Your Ultimate Guide to Sourcing Live Bait Vending Machine

Guide to Live Bait Vending Machine Near Me

- Introduction: Navigating the Global Market for live bait vending machine near me

- Understanding live bait vending machine near me Types and Variations

- Key Industrial Applications of live bait vending machine near me

- Strategic Material Selection Guide for live bait vending machine near me

- In-depth Look: Manufacturing Processes and Quality Assurance for live bait vending machine near me

- Comprehensive Cost and Pricing Analysis for live bait vending machine near me Sourcing

- Spotlight on Potential live bait vending machine near me Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for live bait vending machine near me

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the live bait vending machine near me Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of live bait vending machine near me

- Strategic Sourcing Conclusion and Outlook for live bait vending machine near me

Introduction: Navigating the Global Market for live bait vending machine near me

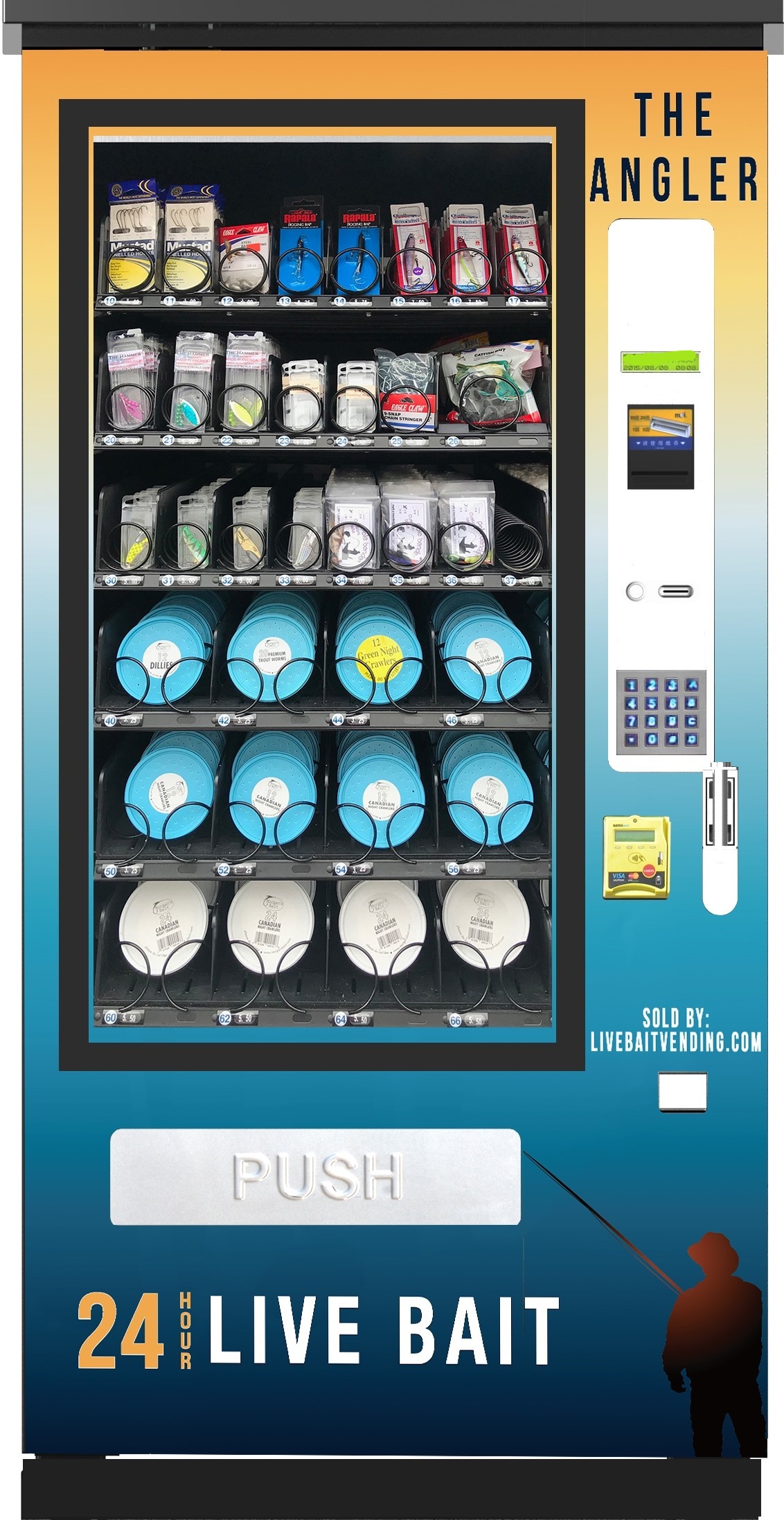

Navigating the global market for live bait vending machines is essential for businesses looking to enhance their offerings in the fishing industry. With the rise in recreational fishing and the demand for convenient bait access, these machines have become a crucial investment for retailers and operators worldwide. The ability to provide live bait on-demand not only attracts more customers but also increases sales opportunities, especially in regions with vibrant fishing communities.

This comprehensive guide delves into the intricacies of live bait vending machines, covering various aspects that are vital for B2B buyers. You will explore different types of machines tailored for various environments, materials used in construction for durability and maintenance, and the manufacturing and quality control processes that ensure reliability. Additionally, we will provide insights into reputable suppliers, cost considerations, and market trends that impact purchasing decisions.

By equipping yourself with this knowledge, you will be empowered to make informed sourcing decisions, enabling your business to thrive in competitive markets. Whether you’re based in Africa, South America, the Middle East, or Europe—such as Saudi Arabia or Poland—this guide aims to facilitate strategic investments in live bait vending machines that align with your operational goals and customer needs. Prepare to enhance your business offerings and capitalize on emerging opportunities in the fishing sector.

Understanding live bait vending machine near me Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Live Bait Vending Machine | Basic design with refrigerated compartments for live bait storage | Fishing shops, bait and tackle stores | Pros: Cost-effective, easy to maintain. Cons: Limited customization options. |

| High-Capacity Vending Machine | Larger compartments, suitable for bulk bait storage and multiple species | Large retail outlets, supermarkets | Pros: Increased inventory, caters to high demand. Cons: Higher initial investment. |

| Mobile Live Bait Vending Machine | Portable design, often trailer-mounted for events and remote locations | Fishing tournaments, outdoor events | Pros: Flexibility in location, attracts a wider audience. Cons: May require additional permits. |

| Automated Live Bait Machine | Advanced technology for remote monitoring and automated sales | E-commerce platforms, remote fishing spots | Pros: 24/7 operation, reduced labor costs. Cons: Higher maintenance and technical support needs. |

| Eco-Friendly Live Bait Machine | Utilizes sustainable materials and energy-efficient systems | Eco-conscious retailers, specialty bait shops | Pros: Appeals to environmentally aware customers. Cons: Potentially higher upfront costs. |

Standard Live Bait Vending Machine

The Standard Live Bait Vending Machine is the most common type, designed with basic refrigeration to store various types of live bait, such as worms and minnows. This model is suitable for small to medium-sized fishing shops and bait stores where demand is predictable. B2B buyers should consider factors like maintenance ease and initial costs, as these machines are generally cost-effective but may lack advanced features.

High-Capacity Vending Machine

For businesses that cater to larger audiences, the High-Capacity Vending Machine offers extensive storage and can handle multiple species of bait. This machine is ideal for large retail outlets and supermarkets that experience high foot traffic. While the initial investment is higher, the increased inventory capacity can lead to higher sales volumes, making it a worthwhile consideration for B2B buyers looking to expand their offerings.

Mobile Live Bait Vending Machine

The Mobile Live Bait Vending Machine is designed for portability, often mounted on trailers for easy transportation to events like fishing tournaments or outdoor festivals. This type appeals to businesses wanting to reach customers in various locations. B2B buyers should evaluate local regulations regarding mobile sales and potential permit requirements, as these can impact the feasibility of this option.

Automated Live Bait Machine

Automated Live Bait Machines leverage advanced technology to allow for remote monitoring and automated sales, making them ideal for e-commerce platforms and remote fishing spots. They operate 24/7, significantly reducing labor costs. However, B2B buyers need to consider the complexity of maintenance and the necessity for technical support, which can add to operational costs.

Eco-Friendly Live Bait Machine

With a growing emphasis on sustainability, the Eco-Friendly Live Bait Machine utilizes sustainable materials and energy-efficient systems. This model is particularly attractive to eco-conscious retailers and specialty bait shops looking to align with environmentally aware customers. While the initial costs may be higher, the long-term benefits of appealing to a niche market can provide a competitive edge for B2B buyers.

Related Video: World’s First Fishing Lure VENDING MACHINE w/ LIVE BAIT (BIG FISH!)

Key Industrial Applications of live bait vending machine near me

| Industry/Sector | Specific Application of live bait vending machine near me | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fishing & Aquaculture | Retail sales of live bait for recreational and commercial fishing | Increased accessibility for customers, 24/7 availability | Local regulations for live bait sales, machine maintenance support |

| Sports & Recreation | Provision of live bait at fishing tournaments and events | Enhances participant experience, convenience for anglers | Event-specific requirements, local demand fluctuations |

| Food & Beverage | Supply of live bait for restaurants specializing in seafood dishes | Unique offerings, fresh ingredients for culinary innovation | Sourcing of quality bait, partnerships with local fishermen |

| Environmental Research | Use in ecological studies and species monitoring | Supports research initiatives, promotes biodiversity | Compliance with environmental regulations, machine durability |

| Education & Training | Educational programs for schools and universities on fishing techniques | Engages students in practical learning, promotes sustainable practices | Curriculum alignment, machine accessibility for students |

Fishing & Aquaculture

In the fishing and aquaculture sectors, live bait vending machines serve as a vital retail solution, providing easy access to live bait for both recreational and commercial fishers. These machines can be strategically placed in high-traffic fishing areas, allowing customers to purchase bait anytime, thus enhancing convenience. International B2B buyers should consider local regulations regarding live bait sales, as compliance is crucial. Additionally, reliable maintenance and support services are essential to ensure the machines function optimally.

Sports & Recreation

For fishing tournaments and recreational events, live bait vending machines offer a unique service that enhances the overall experience for participants. By providing immediate access to bait, these machines eliminate the hassle of searching for supplies, allowing anglers to focus on their competition. Buyers in this sector should assess the specific needs of their events, including peak usage times and the types of bait preferred by participants. Understanding local demand fluctuations can also help in inventory management.

Food & Beverage

Restaurants specializing in seafood can utilize live bait vending machines to procure fresh ingredients, thereby enhancing their culinary offerings. By sourcing live bait directly from vending machines, these establishments can ensure they are using the freshest ingredients available, which is a significant selling point for discerning customers. B2B buyers in this industry must prioritize the quality of the bait and establish partnerships with local fishermen to maintain a consistent supply chain.

Environmental Research

Live bait vending machines can play a crucial role in environmental research and ecological studies. Researchers can use these machines to obtain live specimens for monitoring species and conducting various ecological assessments. For international buyers, it is essential to consider compliance with environmental regulations, ensuring that the machines used are durable and capable of maintaining the viability of live bait over time.

Education & Training

Educational institutions can leverage live bait vending machines as part of their curriculum on fishing techniques and sustainable practices. This hands-on approach engages students and provides them with practical learning experiences. When sourcing these machines, B2B buyers should ensure that they are accessible to students and align with educational goals. Additionally, the machines should be user-friendly to facilitate ease of use in learning environments.

Related Video: What are all the Laboratory Apparatus and their uses?

Strategic Material Selection Guide for live bait vending machine near me

When selecting materials for live bait vending machines, international B2B buyers must consider several factors, including the operating environment, durability, and compliance with local standards. Below is an analysis of four common materials used in the construction of these machines, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from diverse regions.

1. Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand varying temperatures. It typically has a temperature rating of up to 800°F (427°C) and is resistant to rust and staining.

Pros & Cons:

The primary advantage of stainless steel is its durability and long lifespan, making it suitable for outdoor and humid environments. However, it is generally more expensive than other materials, and its manufacturing can be complex due to the need for specialized tools and techniques.

Impact on Application:

Stainless steel is highly compatible with various media, including water and live bait. Its non-reactive nature ensures that it does not alter the quality of the bait.

Specific Considerations:

Buyers in regions like Europe and the Middle East should ensure compliance with ASTM and DIN standards for food-grade materials. In Africa and South America, local regulations regarding food safety should also be considered.

2. Polycarbonate

Key Properties:

Polycarbonate is a lightweight, impact-resistant plastic with a temperature tolerance of -40°F to 240°F (-40°C to 116°C). It offers excellent clarity and UV resistance.

Pros & Cons:

The main advantage of polycarbonate is its lightweight nature and high impact resistance, making it ideal for machine components that may experience physical stress. However, it has lower temperature resistance compared to metals and can be prone to scratching.

Impact on Application:

Polycarbonate is suitable for viewing panels in vending machines, allowing customers to see the bait. It is also compatible with water and various organic materials.

Specific Considerations:

International buyers should check for compliance with JIS standards in Japan and similar regulations in their respective regions. Polycarbonate’s recyclability may appeal to environmentally conscious markets in Europe and South America.

3. Aluminum

Key Properties:

Aluminum is lightweight, corrosion-resistant, and has a melting point of around 1,220°F (660°C). It is also a good conductor of heat, which can be beneficial in temperature-sensitive applications.

Pros & Cons:

Aluminum is cost-effective and easy to machine, making it a popular choice for various components. However, it may not be as durable as stainless steel in harsh environments and can be prone to denting.

Impact on Application:

Aluminum is suitable for structural components and housing of vending machines. Its lightweight nature allows for easier installation and transport.

Specific Considerations:

Buyers should be aware of local corrosion resistance standards, especially in coastal areas of Africa and the Middle East, where saltwater exposure is a concern. Compliance with ASTM standards is also advisable.

4. Galvanized Steel

Key Properties:

Galvanized steel is steel that has been coated with a layer of zinc to prevent corrosion. It typically has a temperature rating similar to that of carbon steel but offers better corrosion resistance.

Pros & Cons:

The primary advantage of galvanized steel is its cost-effectiveness and enhanced durability compared to untreated steel. However, it may still corrode over time if the zinc layer is compromised, and it can be heavier than other materials.

Impact on Application:

Galvanized steel is suitable for the structural framework of vending machines, especially in environments where moisture is present.

Specific Considerations:

International buyers should ensure compliance with local standards for food safety and corrosion resistance. In Europe, adherence to EN standards is crucial, while buyers in South America may need to check local regulations.

Summary Table

| Material | Typical Use Case for live bait vending machine near me | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural and contact surfaces | Excellent durability and corrosion resistance | Higher cost and complex manufacturing | High |

| Polycarbonate | Viewing panels and protective covers | Lightweight and impact-resistant | Lower temperature resistance | Medium |

| Aluminum | Structural components and machine housing | Cost-effective and easy to machine | Less durable than stainless steel | Low |

| Galvanized Steel | Framework and structural components | Cost-effective with good durability | Can corrode over time | Medium |

This material selection guide provides actionable insights for international B2B buyers, ensuring they make informed decisions based on their specific regional requirements and operational needs.

In-depth Look: Manufacturing Processes and Quality Assurance for live bait vending machine near me

Manufacturing Processes for Live Bait Vending Machines

Understanding the manufacturing processes of live bait vending machines is crucial for B2B buyers seeking reliable suppliers. The manufacturing journey typically includes several stages, each vital to ensuring the final product meets industry standards and customer expectations.

Main Stages of Manufacturing

-

Material Preparation

– The initial stage involves sourcing high-quality materials suitable for outdoor use, such as stainless steel, aluminum, and plastics that are resistant to corrosion and environmental factors.

– Suppliers often conduct material inspections to ensure compliance with specified standards, such as ASTM for metals or FDA regulations for plastics that may come into contact with live bait. -

Forming

– Techniques Used: Common forming techniques include CNC machining, laser cutting, and bending. These methods ensure precision and uniformity in the components of the vending machine.

– At this stage, components like the machine body, compartments, and dispensing mechanisms are fabricated. Advanced technologies such as 3D printing may also be employed for prototyping or creating complex parts. -

Assembly

– The assembly process integrates all components, including electronic systems for payment processing, bait dispensing, and user interfaces.

– Automated vs. Manual Assembly: Depending on the scale, assembly can be manual or automated. Automated assembly lines can improve efficiency and reduce human error, while manual assembly allows for more detailed craftsmanship. -

Finishing

– This stage involves surface treatments such as powder coating or painting to enhance durability and aesthetics.

– Quality Checks: Prior to finishing, components undergo inspections for dimensional accuracy and surface defects. Post-finishing, the machines are cleaned and prepared for final assembly.

Quality Assurance in Manufacturing

Quality assurance (QA) is paramount in the production of live bait vending machines to ensure reliability and safety. B2B buyers should be familiar with international standards and industry-specific certifications.

Relevant International Standards

- ISO 9001: This standard focuses on quality management systems and is applicable across various industries. Compliance indicates that the manufacturer has processes in place for consistent quality.

- CE Marking: For products sold in the European Economic Area, CE marking indicates conformity with health, safety, and environmental protection standards.

- API Certification: Particularly relevant for manufacturers dealing with aquatic life, API certification ensures that products are safe for both users and the environment.

QC Checkpoints

-

Incoming Quality Control (IQC)

– At this initial stage, raw materials and components are inspected upon arrival. This includes checking for damage, compliance with specifications, and the presence of necessary certifications. -

In-Process Quality Control (IPQC)

– Throughout the manufacturing process, periodic inspections are conducted to catch any defects early. This may involve monitoring machine calibration, dimensional checks, and functional tests of mechanical components. -

Final Quality Control (FQC)

– Before shipping, each vending machine undergoes a comprehensive final inspection, which includes functionality tests, safety checks, and overall appearance assessments.

Common Testing Methods

- Functional Testing: Ensures that all electronic components, such as payment systems and dispensing mechanisms, operate correctly.

- Environmental Testing: Machines may undergo tests simulating environmental conditions they will face, such as humidity, temperature fluctuations, and exposure to saltwater.

- Performance Testing: Evaluates the machine’s ability to maintain bait quality over time, including temperature control and humidity levels.

Verifying Supplier Quality Control

B2B buyers must take proactive steps to ensure that their suppliers maintain high-quality standards. Here are actionable insights for effective verification:

- Conduct Audits: Regularly schedule audits of potential suppliers to assess their manufacturing processes and quality control systems. This provides firsthand insight into their operations and compliance with standards.

- Request Quality Reports: Suppliers should be willing to provide documentation of their quality control processes, including IQC, IPQC, and FQC reports.

- Engage Third-Party Inspectors: Utilize third-party inspection services to conduct independent evaluations of the manufacturing facility and the products before shipment.

QC and Certification Nuances for International Buyers

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, must be aware of certain nuances in quality control and certification:

- Regional Compliance: Different regions may have specific regulations or standards. For example, Middle Eastern countries may have unique certification requirements that differ from those in Europe.

- Documentation: Ensure that all certifications are not only current but also valid in the destination country. This includes understanding the nuances between CE marking in Europe and other certifications recognized in different regions.

- Cultural Considerations: Understanding cultural differences in business practices can aid in establishing trust with suppliers. Regular communication and relationship building are essential in regions where face-to-face interactions are valued.

In summary, international B2B buyers must prioritize understanding the manufacturing processes and quality assurance protocols of live bait vending machines. By leveraging these insights, they can make informed purchasing decisions that align with their business needs and regulatory requirements.

Related Video: The Most Sophisticated Manufacturing Process In The World Inside The Fab | Intel

Comprehensive Cost and Pricing Analysis for live bait vending machine near me Sourcing

When considering the sourcing of live bait vending machines, it is essential to understand the comprehensive cost structure and pricing dynamics that influence procurement decisions. The total cost of a vending machine encompasses several components, each contributing to the overall expenditure.

Cost Components

-

Materials: The primary materials for live bait vending machines include high-quality plastics, metals, and electronic components. The choice of materials directly impacts durability and functionality. For instance, machines designed for outdoor use may require corrosion-resistant materials, which can increase costs.

-

Labor: Labor costs vary significantly by region and can be influenced by local wage standards. Skilled labor for assembly and installation may incur higher costs, especially in regions with stringent labor laws.

-

Manufacturing Overhead: This includes costs associated with factory operations such as utilities, rent, and administrative expenses. Understanding the manufacturing location can provide insights into these overhead costs, which may vary widely between countries.

-

Tooling: Initial setup costs for molds and production tooling are substantial, particularly for customized machines. Depending on the complexity of the design, these costs can be amortized over larger production runs, making bulk purchases more economical.

-

Quality Control (QC): Ensuring that machines meet quality standards is critical, especially in international markets. QC processes add to the overall cost but are essential for maintaining product reliability and customer satisfaction.

-

Logistics: Shipping costs, including freight and insurance, must be factored into the total cost. The choice of Incoterms (e.g., FOB, CIF) affects responsibility for shipping costs and risks, influencing the final pricing for buyers.

-

Margin: Suppliers typically build in a profit margin, which can vary based on market conditions, competition, and perceived value. Understanding the expected margin can aid in negotiations.

Price Influencers

Several factors can influence the pricing of live bait vending machines:

-

Volume/MOQ: Minimum order quantities (MOQ) often lead to volume discounts. Larger orders can significantly reduce the per-unit cost.

-

Specifications/Customization: Custom features such as branding, size, and technology integration can increase costs. Buyers should assess whether these features add sufficient value to justify higher prices.

-

Materials and Quality Certifications: Machines that meet specific certifications (e.g., CE, ISO) may command higher prices due to the assurance of quality and compliance with safety standards.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established manufacturers may charge more due to their proven track record and support services.

Buyer Tips

To navigate the complexities of pricing and costs effectively, international B2B buyers should consider the following tips:

-

Negotiation: Always negotiate prices and terms. Suppliers may have flexibility, particularly for larger orders or long-term contracts.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes purchase price, maintenance, operational costs, and potential resale value. This holistic view can lead to more informed purchasing decisions.

-

Pricing Nuances: Be aware of regional differences in pricing. For example, factors like import tariffs, currency fluctuations, and local market conditions can significantly affect costs for buyers in Africa, South America, the Middle East, and Europe.

-

Research and Compare: Before finalizing any purchase, gather multiple quotes from different suppliers to compare not only prices but also the value offered in terms of service, warranty, and support.

Disclaimer

Prices discussed in this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough due diligence before making purchasing decisions.

Spotlight on Potential live bait vending machine near me Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘live bait vending machine near me’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for live bait vending machine near me

Key Technical Properties for Live Bait Vending Machines

When considering the procurement of live bait vending machines, several technical specifications are crucial to ensure reliability, efficiency, and user satisfaction. Understanding these properties will help B2B buyers make informed decisions.

- Material Grade: The construction material of the vending machine is critical for durability and resistance to environmental factors. Stainless steel is often preferred due to its corrosion resistance and longevity, especially in outdoor settings. A higher material grade indicates better quality, which translates to lower maintenance costs over time.

Illustrative Image (Source: Google Search)

-

Temperature Control Range: Live bait requires specific temperature conditions to remain viable. Machines should have a temperature control range that can accommodate the needs of different types of bait. For instance, certain live baits thrive at temperatures between 10°C to 15°C. A reliable temperature monitoring system is essential for ensuring bait quality, which in turn affects customer satisfaction.

-

Capacity: This refers to the volume of bait that the machine can hold. Understanding the capacity is vital for businesses that expect high foot traffic or operate in areas with a large fishing community. A larger capacity can reduce the frequency of restocking, thus improving operational efficiency.

-

Power Supply Requirements: The power needs of the machine can vary significantly. Some machines may operate on standard electricity, while others may require specialized power sources. Understanding these requirements is essential for ensuring compatibility with local infrastructure, especially in regions where power supply can be inconsistent.

-

User Interface and Payment Systems: A user-friendly interface is critical for customer engagement. Machines equipped with multiple payment options (cash, credit/debit cards, mobile payments) can cater to a broader audience. Additionally, features like touch screens can enhance the user experience, making it easier for customers to select and purchase their bait.

-

Maintenance and Serviceability: Machines should be designed for easy maintenance. Features such as removable panels for cleaning, accessible internal components for repairs, and availability of spare parts are important considerations. A machine that is difficult to maintain can lead to downtime and lost revenue.

Common Trade Terminology

Familiarizing oneself with industry jargon can greatly enhance communication and negotiation processes in B2B transactions. Here are some essential terms:

-

OEM (Original Equipment Manufacturer): This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of live bait vending machines, understanding OEM relationships can help buyers ensure they are sourcing quality components.

-

MOQ (Minimum Order Quantity): This is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for budgeting and inventory management, as it impacts the total initial investment and ongoing procurement strategies.

-

RFQ (Request for Quotation): An RFQ is a document that a buyer sends to suppliers to request pricing and other details for specific products. For B2B buyers, effectively crafting an RFQ can lead to better pricing and terms, ultimately influencing procurement decisions.

-

Incoterms (International Commercial Terms): These are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is crucial for understanding shipping costs, risks, and delivery obligations, especially when dealing with international suppliers.

-

Lead Time: This term refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is essential for planning inventory and ensuring that the business can meet customer demands without interruption.

-

Warranty Period: This indicates the length of time a manufacturer will cover repairs or replacements for defects in the machine. A longer warranty period can provide peace of mind for buyers, reducing the risk of unexpected costs after purchase.

By grasping these technical specifications and industry terms, B2B buyers can navigate the procurement process for live bait vending machines more effectively, ensuring that their investments meet operational needs and customer expectations.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the live bait vending machine near me Sector

Market Overview & Key Trends

The live bait vending machine sector is experiencing a significant transformation driven by several global trends. The rise of urban fishing and recreational angling has led to increased demand for convenient access to bait. As cities expand, traditional bait shops are being replaced or supplemented by automated vending solutions that offer quick and easy access to live bait, particularly in metropolitan areas. This trend is particularly pronounced in regions like Europe and North America, where urban dwellers are increasingly engaging in outdoor activities.

Additionally, technological advancements are reshaping the market landscape. The integration of IoT (Internet of Things) technology into vending machines allows for real-time monitoring of bait conditions, inventory management, and enhanced customer engagement through mobile apps. For B2B buyers from Africa, South America, and the Middle East, investing in these technologically advanced vending solutions can improve operational efficiency and customer satisfaction.

Emerging markets are also recognizing the potential of this sector. In countries like Saudi Arabia and Poland, there is a growing trend towards the adoption of live bait vending machines in fishing hotspots, tourist areas, and even local parks. This opens new avenues for international partnerships and investment opportunities, particularly for suppliers and manufacturers looking to establish their presence in these burgeoning markets.

Sustainability & Ethical Sourcing in B2B

The sustainability of the live bait vending machine industry is increasingly coming under scrutiny. Environmental impacts associated with sourcing live bait, such as overfishing and habitat destruction, necessitate a commitment to ethical sourcing practices. For B2B buyers, this means prioritizing suppliers who adhere to sustainable harvesting methods and contribute to the conservation of aquatic ecosystems.

Ethical supply chains are vital not only for regulatory compliance but also for enhancing brand reputation. Buyers should seek vendors that possess certifications related to sustainability, such as the Marine Stewardship Council (MSC) or the Aquaculture Stewardship Council (ASC). These certifications ensure that the bait offered is sourced responsibly, minimizing ecological footprints and supporting local fishing communities.

Furthermore, there is an increasing demand for ‘green’ materials in the construction of vending machines themselves. Options like biodegradable components and energy-efficient designs are gaining traction. Incorporating these elements not only meets the growing consumer preference for sustainability but also positions businesses favorably in competitive markets.

Brief Evolution/History

The live bait vending machine industry has evolved significantly since its inception in the late 20th century. Initially, these machines were basic, offering limited varieties of bait and lacking technological sophistication. However, with advancements in automation and consumer preferences shifting towards convenience, the industry has embraced innovations like touch-screen interfaces and real-time inventory tracking.

Today, the sector is characterized by a focus on user experience and sustainability. The integration of smart technology and ethical sourcing practices reflects a broader trend across various industries, indicating that modern consumers are not only seeking convenience but also responsible options. This evolution presents substantial opportunities for international B2B buyers to engage with a dynamic and growing market.

Related Video: What global trade deals are really about (hint: it’s not trade) | Haley Edwards | TEDxMidAtlantic

Frequently Asked Questions (FAQs) for B2B Buyers of live bait vending machine near me

-

What should I consider when vetting suppliers for live bait vending machines?

When vetting suppliers, focus on their experience in manufacturing and supplying live bait vending machines. Look for certifications such as ISO and compliance with local regulations. Request references from previous customers and assess their reputation in international markets. Evaluate their customer service responsiveness and willingness to accommodate specific needs, including machine customization and technical support. A reliable supplier should provide detailed product specifications and demonstrate a commitment to quality control. -

Can I customize the features of the live bait vending machine?

Yes, many manufacturers offer customization options. Common customizations include machine size, payment systems (credit card, mobile payments), product selection, and branding. When discussing customization, ensure that the supplier understands your specific market needs and preferences. Document all agreed-upon features in the contract to prevent misunderstandings. Customization may impact the lead time, so discuss timelines with the supplier early in the process. -

What are the typical minimum order quantities (MOQ) and lead times for these machines?

MOQs can vary significantly by supplier, typically ranging from 5 to 50 units depending on the manufacturer’s capacity and your customization requests. Lead times can also vary, often ranging from 4 to 12 weeks. When negotiating, clarify both the MOQ and lead times based on your business needs and ensure that these are included in your purchase agreement. It’s advisable to place larger orders if you anticipate high demand, as this can often lead to discounts. -

What payment methods are commonly accepted by suppliers?

Payment methods can include wire transfers, letters of credit, and escrow services, depending on the supplier’s policies. For international transactions, using letters of credit provides security for both parties, ensuring that payment is made only after the agreed conditions are met. Discuss payment terms upfront, including any required deposits. Establishing clear payment terms in your contract will help avoid disputes later on. -

How can I ensure quality assurance for the vending machines?

Request detailed quality assurance (QA) processes from your supplier, including their inspection protocols before shipment. Certifications such as CE (for Europe) or UL (for the US) can indicate adherence to quality standards. You may also consider hiring a third-party inspection service to conduct quality checks prior to shipment. Document any QA measures in your contract to hold the supplier accountable for product quality. -

What certifications should I look for in live bait vending machines?

Look for certifications that ensure compliance with safety and environmental standards, such as CE, RoHS, or ISO 9001. These certifications indicate that the machines meet international standards for safety and quality. Additionally, inquire if the machines are compliant with local regulations in your target market, as this can affect importation and usage. Ensure that the supplier can provide documentation for all relevant certifications. -

What logistics considerations should I take into account when importing these machines?

Logistics can include shipping methods (air vs. sea), customs clearance, and delivery timelines. Coordinate with your supplier to understand the best shipping methods based on cost and urgency. Be aware of customs duties and taxes applicable in your country, and ensure that all paperwork is in order for a smooth import process. Consider working with a freight forwarder experienced in handling machinery imports for efficient logistics management. -

How can I handle disputes with suppliers effectively?

To handle disputes effectively, maintain clear and open communication with the supplier throughout the transaction. Document all agreements and communications to have a clear record of expectations. In case of a dispute, first attempt to resolve the issue amicably through discussion. If that fails, refer to the dispute resolution clause in your contract, which may specify mediation or arbitration. Having a clear dispute resolution process in place can save time and costs in resolving conflicts.

Strategic Sourcing Conclusion and Outlook for live bait vending machine near me

In conclusion, the strategic sourcing of live bait vending machines presents a unique opportunity for international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe. The integration of these machines into local markets not only meets the rising demand for convenient fishing supplies but also aligns with the growing trend of automated retail solutions.

Key Takeaways:

- Market Demand: The increasing popularity of recreational fishing creates a robust market for live bait vending machines, especially in areas with high fishing activity.

- Cost Efficiency: Strategic sourcing can lead to significant cost savings in procurement and supply chain management, enhancing profitability.

- Local Partnerships: Building relationships with local suppliers and distributors can facilitate smoother market entry and enhance customer satisfaction.

As you consider expanding your offerings, remember that strategic sourcing is not just about finding suppliers; it’s about building a sustainable, efficient supply chain that supports your business goals. Embrace this opportunity to innovate and grow your market presence—the future of fishing supply distribution is automated, and the time to act is now.