Your Ultimate Guide to Sourcing Doorables Vending Machine

Guide to Doorables Vending Machine

- Introduction: Navigating the Global Market for doorables vending machine

- Understanding doorables vending machine Types and Variations

- Key Industrial Applications of doorables vending machine

- Strategic Material Selection Guide for doorables vending machine

- In-depth Look: Manufacturing Processes and Quality Assurance for doorables vending machine

- Comprehensive Cost and Pricing Analysis for doorables vending machine Sourcing

- Spotlight on Potential doorables vending machine Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for doorables vending machine

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the doorables vending machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of doorables vending machine

- Strategic Sourcing Conclusion and Outlook for doorables vending machine

Introduction: Navigating the Global Market for doorables vending machine

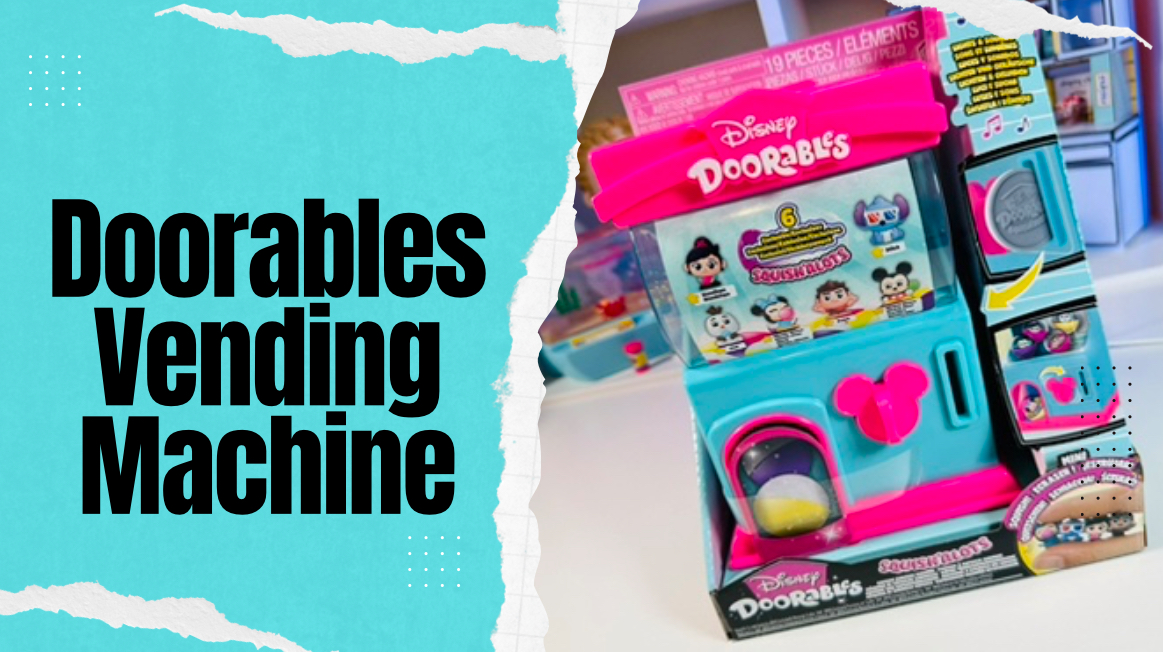

In today’s dynamic retail landscape, the doorables vending machine has emerged as a game-changing solution for businesses looking to enhance consumer engagement and drive sales. These innovative machines not only offer a unique way to sell collectibles and toys but also cater to the growing trend of experiential shopping. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe seek to capitalize on this trend, understanding the nuances of the doorables vending machine market becomes paramount.

This comprehensive guide is designed to empower buyers with critical insights into the various aspects of doorables vending machines. It covers an array of topics, including the different types of machines, suitable materials, and essential manufacturing and quality control standards. Furthermore, buyers will find valuable information on suppliers, cost structures, and current market trends, ensuring they are well-equipped to make informed sourcing decisions.

With a focus on practical solutions, this guide addresses frequently asked questions that often arise in the procurement process. By leveraging this resource, B2B buyers can navigate the complexities of the global market with confidence, ensuring they select the right doorables vending machine to meet their specific business needs. Whether you’re in South Africa or Italy, this guide serves as a roadmap for successful engagement in the burgeoning doorables vending machine sector.

Understanding doorables vending machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Doorable Machine | Standard design, single product dispensing | Retail, offices, schools | Pros: Familiar design, easy maintenance. Cons: Limited product range. |

| Interactive Doorable Machine | Touchscreen interface, customizable options | Entertainment venues, malls | Pros: Engaging user experience, customizable inventory. Cons: Higher initial investment. |

| Mobile Doorable Machine | Portable design, battery-operated | Events, festivals, temporary setups | Pros: Flexibility in location, easy to transport. Cons: Limited capacity compared to stationary machines. |

| Eco-Friendly Doorable Machine | Made from sustainable materials, energy-efficient | Eco-conscious businesses, parks | Pros: Appeals to sustainability values, potential cost savings. Cons: May have higher upfront costs. |

| Smart Doorable Machine | IoT-enabled, real-time inventory tracking | Warehouses, large retailers | Pros: Enhanced operational efficiency, data analytics capabilities. Cons: Requires tech support and maintenance. |

Traditional Doorable Machine

Traditional doorable machines are characterized by their straightforward design, typically dispensing a single product type. They are widely used in retail environments, offices, and schools, where consistent product availability is essential. When considering a purchase, buyers should evaluate the ease of maintenance and the machine’s reliability. However, these machines may limit the product range, which could affect customer satisfaction in diverse markets.

Interactive Doorable Machine

These machines feature a touchscreen interface that allows users to interact with the product selection process. They are particularly effective in entertainment venues and shopping malls, where engaging customers is crucial. B2B buyers should consider the initial investment, as these machines tend to be more expensive. The customizable options and engaging user experience can lead to increased sales, making them a worthwhile investment for businesses seeking to enhance customer interaction.

Mobile Doorable Machine

Mobile doorable machines are designed for portability, often battery-operated, making them ideal for events, festivals, and temporary setups. They offer flexibility in location, allowing businesses to adapt to various settings. However, buyers should be mindful of the limited capacity compared to stationary machines, which could impact sales during peak times. These machines are great for businesses looking to expand their reach without committing to a permanent installation.

Eco-Friendly Doorable Machine

Eco-friendly doorable machines are made from sustainable materials and often feature energy-efficient designs. They appeal to businesses that prioritize sustainability, such as eco-conscious brands and parks. While they may come with higher upfront costs, the long-term savings on energy and the positive brand image can justify the investment. Buyers should consider the potential for increased customer loyalty from environmentally aware consumers.

Smart Doorable Machine

Smart doorable machines are equipped with IoT technology, allowing for real-time inventory tracking and data analytics. They are particularly beneficial for warehouses and large retailers, where operational efficiency is paramount. Buyers should weigh the benefits of enhanced efficiency against the need for ongoing technical support and maintenance. The ability to analyze customer data can provide valuable insights, making these machines a strategic investment for data-driven businesses.

Related Video: satisfying with unboxing Disney Doorables vending machine

Key Industrial Applications of doorables vending machine

| Industry/Sector | Specific Application of doorables vending machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Automated product dispensing | Increased sales through 24/7 availability | Robustness for high foot traffic, inventory management system |

| Hospitality | Guest convenience services | Enhanced guest experience, reduced staff workload | Customization options, maintenance support |

| Manufacturing | Spare parts and tools access | Streamlined operations, reduced downtime | Security features, compatibility with various tools |

| Education | Stationery and supplies distribution | Improved resource accessibility for students | Size and capacity for various supplies, durability |

| Healthcare | Medication dispensing | Improved patient compliance, reduced wait times | Compliance with health regulations, secure access mechanisms |

Retail Sector

In the retail industry, doorables vending machines serve as automated product dispensers, allowing customers to purchase items at any time without the need for staff assistance. This can significantly increase sales, particularly in high-traffic locations, by offering convenience and immediate access to products. For B2B buyers, key considerations include ensuring the machines are robust enough to handle high foot traffic and integrating an inventory management system to monitor stock levels efficiently.

Hospitality Industry

In the hospitality sector, doorables vending machines can provide guests with essential items such as snacks, toiletries, or even local souvenirs. This enhances the guest experience by offering convenience and reducing the workload on staff, allowing them to focus on more critical customer service tasks. Buyers in this industry should look for customization options to align the vending offerings with their brand and ensure reliable maintenance support to keep the machines operational.

Manufacturing Sector

Manufacturers can utilize doorables vending machines to provide employees with quick access to spare parts and tools. This application helps streamline operations by minimizing downtime caused by searching for essential items, thus enhancing productivity. For international buyers, sourcing considerations include ensuring that the machines have security features to prevent theft and are compatible with a variety of tools to meet diverse operational needs.

Education Sector

In educational institutions, doorables vending machines can be used to distribute stationery and supplies, making it easier for students to access necessary materials. This improves resource accessibility and reduces the burden on staff to manage supply distribution. Buyers should consider the size and capacity of the machines to accommodate various supplies and the durability of the machines to withstand daily use by students.

Healthcare Sector

In healthcare settings, doorables vending machines can be employed to dispense medication, ensuring that patients receive their prescriptions efficiently. This application improves patient compliance by making medications readily available and reduces wait times at pharmacies. Buyers in this sector must ensure that the machines comply with health regulations and incorporate secure access mechanisms to protect sensitive medications from unauthorized access.

Related Video: DIY Vending Machine – Arduino based Mechatronics Project

Strategic Material Selection Guide for doorables vending machine

When selecting materials for doorables vending machines, it’s essential to consider the unique requirements of the application, including durability, environmental resistance, and compliance with international standards. Below is an analysis of several common materials used in the manufacturing of doorables vending machines, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand a wide range of temperatures. It typically has a temperature rating of up to 800°C (1472°F) and can handle moderate pressure levels.

Pros & Cons:

Stainless steel is highly durable and resistant to rust, making it suitable for environments with high humidity or exposure to moisture. However, it is more expensive than other metals and can be challenging to machine, increasing manufacturing complexity.

Impact on Application:

This material is ideal for doorables vending machines that may be exposed to water or cleaning agents, ensuring longevity and reliability.

Considerations for International Buyers:

Buyers should ensure compliance with standards such as ASTM A240 for stainless steel grades. In regions like Europe and South America, certifications may be required to meet local regulations.

2. Aluminum

Key Properties:

Aluminum is lightweight and has good corrosion resistance, with a temperature rating of around 200°C (392°F). It is also known for its excellent thermal conductivity.

Pros & Cons:

Aluminum is cost-effective, easy to fabricate, and offers good strength-to-weight ratio. However, it is less durable than stainless steel and may not withstand heavy impacts or high temperatures as effectively.

Impact on Application:

Aluminum is suitable for components that require lightweight construction but may not be ideal for high-stress areas of the vending machine.

Considerations for International Buyers:

Buyers should check for compliance with standards such as ASTM B221 for aluminum extrusions. Additionally, local preferences for aluminum grades may vary by region, affecting sourcing decisions.

3. Polycarbonate

Key Properties:

Polycarbonate is a high-performance thermoplastic known for its impact resistance and transparency. It can withstand temperatures up to 120°C (248°F) and is resistant to UV radiation.

Pros & Cons:

The primary advantage of polycarbonate is its lightweight nature and high impact resistance, making it ideal for protective covers. However, it can be more expensive than other plastics and may scratch easily.

Impact on Application:

This material is particularly useful for transparent panels in vending machines, allowing visibility of products while providing a durable barrier.

Considerations for International Buyers:

Compliance with standards such as ASTM D635 for flammability is crucial. In regions like the Middle East, where UV exposure is high, selecting UV-stabilized polycarbonate is advisable.

4. Carbon Steel

Key Properties:

Carbon steel is known for its strength and toughness, with a temperature rating typically around 400°C (752°F). It is less resistant to corrosion compared to stainless steel.

Pros & Cons:

This material is cost-effective and offers high strength, making it suitable for structural components. However, it requires protective coatings to prevent rust and corrosion, which can add to maintenance costs.

Impact on Application:

Carbon steel is suitable for internal components of the vending machine that are not exposed to moisture or corrosive environments.

Considerations for International Buyers:

Buyers should ensure compliance with standards such as ASTM A36 for structural steel. In regions like Africa, where humidity may vary, additional protective measures may be necessary.

Summary Table

| Material | Typical Use Case for doorables vending machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | External casing and structural components | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Aluminum | Lightweight components and frames | Cost-effective and easy to fabricate | Less durable under heavy impact | Medium |

| Polycarbonate | Transparent panels for product visibility | High impact resistance | Scratches easily and higher cost | Medium |

| Carbon Steel | Internal structural components | High strength and cost-effective | Requires protective coatings for corrosion | Low |

This guide provides a comprehensive overview of material options for doorables vending machines, facilitating informed decisions for international B2B buyers. Understanding the properties and implications of each material will help ensure the selection of the most suitable components for various operational environments.

In-depth Look: Manufacturing Processes and Quality Assurance for doorables vending machine

Manufacturing Processes for Doorables Vending Machines

The manufacturing of doorables vending machines involves a series of intricate processes aimed at ensuring functionality, durability, and aesthetic appeal. Understanding these stages is critical for B2B buyers, especially those operating in diverse regions like Africa, South America, the Middle East, and Europe. Here’s an overview of the main stages involved in the manufacturing process:

1. Material Preparation

Selection of Materials

The first step in the manufacturing process is selecting the appropriate materials. Common materials include:

- Metal: Typically steel or aluminum for the structure, providing strength and durability.

- Plastics: Used for internal components and decorative elements due to their lightweight and moldable properties.

- Electronics: Components like sensors, displays, and payment systems are sourced from specialized suppliers.

Cutting and Shaping

Materials undergo cutting and shaping using advanced machinery such as laser cutters or CNC machines. This stage ensures that all components meet the precise dimensions required for assembly.

2. Forming

Molding and Fabrication

For plastic parts, injection molding is a prevalent technique. This process involves heating plastic pellets until they become liquid and then injecting them into molds to create specific shapes. For metal parts, processes like stamping or bending may be employed to achieve the desired configurations.

Component Manufacturing

At this stage, various components, including the chassis, doors, and internal mechanisms, are manufactured. Precision is key, as any discrepancies can affect the overall assembly and functionality of the vending machine.

3. Assembly

Component Assembly

Once all parts are ready, assembly begins. This process typically follows a sequential approach where each component is added in a specific order. Automated assembly lines are common in large-scale manufacturing, enhancing efficiency and consistency.

Integration of Electronics

The integration of electronic components occurs during assembly. This includes installing payment systems, display screens, and sensors. Proper wiring and connections are crucial to ensure the machine operates as intended.

4. Finishing

Surface Treatment

After assembly, machines undergo surface treatment processes such as powder coating or painting. These treatments enhance durability and aesthetic appeal, making the machines more attractive to potential buyers.

Quality Control Checks

Final checks are conducted to ensure all components function correctly. This stage may involve visual inspections and operational tests.

Quality Assurance

Quality assurance is a vital aspect of the manufacturing process for doorables vending machines. Adhering to international and industry-specific standards ensures that products are reliable and safe for use. Here are the key elements of quality assurance relevant to B2B buyers:

International Standards

ISO 9001 Certification

ISO 9001 is an internationally recognized standard for quality management systems. It ensures that organizations consistently provide products that meet customer and regulatory requirements. B2B buyers should prioritize suppliers with ISO 9001 certification to guarantee a commitment to quality.

CE Marking

In Europe, CE marking is essential for products, indicating compliance with health, safety, and environmental protection standards. Buyers in Europe should verify that vending machines are CE marked, ensuring they meet EU regulations.

API Standards

For vending machines that incorporate technology, adherence to API (Application Programming Interface) standards may be necessary, especially for software integration and connectivity.

Quality Control Checkpoints

Quality control checkpoints are strategically placed throughout the manufacturing process to ensure standards are met:

- Incoming Quality Control (IQC): This involves inspecting raw materials and components upon arrival to ensure they meet specified standards before production begins.

- In-Process Quality Control (IPQC): Conducted during the manufacturing process, IPQC checks ensure that each stage meets quality standards and identifies any issues early.

- Final Quality Control (FQC): This final inspection ensures that the completed vending machines meet all specifications and are ready for distribution.

Common Testing Methods

Testing methods employed to assess the quality of doorables vending machines include:

- Functional Testing: Ensures all electronic components work correctly and that the machine operates as intended.

- Durability Testing: Machines are subjected to stress tests to evaluate their performance under extreme conditions.

- Safety Testing: Compliance with safety regulations is verified, ensuring that the machines pose no risk to users.

Verifying Supplier Quality Control

For B2B buyers, verifying the quality control measures of potential suppliers is crucial. Here are some actionable strategies:

- Supplier Audits: Conduct regular audits of suppliers to assess their quality management practices and adherence to international standards.

- Request Quality Reports: Suppliers should provide documentation of their quality control processes, including test results and compliance certifications.

- Third-Party Inspections: Engage independent third-party agencies to inspect manufacturing processes and product quality, providing an unbiased assessment.

Nuances for International Buyers

International buyers, particularly from diverse regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances when it comes to quality control:

- Understanding Regional Regulations: Different regions may have unique regulatory requirements. For example, South Africa has specific compliance standards that may differ from those in Europe or the Middle East.

- Cultural Considerations: Building relationships with suppliers may involve understanding cultural nuances and business practices, which can impact negotiations and quality expectations.

- Logistics and Supply Chain Challenges: Buyers should consider logistics and potential supply chain disruptions that may affect the delivery and quality of products.

By understanding these manufacturing processes and quality assurance standards, B2B buyers can make informed decisions when sourcing doorables vending machines, ensuring they select reliable suppliers that meet their quality expectations.

Related Video: Lean Manufacturing – Lean Factory Tour – FastCap

Comprehensive Cost and Pricing Analysis for doorables vending machine Sourcing

The cost structure and pricing for sourcing doorables vending machines involve multiple components that international B2B buyers should consider. Understanding these elements can help buyers negotiate better deals and optimize their procurement strategies.

Cost Components

-

Materials: The choice of materials significantly impacts the cost. High-quality components such as durable plastics and electronic parts may increase initial costs but contribute to longevity and lower maintenance expenses.

-

Labor: Labor costs vary by region. In countries with higher labor costs, such as those in Europe, expect to pay more for manufacturing. Conversely, sourcing from regions with lower labor costs can reduce overall expenses.

-

Manufacturing Overhead: This includes utilities, rent, and administrative expenses associated with production. Overhead rates can differ widely based on the production facility’s location and operational efficiency.

-

Tooling: If customization is required, tooling costs can rise significantly. Buyers should inquire about the initial investment needed for molds or special equipment tailored to their specifications.

-

Quality Control (QC): Implementing robust QC processes can add to costs but is essential for ensuring product reliability. Buyers should assess whether the supplier’s QC processes align with their quality standards.

-

Logistics: Shipping costs, including freight, customs duties, and insurance, can dramatically affect total costs. Buyers need to consider the logistics network of the supplier and potential delays that may incur extra charges.

Illustrative Image (Source: Google Search)

- Margin: Suppliers will include a profit margin in their pricing. Understanding typical margins in the industry can help buyers identify reasonable pricing.

Price Influencers

Several factors influence the pricing of doorables vending machines:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often result in lower per-unit costs due to economies of scale. Negotiating for better rates on higher quantities can be beneficial.

-

Specifications/Customization: Custom features or specifications can drive up costs. Buyers should evaluate the necessity of customizations against their budget and market demand.

-

Materials and Quality/Certifications: Premium materials and certifications (e.g., ISO standards) can justify higher prices. Buyers in regions with strict regulatory compliance should prioritize suppliers who meet these standards.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge more due to their proven track record, while newer companies may offer lower prices to attract business.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for determining responsibilities in shipping and delivery. These terms can affect the total cost and risk associated with international transactions.

Buyer Tips

-

Negotiation: Always approach negotiations with a clear understanding of your budget and the value you expect. Leverage your buying power, especially if you represent a larger organization.

-

Cost Efficiency: Consider the Total Cost of Ownership (TCO), which includes purchase price, operational costs, maintenance, and disposal. A cheaper upfront price may lead to higher costs over time if quality is compromised.

-

Pricing Nuances: Be aware of regional pricing trends. For instance, buyers from Africa or South America may encounter different pricing structures compared to those in Europe due to varying market conditions and economic factors.

-

Supplier Relationships: Building strong relationships with suppliers can lead to better terms and pricing. Regular communication can also provide insights into potential cost-saving opportunities.

Disclaimer

Prices mentioned in this analysis are indicative and subject to fluctuations based on market conditions, supplier capabilities, and regional economic factors. Buyers are encouraged to conduct thorough market research and engage with multiple suppliers to obtain accurate pricing.

Spotlight on Potential doorables vending machine Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘doorables vending machine’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for doorables vending machine

When considering the purchase of doorables vending machines, it’s essential for B2B buyers to understand the critical technical properties and trade terminology associated with these products. This knowledge not only aids in making informed purchasing decisions but also enhances negotiation capabilities and supplier relationships.

Key Technical Properties

-

Material Grade

– Definition: The classification of materials based on their mechanical and chemical properties, commonly defined by industry standards.

– Importance: High-grade materials ensure durability and longevity of vending machines, reducing maintenance costs and increasing customer satisfaction. Buyers should verify that the materials used can withstand environmental conditions specific to their market regions, such as humidity in tropical climates or cold in northern Europe. -

Tolerance

– Definition: The allowable variation in a physical dimension, which is crucial for the proper functioning of machine components.

– Importance: Accurate tolerances are critical for the seamless operation of the vending machines. Poor tolerance can lead to mechanical failures, affecting reliability and potentially leading to revenue loss. Buyers should inquire about the tolerances provided in the machine specifications to ensure quality. -

Power Consumption

– Definition: The amount of electrical energy consumed by the vending machine during operation.

– Importance: Understanding power consumption is vital for evaluating operational costs. Machines with lower energy consumption can lead to significant savings over time, especially in regions with high electricity costs. Buyers should seek energy-efficient models that comply with international energy standards. -

Capacity

– Definition: The number of products the vending machine can hold, typically measured in units or volume.

– Importance: A machine’s capacity directly affects its profitability. Buyers must assess market demand and select machines that can accommodate the expected volume while maintaining product freshness. Additionally, understanding the capacity helps in inventory management. -

Dimensions and Weight

– Definition: The physical size and weight of the vending machine.

– Importance: Buyers need to consider space constraints in their intended installation locations. Understanding the dimensions ensures that the machine fits within the designated area and that it can be easily transported and installed. Weight is also essential for shipping costs and installation requirements. -

User Interface

– Definition: The design and functionality of the machine’s control panel and payment system.

– Importance: A user-friendly interface enhances customer experience and can lead to increased sales. Buyers should evaluate whether the interface supports multiple languages and payment methods, which is especially important in diverse markets.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of vending machines, knowing if the supplier is an OEM can assure quality and reliability. -

MOQ (Minimum Order Quantity)

– The smallest amount of product that a supplier is willing to sell. Understanding MOQ is crucial for budgeting and inventory planning, as it can affect initial capital outlay and stock levels. -

RFQ (Request for Quotation)

– A document sent to suppliers requesting pricing and terms for specific products. Buyers should use RFQs to gather competitive pricing and terms, helping to make informed purchasing decisions. -

Incoterms (International Commercial Terms)

– A set of rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for understanding shipping costs and liabilities, impacting overall purchasing strategy. -

Lead Time

– The time taken from placing an order to delivery. Understanding lead times helps in planning for inventory and ensuring timely availability of vending machines in the market. -

Warranty

– A guarantee provided by the manufacturer regarding the condition of the vending machine and the terms under which repairs or replacements will be made. A robust warranty can safeguard against unexpected costs and provide peace of mind for buyers.

By grasping these essential properties and terminologies, international B2B buyers can navigate the complexities of purchasing doorables vending machines more effectively, ensuring that their investments yield the best possible returns.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the doorables vending machine Sector

Market Overview & Key Trends

The doorables vending machine sector is experiencing significant growth driven by several global factors. Increasing urbanization, especially in regions like Africa and South America, is fueling demand for convenience-oriented retail solutions. As populations grow and lifestyles become busier, the need for accessible, quick-service options is paramount. Additionally, advancements in technology, such as cashless payment systems and smart vending solutions, are reshaping how consumers interact with vending machines. These innovations not only improve the customer experience but also enhance inventory management for businesses.

Emerging B2B trends in sourcing include the integration of artificial intelligence (AI) and data analytics to optimize machine placement and product offerings based on consumer behavior. For international buyers, particularly in Europe and the Middle East, the trend towards personalization in vending experiences is becoming vital. Companies are increasingly looking for vendors that can provide customizable options that cater to local tastes and preferences. Moreover, partnerships with local suppliers are essential for ensuring rapid response to market demands and reducing logistical challenges.

International B2B buyers should also note the competitive landscape. As the market matures, distinguishing factors such as technology integration, service reliability, and brand reputation will play a critical role in procurement decisions. Buyers should focus on suppliers that not only offer innovative products but also demonstrate a strong understanding of regional market dynamics.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a cornerstone of the doorables vending machine sector, influencing both sourcing strategies and consumer preferences. The environmental impact of vending machines, particularly regarding energy consumption and waste generation, is under scrutiny. Buyers are increasingly prioritizing machines that utilize energy-efficient technologies and eco-friendly materials. For instance, selecting vending machines constructed from recyclable materials can significantly reduce their carbon footprint.

The importance of ethical supply chains cannot be overstated. International buyers should seek vendors who are committed to transparency and fair labor practices within their supply chains. Certifications such as ISO 14001 for environmental management and Fair Trade certifications can provide assurance of a supplier’s commitment to sustainability. Additionally, sourcing from local suppliers not only supports regional economies but also minimizes transportation emissions, aligning with the growing consumer demand for sustainable practices.

To enhance their brand image and appeal to eco-conscious consumers, businesses should consider integrating ‘green’ certifications into their procurement criteria. This can include using machines that are certified by recognized environmental organizations, ensuring that the entire lifecycle of the product adheres to sustainable practices.

Brief Evolution/History

The evolution of vending machines can be traced back to ancient Greece, where simple coin-operated devices dispensed holy water. However, the modern iteration of vending machines began in the late 19th century, with machines dispensing items like postcards and gum. By the 20th century, vending machines had expanded to offer a wide range of products, from snacks to beverages, and eventually to more specialized offerings like doorables.

The introduction of technology in the 1980s revolutionized the industry, leading to the development of electronic vending machines that could accept various forms of payment and offer more sophisticated inventory management systems. Today, the focus has shifted towards smart vending solutions that leverage IoT (Internet of Things) technology, enabling real-time data analytics and enhanced customer engagement. This historical context is crucial for B2B buyers, as understanding these developments can inform procurement decisions and partnerships in the current market landscape.

Related Video: Is global trade transforming? | Counting the Cost

Frequently Asked Questions (FAQs) for B2B Buyers of doorables vending machine

-

What should I consider when vetting suppliers for doorables vending machines?

When vetting suppliers, prioritize their experience in manufacturing vending machines, specifically doorables models. Check for industry certifications such as ISO or CE, which indicate adherence to quality standards. Additionally, assess their reputation through customer reviews and case studies. It’s beneficial to request references from other international buyers, particularly those in your region, to gauge their reliability and service quality. -

Can I customize the vending machines to fit my brand?

Yes, many suppliers offer customization options for vending machines. This can include branding with your logo, color schemes, and specific configurations to cater to your target market. Discuss your requirements upfront and ask for examples of past custom projects. Ensure that the supplier can accommodate your requests without significantly extending lead times or increasing costs. -

What are the minimum order quantities (MOQ) and lead times for doorables vending machines?

MOQs can vary widely between suppliers, typically ranging from 10 to 50 units for initial orders. Lead times may also differ based on customization and order size, usually spanning from 4 to 12 weeks. When negotiating, clarify these aspects to avoid delays in your supply chain. Some suppliers may offer lower MOQs for trial orders, which can be advantageous for testing market demand. -

What payment terms are standard for international purchases of vending machines?

Standard payment terms often include a deposit (20-50%) upon order confirmation, with the balance due before shipping. Many suppliers accept various payment methods, including bank transfers, letters of credit, and online payment platforms. Ensure to discuss and agree on terms that protect both parties, such as escrow services for larger transactions, to mitigate risks associated with international payments. -

How can I ensure quality assurance and certifications for the vending machines?

Request documentation of quality assurance processes from the supplier, including their manufacturing standards and inspection protocols. Certifications like ISO 9001 or CE mark are indicators of quality compliance. Additionally, inquire about the possibility of third-party inspections before shipment, which can provide an added layer of assurance regarding product quality and safety. -

What logistics considerations should I keep in mind when importing vending machines?

Logistics can be complex, particularly for bulky items like vending machines. Determine the most cost-effective shipping method (air vs. sea) based on your timeline and budget. Work with a freight forwarder experienced in handling machinery to navigate customs regulations and ensure proper documentation. Also, consider potential tariffs and duties when calculating the total landed cost. -

How should disputes or issues with the supplier be handled?

Establish clear communication channels and protocols for addressing disputes at the outset of your relationship. Document all agreements and communications to provide clarity in case of conflicts. If issues arise, attempt to resolve them directly with the supplier. If necessary, consider mediation or arbitration as a means to resolve disputes without resorting to legal action, which can be costly and time-consuming. -

What are the common features and technologies available in doorables vending machines?

Modern doorables vending machines often come equipped with features like touchless payment systems, smart inventory management, and remote monitoring capabilities. Some models may also offer customizable interfaces for enhanced customer interaction. When sourcing, evaluate the technology options that align with your business model and customer preferences to enhance user experience and operational efficiency.

Strategic Sourcing Conclusion and Outlook for doorables vending machine

The successful integration of doorables vending machines into your business strategy hinges on effective strategic sourcing. By prioritizing partnerships with reliable suppliers, you can ensure a steady flow of innovative products that meet market demands across diverse regions. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should focus on sourcing vendors who not only provide quality machines but also offer comprehensive support and adaptable solutions tailored to local consumer preferences.

Key takeaways include:

- Market Research: Understand regional preferences and demand trends to make informed purchasing decisions.

- Supplier Relationships: Build strong, collaborative relationships with suppliers to enhance negotiation power and ensure consistent quality.

- Sustainability: Consider the environmental impact of sourcing decisions, as sustainability is increasingly influencing consumer choices.

Looking ahead, the doorables vending machine market presents significant growth opportunities. Investing in strategic sourcing today will position your business for success tomorrow. Embrace innovation, leverage local insights, and connect with partners who share your vision for a sustainable and profitable future. Now is the time to act and enhance your vending machine offerings!

Illustrative Image (Source: Google Search)