Your Ultimate Guide to Sourcing The Time I Got Reincarnated

Guide to The Time I Got Reincarnated As A Vending Machine

- Introduction: Navigating the Global Market for the time i got reincarnated as a vending machine

- Understanding the time i got reincarnated as a vending machine Types and Variations

- Key Industrial Applications of the time i got reincarnated as a vending machine

- Strategic Material Selection Guide for the time i got reincarnated as a vending machine

- In-depth Look: Manufacturing Processes and Quality Assurance for the time i got reincarnated as a vending machine

- Comprehensive Cost and Pricing Analysis for the time i got reincarnated as a vending machine Sourcing

- Spotlight on Potential the time i got reincarnated as a vending machine Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for the time i got reincarnated as a vending machine

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the the time i got reincarnated as a vending machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of the time i got reincarnated as a vending machine

- Strategic Sourcing Conclusion and Outlook for the time i got reincarnated as a vending machine

Introduction: Navigating the Global Market for the time i got reincarnated as a vending machine

The global market for vending machines, particularly those inspired by the popular series “The Time I Got Reincarnated as a Vending Machine,” is rapidly evolving, offering unique opportunities for international B2B buyers. As businesses seek innovative solutions to enhance customer engagement and streamline sales processes, vending machines have emerged as a versatile and appealing option. This guide serves as a comprehensive resource, addressing the critical aspects of vending machine procurement including types, materials, manufacturing quality control, supplier selection, cost analysis, market trends, and frequently asked questions.

Understanding the nuances of this market is vital for buyers from diverse regions such as Africa, South America, the Middle East, and Europe. For instance, in Argentina, the demand for automated retail solutions is on the rise, while in France, the focus is on eco-friendly materials and smart technology integration. By exploring the various models available—from traditional snack dispensers to advanced machines equipped with cashless payment systems—businesses can make informed sourcing decisions that align with their operational goals.

This guide empowers B2B buyers by providing actionable insights and detailed information to navigate the complexities of sourcing vending machines. With a focus on quality, cost-effectiveness, and supplier reliability, it aims to enhance your strategic purchasing approach in a competitive global marketplace.

Understanding the time i got reincarnated as a vending machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Vending Machine | Basic functionality with a range of snacks and drinks | Retail, schools, offices | Pros: Low initial investment; Cons: Limited product range |

| Customized Vending Solutions | Tailored to specific product offerings or branding | Corporate gifting, promotional events | Pros: High customization; Cons: Higher cost and complexity |

| Smart Vending Machines | Equipped with IoT technology for real-time inventory tracking | Logistics, smart cities, tech hubs | Pros: Enhanced data analytics; Cons: Potential technical issues |

| Eco-Friendly Vending Machines | Made from sustainable materials with energy-efficient designs | Green businesses, eco-conscious brands | Pros: Positive brand image; Cons: May be pricier to procure |

| Multi-Function Vending Machines | Combines vending with additional services (e.g., ATM, kiosk) | Airports, malls, transportation hubs | Pros: Versatile service options; Cons: Higher maintenance needs |

Standard Vending Machine

Standard vending machines are the most common type found in various settings, offering a straightforward selection of snacks and beverages. These machines are suitable for businesses looking for a low-cost entry into automated sales. B2B buyers should consider their target audience and location, as foot traffic and consumer preferences will dictate product selection. The primary advantage is a low initial investment; however, the limited product range may not meet the diverse needs of all customers.

Customized Vending Solutions

Customized vending solutions are tailored specifically to the needs of a business or event, allowing for unique product offerings and branding opportunities. This type is particularly beneficial for corporate gifting and promotional events where businesses seek to make a memorable impact. Buyers should evaluate the potential return on investment against the higher costs associated with customization. The primary advantage is the ability to create a personalized customer experience, while the downside is the complexity and expense involved in the setup.

Smart Vending Machines

Smart vending machines incorporate IoT technology, enabling real-time inventory management and data analytics. This technology is ideal for logistics companies and smart city initiatives, where tracking product availability can significantly enhance efficiency. B2B buyers must consider their technological infrastructure and the potential need for ongoing tech support. While these machines offer advanced features that can drive sales, they may also face technical issues that could disrupt service.

Eco-Friendly Vending Machines

Eco-friendly vending machines are designed with sustainable materials and energy-efficient operations, catering to businesses focused on environmental responsibility. These machines are particularly appealing to green businesses and brands that want to enhance their sustainability image. Buyers should weigh the benefits of a positive brand association against the potentially higher procurement costs. The key advantage is attracting eco-conscious consumers, but the higher initial investment may be a barrier for some businesses.

Multi-Function Vending Machines

Multi-function vending machines provide a combination of services, such as cash withdrawal through ATMs or interactive kiosks for information. These machines are commonly found in high-traffic areas like airports and malls, where consumers appreciate the convenience of multiple services in one location. B2B buyers should assess the maintenance requirements and operational complexities, as these machines can be more demanding than standard models. Their versatility is a significant advantage, but the increased maintenance needs may deter some buyers.

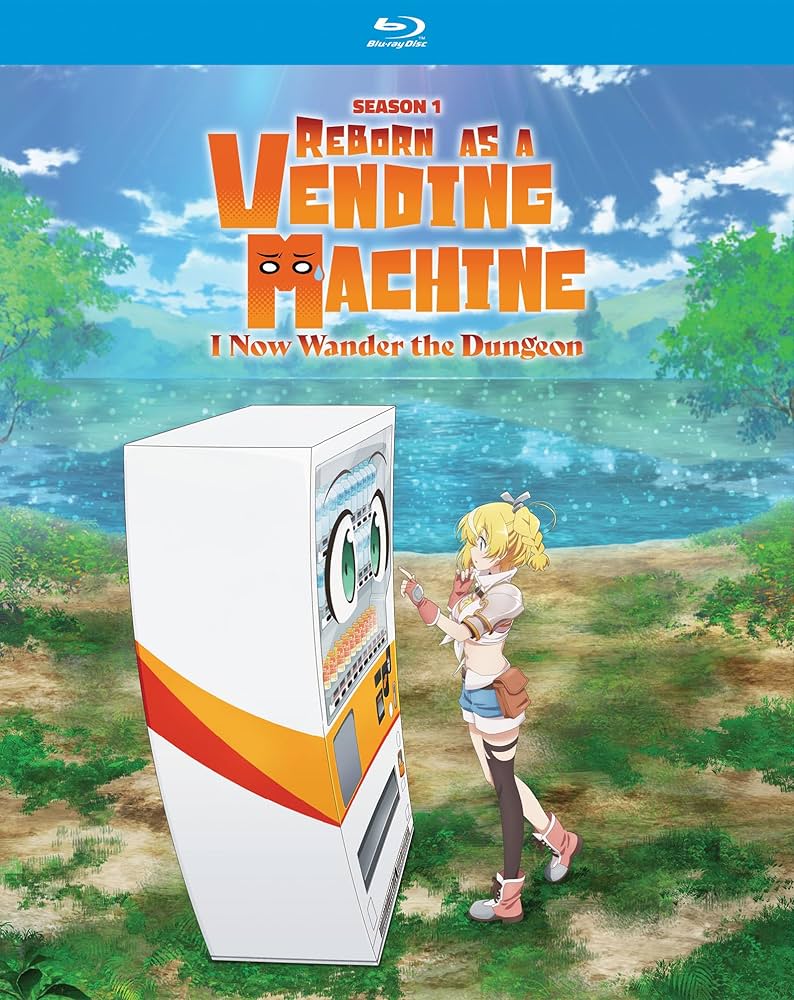

Related Video: reborn as a vending machine episode 1-12 english dub

Key Industrial Applications of the time i got reincarnated as a vending machine

| Industry/Sector | Specific Application of the time i got reincarnated as a vending machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Automated product dispensing and sales tracking | Increased efficiency, reduced labor costs | Reliability of vending technology, ease of maintenance |

| Hospitality | In-room vending solutions for hotels and resorts | Enhanced guest experience, 24/7 accessibility | Product variety, compliance with health standards |

| Education | Snack and beverage vending in schools and universities | Promotes healthy eating, generates additional revenue | Nutritional standards, age-appropriate offerings |

| Corporate Offices | On-site vending for employee breaks and refreshments | Boosts employee morale, reduces downtime | Variety of options, user-friendly interfaces |

| Event Management | Vending solutions for festivals and large gatherings | Quick service, cashless payment options | Scalability, robust payment systems |

Retail

In the retail sector, vending machines that dispense a variety of products provide a convenient shopping experience for consumers. They can be strategically placed in high-traffic areas, allowing businesses to maximize sales without the need for full-time staff. International buyers should consider reliability and ease of maintenance when sourcing these machines, as downtime can lead to lost revenue.

Hospitality

Hotels and resorts can enhance their guest experience by offering in-room vending solutions. These machines provide guests with 24/7 access to snacks and beverages, improving customer satisfaction and convenience. Buyers in the hospitality sector need to ensure that the products offered comply with health standards and cater to diverse tastes, which is essential for maintaining a positive brand image.

Education

Vending machines in educational institutions serve as a practical solution for providing snacks and beverages to students. They can be programmed to promote healthy eating habits by offering nutritious options. B2B buyers from schools and universities should prioritize nutritional standards and age-appropriate offerings to align with educational goals and promote student well-being.

Corporate Offices

On-site vending machines in corporate environments can significantly boost employee morale by providing convenient snack and beverage options. This reduces downtime and encourages breaks, which can lead to increased productivity. When sourcing vending machines for corporate use, businesses should focus on the variety of options available and ensure that the interfaces are user-friendly for all employees.

Event Management

Vending machines are increasingly popular at events, festivals, and large gatherings, providing quick service and cashless payment options. This convenience allows organizers to cater to large crowds efficiently. Key considerations for international buyers include scalability of the vending solutions to accommodate varying attendance levels and the robustness of payment systems to handle diverse transaction methods.

Related Video: Fantasy Girl has Never Seen a Vending Machine | Reborn as a Vending Machine I Now Wander the Dungeon

Strategic Material Selection Guide for the time i got reincarnated as a vending machine

Material Analysis for Vending Machine Applications

When selecting materials for the vending machine featured in “The Time I Got Reincarnated as a Vending Machine,” it is crucial to consider properties that affect performance, durability, and compliance with international standards. Below, we analyze four common materials used in vending machine construction.

1. Stainless Steel

Key Properties: Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand a range of temperatures and pressures. It is commonly used in environments where hygiene is paramount, as it is easy to clean and maintain.

Pros & Cons: The primary advantage of stainless steel is its durability and resistance to rust and staining. However, it can be more expensive than other materials, and its manufacturing processes may require specialized equipment, increasing complexity.

Impact on Application: Stainless steel is particularly suitable for vending machines that dispense food and beverages, as it prevents contamination and maintains product integrity.

Considerations for International Buyers: Compliance with food safety standards is essential, especially in regions like Europe, where regulations are stringent. Buyers should ensure that the stainless steel grades used meet standards such as ASTM A240 or EN 10088.

2. Polycarbonate

Key Properties: Polycarbonate is a lightweight, impact-resistant thermoplastic known for its clarity and UV resistance. It can withstand a wide range of temperatures and is often used in transparent components of vending machines.

Pros & Cons: The main advantage of polycarbonate is its high impact resistance, making it less likely to shatter compared to glass. However, it may not be as scratch-resistant and can yellow over time when exposed to UV light.

Impact on Application: Polycarbonate is ideal for display panels in vending machines, allowing visibility of products while protecting them from external damage.

Considerations for International Buyers: Buyers should be aware of the specific grades of polycarbonate that comply with safety standards in their region, such as those set by ANSI or ISO. Additionally, the environmental impact of polycarbonate recycling should be considered.

3. Aluminum

Key Properties: Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity. It is often used for structural components and casings in vending machines.

Pros & Cons: Aluminum offers a favorable strength-to-weight ratio, making it easy to handle and install. However, it can be more expensive than some other metals and may require additional coatings for enhanced corrosion resistance.

Impact on Application: Aluminum is suitable for vending machines placed in outdoor environments, where exposure to the elements is a concern. Its lightweight nature also aids in mobility and installation.

Considerations for International Buyers: Compliance with international standards such as ASTM B221 for aluminum extrusions is crucial. Buyers should also consider the availability of aluminum in their local markets to avoid supply chain issues.

4. Glass

Key Properties: Glass is a rigid, transparent material that is chemically resistant and can provide a high level of aesthetics. It is often used in the doors and windows of vending machines.

Pros & Cons: The primary advantage of glass is its clarity and ability to provide a premium look. However, it is fragile and can break easily, which may pose safety concerns.

Impact on Application: Glass is ideal for showcasing products, enhancing the visual appeal of the vending machine. However, it requires careful handling and installation to prevent breakage.

Considerations for International Buyers: Buyers should ensure that the glass used meets safety standards such as ANSI Z97.1 or EN 12150 for tempered glass. Additionally, the weight of glass may affect shipping costs and installation logistics.

Summary Table

| Material | Typical Use Case for the time i got reincarnated as a vending machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural components, food-safe areas | Excellent corrosion resistance | Higher cost, manufacturing complexity | High |

| Polycarbonate | Display panels, transparent sections | High impact resistance | Less scratch-resistant, UV yellowing | Medium |

| Aluminum | Structural components, casings | Lightweight, good corrosion resistance | Higher cost, may need coatings | Medium |

| Glass | Doors and windows for product visibility | Aesthetic appeal | Fragile, safety concerns | Medium |

This analysis provides a comprehensive overview of material options for international B2B buyers, emphasizing key properties, advantages, disadvantages, and compliance considerations tailored to specific regional markets.

In-depth Look: Manufacturing Processes and Quality Assurance for the time i got reincarnated as a vending machine

Manufacturing Processes for Vending Machines

The manufacturing of vending machines, particularly those inspired by “The Time I Got Reincarnated as a Vending Machine,” involves a series of well-coordinated processes that ensure the final product is not only functional but also meets the aesthetic and operational expectations of end-users. Below are the primary stages involved in the manufacturing process.

1. Material Preparation

This initial stage focuses on sourcing and preparing the materials required for the vending machines. Typically, materials include:

- Metal Sheets: Used for the body and structural components.

- Plastic Components: For buttons, display screens, and internal mechanisms.

- Electrical Components: Including wiring, control systems, and payment processing units.

Key Techniques:

– Laser Cutting: Precisely cuts metal sheets into required shapes.

– Injection Molding: Creates plastic parts with intricate designs.

– Quality Sourcing: Ensures materials meet international standards, which is critical for international buyers.

2. Forming

In this phase, the prepared materials are shaped into the necessary components of the vending machine.

Key Techniques:

– Press Forming: Metal sheets are shaped using hydraulic or mechanical presses.

– Vacuum Forming: Used for creating plastic parts by heating and molding over a form.

The quality of forming directly affects the durability and performance of the vending machines, making this a crucial stage in the manufacturing process.

3. Assembly

Once components are formed, the next step is assembling them into a complete vending machine.

Key Steps:

– Mechanical Assembly: Involves fitting together metal and plastic parts.

– Electrical Assembly: Connecting wiring, control systems, and payment mechanisms.

Key Techniques:

– Robotic Assembly Lines: Improve efficiency and precision.

– Manual Assembly: For intricate components that require a human touch.

Proper assembly is vital to ensure that all parts fit correctly and function as intended, which impacts the machine’s reliability and user experience.

4. Finishing

The final stage involves adding any necessary finishing touches to the vending machines to enhance their appearance and functionality.

Key Techniques:

– Painting and Coating: To protect surfaces and provide aesthetic appeal.

– Testing and Calibration: Ensuring that all systems work correctly before the machine is packaged for shipping.

Finishing not only contributes to the visual appeal but also helps in enhancing the durability of the machines against environmental factors.

Quality Assurance Processes

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that each vending machine meets both company and international standards.

International Standards

Adhering to international quality standards is crucial for gaining trust from B2B buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe. Some relevant standards include:

- ISO 9001: A global standard for quality management systems.

- CE Marking: Indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

- API (American Petroleum Institute) Standards: Relevant for machines intended for specific environments, like oil and gas sectors.

Quality Control Checkpoints

Quality control is typically divided into several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Inspecting materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process to catch any defects early.

- Final Quality Control (FQC): Comprehensive testing of the finished product to confirm it meets quality standards before shipment.

Common Testing Methods

Several testing methods are employed to verify the quality of the vending machines, including:

- Functional Testing: Ensures all components operate correctly.

- Stress Testing: Evaluates the machine’s performance under extreme conditions.

- Safety Testing: Verifies compliance with safety standards to protect users.

Verifying Supplier Quality Control

For international B2B buyers, verifying the quality control processes of suppliers is critical. Here are actionable steps to ensure supplier reliability:

- Audits: Conduct regular audits of suppliers to assess their quality management systems and processes.

- Quality Reports: Request detailed quality reports that outline testing results and compliance with relevant standards.

- Third-Party Inspections: Engage third-party organizations to conduct independent quality checks, providing an unbiased assessment of the supplier’s processes.

Quality Control Nuances for International Buyers

When sourcing vending machines from international suppliers, especially in regions like Africa, South America, the Middle East, and Europe, it is essential to understand the nuances of quality control:

- Cultural and Regulatory Differences: Different regions may have varying standards and expectations regarding quality. Familiarize yourself with local regulations and industry standards that may affect product quality.

- Communication: Establish clear communication channels with suppliers to ensure that quality expectations are understood and met.

- Documentation: Ensure that all quality assurance processes and certifications are documented and available for review.

By emphasizing robust manufacturing processes and stringent quality assurance practices, B2B buyers can confidently source vending machines that align with their operational needs and quality expectations. This not only enhances their purchasing decisions but also fosters long-term partnerships with reliable suppliers.

Related Video: The Most Sophisticated Manufacturing Process In The World Inside The Fab | Intel

Comprehensive Cost and Pricing Analysis for the time i got reincarnated as a vending machine Sourcing

Cost Structure Analysis

When sourcing products like those inspired by “The Time I Got Reincarnated as a Vending Machine,” it is crucial for international B2B buyers to understand the various cost components involved in the manufacturing and distribution process. Below is a breakdown of key cost components:

- Materials: The raw materials used in the production of vending machines significantly impact costs. These include metals, plastics, electronic components, and specialized parts. Prices can vary widely based on local availability and market demand.

Illustrative Image (Source: Google Search)

-

Labor: Labor costs can differ dramatically between regions. In countries with lower labor costs, such as parts of South America and Africa, manufacturers may offer more competitive pricing. However, quality and skills should be assessed to ensure product standards.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, including utilities, rent, and salaries of non-production staff. Efficient manufacturing processes can help minimize these overheads.

-

Tooling: The initial investment in tooling and machinery can be significant, particularly for customized vending machines. Buyers should consider whether the tooling costs can be amortized over large production runs to reduce per-unit costs.

-

Quality Control (QC): Ensuring product quality through rigorous QC processes can add to costs but is essential for maintaining standards. Buyers should weigh the cost of poor quality against the investment in robust QC measures.

-

Logistics: Shipping and handling costs are critical, especially for international buyers. Factors such as shipping routes, freight methods, and local tariffs can significantly influence total costs.

-

Margin: Supplier margins will vary, reflecting their market positioning, brand value, and operational costs. Understanding these margins can help buyers negotiate better pricing.

Pricing Influencers

Several factors influence the pricing of vending machines:

-

Volume/MOQ: Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should negotiate minimum order quantities (MOQs) that align with their needs.

-

Specifications/Customization: Custom features can raise costs. Buyers should clearly define their requirements to avoid unnecessary expenses.

-

Materials: The choice of materials directly impacts the price. High-quality, durable materials may have a higher upfront cost but can reduce long-term maintenance and replacement expenses.

-

Quality/Certifications: Certifications for safety and compliance can add costs but are essential for market acceptance, especially in regulated regions like Europe.

-

Supplier Factors: The reputation, reliability, and capabilities of suppliers can affect pricing. A well-established supplier may offer higher prices but can provide better support and quality assurance.

-

Incoterms: The terms of shipping (e.g., FOB, CIF) can influence total costs. Understanding these terms is vital for calculating landed costs.

Buyer Tips

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, the following strategies can enhance cost-efficiency:

-

Negotiation: Leverage multiple supplier quotes to negotiate better terms. Building long-term relationships can also lead to favorable pricing and terms.

-

Total Cost of Ownership (TCO): Evaluate the TCO, which includes purchase price, maintenance, operation costs, and disposal expenses. This comprehensive view helps in selecting the best value proposition.

-

Pricing Nuances: Be aware of regional pricing variations and currency fluctuations that can impact total costs. It is advisable to lock in prices early in the procurement process to mitigate risks associated with price volatility.

-

Supplier Evaluation: Assess potential suppliers not only on price but also on their ability to deliver quality, reliability, and service support. This holistic approach can lead to better sourcing decisions.

Disclaimer

Prices and costs mentioned in this analysis are indicative and can vary based on market conditions, specific supplier offerings, and buyer negotiation outcomes. It is recommended to conduct thorough market research and supplier assessments to obtain accurate pricing information tailored to specific needs.

Spotlight on Potential the time i got reincarnated as a vending machine Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘the time i got reincarnated as a vending machine’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for the time i got reincarnated as a vending machine

Key Technical Properties

When considering the procurement of vending machines, particularly those inspired by the anime “The Time I Got Reincarnated as a Vending Machine,” understanding the technical specifications is crucial for ensuring quality and performance. Here are some essential properties to consider:

-

Material Grade

The material grade refers to the quality and type of materials used in the construction of the vending machine. Common materials include stainless steel for durability and plastic for lightweight designs. A higher material grade often leads to better longevity and resistance to wear, which is vital for machines operating in diverse environments. -

Power Consumption

This specification indicates how much electrical energy the vending machine requires to operate efficiently. Energy-efficient models can significantly reduce operational costs, making them more appealing to businesses, especially in regions where electricity costs are high. -

Capacity

The capacity of a vending machine refers to the number of items it can hold. This is an important factor for B2B buyers, as larger capacities can mean fewer restocking trips and higher sales potential. It’s essential to align the capacity with the expected foot traffic and product turnover rate. -

User Interface Technology

Modern vending machines often feature touchscreens or mobile payment systems. The type of user interface can greatly affect customer experience and sales. Machines that offer multiple payment options (like contactless payments) are increasingly preferred, as they cater to tech-savvy consumers. -

Operating Temperature Range

This property indicates the temperature limits within which the vending machine can effectively operate. Understanding this range is crucial, particularly for buyers in regions with extreme weather conditions, as it impacts machine reliability and product integrity. -

Maintenance Requirements

Maintenance specifications outline how often and what types of service the vending machines require. Machines that are easier to maintain can lead to lower operational downtime and cost savings over time, making them a better investment for businesses.

Industry Terminology

Familiarity with industry jargon can enhance communication and negotiation between buyers and suppliers. Here are several key terms to know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify reputable suppliers and ensure they receive quality components. -

MOQ (Minimum Order Quantity)

This is the smallest number of units a supplier is willing to sell. Knowing the MOQ helps buyers plan their budgets and inventory levels, especially when launching new products or entering new markets.

Illustrative Image (Source: Google Search)

-

RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing and terms for specific products or services. It is a critical step in the procurement process, enabling buyers to compare offers and make informed decisions. -

Incoterms

Short for International Commercial Terms, these are pre-defined commercial terms published by the International Chamber of Commerce. They are crucial for defining the responsibilities of buyers and sellers in international trade, including shipping, insurance, and tariffs. -

Lead Time

This term refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is essential for inventory management and ensuring that businesses can meet customer demand without delays. -

Warranty

A warranty is a guarantee provided by the manufacturer regarding the condition of the product. It typically covers repairs or replacements for a specified period. Buyers should carefully consider warranty terms to ensure they are protected against defects or malfunctions.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing vending machines, ultimately leading to better purchasing outcomes and enhanced operational efficiency.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the the time i got reincarnated as a vending machine Sector

Market Overview & Key Trends

The global vending machine market, particularly in the niche of “the time I got reincarnated as a vending machine,” is driven by several key factors. Increased urbanization, changing consumer behaviors, and the demand for convenience are significant contributors to market growth. As consumers seek quick access to products, vending machines are evolving to offer a wider range of items, including healthy snacks, beverages, and even tech gadgets.

Emerging technologies are also reshaping the sector. Innovations such as contactless payments, IoT-enabled machines, and AI-driven inventory management are becoming increasingly prevalent. These technologies not only enhance consumer experience but also improve operational efficiency for B2B buyers. In regions like Africa and South America, where traditional retail infrastructure may be lacking, vending machines present a viable channel for product distribution.

Furthermore, sustainability is becoming a crucial consideration in sourcing trends. B2B buyers are increasingly looking for suppliers that prioritize eco-friendly practices, from the materials used in vending machines to the products they dispense. This trend is particularly strong in Europe, where regulations around sustainability are more stringent, influencing purchasing decisions across various sectors, including vending.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer a buzzword; it is a necessity in the vending machine sector. The environmental impact of production, operation, and disposal of vending machines is significant. As such, international B2B buyers must consider suppliers who implement sustainable practices. This includes using recyclable materials for machine construction, energy-efficient components, and eco-friendly products.

Ethical sourcing is equally important. Buyers should prioritize suppliers that maintain transparent supply chains and adhere to ethical labor practices. Certifications such as Fair Trade, Rainforest Alliance, and ISO 14001 for environmental management can guide buyers in selecting reputable suppliers. Additionally, incorporating ‘green’ products in vending offerings, such as organic snacks or biodegradable packaging, not only meets consumer demand but also aligns with corporate social responsibility goals.

By focusing on sustainability and ethical sourcing, businesses can improve their brand reputation, attract environmentally conscious consumers, and comply with increasingly stringent regulations.

Brief Evolution/History

The concept of vending machines dates back to ancient times, with the earliest known devices appearing in Egypt around 215 BC, dispensing holy water. However, the modern vending machine era began in the early 20th century, with machines offering cigarettes, gum, and other snacks in public spaces. Over the decades, the industry has transformed significantly, adapting to technological advancements and changing consumer preferences.

In recent years, the rise of digital payment systems and smart vending technology has further revolutionized the sector. Today, vending machines are not just about convenience; they are integral to the retail ecosystem, enabling brands to reach diverse markets effectively. As the landscape continues to evolve, B2B buyers in this niche must stay informed about technological advancements and sustainability trends to remain competitive.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of the time i got reincarnated as a vending machine

-

What criteria should I use to vet suppliers for ‘The Time I Got Reincarnated as a Vending Machine’ products?

When vetting suppliers, focus on their industry experience, reputation, and the quality of their products. Request case studies or references from previous clients, and verify their certifications related to international standards. Engage in direct communication to assess their responsiveness and willingness to accommodate your specific needs. Additionally, evaluate their financial stability, as this can impact their ability to fulfill large orders and adhere to timelines. -

Can I customize the products based on my market needs?

Yes, many suppliers offer customization options. It’s crucial to communicate your specific requirements early in the negotiation process. Discuss aspects such as design modifications, packaging preferences, and branding elements. Ensure that the supplier can meet your quality standards while accommodating these customizations. Be aware that customization may affect the minimum order quantity (MOQ) and lead times. -

What are the typical minimum order quantities (MOQ) and lead times for these products?

MOQs and lead times can vary significantly depending on the supplier and the complexity of the order. Generally, MOQs can range from 100 to several thousand units, while lead times may be anywhere from 4 to 12 weeks. It’s advisable to clarify these details upfront and negotiate terms that align with your business needs. Consider discussing options for smaller trial orders to assess product quality before committing to larger quantities. -

What payment terms are commonly offered for international transactions?

Payment terms can vary by supplier but typically include options such as advance payment, Letter of Credit (LC), or payment on delivery. It’s important to negotiate favorable terms that mitigate risk, especially for larger orders. Be cautious of suppliers requesting full payment upfront, and consider using secure payment platforms that provide buyer protection. Establish a clear agreement on payment timelines and methods to avoid disputes. -

How can I ensure the quality of the products I receive?

To ensure product quality, request samples before placing a large order. Establish quality assurance protocols with the supplier, including inspections at various production stages. Verify that the supplier holds relevant quality certifications, such as ISO or equivalent standards. Consider hiring a third-party inspection service to conduct quality checks before shipment, particularly if you are importing from overseas. -

What certifications should I look for when sourcing these products?

Look for certifications that align with international standards, such as ISO 9001 for quality management and CE marking for compliance with European safety standards. Depending on your market, additional certifications may be necessary, such as FDA approval for food-related products or RoHS compliance for electronic devices. Confirm that the supplier can provide documentation for these certifications to ensure compliance with local regulations. -

What logistics considerations should I keep in mind?

Logistics is a critical aspect of international sourcing. Discuss shipping options with your supplier, including Incoterms (e.g., FOB, CIF) that dictate the responsibilities of both parties. Evaluate the supplier’s ability to handle customs documentation and duties, and consider using freight forwarders with experience in your target market. Ensure you have a clear understanding of delivery timelines and the potential for delays due to customs or transport issues. -

How should I handle disputes or issues with my supplier?

Establish a clear dispute resolution process in your contract, including mediation or arbitration clauses. Maintain open communication with your supplier to address issues as they arise. Document all correspondence and agreements related to your order to provide a clear reference if disputes occur. If necessary, seek legal counsel familiar with international trade laws to navigate complex disputes effectively.

Strategic Sourcing Conclusion and Outlook for the time i got reincarnated as a vending machine

In conclusion, the insights derived from the narrative of “The Time I Got Reincarnated as a Vending Machine” highlight the pivotal role of strategic sourcing in the B2B landscape. International buyers from regions such as Africa, South America, the Middle East, and Europe can leverage these insights to enhance their procurement strategies. Key takeaways include:

- Understanding Consumer Preferences: The ability to adapt offerings based on regional consumer demands is critical. Tailoring products and services to meet the local tastes and preferences can significantly enhance market penetration.

- Building Supplier Relationships: Establishing strong partnerships with suppliers not only ensures consistent quality but also fosters innovation and responsiveness to market changes.

- Embracing Technology: Utilizing technology for data analysis and supply chain management can streamline operations and drive efficiency.

As we look forward, it is imperative for B2B buyers to remain agile and proactive. The evolving marketplace demands a forward-thinking approach to sourcing strategies. Embrace these lessons and invest in sustainable sourcing practices that will not only secure your position in the market but also contribute to long-term success. The time to act is now—make informed sourcing decisions that pave the way for future growth and resilience.