Your Ultimate Guide to Sourcing Baby Vending Machine

Guide to Baby Vending Machine

- Introduction: Navigating the Global Market for baby vending machine

- Understanding baby vending machine Types and Variations

- Key Industrial Applications of baby vending machine

- Strategic Material Selection Guide for baby vending machine

- In-depth Look: Manufacturing Processes and Quality Assurance for baby vending machine

- Comprehensive Cost and Pricing Analysis for baby vending machine Sourcing

- Spotlight on Potential baby vending machine Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for baby vending machine

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the baby vending machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of baby vending machine

- Strategic Sourcing Conclusion and Outlook for baby vending machine

Introduction: Navigating the Global Market for baby vending machine

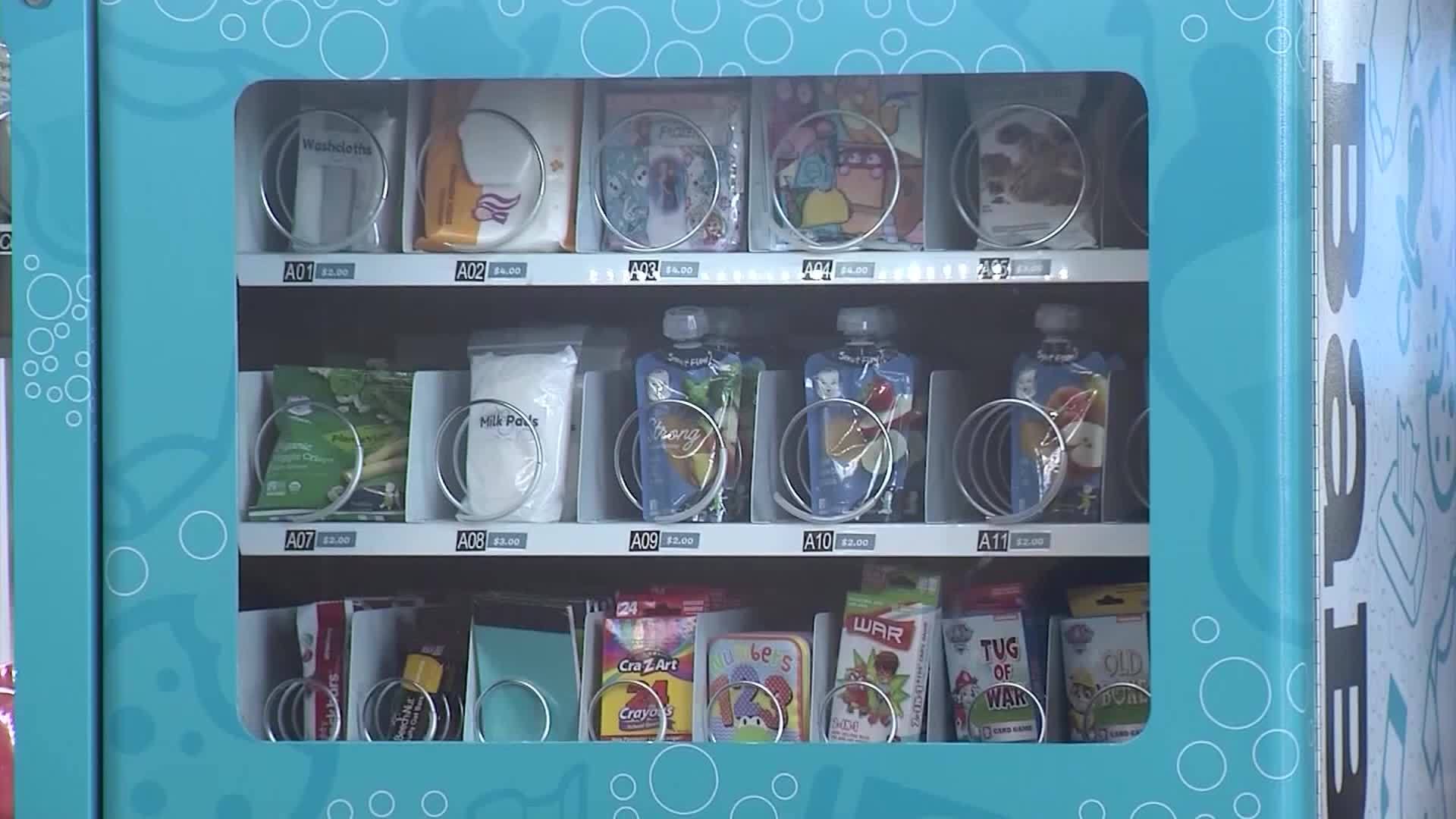

In today’s fast-paced world, the demand for convenience and innovative solutions has led to the emergence of unique products such as baby vending machines. These automated kiosks offer parents easy access to essential baby products, ranging from diapers and baby formula to wipes and even toys, all at the touch of a button. For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding the dynamics of the baby vending machine market is crucial for capitalizing on this growing trend.

This comprehensive guide delves into the various types of baby vending machines available, the materials used in their production, and the manufacturing and quality control processes that ensure safety and reliability. Additionally, it highlights key suppliers and provides insights into cost structures, enabling informed budgeting and procurement strategies. The guide also explores market trends and consumer preferences, offering valuable data to help buyers make strategic sourcing decisions.

By equipping B2B buyers with essential knowledge and actionable insights, this guide serves as a vital resource for navigating the global market for baby vending machines. Whether you are a retailer seeking to diversify your product offerings or an entrepreneur looking to enter this lucrative market, understanding these facets will empower you to make informed, strategic decisions that align with your business goals.

Understanding baby vending machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Automated Baby Formula Dispenser | Dispenses pre-packaged baby formula with adjustable portions | Hospitals, daycare centers, retail stores | Pros: Reduces preparation time; ensures accurate servings. Cons: Requires regular maintenance and supply chain management. |

| Baby Food Vending Machine | Offers a variety of baby food jars and pouches, often refrigerated | Grocery stores, airports, and family-friendly venues | Pros: Convenient for parents on-the-go; diverse product offerings. Cons: Potentially high initial investment; may require frequent restocking. |

| Diaper Vending Machine | Provides diapers in various sizes, often with additional baby care products | Malls, parks, and public restrooms | Pros: Addresses urgent needs for parents; high turnover rate. Cons: Limited product range; requires strategic placement for maximum usage. |

| Baby Care Essentials Kiosk | Sells a range of baby-related products like wipes, bottles, and pacifiers | Hospitals, hotels, and airports | Pros: One-stop-shop for parents; can enhance customer experience. Cons: May face competition from traditional retail; requires effective marketing. |

| Breast Milk Storage and Dispensing Unit | Allows storage and dispensing of breast milk in a hygienic manner | Hospitals and lactation stations | Pros: Supports breastfeeding mothers; promotes health benefits. Cons: Higher regulatory standards; requires user education and maintenance. |

Automated Baby Formula Dispenser

This type of vending machine is designed to dispense pre-packaged baby formula in adjustable portions. It is particularly suitable for environments like hospitals and daycare centers, where quick and accurate feeding solutions are essential. B2B buyers should consider the machine’s maintenance needs and the reliability of the supply chain for formula replenishment, as these factors are critical to maintaining service quality.

Baby Food Vending Machine

These machines offer a variety of baby food options, including jars and pouches, often kept in refrigerated compartments for freshness. They are ideal for grocery stores, airports, and other family-friendly venues, providing convenience for parents on the go. Buyers should evaluate the machine’s product variety and the frequency of restocking to ensure it meets consumer demand effectively.

Diaper Vending Machine

Diaper vending machines provide immediate access to diapers of various sizes and often include other baby care products. They are best placed in high-traffic areas like malls, parks, and public restrooms, where parents may urgently need supplies. B2B buyers should assess the machine’s location strategy and the range of products offered to maximize usage and profitability.

Baby Care Essentials Kiosk

These kiosks offer a range of baby-related products, including wipes, bottles, and pacifiers, catering to parents’ diverse needs. Ideal for hospitals, hotels, and airports, these kiosks can enhance the customer experience by providing a convenient one-stop-shop. Buyers should consider the competitive landscape and marketing strategies to ensure the kiosk stands out in a crowded market.

Breast Milk Storage and Dispensing Unit

This specialized vending machine allows for the hygienic storage and dispensing of breast milk, supporting breastfeeding mothers in environments like hospitals and lactation stations. Buyers should be aware of the higher regulatory standards and the need for user education to ensure safe and effective operation. The investment in such machines can promote health benefits and improve maternal support services.

Related Video: Machine Learning in 2024 – Beginner’s Course

Key Industrial Applications of baby vending machine

| Industry/Sector | Specific Application of baby vending machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | In hospitals for new parents | Provides immediate access to baby essentials, improving patient satisfaction | Compliance with health regulations, ease of use, and hygiene standards |

| Educational Institutions | In schools and daycare centers | Offers convenience for parents, promoting child health and wellness | Durable design, product variety, and payment options |

| Retail | In shopping malls and supermarkets | Increases foot traffic and impulse purchases, enhancing customer experience | Location strategy, product supply chain, and maintenance support |

| Hospitality | In hotels and resorts | Enhances guest experience, providing 24/7 access to baby products | Customization options, reliability, and branding potential |

| Urban Development | In public spaces and transportation hubs | Meets the needs of urban families, promoting convenience and accessibility | Security features, payment system integration, and local regulations compliance |

Healthcare Applications

In healthcare settings, baby vending machines are particularly valuable in hospitals where new parents may require immediate access to baby essentials such as diapers, formula, and wipes. These machines alleviate the stress of searching for supplies in unfamiliar environments, thereby enhancing patient satisfaction and convenience. For international buyers, sourcing considerations include ensuring compliance with local health regulations, maintaining high hygiene standards, and selecting machines that are user-friendly for a diverse clientele.

Educational Institutions

Schools and daycare centers can benefit significantly from baby vending machines by providing essential items for parents who drop off their children. This application not only supports child health and wellness but also fosters a community-focused environment. Buyers in this sector should prioritize durability and reliability in machine design, as well as a variety of products that cater to different age groups. Payment options should also be flexible to accommodate various user preferences.

Retail Sector

In retail environments such as shopping malls and supermarkets, baby vending machines can serve as a strategic tool to increase foot traffic and drive impulse purchases. They offer parents the convenience of accessing baby products while they shop, enhancing the overall shopping experience. When sourcing machines for retail, businesses should consider the optimal placement of machines, the supply chain for restocking products, and the provision of maintenance support to ensure uninterrupted service.

Hospitality Sector

Hotels and resorts can significantly enhance their guest experience by installing baby vending machines that offer a range of baby products. This service caters to families traveling with infants, providing them with 24/7 access to necessary items. Buyers in the hospitality sector should look for customization options that align with their brand identity, as well as the reliability of the machines to avoid service interruptions that could affect guest satisfaction.

Urban Development

In urban development projects, incorporating baby vending machines in public spaces and transportation hubs addresses the needs of families on the go. These machines provide essential items, making urban living more convenient for parents. Key sourcing considerations for this application include the integration of secure payment systems, compliance with local regulations, and the ability to withstand outdoor conditions. The machines should also be strategically placed to maximize accessibility for families.

Related Video: LABORATORY APPARATUS AND THEIR USES

Strategic Material Selection Guide for baby vending machine

When selecting materials for baby vending machines, it is crucial to consider properties that ensure safety, durability, and compliance with international standards. Below is an analysis of four common materials used in the construction of baby vending machines, focusing on their key properties, advantages and disadvantages, and specific considerations for international B2B buyers.

1. Stainless Steel (e.g., AISI 304)

Key Properties: Stainless steel is renowned for its excellent corrosion resistance, high strength, and ability to withstand a wide range of temperatures. It is also non-reactive, making it suitable for food contact applications.

Pros & Cons:

– Pros: Highly durable, resistant to rust and staining, easy to clean, and maintains a professional appearance.

– Cons: Higher cost compared to other materials, can be prone to scratching, and requires specific fabrication techniques.

Impact on Application: Stainless steel is ideal for parts that come into direct contact with baby products, ensuring hygiene and safety. Its resistance to corrosion makes it suitable for environments with high humidity or exposure to cleaning agents.

Considerations for International Buyers: Compliance with food safety standards (e.g., FDA in the U.S., EU regulations) is essential. Buyers should also consider local preferences for stainless steel grades and finishes.

2. Polycarbonate

Key Properties: Polycarbonate is a high-performance plastic known for its impact resistance and transparency. It can withstand temperatures up to 120°C and has good UV resistance.

Pros & Cons:

– Pros: Lightweight, shatter-resistant, offers excellent visibility for product display, and is cost-effective.

– Cons: Can be susceptible to scratching and yellowing over time, and may not be as durable as metals under heavy stress.

Impact on Application: Polycarbonate is often used for windows and protective covers, providing visibility while ensuring safety. Its lightweight nature aids in the overall portability of the vending machine.

Considerations for International Buyers: Ensure compliance with relevant safety standards (e.g., ASTM D256 for impact resistance). Buyers should also check for certifications related to food safety, especially in regions with stringent regulations.

3. Aluminum

Key Properties: Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity. It can be anodized for enhanced durability and aesthetic appeal.

Pros & Cons:

– Pros: Lightweight, cost-effective, easy to fabricate, and offers good strength-to-weight ratio.

– Cons: Less durable than stainless steel under heavy loads, can corrode if not properly treated, and may require additional coatings for food safety.

Impact on Application: Aluminum is often used for structural components and frames, contributing to the overall weight reduction of the vending machine while maintaining strength.

Considerations for International Buyers: Buyers should verify that the aluminum used meets local standards (e.g., ASTM, DIN) for food contact applications. Anodizing processes should comply with environmental regulations, particularly in Europe.

4. High-Density Polyethylene (HDPE)

Key Properties: HDPE is a strong, lightweight plastic that is resistant to impact, moisture, and chemicals. It can operate effectively at temperatures up to 120°C.

Pros & Cons:

– Pros: Cost-effective, excellent chemical resistance, and easy to mold into complex shapes.

– Cons: Less rigid than metals, may deform under high temperatures, and can be less aesthetically pleasing.

Impact on Application: HDPE is suitable for internal components and storage areas within the vending machine, providing a safe environment for baby products.

Considerations for International Buyers: Ensure that HDPE complies with food safety standards and regulations in the target market. Buyers should also check for certifications related to environmental impact, particularly in regions with strict recycling laws.

Summary Table

| Material | Typical Use Case for baby vending machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel (e.g., AISI 304) | Structural components, food contact surfaces | Highly durable, corrosion-resistant | Higher cost, prone to scratching | High |

| Polycarbonate | Windows, protective covers | Lightweight, shatter-resistant | Susceptible to scratching, yellowing | Medium |

| Aluminum | Structural frames, supports | Lightweight, cost-effective | Less durable under heavy loads | Medium |

| High-Density Polyethylene (HDPE) | Internal components, storage areas | Cost-effective, excellent chemical resistance | Less rigid, may deform under heat | Low |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling them to make informed decisions when sourcing materials for baby vending machines. Understanding the properties and implications of each material will help ensure compliance with local regulations and meet market expectations.

In-depth Look: Manufacturing Processes and Quality Assurance for baby vending machine

Manufacturing a baby vending machine involves several critical stages, each requiring precise techniques to ensure the final product meets safety and quality standards. This section outlines the manufacturing processes, quality assurance measures, and international standards relevant to B2B buyers, particularly from Africa, South America, the Middle East, and Europe.

Manufacturing Processes

1. Material Preparation

The first step in the manufacturing process is the selection and preparation of materials. Common materials include:

- Metal Framework: Typically steel or aluminum, providing durability and stability.

- Plastic Components: High-density polyethylene (HDPE) or polycarbonate for the outer shell, which is lightweight and resistant to impact.

- Electronic Components: Microcontrollers, sensors, and payment systems that facilitate the operation of the vending machine.

Each material must be sourced from reputable suppliers, ensuring compliance with safety regulations. B2B buyers should verify the material certifications, such as RoHS compliance for electronic components.

2. Forming

The forming stage involves shaping the prepared materials into usable components. Key techniques include:

- Injection Molding: Used for creating plastic parts such as the machine’s exterior and dispensing mechanisms. This method ensures precision and uniformity.

- Metal Stamping: Employed to create the machine’s frame and structural supports, offering strength and resilience.

- CNC Machining: For precise fabrication of complex parts that require tight tolerances.

B2B buyers should look for manufacturers that utilize advanced technologies in forming processes to enhance product quality.

3. Assembly

During the assembly stage, all components are brought together to create the final product. This process includes:

- Component Integration: Electronics, sensors, and mechanical parts are assembled according to engineering specifications.

- Wiring and Testing: Electrical components are connected, and initial functionality tests are conducted to ensure all systems operate correctly.

Proper assembly techniques are crucial, as improper integration can lead to operational failures or safety hazards. Buyers should inquire about the assembly line’s efficiency and the experience of the workforce involved.

4. Finishing

The finishing stage enhances the machine’s aesthetic appeal and protects it from environmental factors. Techniques include:

- Surface Treatment: Processes like powder coating or anodizing for metal parts, providing a durable and attractive finish.

- Quality Control Checks: Final inspections are performed to ensure all parts are installed correctly and that the machine meets design specifications.

B2B buyers should confirm that manufacturers have robust finishing processes to ensure longevity and visual appeal.

Quality Assurance

Quality assurance (QA) is a critical component in the manufacturing of baby vending machines. It ensures that the final product is safe, reliable, and compliant with international standards.

International Standards

Manufacturers should adhere to various international standards, including:

- ISO 9001: This standard outlines criteria for a quality management system, ensuring consistent product quality and continuous improvement.

- CE Marking: Required for products sold within the European Economic Area, indicating compliance with health, safety, and environmental protection standards.

- API Standards: Relevant for specific components, particularly those involving food safety and hygiene.

B2B buyers must ensure that the supplier can provide documentation confirming compliance with these standards.

Quality Control Checkpoints

Quality control (QC) involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Inspects raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Monitors production processes to catch defects early, maintaining control over the manufacturing environment.

- Final Quality Control (FQC): Conducts a comprehensive inspection of the finished product, ensuring it meets all specifications before shipping.

Common Testing Methods

Testing methods used in the quality assurance process include:

- Functional Testing: Verifying that all features operate as intended.

- Safety Testing: Ensuring that the machine complies with safety regulations and standards.

- Durability Testing: Assessing the machine’s performance under various conditions to simulate real-world usage.

Verifying Supplier Quality Control

B2B buyers should implement strategies to verify the quality control processes of suppliers:

- Supplier Audits: Conduct regular audits of potential suppliers to assess their manufacturing practices, quality control systems, and adherence to international standards.

- Quality Reports: Request detailed quality assurance reports that outline testing results, compliance certifications, and any corrective actions taken.

- Third-Party Inspections: Engage third-party inspection services to evaluate the manufacturing process and product quality, providing an unbiased assessment.

QC and Certification Nuances for International Buyers

International buyers must be aware of specific nuances in quality control and certification processes. For instance:

- Regional Regulations: Different regions may have unique regulatory requirements. Buyers from Africa, South America, and the Middle East should familiarize themselves with local compliance standards that may not align with international norms.

- Language Barriers: Ensure that all documentation, including quality reports and certifications, is available in a language that all stakeholders understand to avoid misinterpretations.

- Cultural Differences: Be mindful of cultural attitudes towards quality assurance and customer service, which can affect supplier relationships and expectations.

By understanding the manufacturing processes and quality assurance measures specific to baby vending machines, B2B buyers can make informed decisions, ensuring they partner with reputable suppliers who prioritize safety and quality in their products.

Related Video: PET Plastic Bottle Manufacturing Process Step-by-Step Introduction

Comprehensive Cost and Pricing Analysis for baby vending machine Sourcing

In the competitive landscape of baby vending machines, understanding the cost structure and pricing dynamics is crucial for international B2B buyers, especially those operating in Africa, South America, the Middle East, and Europe. This analysis covers the key cost components, pricing influencers, and actionable buyer tips to help optimize sourcing strategies.

Cost Components

-

Materials: The primary costs stem from the raw materials used in manufacturing baby vending machines. Common materials include metal for the frame, plastic for the casing, and electronic components for payment processing and inventory management. The choice of materials can significantly impact both durability and overall costs.

-

Labor: Labor costs vary depending on the region of production. Regions with lower labor costs, like parts of Asia, may offer more competitive pricing. However, it’s essential to consider the skill level required for assembly and quality assurance, which can affect labor costs.

-

Manufacturing Overhead: This includes costs associated with factory operations, such as utilities, rent, and equipment depreciation. Efficient manufacturing processes can help minimize overhead costs, leading to better pricing for buyers.

-

Tooling: Initial setup costs for molds and specialized equipment can be substantial, particularly for customized machines. Buyers should inquire about tooling costs and whether these can be amortized over larger order quantities.

-

Quality Control (QC): Implementing rigorous QC procedures ensures that machines meet safety standards and operational specifications. While this may add to upfront costs, it reduces the risk of defects and associated costs in the long run.

-

Logistics: Shipping costs, including freight and insurance, are critical, especially for international buyers. Understanding Incoterms is vital as they define the responsibilities of buyers and sellers in the transportation process.

-

Margin: Suppliers will add a profit margin to their total costs. This margin can vary widely based on the supplier’s market position, relationship with buyers, and the competitive landscape.

Price Influencers

-

Volume/MOQ: Purchasing in larger volumes often leads to better pricing due to economies of scale. Buyers should negotiate Minimum Order Quantities (MOQs) to leverage lower prices.

-

Specifications/Customization: Custom features or specifications can increase costs. Buyers should evaluate whether these enhancements are essential or if standard models suffice.

-

Materials and Quality Certifications: Higher-quality materials and certifications (e.g., safety standards) can elevate costs. Buyers should weigh the benefits of these factors against their budget constraints.

-

Supplier Factors: Supplier reputation, reliability, and service can influence pricing. Established suppliers may command higher prices due to their reliability and product quality.

-

Incoterms: Understanding the terms of sale can affect overall costs. Buyers should negotiate terms that minimize their exposure to additional charges during transit.

Buyer Tips

-

Negotiate Wisely: Engage suppliers in negotiations, emphasizing long-term relationships. Discuss potential discounts for bulk orders or repeat business.

-

Focus on Cost Efficiency: Analyze the Total Cost of Ownership (TCO), including maintenance, operational efficiency, and lifecycle costs, rather than just initial purchase price.

-

Understand Pricing Nuances: Be aware of regional pricing differences, particularly in emerging markets. Currency fluctuations and local economic conditions can affect costs.

-

Conduct Supplier Audits: Regularly assess supplier performance to ensure quality standards are met. This can prevent costly defects and enhance trust.

-

Consider Local Sourcing: Where possible, explore local suppliers to reduce logistics costs and lead times, which can be particularly beneficial in regions with complex import regulations.

Disclaimer

Prices in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough due diligence and consult multiple suppliers to ensure competitive pricing.

Spotlight on Potential baby vending machine Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘baby vending machine’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for baby vending machine

When considering the procurement of baby vending machines, understanding the essential technical properties and trade terminology is vital for making informed decisions. This section outlines key specifications and industry jargon relevant to international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe.

Key Technical Properties

-

Material Grade

– Definition: This refers to the quality of materials used in the construction of the vending machine, such as stainless steel or high-grade plastic.

– Importance: High-quality materials ensure durability and safety, especially since these machines dispense products for infants. Buyers should verify compliance with international safety standards to avoid potential liabilities. -

Tolerance Levels

– Definition: Tolerance levels indicate the acceptable range of variation in the machine’s dimensions and components.

– Importance: Precise tolerances are crucial for the machine’s functionality and reliability. Variations outside specified tolerances can lead to operational issues, impacting customer satisfaction and revenue. -

Power Consumption

– Definition: This specification outlines the amount of electrical power the vending machine requires to operate efficiently.

– Importance: Low power consumption is essential for reducing operational costs, particularly in regions where electricity costs are high. Understanding this property can help buyers choose energy-efficient models that align with sustainability goals. -

Capacity

– Definition: Capacity refers to the number of products the vending machine can store and dispense at one time.

– Importance: Buyers must consider the expected foot traffic and sales volume when selecting a machine with appropriate capacity. A machine that is too small may lead to stock-outs, while one that is too large could incur unnecessary costs.

Illustrative Image (Source: Google Search)

-

User Interface

– Definition: The user interface encompasses the display and controls that customers interact with when using the vending machine.

– Importance: An intuitive user interface enhances customer experience, leading to increased sales. Features such as touch screens or multilingual options can be particularly beneficial in diverse markets. -

Security Features

– Definition: Security features include locks, tamper-proof designs, and cash handling systems that protect the machine from theft and vandalism.

– Importance: Investing in robust security features is critical for safeguarding inventory and cash, especially in high-risk areas. This can significantly reduce losses and ensure a stable return on investment.

Common Trade Terms

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts and equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships helps buyers identify reliable suppliers for replacement parts or custom solutions tailored to their specific needs. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ is essential for budgeting and inventory management. Buyers should negotiate MOQs to align with their purchasing capabilities and avoid excess stock. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers to request pricing and availability for specific products.

– Importance: An RFQ helps buyers gather multiple quotes, enabling them to make competitive purchasing decisions. It’s crucial for ensuring transparency and cost-effectiveness in procurement. -

Incoterms (International Commercial Terms)

– Definition: A set of rules that define the responsibilities of buyers and sellers in international transactions.

– Importance: Familiarity with Incoterms is vital for understanding shipping responsibilities, costs, and risk management. This knowledge can prevent disputes and enhance negotiation strategies. -

Lead Time

– Definition: The amount of time from placing an order to its delivery.

– Importance: Understanding lead times is critical for planning inventory and sales strategies. Buyers should factor in lead times when making purchasing decisions to ensure timely product availability. -

Warranty Period

– Definition: The duration for which the manufacturer guarantees the machine against defects.

– Importance: A comprehensive warranty period can significantly reduce the total cost of ownership by protecting against unforeseen repairs. Buyers should carefully review warranty terms to understand coverage and limitations.

By grasping these technical specifications and industry terms, B2B buyers can make informed decisions that align with their operational goals and market demands, ensuring a successful investment in baby vending machines.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the baby vending machine Sector

Market Overview & Key Trends

The baby vending machine sector is experiencing significant growth driven by several global factors. Increasing urbanization and the fast-paced lifestyle of parents are leading to a higher demand for convenience in childcare products. As a result, B2B buyers are increasingly focusing on the integration of technology into vending solutions. Smart vending machines equipped with IoT capabilities allow for real-time inventory management and enhanced customer interactions, making them particularly appealing to businesses in Africa, South America, the Middle East, and Europe.

Illustrative Image (Source: Google Search)

Emerging trends in sourcing highlight a shift towards customizable vending solutions that cater to local preferences. For instance, machines that offer organic baby food or eco-friendly diapers are gaining traction, particularly in markets like the UAE and Europe, where sustainability is a key consumer concern. Additionally, the rise of contactless payment options is enhancing the user experience, making it essential for B2B buyers to consider these technologies when sourcing equipment.

Market dynamics are also influenced by regulatory standards, particularly around safety and product quality. Buyers should be aware of local regulations that govern the sale of baby products and ensure that their vending solutions comply with these standards to avoid potential legal issues. Overall, the convergence of technology, customization, and regulatory compliance is shaping the future of the baby vending machine market.

Sustainability & Ethical Sourcing in B2B

As sustainability becomes a focal point in global trade, B2B buyers in the baby vending machine sector must prioritize ethical sourcing and environmental responsibility. The production and disposal of vending machines can have a significant environmental impact, making it vital for buyers to seek out suppliers who utilize sustainable materials and practices. This includes sourcing components from manufacturers that adhere to green certifications such as ISO 14001, which focuses on effective environmental management systems.

Moreover, the demand for ‘green’ certifications is rising among consumers, who increasingly prefer products that align with their values. For baby vending machines, this could mean offering products that are organic, non-toxic, and packaged in recyclable materials. Suppliers that can demonstrate a commitment to sustainability not only enhance their appeal to conscientious consumers but also gain a competitive edge in the marketplace.

Incorporating sustainability into the supply chain can also lead to cost savings over time. By investing in energy-efficient machines and sustainable product offerings, businesses can reduce operational costs while also appealing to a growing demographic of eco-conscious parents. This dual focus on sustainability and cost-effectiveness is crucial for B2B buyers aiming to establish long-term success in the baby vending machine sector.

Brief Evolution/History

The concept of vending machines has evolved significantly since their inception, with early machines primarily dispensing snacks and beverages. The introduction of baby vending machines can be traced back to the early 2000s, when convenience for parents became a primary concern. Initially, these machines offered basic baby products like diapers and wipes; however, they have since transformed into sophisticated units that provide a wide range of items, including organic baby food and breastfeeding supplies.

This evolution has been largely fueled by advancements in technology, which have allowed for greater customization and enhanced user experiences. Today, the focus is not only on convenience but also on providing high-quality, safe products for infants and toddlers. As the market continues to grow, B2B buyers must remain aware of these historical trends to identify future opportunities and challenges in the baby vending machine landscape.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of baby vending machine

-

What key factors should I consider when vetting suppliers for baby vending machines?

When vetting suppliers, prioritize their experience in manufacturing baby vending machines, their reputation in the industry, and customer reviews. Check for certifications such as ISO 9001, which indicates quality management systems. Engage in direct communication to assess their responsiveness and willingness to accommodate your needs. Additionally, inquire about their after-sales support and warranty terms, as these can be crucial for long-term partnerships. -

Can I customize the baby vending machines to suit my market needs?

Yes, many manufacturers offer customization options for baby vending machines, including design, size, and product offerings. Discuss your specific requirements, such as branding, product types (e.g., diapers, baby food), and machine features (e.g., payment systems). Ensure that the supplier has a clear process for customization and that they can provide samples or prototypes before full production. -

What is the typical minimum order quantity (MOQ) and lead time for baby vending machines?

MOQs can vary widely depending on the supplier and customization level, ranging from 10 to 100 units. Lead times generally range from 4 to 12 weeks, influenced by factors such as order size, customization complexity, and supplier location. Always confirm these details upfront and consider discussing potential for bulk discounts or flexible arrangements, especially if you anticipate future orders. -

What payment options are available for purchasing baby vending machines?

Payment options typically include wire transfers, letters of credit, and PayPal, depending on the supplier’s policies. For larger orders, using a letter of credit can provide additional security for both parties. Be sure to clarify payment terms, including deposits and final payment timelines, to ensure a smooth transaction process. Always consider negotiating terms that protect your interests, such as payment upon delivery or inspection. -

How can I ensure quality assurance and compliance with safety standards?

Request documentation of quality assurance protocols from your supplier, including production processes and safety standards compliance. Verify that the machines meet relevant international safety standards, such as CE marking in Europe or other local certifications. Conduct a factory audit if possible, or consider third-party inspection services to ensure the products meet your quality expectations before shipment. -

What logistics considerations should I keep in mind when importing baby vending machines?

Logistics play a crucial role in international trade. Consider the cost and reliability of shipping methods, including freight forwarders who specialize in heavy machinery. Understand customs regulations in your country and ensure all necessary documentation is prepared to avoid delays. It’s also wise to discuss delivery timelines with your supplier and plan for any potential contingencies. -

What steps should I take if I encounter a dispute with my supplier?

In case of a dispute, start by addressing the issue directly with your supplier through clear and professional communication. Document all interactions and agreements. If resolution is not achieved, consult the terms of your contract regarding dispute resolution mechanisms, such as mediation or arbitration. Involving a third-party mediator can often help facilitate a resolution without escalating the situation further. -

What are the best practices for maintaining a long-term relationship with suppliers?

Building a strong relationship with your suppliers involves regular communication, transparency, and mutual respect. Provide feedback on their products and services, and be open to discussing improvements. Establishing a partnership mentality can lead to better pricing, priority service, and more favorable terms over time. Additionally, consider periodic visits to their facilities, which can strengthen trust and collaboration.

Strategic Sourcing Conclusion and Outlook for baby vending machine

The strategic sourcing of baby vending machines offers significant opportunities for international buyers, particularly in Africa, South America, the Middle East, and Europe. Key takeaways include the importance of understanding local market needs, regulatory compliance, and consumer preferences. By engaging with reliable suppliers and utilizing comprehensive sourcing strategies, businesses can enhance their competitive edge while ensuring product quality and sustainability.

Value of Strategic Sourcing:

Strategic sourcing not only minimizes costs but also strengthens supply chain resilience. Buyers should prioritize partnerships with manufacturers who demonstrate a commitment to innovation and customer service. This approach fosters long-term relationships, essential for adapting to market changes and consumer demands.

As the demand for baby vending machines continues to rise, particularly in urban areas, the potential for growth is substantial. Looking ahead, international B2B buyers are encouraged to explore emerging markets and leverage technological advancements in vending solutions. By doing so, they can capitalize on new trends and ensure they meet the evolving needs of parents and caregivers.

In conclusion, seizing these opportunities requires a proactive approach to sourcing—consider this a call to action to invest in strategic partnerships that will drive your business forward in this dynamic market.