investment for B2B buyers seeking to differentiate their offerings in an increasingly competitive market.

Related Video: Chapter 9: International Trade

Frequently Asked Questions (FAQs) for B2B Buyers of antique candy vending machine

-

What should I consider when vetting suppliers for antique candy vending machines?

When vetting suppliers, prioritize their experience in the industry and reputation. Check for customer reviews and testimonials, and request references from previous clients. Ensure the supplier has expertise in exporting to your region and is familiar with local regulations. Request documentation that demonstrates compliance with quality standards and certifications relevant to antique vending machines. Engaging in video calls or factory visits can also provide valuable insights into the supplier’s operations and product quality. -

Can I customize the antique candy vending machines according to my branding needs?

Many suppliers offer customization options, including design, color, and branding elements. When discussing customization, clearly communicate your requirements, such as logo placement and color schemes. Be aware that customization may affect lead times and minimum order quantities (MOQs). It’s advisable to request samples or prototypes before finalizing the order to ensure the design aligns with your expectations. -

What are the typical minimum order quantities (MOQs) and lead times for antique candy vending machines?

MOQs can vary significantly by supplier and the complexity of the order. Generally, MOQs for antique candy vending machines range from 10 to 50 units. Lead times typically range from 4 to 12 weeks, depending on customization and the supplier’s production capacity. Always confirm these details in advance to avoid delays and ensure that your procurement schedule aligns with your business needs. -

What payment methods are commonly accepted by suppliers of antique candy vending machines?

Most suppliers accept various payment methods, including bank transfers, letters of credit, and online payment platforms. For international transactions, bank transfers are often preferred due to their security. Negotiate payment terms that protect both parties, such as a deposit upfront and the balance upon delivery. It’s wise to clarify payment methods before placing an order to ensure smooth transactions. -

How can I ensure quality assurance for antique candy vending machines?

Establishing quality assurance (QA) protocols is crucial. Request certifications such as ISO or CE that verify the machinery meets safety and quality standards. Conduct factory audits if possible, and insist on pre-shipment inspections to verify that products meet your specifications. Additionally, consider using third-party inspection services for added assurance before the shipment leaves the supplier’s facility. -

What logistics considerations should I keep in mind when importing antique candy vending machines?

Logistics play a critical role in international trade. Discuss shipping options with your supplier, including freight forwarders and customs clearance processes. Understand the shipping costs, expected delivery times, and any potential tariffs or duties. It is also essential to have a reliable logistics partner to handle the transportation and ensure your machines arrive safely and on time. -

What steps should I take if I encounter a dispute with my supplier?

In the event of a dispute, maintain clear and professional communication with your supplier. Document all correspondence and agreements to provide evidence. Refer to your contract for dispute resolution procedures, which may include mediation or arbitration. If necessary, consider involving a legal expert familiar with international trade laws to navigate the situation effectively. -

What are the key certifications I should look for when sourcing antique candy vending machines?

Key certifications to look for include ISO 9001 for quality management systems and CE marking for compliance with European health and safety regulations. Depending on your market, additional certifications like UL or RoHS may also be relevant. Always request copies of certifications and verify their validity to ensure the equipment meets the necessary safety and performance standards for your region.

Illustrative Image (Source: Google Search)

Strategic Sourcing Conclusion and Outlook for antique candy vending machine

The antique candy vending machine market presents a unique opportunity for international B2B buyers to tap into a niche that combines nostalgia with profitability. As highlighted throughout this guide, strategic sourcing is essential for securing quality machines that resonate with consumers while ensuring competitive pricing and reliable supply chains.

Key takeaways include the importance of understanding regional preferences and trends, particularly in markets such as Africa, South America, the Middle East, and Europe. Buyers should prioritize partnerships with reputable suppliers who can provide authentic machines, as well as modern adaptations that enhance user experience.

In conclusion, as the demand for vintage aesthetics continues to rise, now is the time for B2B buyers to invest in antique candy vending machines. By leveraging strategic sourcing practices, businesses can position themselves advantageously within this growing market. We encourage you to explore partnerships that align with your business goals and to act swiftly to capitalize on this trend. Engage with suppliers who can deliver both quality and authenticity, ensuring your offerings stand out in a competitive landscape.