Your Ultimate Guide to Sourcing Panty Vending Machine

Guide to Panty Vending Machine

- Introduction: Navigating the Global Market for panty vending machine

- Understanding panty vending machine Types and Variations

- Key Industrial Applications of panty vending machine

- Strategic Material Selection Guide for panty vending machine

- In-depth Look: Manufacturing Processes and Quality Assurance for panty vending machine

- Comprehensive Cost and Pricing Analysis for panty vending machine Sourcing

- Spotlight on Potential panty vending machine Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for panty vending machine

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the panty vending machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of panty vending machine

- Strategic Sourcing Conclusion and Outlook for panty vending machine

Introduction: Navigating the Global Market for panty vending machine

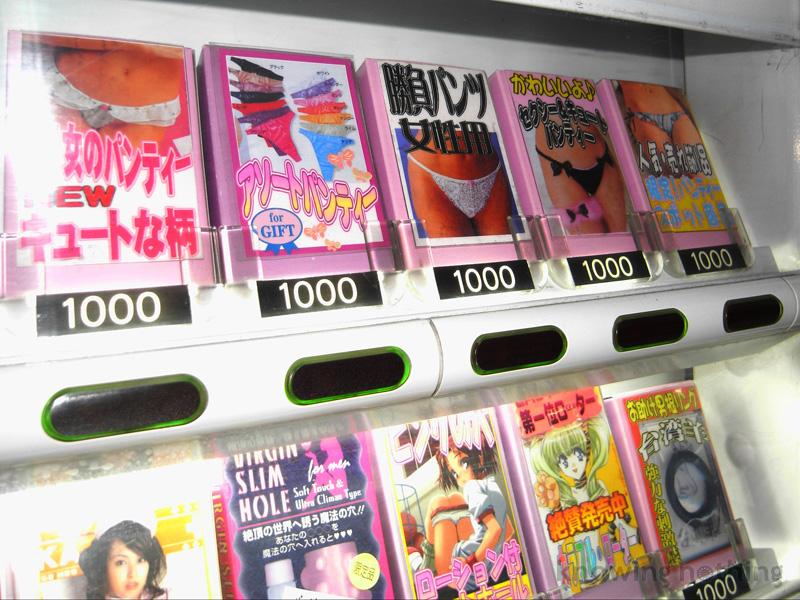

In the evolving landscape of consumer convenience, panty vending machines have emerged as a unique and lucrative opportunity for B2B buyers across various global markets. These automated retail solutions not only cater to an increasing demand for discreet, on-the-go purchases but also represent a growing trend towards innovative vending solutions. As urbanization accelerates and lifestyles change, the need for accessible personal products in public spaces becomes paramount, making panty vending machines an essential addition to retail strategies.

This comprehensive guide delves into the multifaceted world of panty vending machines, offering valuable insights into their various types, materials, and manufacturing processes. It also covers quality control measures, supplier options, and associated costs, empowering international B2B buyers to make informed sourcing decisions. The guide addresses market trends and consumer preferences, providing a holistic view that is particularly beneficial for buyers from Africa, South America, the Middle East, and Europe, including Australia and the UK.

By equipping buyers with essential knowledge and actionable insights, this guide aims to streamline the procurement process, enhance supplier negotiations, and ultimately drive successful business outcomes. Whether you are a retailer seeking to diversify product offerings or an entrepreneur exploring new ventures, understanding the dynamics of the panty vending machine market will position you for success in this innovative sector.

Understanding panty vending machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Vending Machine | Basic design, single product offering | Retail shops, convenience stores | Pros: Low cost, easy to operate. Cons: Limited product variety. |

| Smart Vending Machine | Digital payment options, inventory tracking | High-traffic areas, malls | Pros: Enhanced user experience, data analytics. Cons: Higher upfront investment. |

| Luxury Vending Machine | Premium products, upscale design | Hotels, spas, upscale retail | Pros: Attracts affluent customers, unique branding opportunity. Cons: High maintenance costs. |

| Customizable Vending Machine | Tailored product offerings, branding options | Events, trade shows, niche markets | Pros: Flexibility in product selection, brand visibility. Cons: Potentially longer lead times for setup. |

| Eco-Friendly Vending Machine | Sustainable materials, eco-conscious products | Health-conscious markets, eco-friendly stores | Pros: Appeals to eco-conscious consumers, positive brand image. Cons: May have higher initial costs. |

Standard Vending Machine

The standard vending machine is the most basic type, typically offering a single product category, such as snacks or beverages. These machines are widely used in retail shops and convenience stores, providing a cost-effective solution for quick sales. Buyers should consider the machine’s ease of operation and maintenance, although the limited product variety may not meet diverse consumer demands.

Smart Vending Machine

Smart vending machines incorporate advanced technology, including digital payment systems and inventory tracking. Ideal for high-traffic areas such as malls, these machines enhance the user experience and allow operators to gather valuable sales data. While the initial investment is higher compared to standard machines, the potential for increased sales and customer engagement can justify the costs for B2B buyers.

Luxury Vending Machine

Luxury vending machines focus on premium products and feature upscale designs, making them suitable for environments like hotels, spas, and upscale retail locations. These machines attract affluent customers and provide unique branding opportunities. However, buyers must be mindful of the higher maintenance costs associated with keeping luxury products in stock and ensuring a high-quality presentation.

Customizable Vending Machine

Customizable vending machines allow businesses to tailor product offerings and incorporate branding elements. They are particularly effective at events, trade shows, and in niche markets where specific consumer preferences exist. The flexibility in product selection can enhance brand visibility, but buyers should be aware of potentially longer lead times for setup and customization.

Eco-Friendly Vending Machine

Eco-friendly vending machines focus on sustainability, using environmentally friendly materials and offering eco-conscious products. They are increasingly popular in health-conscious markets and eco-friendly stores. While these machines can attract a growing segment of eco-conscious consumers and enhance brand image, the initial costs may be higher, requiring careful consideration of ROI for B2B buyers.

Related Video: Machine Learning in 2024 – Beginner’s Course

Key Industrial Applications of panty vending machine

| Industry/Sector | Specific Application of Panty Vending Machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Hotel room amenities | Enhances guest experience and convenience | Compact design, easy maintenance, payment system integration |

| Retail | Shopping malls and retail stores | Provides quick access to personal items | Stock variety, machine size, security features |

| Events and Entertainment | Concerts, festivals, and sporting events | Meets urgent needs in high-traffic areas | Durability, cashless payment options, branding opportunities |

| Health and Wellness | Gyms and fitness centers | Encourages hygiene and personal care | Robust design, product variety, user-friendly interface |

| Education | Universities and colleges | Supports student well-being and convenience | Size, product range, ease of use for diverse demographics |

In the hospitality sector, panty vending machines are increasingly used in hotels to enhance guest experience. These machines provide a convenient solution for travelers who may need personal items at odd hours. For B2B buyers, it’s essential to consider compact designs that fit within limited space, ease of maintenance for hotel staff, and seamless payment system integrations to ensure a hassle-free transaction process for guests.

In retail, panty vending machines are strategically placed in shopping malls and stores, offering customers quick access to personal items. This not only caters to immediate consumer needs but also drives impulse purchases. Buyers in this sector should focus on the variety of stock available, the machine’s size to fit retail layouts, and security features to prevent theft and ensure product safety.

For events and entertainment venues, such as concerts and festivals, panty vending machines serve as a practical solution for attendees. High foot traffic necessitates quick access to hygiene products. B2B buyers should prioritize machines that are durable enough to withstand heavy use, offer cashless payment options for convenience, and allow for branding opportunities to enhance event visibility.

In the health and wellness industry, particularly in gyms and fitness centers, panty vending machines promote hygiene by providing necessary personal items. This encourages members to maintain personal care routines. Buyers in this sector should look for robust designs that can withstand frequent use, a diverse product range to meet various customer preferences, and user-friendly interfaces that make transactions straightforward.

Lastly, in the education sector, universities and colleges can benefit from panty vending machines by supporting student well-being. These machines can be placed in dormitories or common areas, providing easy access to essential items. Key considerations for buyers include the size of the machine to accommodate various locations, the range of products offered to cater to a diverse student body, and ease of use to ensure accessibility for all students.

Related Video: USES OF ROBOTS | Robotics in Daily Life

Strategic Material Selection Guide for panty vending machine

When selecting materials for panty vending machines, international B2B buyers must consider various factors that influence product performance, durability, and compliance with regional standards. Below is an analysis of four common materials used in the construction of panty vending machines, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

1. Stainless Steel

Key Properties: Stainless steel is known for its excellent corrosion resistance, high tensile strength, and ability to withstand a wide range of temperatures. It typically has a temperature rating of up to 800°F (427°C) and is resistant to rust and staining.

Pros & Cons: The primary advantage of stainless steel is its durability and low maintenance requirements. It is also aesthetically pleasing, making it suitable for high-traffic areas. However, stainless steel can be more expensive than other materials, and its manufacturing process can be complex, leading to higher production costs.

Impact on Application: Stainless steel is compatible with various environments and is ideal for locations with high humidity or exposure to cleaning chemicals. It maintains its integrity and appearance over time, which is crucial for consumer-facing products.

Considerations for International Buyers: Buyers should ensure compliance with local standards, such as ASTM or DIN, for material quality and safety. Additionally, the supply chain logistics for stainless steel can vary significantly by region, affecting lead times and costs.

2. Powder-Coated Steel

Key Properties: Powder-coated steel provides a protective layer that enhances corrosion resistance and wear resistance. It can withstand moderate temperatures and is available in various colors and finishes.

Pros & Cons: The main advantage of powder-coated steel is its cost-effectiveness and the aesthetic options it offers. It is generally less expensive than stainless steel while still providing decent durability. However, if the coating gets scratched, it can lead to rusting underneath, compromising the material’s integrity.

Impact on Application: This material is suitable for indoor vending machines where exposure to harsh environments is limited. It is less ideal for outdoor settings or areas with high moisture levels.

Considerations for International Buyers: Buyers should verify the quality of the powder coating and ensure it meets local standards for durability and safety. The availability of color options may also vary by region, influencing design choices.

3. Aluminum

Key Properties: Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity. It typically has a temperature rating of up to 400°F (204°C) and is easy to machine.

Pros & Cons: The lightweight nature of aluminum makes it easier to transport and install. It is also resistant to corrosion, which is beneficial in humid environments. However, aluminum is generally less durable than stainless steel and can be more susceptible to dents and scratches.

Impact on Application: Aluminum is suitable for vending machines in environments where weight savings are crucial, such as mobile vending units. Its corrosion resistance makes it a good choice for coastal areas.

Considerations for International Buyers: Buyers should consider the specific alloy used, as different grades of aluminum have varying properties. Compliance with local standards for aluminum products is also essential, especially in regions with strict regulations.

4. High-Impact Plastic

Key Properties: High-impact plastic is lightweight, resistant to impact, and can be molded into complex shapes. It generally has a lower temperature tolerance compared to metals but is often rated for use in a wide range of conditions.

Pros & Cons: The key advantage of high-impact plastic is its cost-effectiveness and ease of manufacturing. It can be produced in various colors and designs, making it visually appealing. However, it may not be as durable as metal options and can degrade over time when exposed to UV light.

Impact on Application: This material is ideal for indoor vending machines or those in low-traffic areas. It is less suitable for outdoor use or in environments where heavy wear and tear are expected.

Considerations for International Buyers: Buyers should confirm that the plastic meets safety standards and is suitable for food contact if applicable. The environmental impact of plastic materials is also a growing concern, particularly in regions with stringent environmental regulations.

Summary Table

| Material | Typical Use Case for panty vending machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | High-traffic areas, outdoor environments | Excellent durability and corrosion resistance | Higher cost and complex manufacturing | High |

| Powder-Coated Steel | Indoor vending machines | Cost-effective with aesthetic options | Vulnerable to scratches, leading to rust | Medium |

| Aluminum | Mobile vending units, coastal areas | Lightweight and corrosion-resistant | Less durable, susceptible to dents | Medium |

| High-Impact Plastic | Indoor, low-traffic areas | Cost-effective and easy to manufacture | Less durable, can degrade under UV exposure | Low |

This strategic material selection guide provides essential insights for international B2B buyers, enabling informed decisions when sourcing materials for panty vending machines.

In-depth Look: Manufacturing Processes and Quality Assurance for panty vending machine

The manufacturing process of panty vending machines involves several critical stages, each designed to ensure the final product meets quality and functionality standards. Understanding these processes is essential for international B2B buyers, especially when sourcing from diverse markets in Africa, South America, the Middle East, and Europe.

Manufacturing Process

1. Material Preparation

The first step in the manufacturing process is the selection and preparation of materials. Common materials used for panty vending machines include:

- Metal Components: Steel or aluminum is often used for the frame due to its durability and resistance to wear and corrosion.

- Plastic Parts: High-density polyethylene (HDPE) or polycarbonate is used for components like the vending mechanism and housing, providing lightweight yet sturdy options.

- Electrical Components: Wiring, sensors, and control systems are sourced to ensure reliable operation and user-friendly interfaces.

Materials are typically sourced from certified suppliers to ensure compliance with international standards. B2B buyers should verify the material specifications through documentation to ensure they meet local regulations.

2. Forming

Once materials are prepared, the forming stage begins. This involves various techniques such as:

- Metal Stamping: Sheets of metal are stamped into specific shapes and sizes for the machine’s structure. This is done using hydraulic presses that ensure precision and consistency.

- Injection Molding: Plastic components are created using injection molding, where molten plastic is injected into molds. This process allows for high-volume production with consistent quality.

- Cutting and Machining: Additional shaping of metal components may be required through cutting and machining to achieve precise dimensions.

B2B buyers should inquire about the machinery and techniques used in this stage, as they can impact both the cost and quality of the final product.

3. Assembly

The assembly process involves combining the various components into a complete vending machine. This typically includes:

- Mechanical Assembly: Assembling the frame, vending mechanism, and any moving parts. This process often involves the use of automated machinery, ensuring efficiency and accuracy.

- Electrical Assembly: Installing wiring, sensors, and control systems. This step is crucial for ensuring the machine operates correctly and safely.

- Final Assembly: Adding finishing touches, such as branding, user interfaces, and safety features.

Quality assurance during assembly is vital. B2B buyers can request details on the assembly line processes and the qualifications of the personnel involved.

4. Finishing

The finishing stage includes painting, coating, or applying decals to enhance the aesthetic appeal and protect the machine from environmental factors. Techniques may include:

- Powder Coating: This provides a durable finish that is resistant to scratches and corrosion.

- Screen Printing: Used for branding and providing operational instructions directly on the machine.

Buyers should verify that the finishing methods used are suitable for their target market’s climate and usage conditions.

Quality Assurance

Quality assurance (QA) is a critical aspect of manufacturing panty vending machines, ensuring that each unit meets specified standards before reaching the market.

International Standards

Several international standards are relevant to the manufacturing and quality assurance of vending machines:

- ISO 9001: This standard outlines requirements for a quality management system (QMS) and is crucial for suppliers aiming to demonstrate consistent quality and customer satisfaction.

- CE Marking: Required for products sold within the European Economic Area, ensuring compliance with safety, health, and environmental protection standards.

- API Standards: While primarily for oil and gas, similar principles can be applied to manufacturing processes, ensuring robustness and reliability.

B2B buyers should confirm that their suppliers are compliant with these standards, which can significantly affect market entry and product acceptance.

Quality Control Checkpoints

Quality control (QC) involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Inspecting raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Monitoring the manufacturing process at various stages to identify defects early.

- Final Quality Control (FQC): Conducting thorough inspections of the completed machines to ensure they function correctly and meet all specifications.

B2B buyers should request reports from these checkpoints to assess the supplier’s commitment to quality.

Common Testing Methods

Testing methods employed during quality control may include:

- Functional Testing: Ensuring that the vending machine operates correctly under various conditions.

- Durability Testing: Simulating long-term usage to assess wear and tear on components.

- Safety Testing: Verifying that all electrical components comply with safety standards to prevent hazards.

Buyers can ask suppliers about their testing procedures and request access to testing reports as part of their due diligence.

Verifying Supplier Quality Control

To ensure reliable quality control practices, B2B buyers should consider the following:

- Supplier Audits: Conducting on-site audits of manufacturing facilities to assess compliance with quality standards.

- Quality Reports: Requesting detailed quality assurance reports, including testing results and certifications.

- Third-Party Inspections: Engaging independent third-party inspectors to validate the supplier’s QC processes and product quality.

Understanding these processes and standards will empower international B2B buyers to make informed decisions when sourcing panty vending machines, ensuring they receive high-quality products that meet their market needs.

Related Video: Most Satisfying Factory Production Processes And Heavy-Duty Factory Machines!

Comprehensive Cost and Pricing Analysis for panty vending machine Sourcing

When sourcing panty vending machines, understanding the comprehensive cost structure and pricing dynamics is essential for international B2B buyers. The following analysis outlines the key cost components, pricing influencers, and actionable buyer tips to optimize purchasing strategies.

Cost Components

-

Materials: The primary materials used in panty vending machines include metal for the chassis, plastic for the dispensing mechanism, and electronic components for payment systems. The choice of materials significantly affects the overall cost. Higher-quality materials may lead to increased durability and a longer lifespan but come at a higher initial investment.

-

Labor: Labor costs vary based on geographical location and the complexity of manufacturing processes. In regions with lower labor costs, such as parts of Africa and South America, buyers may find more competitive pricing. However, it’s crucial to ensure that labor practices adhere to local regulations and standards.

-

Manufacturing Overhead: This includes indirect costs associated with the production process, such as utilities, rent, and administrative expenses. Efficient manufacturing processes can reduce overhead costs, impacting the final pricing of the machines.

-

Tooling: Tooling costs involve the expense of molds and dies used in the production of vending machines. Custom designs or modifications will increase tooling expenses, which should be factored into the total cost.

-

Quality Control (QC): Ensuring that machines meet quality standards involves additional costs for testing and inspections. Buyers should prioritize suppliers with robust QC processes, as this can minimize long-term operational issues.

-

Logistics: Shipping and handling costs can vary widely depending on the origin of the goods, destination, and chosen Incoterms. Buyers must consider both domestic and international shipping rates when calculating total costs.

Illustrative Image (Source: Google Search)

- Margin: Suppliers typically include a profit margin in their pricing. Understanding standard margins in the vending machine industry can help buyers gauge whether the offered prices are competitive.

Price Influencers

-

Volume/MOQ: Larger orders can significantly reduce the unit price due to economies of scale. Buyers should negotiate minimum order quantities (MOQs) that align with their inventory and demand projections.

-

Specifications/Customization: Custom features or specific branding requirements can increase costs. Buyers should clarify their needs upfront to avoid unexpected expenses.

-

Materials Quality/Certifications: Higher-quality materials or compliance with specific certifications (e.g., safety standards) may come at a premium. Buyers should weigh the benefits of investing in quality against potential future costs related to maintenance and replacements.

-

Supplier Factors: The reputation, reliability, and location of suppliers can influence pricing. Established suppliers may charge more due to their experience and service quality.

-

Incoterms: Different Incoterms can affect shipping costs and responsibilities. Understanding these terms is critical for budgeting and risk management.

Buyer Tips

-

Negotiation: Engage in proactive negotiations with suppliers. Understand the cost breakdown to leverage discussions effectively.

-

Cost-Efficiency: Look beyond the initial purchase price. Consider factors like maintenance, energy consumption, and warranty terms to calculate the Total Cost of Ownership (TCO).

-

Pricing Nuances: International buyers should be aware of fluctuating currency rates and potential tariffs that can affect overall costs. Building relationships with suppliers can also lead to better pricing arrangements over time.

-

Research and Due Diligence: Conduct thorough research on potential suppliers and their market standing. Request samples or prototypes to evaluate quality before committing to larger orders.

Disclaimer

Prices mentioned in this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. Always consult with multiple suppliers to ensure competitive pricing and favorable terms.

Spotlight on Potential panty vending machine Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘panty vending machine’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for panty vending machine

When considering the procurement of panty vending machines, it is essential for international B2B buyers to understand the key technical properties and trade terminology that govern this specialized market. Knowledge of these aspects can lead to informed purchasing decisions and successful operational integration.

Critical Technical Properties

-

Material Grade

– Definition: The quality of materials used in manufacturing the vending machine, typically stainless steel or high-grade plastic.

– Importance: High-quality materials ensure durability and resistance to wear and tear, particularly important in high-traffic environments. Buyers should seek machines with corrosion-resistant finishes to maintain aesthetics and functionality. -

Dimensions and Weight Capacity

– Definition: The physical size of the vending machine and its maximum load capacity.

– Importance: Understanding dimensions is crucial for fitting machines in designated locations, especially in retail environments. Weight capacity should be adequate to support the volume of products offered, ensuring that machines can operate effectively without risk of malfunction. -

Power Requirements

– Definition: The electrical specifications needed for the machine to operate, including voltage and wattage.

– Importance: Machines must be compatible with local power supply standards in various regions. Buyers should consider energy-efficient models to minimize operational costs and comply with environmental regulations.

Illustrative Image (Source: Google Search)

-

User Interface Technology

– Definition: The technology used for customer interaction, which may include touch screens, card readers, or mobile payment options.

– Importance: Advanced interfaces improve customer experience and can increase sales. Understanding the technological capabilities can also inform decisions on maintenance and upgrades. -

Security Features

– Definition: The mechanisms in place to prevent theft and vandalism, such as reinforced locks and anti-tamper designs.

– Importance: Security is a significant concern for machines placed in public or unsupervised areas. Robust security features protect inventory and revenue, making it a crucial specification for buyers.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts and equipment that may be marketed by another manufacturer.

– Context: Buyers often collaborate with OEMs for custom machine designs that meet specific market needs, ensuring that the machines are tailored for their target demographics. -

MOQ (Minimum Order Quantity)

– Definition: The smallest number of units that a supplier is willing to sell.

– Context: Understanding MOQ is essential for budgeting and inventory planning. Buyers should negotiate terms that align with their sales forecasts and storage capabilities. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers to request pricing and terms for specific products or services.

– Context: An RFQ helps buyers compare offers and make informed decisions. It is crucial for obtaining competitive pricing and understanding the total cost of ownership. -

Incoterms (International Commercial Terms)

– Definition: A series of pre-defined commercial terms published by the International Chamber of Commerce, which clarify the responsibilities of buyers and sellers in international transactions.

– Context: Familiarity with Incoterms is vital for understanding shipping responsibilities, costs, and risks associated with the delivery of vending machines, especially when importing from different regions. -

Lead Time

– Definition: The amount of time taken from placing an order to the delivery of the product.

– Context: Knowing the lead time helps buyers plan their inventory effectively and ensure that machines are available when needed, particularly in preparation for peak sales periods.

By grasping these technical specifications and trade terms, B2B buyers can enhance their procurement strategies, ensuring that they select the right panty vending machines that meet their operational needs and market demands.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the panty vending machine Sector

Market Overview & Key Trends

The panty vending machine sector is undergoing a transformative phase driven by evolving consumer needs, technological advancements, and changing retail landscapes. International B2B buyers should be aware of several key trends shaping this market:

-

Increased Demand for Convenience: As urban lifestyles become busier, the demand for convenient solutions has surged. Panty vending machines provide an immediate solution for consumers, particularly in high-traffic areas such as shopping malls, airports, and universities.

-

Technological Integration: Modern vending machines are increasingly equipped with cashless payment systems, touch screens, and inventory management software. This tech integration not only enhances user experience but also facilitates real-time data collection for better inventory control and sales analytics, crucial for B2B buyers looking to optimize their operations.

-

Sustainability Initiatives: There is a growing emphasis on eco-friendly products and practices within the panty vending machine sector. Buyers are increasingly seeking machines that offer sustainable and ethically sourced products, reflecting a broader global trend toward corporate responsibility.

-

Emerging Markets: Regions such as Africa and South America are seeing a rise in disposable income and urbanization, creating new opportunities for vending solutions. B2B buyers should explore partnerships with local distributors to penetrate these markets effectively.

-

Customization and Branding: The ability to customize vending machines with unique branding and product offerings is becoming a competitive advantage. This trend allows businesses to cater to specific demographics and enhance brand visibility.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a non-negotiable aspect of the panty vending machine market. International B2B buyers must consider the environmental impacts associated with the sourcing and production of products offered in these machines. Key factors include:

-

Material Selection: The use of organic, biodegradable, or recycled materials for packaging and products can significantly reduce the environmental footprint. Buyers should prioritize suppliers who adhere to sustainable practices and materials.

-

Ethical Supply Chains: Transparency in the supply chain is crucial. Buyers should seek partnerships with manufacturers that ensure fair labor practices and ethical sourcing of raw materials. Certifications such as Fair Trade and Global Organic Textile Standard (GOTS) can guide buyers in selecting responsible suppliers.

-

Green Certifications: Vending machine manufacturers are increasingly obtaining certifications for energy efficiency and environmental impact. Buyers should look for machines that are certified by recognized organizations, as this not only enhances brand reputation but also aligns with consumer expectations for sustainability.

By aligning sourcing practices with sustainability goals, B2B buyers can not only meet consumer demand but also contribute positively to global sustainability efforts.

Brief Evolution/History

The concept of vending machines has evolved significantly since their inception in the late 19th century. Initially focused on providing simple snacks and beverages, the vending machine industry has diversified dramatically. The introduction of panty vending machines in the early 2000s marked a significant shift, catering specifically to women’s needs for convenience and privacy. Over the years, advancements in technology, coupled with a heightened awareness of sustainability, have shaped the current landscape of this niche market. As a result, today’s panty vending machines are not only functional but also reflect broader trends in consumer behavior, technology, and corporate responsibility.

In conclusion, international B2B buyers must navigate these evolving market dynamics and sustainability considerations to successfully engage with the panty vending machine sector. By staying informed about trends and prioritizing ethical sourcing, buyers can position themselves effectively in this growing market.

Related Video: Is global trade transforming? | Counting the Cost

Frequently Asked Questions (FAQs) for B2B Buyers of panty vending machine

-

What should I consider when vetting suppliers for panty vending machines?

When vetting suppliers, prioritize their experience in the vending machine industry, specifically with panty vending machines. Verify their business credentials, check for certifications (such as ISO), and seek reviews or testimonials from previous clients. Additionally, request references and conduct background checks to ensure they have a reliable track record. Consider visiting their facility if possible, as this can provide insights into their production capacity and quality control processes. -

Can I customize the panty vending machines to suit my brand?

Yes, many suppliers offer customization options for panty vending machines. You can typically select colors, branding elements, and even machine features such as payment systems or inventory types. Discuss your specific requirements with potential suppliers during the initial negotiations. Providing them with your brand guidelines will help ensure that the final product aligns with your branding strategy.

-

What are the typical minimum order quantities (MOQ) and lead times for panty vending machines?

Minimum order quantities can vary widely among suppliers, often ranging from 5 to 100 units. It’s essential to clarify this during your initial discussions. Lead times can also differ based on customization requirements and the supplier’s production schedule, typically ranging from 4 to 12 weeks. Always confirm these details in advance to align your inventory needs with your business timeline. -

What payment terms should I expect when sourcing from international suppliers?

Payment terms vary by supplier but generally include options such as advance payment, letters of credit, or payment upon delivery. Ensure you negotiate terms that protect your interests, such as partial payments before shipment and the balance upon receipt. Be aware of currency fluctuations, and consider using a secure payment platform to mitigate risks associated with international transactions. -

What quality assurance measures should I look for in panty vending machines?

Look for suppliers that adhere to international quality standards, such as ISO 9001. Request documentation of their quality assurance processes, including inspection protocols and testing procedures. Additionally, inquire about warranties and after-sales support. A reputable supplier should provide clear information on how they handle defects and maintenance, ensuring that you can rely on their products. -

How do logistics work when importing panty vending machines?

Logistics involve several steps, including shipping, customs clearance, and delivery. Work with suppliers who have experience in international shipping and can guide you through the process. Ensure they provide clear shipping terms (like Incoterms) and consider hiring a freight forwarder to handle logistics on your behalf. Understanding your import duties and taxes in advance can also help prevent unexpected costs. -

What should I do if there is a dispute with the supplier?

In the event of a dispute, start by attempting to resolve the issue directly with the supplier through clear communication. Document all interactions and agreements. If the issue remains unresolved, refer to the terms outlined in your contract regarding dispute resolution. Consider mediation or arbitration as alternatives to litigation, as these can be less costly and more efficient for international disputes. -

Are there specific certifications I should look for when sourcing panty vending machines?

Yes, look for certifications that demonstrate compliance with safety and quality standards, such as CE (European Conformity) for the European market, UL (Underwriters Laboratories) for North America, and ISO certifications. These certifications ensure that the machines meet necessary safety and environmental regulations. Additionally, inquire about any local certifications required in your target market to ensure compliance.

Strategic Sourcing Conclusion and Outlook for panty vending machine

The strategic sourcing of panty vending machines presents a unique opportunity for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. As consumer preferences evolve, the demand for convenience and accessibility in personal care products is on the rise. Buyers should focus on establishing strong relationships with reliable manufacturers and distributors that offer quality machines tailored to local market needs.

Key takeaways include:

- Market Understanding: Conduct thorough research to understand regional consumer behaviors and preferences, which can inform product selection and machine placement.

- Supplier Evaluation: Prioritize suppliers with a proven track record of quality and reliability. Assess their capacity to meet demand and their responsiveness to market changes.

- Technological Integration: Embrace innovations such as cashless payment systems and smart inventory management to enhance user experience and operational efficiency.

Looking ahead, the panty vending machine market is poised for growth, driven by urbanization and changing consumer habits. International buyers are encouraged to act proactively, leveraging strategic sourcing to capitalize on this emerging trend. By investing in this niche market, businesses can not only meet consumer needs but also position themselves as leaders in a rapidly evolving retail landscape.