Your Ultimate Guide to Sourcing Airheads Underwater Vending

Guide to Airheads Underwater Vending Machine

- Introduction: Navigating the Global Market for airheads underwater vending machine

- Understanding airheads underwater vending machine Types and Variations

- Key Industrial Applications of airheads underwater vending machine

- Strategic Material Selection Guide for airheads underwater vending machine

- In-depth Look: Manufacturing Processes and Quality Assurance for airheads underwater vending machine

- Comprehensive Cost and Pricing Analysis for airheads underwater vending machine Sourcing

- Spotlight on Potential airheads underwater vending machine Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for airheads underwater vending machine

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the airheads underwater vending machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of airheads underwater vending machine

- Strategic Sourcing Conclusion and Outlook for airheads underwater vending machine

Introduction: Navigating the Global Market for airheads underwater vending machine

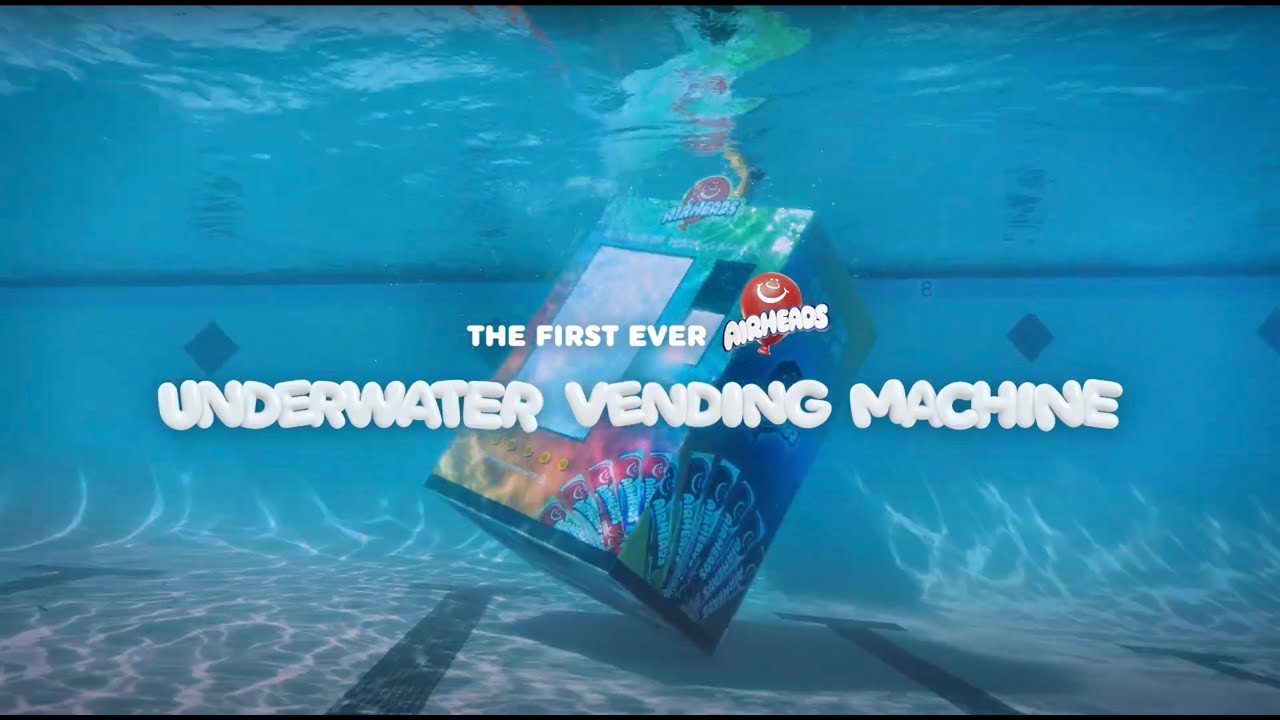

The emergence of the Airheads Underwater Vending Machine marks a pivotal innovation in the realm of aquatic leisure and recreational facilities. As international B2B buyers increasingly seek unique solutions to enhance customer experiences in water parks, resorts, and coastal attractions, this vending machine offers a novel way to deliver convenience and fun. By providing easy access to a variety of snacks and beverages underwater, businesses can significantly boost customer satisfaction and engagement, ultimately driving revenue growth.

This comprehensive guide delves into the multifaceted landscape of the Airheads Underwater Vending Machine, addressing critical aspects that empower informed sourcing decisions. Buyers will explore various types of vending machines suited for different environments, the materials used in construction to withstand aquatic conditions, and the importance of manufacturing quality control to ensure reliability and safety. Additionally, the guide provides insights into reputable suppliers across regions, a breakdown of cost considerations, and an analysis of the current market trends.

With a focus on international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, this resource equips stakeholders with the knowledge needed to navigate the complexities of sourcing this innovative product. By addressing frequently asked questions, this guide serves as a vital tool for businesses looking to capitalize on the growing demand for unique vending solutions in aquatic settings, ensuring they make well-informed decisions that align with their operational goals.

Understanding airheads underwater vending machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Underwater Vending Machine | Operates at shallow depths; manual or automated dispensing | Aquatic parks, resorts | Pros: Easy to maintain; Cons: Limited capacity for deep water use |

| Deep-Sea Vending Machine | Designed for extreme underwater conditions; robust materials | Marine research, deep-sea tourism | Pros: High durability; Cons: Higher cost and complex installation |

| Solar-Powered Underwater Vending Machine | Utilizes solar panels for energy; eco-friendly design | Eco-tourism, sustainable facilities | Pros: Low operational costs; Cons: Dependent on sunlight availability |

| Interactive Underwater Vending Machine | Features touchscreen interface; offers diverse product range | Aquariums, underwater events | Pros: Engaging customer experience; Cons: Higher maintenance needs |

| Customizable Underwater Vending Machine | Modular design for tailored solutions; various sizes available | Specialized aquatic environments | Pros: Flexible configurations; Cons: Longer lead times for production |

Standard Underwater Vending Machine

The standard underwater vending machine is typically designed for shallow aquatic environments, making it suitable for use in aquatic parks and resorts. These machines often feature manual or automated dispensing mechanisms, allowing for easy operation. B2B buyers should consider the ease of maintenance and operational costs, though they may find limitations in capacity and depth suitability for more challenging underwater environments.

Deep-Sea Vending Machine

Deep-sea vending machines are engineered to withstand the pressures and conditions of deeper waters. They are constructed from robust materials that ensure durability and functionality in extreme environments, making them ideal for marine research and deep-sea tourism. Buyers in these sectors should weigh the advantages of high durability against the higher costs and complexity of installation, which may require specialized expertise.

Illustrative Image (Source: Google Search)

Solar-Powered Underwater Vending Machine

These eco-friendly vending machines harness solar energy to operate, making them a sustainable choice for businesses focused on environmental responsibility. They are particularly well-suited for eco-tourism ventures and facilities that promote sustainability. While they offer low operational costs and a reduced carbon footprint, buyers must consider the machine’s reliance on sunlight, which can limit functionality in low-light conditions.

Interactive Underwater Vending Machine

Featuring touchscreen interfaces, interactive underwater vending machines provide a unique and engaging customer experience. They can offer a diverse range of products, making them perfect for aquariums and underwater events. While they enhance customer interaction, buyers should be aware of the increased maintenance needs and potential technical issues that may arise from the complexity of the technology.

Customizable Underwater Vending Machine

These machines are designed with modular components, allowing for tailored solutions that fit specific business needs. Their flexibility makes them suitable for various aquatic environments, enabling businesses to adapt the machine’s size and features. B2B buyers should appreciate the benefits of customization but should also be prepared for longer lead times in production due to the bespoke nature of these machines.

Related Video: CS 198-126: Lecture 12 – Diffusion Models

Key Industrial Applications of airheads underwater vending machine

| Industry/Sector | Specific Application of airheads underwater vending machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Marine Tourism | Underwater snacks and beverage vending | Enhances visitor experience, increases revenue | Water resistance, energy source, product variety |

| Aquaculture | Supply of fish feed | Improves efficiency in feeding processes | Compatibility with feed types, durability, maintenance needs |

| Underwater Research | Provision of research materials | Facilitates continuous research operations | Customization options, retrieval methods, logistics |

| Offshore Construction | On-site equipment and tool vending | Reduces downtime, increases operational efficiency | Robustness against harsh environments, inventory management |

| Environmental Monitoring | Delivery of monitoring devices and sensors | Streamlines data collection, enhances research accuracy | Sensor compatibility, connectivity options, maintenance support |

Marine Tourism

In the marine tourism sector, airheads underwater vending machines can serve as innovative points for offering snacks and beverages to divers and snorkelers. By providing convenient access to refreshments, businesses can enhance the visitor experience and increase revenue through additional sales. International B2B buyers should consider the machine’s water resistance and energy sources, as well as the variety of products that can be offered, to cater to diverse tourist preferences.

Aquaculture

Aquaculture operations can utilize underwater vending machines to supply fish feed directly to various depths. This application improves feeding efficiency, as it allows for targeted delivery to fish populations without the need for divers. Buyers in this sector must ensure that the vending machines are compatible with different feed types and durable enough to withstand underwater conditions, while also considering maintenance needs to ensure continuous operation.

Underwater Research

For underwater research institutions, airheads underwater vending machines can provide essential materials and tools needed for experiments and data collection. This facilitates continuous research operations, allowing scientists to focus on their work without frequent trips to the surface. Buyers should look for customization options that meet specific research requirements, as well as efficient retrieval methods for the items dispensed, to optimize their research efforts.

Offshore Construction

In the offshore construction industry, these vending machines can dispense tools and equipment needed on-site, significantly reducing downtime for workers. By having immediate access to necessary items, projects can proceed more smoothly and efficiently. International buyers should focus on the robustness of the machines against harsh marine environments and effective inventory management systems to ensure that the right tools are available when needed.

Environmental Monitoring

Environmental monitoring initiatives can benefit from the use of airheads underwater vending machines for the delivery of monitoring devices and sensors. This streamlined approach to data collection enhances research accuracy and operational efficiency. Buyers should consider sensor compatibility, connectivity options for data transmission, and ongoing maintenance support to ensure the effectiveness of their monitoring programs.

Related Video: FANUC Industrial Robots | AUDI Case Study

Strategic Material Selection Guide for airheads underwater vending machine

When selecting materials for airheads underwater vending machines, it is crucial to consider factors such as performance, durability, cost, and regional compliance. Below is an analysis of four common materials used in the construction of these machines, focusing on their properties, advantages, disadvantages, and implications for international buyers, particularly in Africa, South America, the Middle East, and Europe.

1. Stainless Steel (e.g., 316L)

Key Properties: Stainless steel, particularly 316L, is known for its excellent corrosion resistance, especially in marine environments. It can withstand high pressures and temperatures, making it suitable for underwater applications.

Pros & Cons: The primary advantage of stainless steel is its durability and resistance to rust and corrosion, which extends the lifespan of the vending machine. However, it is more expensive than other materials and can be challenging to fabricate, requiring specialized equipment and skills.

Impact on Application: Stainless steel is compatible with a wide range of media, including fresh and saltwater, making it ideal for underwater applications. Its resistance to biofouling is also beneficial in aquatic environments.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM and DIN. In regions like Europe and South America, there is a preference for stainless steel due to its longevity and low maintenance requirements.

2. Polycarbonate

Key Properties: Polycarbonate is a lightweight, impact-resistant thermoplastic that offers good clarity and UV resistance. It can operate effectively within a range of temperatures but is less resistant to extreme pressures compared to metals.

Pros & Cons: The main advantage of polycarbonate is its lightweight nature, which reduces shipping costs and simplifies installation. However, it is more susceptible to scratching and may not be suitable for high-pressure environments.

Impact on Application: Polycarbonate is often used for protective covers or windows in vending machines, providing visibility while protecting internal components. It is not ideal for direct contact with aggressive chemicals or high-pressure water.

Considerations for International Buyers: Buyers should verify compliance with local regulations regarding plastics, especially in regions with strict environmental laws like Europe. The cost-effectiveness of polycarbonate can be appealing to buyers in Africa and South America.

3. Aluminum Alloy (e.g., 6061)

Key Properties: Aluminum alloys, particularly 6061, are lightweight and possess good corrosion resistance. They can be anodized to enhance their protective qualities, making them suitable for marine environments.

Pros & Cons: Aluminum is relatively inexpensive and easy to machine, which can lower manufacturing costs. However, it has lower strength compared to stainless steel and may require additional protective coatings in corrosive environments.

Impact on Application: Aluminum is suitable for structural components of vending machines, providing a balance between weight and strength. However, its lower resistance to corrosion compared to stainless steel can be a limitation in saltwater applications.

Considerations for International Buyers: Compliance with standards such as JIS and ASTM is essential. Buyers in the Middle East and Africa may find aluminum a cost-effective option, but they should consider the environmental conditions where the machines will be deployed.

4. High-Density Polyethylene (HDPE)

Key Properties: HDPE is a robust thermoplastic known for its resistance to impact and chemicals. It can operate effectively in a wide temperature range but is less rigid than metals.

Pros & Cons: HDPE is cost-effective and easy to fabricate, making it suitable for various applications in vending machines. However, it may not withstand high temperatures or pressures as well as metals.

Impact on Application: HDPE is often used for internal components and housing, providing excellent chemical resistance. Its lightweight nature can reduce overall machine weight, aiding in transport and installation.

Considerations for International Buyers: Buyers should check for compliance with local environmental regulations, especially in Europe, where sustainability is a priority. HDPE’s affordability makes it attractive for markets in Africa and South America.

Summary Table

| Material | Typical Use Case for airheads underwater vending machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel (e.g., 316L) | Structural components, external casing | Excellent corrosion resistance | Higher cost and complex fabrication | High |

| Polycarbonate | Protective covers, visibility panels | Lightweight and impact-resistant | Susceptible to scratching | Medium |

| Aluminum Alloy (e.g., 6061) | Structural components, frames | Cost-effective and easy to machine | Lower strength and corrosion resistance | Medium |

| High-Density Polyethylene (HDPE) | Internal components, housing | Cost-effective and easy to fabricate | Limited temperature and pressure resistance | Low |

This strategic material selection guide provides essential insights for international B2B buyers, enabling them to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for airheads underwater vending machine

Manufacturing Processes for Airheads Underwater Vending Machines

The manufacturing of airheads underwater vending machines involves several critical stages, each designed to ensure that the final product meets operational efficiency and durability standards. Understanding these processes is vital for B2B buyers looking to source reliable equipment.

1. Material Preparation

The first step in the manufacturing process is material preparation. This involves selecting high-quality, corrosion-resistant materials suitable for underwater environments, such as stainless steel and specialized plastics. The materials undergo thorough inspections to check for defects and ensure they meet industry specifications.

- Key Considerations:

- Material Selection: Choose materials based on environmental resistance, mechanical properties, and compliance with international standards.

- Supplier Verification: Ensure that material suppliers provide certifications and documentation regarding the quality and compliance of their products.

2. Forming

Once materials are prepared, they undergo forming processes, which may include cutting, bending, and molding. Advanced techniques such as CNC machining and laser cutting are often employed to achieve precision and minimize waste.

- Key Techniques:

- CNC Machining: Allows for precise shaping of components, which is essential for the intricate design of vending machines.

- Injection Molding: Used for plastic components, ensuring consistent quality and detail.

3. Assembly

The assembly stage involves the integration of various components, including mechanical, electronic, and software systems. This stage is critical for ensuring that all parts fit together seamlessly and function as intended.

- Assembly Techniques:

- Automated Assembly: Increases efficiency and consistency in the assembly process.

- Manual Assembly: Essential for complex assemblies that require skilled labor to ensure proper fit and function.

4. Finishing

Finishing processes enhance the aesthetic and functional qualities of the vending machines. This may include surface treatments, painting, and waterproofing to ensure longevity in harsh underwater conditions.

- Finishing Techniques:

- Powder Coating: Provides a durable and corrosion-resistant finish.

- Sealing: Ensures that all electronic components are protected from water ingress.

Quality Assurance (QA) in Manufacturing

Quality assurance is a critical aspect of the manufacturing process for airheads underwater vending machines. Implementing robust QA protocols ensures that products meet both international standards and customer expectations.

International Standards

International quality standards such as ISO 9001 are fundamental to the QA process. These standards focus on the effectiveness of quality management systems and continuous improvement.

- ISO 9001: Ensures that manufacturers maintain high-quality processes and can consistently deliver products that meet customer and regulatory requirements.

- CE Marking: Indicates compliance with European safety, health, and environmental protection standards, which is crucial for products sold in Europe.

Industry-Specific Standards

Certain industry-specific certifications may also apply:

- API Standards: Relevant for underwater applications, particularly in oil and gas industries, where equipment must withstand high-pressure environments.

- UL Certification: Ensures that electrical components meet safety standards, which is vital for vending machines operating underwater.

Quality Control Checkpoints

Effective quality control (QC) involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This initial stage checks raw materials and components for defects before they enter the production line.

- In-Process Quality Control (IPQC): During manufacturing, regular inspections ensure that processes remain within specified tolerances.

- Final Quality Control (FQC): The finished product undergoes comprehensive testing to confirm it meets all design specifications and safety standards.

Common Testing Methods

Various testing methods are employed to ensure the quality and functionality of the vending machines:

- Functional Testing: Verifies that the machine operates correctly under simulated conditions.

- Waterproof Testing: Ensures that all components are sealed and can withstand underwater pressure.

- Stress Testing: Assesses the durability of materials and components under extreme conditions.

Verifying Supplier Quality Control

For B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is essential:

- Audits: Conducting regular audits of suppliers can provide insight into their manufacturing practices and compliance with quality standards.

- Quality Reports: Requesting detailed quality reports can help assess the supplier’s adherence to QA protocols.

- Third-Party Inspections: Utilizing third-party inspection services can offer an unbiased evaluation of the supplier’s manufacturing and quality control processes.

Navigating Quality Control Nuances for International Buyers

International buyers must be aware of various nuances related to quality control when sourcing underwater vending machines:

- Regulatory Compliance: Different regions may have varying regulatory requirements that must be met, such as environmental regulations or safety standards.

- Cultural Considerations: Understanding cultural differences in business practices can aid in effective communication with suppliers and ensure smoother transactions.

- Logistics and Transport: Consider the implications of transporting goods across borders, including potential delays and customs regulations that may affect product quality during transit.

Conclusion

B2B buyers seeking to invest in airheads underwater vending machines should prioritize understanding the manufacturing processes and quality assurance protocols involved. By focusing on material selection, manufacturing techniques, quality standards, and verification methods, buyers can make informed decisions that align with their operational needs and quality expectations. This comprehensive approach not only enhances the reliability of the products sourced but also strengthens the overall supply chain management process.

Related Video: Inside the Airheads Candy Factory

Comprehensive Cost and Pricing Analysis for airheads underwater vending machine Sourcing

When sourcing airheads underwater vending machines, understanding the comprehensive cost structure and pricing dynamics is essential for B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. This analysis will delve into the key cost components, influential pricing factors, and provide actionable tips for buyers to enhance their procurement strategies.

Cost Components

-

Materials: The primary materials for manufacturing underwater vending machines include high-grade stainless steel, corrosion-resistant components, and electronic parts. The choice of materials significantly affects the durability and functionality of the machines, which can influence the overall cost.

-

Labor: Labor costs vary widely depending on the manufacturing location. Countries with lower labor costs may offer competitive pricing, but it’s crucial to assess the skill level and training of the workforce, as this can impact quality.

-

Manufacturing Overhead: This includes expenses related to factory operations such as utilities, rent, and administrative costs. Understanding the overhead can help buyers gauge the pricing structure of different suppliers.

-

Tooling: Initial tooling costs for custom designs can be substantial. Buyers should consider these costs when evaluating quotes, particularly if they require unique specifications.

-

Quality Control (QC): Implementing stringent QC processes is vital to ensure product reliability. Suppliers with robust QC measures may charge higher prices but offer better assurance of quality.

-

Logistics: Transportation costs, including shipping and handling, can vary based on the distance from the supplier and the chosen Incoterms. Import duties and taxes should also be factored into the total cost.

-

Margin: Suppliers will typically add a profit margin, which can fluctuate based on market demand and competitive pressures. Understanding the supplier’s margin can provide insights into potential negotiation leeway.

Price Influencers

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly affect pricing. Higher volumes usually lead to lower per-unit costs, making it advantageous for buyers to consolidate orders when possible.

-

Specifications/Customization: Customized machines tailored to specific needs often come at a premium. Buyers should balance the need for customization against their budget constraints.

-

Materials: The selection of materials not only impacts durability but also cost. Opting for standard materials rather than specialty options can reduce expenses.

-

Quality/Certifications: Machines that meet international quality standards or possess certifications (e.g., ISO) may be priced higher but provide better assurance of performance and safety.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their proven track record, while newer entrants might offer competitive pricing to gain market share.

-

Incoterms: Understanding Incoterms is crucial for determining who bears shipping costs and risks. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect the total landed cost of the machines.

Buyer Tips

-

Negotiate: Engage in open discussions with suppliers to negotiate pricing, especially for bulk orders. Leverage your position as a potential long-term customer to secure better terms.

-

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes purchase price, maintenance, and operating costs over the machine’s lifecycle. This holistic view can lead to better purchasing decisions.

-

Understand Pricing Nuances: International buyers should be aware of currency fluctuations, local economic conditions, and geopolitical factors that may affect pricing and availability.

-

Conduct Market Research: Stay informed about market trends and competitor pricing to make well-informed sourcing decisions.

-

Request Detailed Quotes: Obtain comprehensive quotes that break down costs by component. This transparency can aid in comparing suppliers and understanding where savings can be made.

Disclaimer

Prices mentioned in this analysis are indicative and subject to change based on market conditions, supplier negotiations, and specific buyer requirements. Always seek updated quotes and conduct thorough due diligence before finalizing any procurement decisions.

Spotlight on Potential airheads underwater vending machine Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘airheads underwater vending machine’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for airheads underwater vending machine

Key Technical Properties of Airheads Underwater Vending Machines

-

Material Grade

The construction of airheads underwater vending machines typically utilizes marine-grade stainless steel or specialized plastics. Marine-grade materials are essential due to their corrosion resistance in saltwater environments, which significantly enhances the machine’s lifespan. For B2B buyers, selecting the right material grade is crucial to minimize maintenance costs and ensure durability. -

Waterproofing Standards

These vending machines must meet specific waterproofing standards, often rated IP68, which indicates they can be submerged in water for extended periods without damage. This specification is vital for ensuring the machine operates reliably in underwater settings. Buyers should prioritize vendors that provide clear certification of these standards to ensure compliance with local regulations and environmental conditions. -

Operating Temperature Range

The machines are designed to function effectively within a certain temperature range, typically from -10°C to +50°C. This range ensures that the machine can operate in various climates, from tropical waters to cooler environments. Understanding this specification helps buyers assess whether the machine will perform reliably in their intended location. -

Power Supply Specifications

Airheads underwater vending machines often require a specific voltage and power supply configuration, typically operating on low-voltage systems (e.g., 12V or 24V). This specification is important for ensuring compatibility with existing infrastructure and for the safety of users. Buyers should confirm that the power requirements align with their local electrical standards to avoid costly modifications. -

User Interface Design

The usability of the vending machine is enhanced by an intuitive user interface, often featuring touch screens or button panels that are easy to operate even in underwater conditions. A user-friendly design is crucial for maximizing customer satisfaction and sales, making it an essential consideration for B2B buyers focused on consumer experience.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of airheads underwater vending machines, understanding OEM relationships is essential for buyers who are sourcing components or requiring customized solutions. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of goods that a supplier is willing to sell. For B2B buyers, especially those in regions like Africa and South America, negotiating favorable MOQs can significantly impact cash flow and inventory management. It is advisable to inquire about MOQs during the procurement process to ensure alignment with business needs. -

RFQ (Request for Quotation)

An RFQ is a standard business process to invite suppliers to bid on specific products or services. In the context of underwater vending machines, issuing an RFQ allows buyers to obtain competitive pricing and terms from multiple suppliers, facilitating better negotiation and cost management. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in international transactions. Understanding these terms is crucial for B2B buyers engaging in cross-border purchases of underwater vending machines, as they clarify costs, risks, and responsibilities related to shipping and delivery. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the goods. For international buyers, understanding lead times for airheads underwater vending machines is critical for project planning and inventory management. It is advisable to discuss and confirm lead times with suppliers to ensure timely delivery.

By familiarizing themselves with these technical properties and trade terms, international B2B buyers can make informed decisions that align with their operational needs and market expectations.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the airheads underwater vending machine Sector

Global drivers in the airheads underwater vending machine sector are increasingly shaped by technological advancements and changing consumer behaviors. The rise of automation and smart vending solutions is propelling the market forward. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are witnessing a shift towards integrated solutions that offer real-time inventory tracking and contactless payment options. For instance, the adoption of IoT technology is enhancing operational efficiencies, enabling businesses to monitor machine performance and stock levels remotely.

Current sourcing trends highlight a growing preference for suppliers who can provide innovative designs that cater to specific market needs. In regions such as Nigeria and Spain, buyers are increasingly seeking customizable vending machines that can accommodate local tastes and preferences. Moreover, sustainability is becoming a key consideration, with buyers prioritizing vendors that utilize eco-friendly materials and practices. As competition intensifies, companies that leverage data analytics to understand consumer trends and preferences will gain a competitive edge in the marketplace.

Sustainability & Ethical Sourcing in B2B

Sustainability and ethical sourcing are critical components in the airheads underwater vending machine sector, as environmental awareness continues to grow among consumers and businesses alike. The production of vending machines often involves materials that can be detrimental to the environment, such as plastics and metals. Therefore, it is essential for B2B buyers to consider suppliers that utilize sustainable materials and adhere to environmentally friendly manufacturing processes.

Furthermore, ethical supply chains are gaining traction as buyers increasingly demand transparency regarding the sourcing of materials. Certifications such as ISO 14001 for environmental management and Fair Trade standards are becoming important benchmarks for companies in this sector. Buyers should look for vendors that can demonstrate compliance with these standards, ensuring that their products are not only environmentally friendly but also socially responsible. This commitment to sustainability not only enhances brand reputation but also resonates with an eco-conscious consumer base.

Brief Evolution/History

The airheads underwater vending machine sector has evolved significantly over the past few decades. Initially, vending machines were simple coin-operated devices that offered limited product selections. However, technological advancements have transformed these machines into sophisticated retail solutions capable of serving diverse consumer needs. The introduction of touch screens, cashless payment systems, and product customization options has paved the way for a more interactive consumer experience.

As businesses recognize the potential of these machines in providing convenience and accessibility, the sector is poised for further growth. Emerging markets in Africa and South America are particularly promising, as urbanization and changing lifestyles drive demand for innovative vending solutions. In summary, the evolution of airheads underwater vending machines reflects broader trends in technology, consumer preferences, and sustainability, providing ample opportunities for international B2B buyers.

Related Video: Is global trade transforming? | Counting the Cost

Frequently Asked Questions (FAQs) for B2B Buyers of airheads underwater vending machine

-

What factors should I consider when vetting suppliers for airheads underwater vending machines?

When vetting suppliers, focus on their industry experience, reputation, and client testimonials. Verify their certifications, such as ISO or local quality standards, to ensure compliance with international trade regulations. Assess their production capacity to meet your demand and their ability to provide ongoing support. Additionally, consider their payment terms and flexibility, as well as their responsiveness to inquiries, which can indicate their customer service quality. -

Can airheads underwater vending machines be customized for my specific market?

Yes, many manufacturers offer customization options to suit local market needs. This can include branding, product selection, machine color, and features tailored to consumer preferences. When discussing customization, clearly outline your requirements and ensure the supplier can accommodate them. It’s advisable to request prototypes or samples before finalizing the order to confirm that the modifications meet your expectations. -

What are the typical minimum order quantities (MOQ) and lead times for these machines?

MOQs can vary significantly between suppliers, ranging from a few units to hundreds, depending on their production capabilities. Lead times typically range from 4 to 12 weeks, influenced by the complexity of customization and the supplier’s workload. Always clarify these details upfront and consider negotiating terms that align with your inventory needs, especially if you are entering a new market or testing demand. -

What payment methods are commonly accepted by suppliers of airheads underwater vending machines?

Suppliers often accept various payment methods, including bank transfers, letters of credit, and PayPal. For larger orders, letters of credit are preferred as they provide security for both parties. Always confirm payment terms before placing an order, and consider using an escrow service for added security, especially when dealing with new suppliers to mitigate risks of fraud or disputes. -

How can I ensure quality assurance and necessary certifications for the vending machines?

Request detailed documentation of quality assurance processes from your supplier, including their quality control procedures and test results. Verify if the machines comply with relevant international standards, such as CE marking in Europe or local safety certifications. It is also advisable to conduct factory audits or hire third-party inspection services to ensure that the products meet your quality expectations before shipment.

Illustrative Image (Source: Google Search)

-

What logistics considerations should I keep in mind when importing these machines?

Consider the logistics of shipping, including freight costs, shipping duration, and customs regulations in your country. Work with a freight forwarder experienced in handling large machinery to navigate potential challenges. Additionally, ensure that your supplier is familiar with export documentation requirements and can assist in preparing necessary paperwork to avoid delays at customs. -

What should I do if there’s a dispute with my supplier?

In the event of a dispute, start by communicating directly with your supplier to resolve the issue amicably. Document all correspondence and agreements to provide a clear record. If direct communication fails, refer to the terms outlined in your contract regarding dispute resolution, which may include mediation or arbitration. Consider consulting legal counsel experienced in international trade to explore your options and protect your interests. -

Are there any specific regulations I should be aware of when importing vending machines to my country?

Each country has its own regulations regarding the import of machinery, including safety standards and environmental regulations. Research your local laws to understand any import duties, taxes, or certifications required for vending machines. It may also be beneficial to consult with a customs broker who can provide guidance on compliance and help streamline the import process, ensuring that all legal requirements are met.

Strategic Sourcing Conclusion and Outlook for airheads underwater vending machine

In conclusion, the strategic sourcing of the Airheads Underwater Vending Machine presents a unique opportunity for international B2B buyers across diverse markets such as Africa, South America, the Middle East, and Europe. Key takeaways emphasize the importance of understanding local preferences, regulatory requirements, and logistical considerations to ensure successful market entry and operation.

Value of Strategic Sourcing: Engaging with reliable suppliers and manufacturers can enhance product quality while optimizing cost-efficiency. By leveraging data analytics and market insights, businesses can make informed decisions that align with their strategic objectives.

Looking Ahead: As consumer interest in innovative vending solutions grows, the Airheads Underwater Vending Machine is poised to capitalize on this trend. International buyers are encouraged to explore partnerships that not only offer competitive pricing but also foster long-term relationships built on trust and mutual growth.

Take action today—evaluate your sourcing strategies, identify potential suppliers, and consider how the unique attributes of the Airheads Underwater Vending Machine can differentiate your offerings in a rapidly evolving marketplace.