Your Ultimate Guide to Sourcing Fish Vending Machine Near Me

Guide to Fish Vending Machine Near Me

- Introduction: Navigating the Global Market for fish vending machine near me

- Understanding fish vending machine near me Types and Variations

- Key Industrial Applications of fish vending machine near me

- Strategic Material Selection Guide for fish vending machine near me

- In-depth Look: Manufacturing Processes and Quality Assurance for fish vending machine near me

- Comprehensive Cost and Pricing Analysis for fish vending machine near me Sourcing

- Spotlight on Potential fish vending machine near me Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for fish vending machine near me

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the fish vending machine near me Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of fish vending machine near me

- Strategic Sourcing Conclusion and Outlook for fish vending machine near me

Introduction: Navigating the Global Market for fish vending machine near me

The rising demand for fresh and convenient seafood options has led to the innovative emergence of fish vending machines, a solution that caters to both consumers and businesses alike. For international B2B buyers, particularly those operating in regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of sourcing these machines is crucial. With the ability to provide high-quality fish products in a user-friendly manner, fish vending machines not only enhance customer satisfaction but also streamline inventory management for vendors.

This comprehensive guide delves into the multifaceted world of fish vending machines, offering insights into various types of machines available on the market, the materials used in their construction, and the manufacturing and quality control processes that ensure product reliability. Additionally, we will explore cost considerations, supplier options, and the overall market landscape for these machines, equipping buyers with the knowledge needed to make informed purchasing decisions.

By addressing common FAQs and providing actionable tips throughout the guide, B2B buyers will gain a deeper understanding of how to effectively navigate the global market for fish vending machines. This resource aims to empower businesses in making strategic choices that enhance their operations, meet consumer demands, and ultimately drive profitability in a competitive environment.

Understanding fish vending machine near me Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Automated Fresh Fish Dispenser | Refrigerated storage, real-time stock monitoring | Retail fish markets, supermarkets | Pros: Fresh product, minimal labor; Cons: High initial cost, maintenance required. |

| Frozen Fish Vending Machine | Offers frozen fish products, energy-efficient design | Convenience stores, gas stations | Pros: Longer shelf life, low spoilage; Cons: Limited variety, potential quality concerns. |

| Mobile Fish Vending Units | Portable, can be relocated easily, solar-powered | Events, festivals, temporary markets | Pros: Flexibility, low setup cost; Cons: Limited capacity, may require frequent restocking. |

| Multi-Product Seafood Vending | Variety of seafood options, customizable interfaces | Restaurants, catering services | Pros: Diverse offerings, attracts different customer segments; Cons: Complexity in inventory management. |

| Self-Service Fish Selection Kiosks | Interactive touchscreens, user-friendly design | High-traffic areas, urban centers | Pros: Engages consumers, reduces staff need; Cons: Higher operational costs, technology reliance. |

Automated Fresh Fish Dispenser

This type of vending machine specializes in providing fresh fish directly to consumers. Equipped with refrigerated storage, these dispensers ensure optimal temperature control and real-time stock monitoring. They are particularly suited for retail fish markets and supermarkets where freshness is paramount. When considering this option, B2B buyers should evaluate the initial investment and ongoing maintenance requirements against the potential for high-quality, fresh product sales.

Frozen Fish Vending Machine

Frozen fish vending machines focus on delivering a range of frozen seafood products. Their energy-efficient designs help maintain low operational costs while extending product shelf life. These machines are commonly found in convenience stores and gas stations, catering to consumers seeking quick meal options. Buyers should weigh the benefits of reduced spoilage against the limitations of product variety and potential quality concerns associated with frozen goods.

Mobile Fish Vending Units

Mobile fish vending units provide flexibility and adaptability, making them ideal for events, festivals, and temporary markets. Often solar-powered, these units can be relocated easily to meet demand fluctuations. While they require lower setup costs and offer a unique selling proposition, B2B buyers should consider the limited capacity and the necessity for frequent restocking, especially during busy periods.

Multi-Product Seafood Vending

These vending machines offer a diverse selection of seafood options, allowing businesses to customize their product offerings based on local demand. They are particularly useful for restaurants and catering services that want to provide fresh seafood without extensive inventory management. Buyers should consider the complexity involved in managing multiple product lines and the potential for attracting a wider customer base.

Self-Service Fish Selection Kiosks

These kiosks feature interactive touchscreens that enhance the consumer experience by allowing customers to select their seafood preferences. They are ideal for high-traffic areas and urban centers, where engaging consumers can lead to increased sales. While they reduce the need for staff and can streamline operations, buyers must account for the higher operational costs and reliance on technology, which may require regular updates and maintenance.

Related Video: Buying Every Fish From the Live Fish Vending Machine… deadly fish

Key Industrial Applications of fish vending machine near me

| Industry/Sector | Specific Application of fish vending machine near me | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Urban fish retailing | Increased accessibility to fresh seafood | Local regulations on food safety, machine durability |

| Hospitality | On-site fish supply for restaurants | Fresh, high-quality ingredients for menu items | Supply chain logistics, machine maintenance support |

| Food Service | Catering services for events | Quick service and diverse seafood options | Machine capacity, range of products offered |

| Aquaculture | Direct sales from fish farms | Enhanced revenue streams and market reach | Compliance with local aquaculture regulations, machine design |

| Health & Wellness | Automated health-focused seafood sales | Promotes healthy eating habits among consumers | Nutritional information display, freshness tracking |

Retail

In urban environments, fish vending machines serve as an innovative solution for retail businesses aiming to provide consumers with fresh seafood. These machines can be strategically placed in high-traffic areas, allowing customers to access quality fish conveniently. For international B2B buyers, it’s crucial to consider local regulations regarding food safety and hygiene standards, as well as the machine’s durability to withstand outdoor conditions.

Hospitality

Restaurants can greatly benefit from fish vending machines by utilizing them as on-site supply sources. This not only ensures a steady flow of fresh seafood but also enhances menu quality and customer satisfaction. Buyers in this sector should focus on the logistics of supply chains, ensuring that machines are stocked regularly and that maintenance support is readily available to avoid disruptions.

Food Service

Catering services can leverage fish vending machines to provide quick and diverse seafood options at events. These machines can streamline the ordering process, allowing guests to select their desired seafood with minimal wait times. Buyers should assess the machine’s capacity and the variety of products it can offer, ensuring that it meets the demands of different events and customer preferences.

Aquaculture

Fish farms can utilize vending machines for direct sales, creating a new revenue stream and increasing market reach. By selling fresh fish directly to consumers, farms can cut out middlemen and improve profit margins. Buyers must ensure compliance with local aquaculture regulations and consider the machine’s design to facilitate easy loading and unloading of products.

Health & Wellness

Automated seafood vending machines can cater to the growing health-conscious market by offering fresh, nutritious fish options. These machines can promote healthy eating habits and provide essential nutritional information to consumers. Key considerations for buyers include the ability to display nutritional data and track the freshness of products, ensuring that consumers are receiving the best quality.

Strategic Material Selection Guide for fish vending machine near me

When selecting materials for fish vending machines, it is essential to consider a range of factors that influence performance, durability, and compliance with international standards. Here, we analyze four common materials used in the construction of fish vending machines, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Stainless Steel

Key Properties: Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand high temperatures. It is also non-reactive, making it suitable for food contact applications.

Pros & Cons: The durability of stainless steel is one of its main advantages, providing a long service life even in harsh environments. However, it is generally more expensive than other materials, which can increase the initial investment cost. Manufacturing complexity can also be higher due to the need for specialized tools and techniques.

Impact on Application: Stainless steel is compatible with various media, including fresh and saltwater, making it ideal for fish vending machines. Its hygienic properties are crucial for maintaining food safety standards.

Considerations for International Buyers: Compliance with food safety regulations is paramount. Buyers should ensure that the stainless steel grades used (e.g., 304, 316) meet local standards such as ASTM or DIN. In regions like Europe, specific grades may be preferred for their corrosion resistance in marine environments.

Aluminum

Key Properties: Aluminum is lightweight, has good corrosion resistance, and excellent thermal conductivity. It is often anodized to enhance its protective properties.

Pros & Cons: The low weight of aluminum makes it easier to handle and install, reducing shipping costs. However, it is less durable than stainless steel and can be prone to dents and scratches. The cost is typically lower than stainless steel, making it an attractive option for budget-conscious buyers.

Impact on Application: Aluminum is suitable for applications where weight savings are critical, but it may not be ideal for environments with high exposure to saltwater unless properly treated.

Considerations for International Buyers: Buyers should check for compliance with local regulations regarding material safety and food contact. Standards like JIS may apply in Japan, while European buyers should consider EN standards for material safety.

Polycarbonate

Key Properties: Polycarbonate is a strong, impact-resistant plastic that offers good clarity and UV resistance. It is lightweight and can be molded into complex shapes.

Pros & Cons: The primary advantage of polycarbonate is its impact resistance, making it less likely to shatter compared to glass. However, it is not as heat-resistant as metals and can degrade under prolonged UV exposure. The cost is generally lower than metals, making it a cost-effective choice for certain applications.

Impact on Application: Polycarbonate is often used for protective covers and viewing windows in vending machines. It is suitable for environments where visibility is essential, but care must be taken to ensure it is not exposed to extreme temperatures.

Considerations for International Buyers: Compliance with safety standards for food contact is critical. Buyers should verify that the polycarbonate used meets standards such as FDA regulations in the U.S. or EU regulations in Europe.

Carbon Steel

Key Properties: Carbon steel is known for its high strength and durability. However, it is susceptible to corrosion and requires protective coatings for food applications.

Pros & Cons: The primary advantage of carbon steel is its cost-effectiveness and strength, making it suitable for structural components. However, its susceptibility to rust and corrosion limits its use in direct contact with food unless properly coated.

Impact on Application: Carbon steel can be used in non-corrosive environments or for components that do not come into direct contact with fish. Proper coating is essential to prevent contamination.

Considerations for International Buyers: Buyers should ensure that carbon steel components comply with relevant standards for food safety, such as ASTM A36 for structural steel. In regions like Africa and South America, local standards may also apply.

Summary Table

| Material | Typical Use Case for fish vending machine near me | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural components and food contact surfaces | Excellent corrosion resistance and durability | Higher initial cost and manufacturing complexity | High |

| Aluminum | Framework and non-food contact parts | Lightweight and cost-effective | Less durable than stainless steel | Medium |

| Polycarbonate | Protective covers and viewing windows | Impact-resistant and lightweight | Not as heat-resistant and UV degradation | Low |

| Carbon Steel | Structural supports and non-food contact areas | Cost-effective and strong | Susceptible to corrosion without coatings | Low |

This guide provides a comprehensive overview of the materials suitable for fish vending machines, highlighting key properties and considerations that international B2B buyers should keep in mind when making their selections.

In-depth Look: Manufacturing Processes and Quality Assurance for fish vending machine near me

Manufacturing Processes for Fish Vending Machines

The manufacturing of fish vending machines involves a series of systematic processes designed to ensure that the final product is reliable, efficient, and meets market needs. For B2B buyers, understanding these processes can help in evaluating suppliers and ensuring that quality standards are met.

Material Preparation

The first stage in manufacturing fish vending machines is material preparation. This involves sourcing high-quality materials suitable for food storage and dispensing. Common materials include:

- Stainless Steel: Preferred for its corrosion resistance and ease of cleaning, essential for food safety.

- Polycarbonate: Often used for windows or displays due to its durability and transparency.

- Insulation Materials: Such as polyurethane foam, used to maintain optimal temperatures for fish preservation.

Quality assurance begins at this stage, as material defects can lead to increased costs and product failures later in the process.

Forming

Once materials are prepared, the next step is forming. This typically involves processes such as:

- Laser Cutting: For precision cuts on metal sheets to create the body of the machine.

- Injection Molding: Used for creating plastic components like buttons and internal structures.

- Bending and Shaping: Metal sheets are bent into the desired shapes using hydraulic presses.

Advanced technologies, such as CNC (Computer Numerical Control) machines, are often employed to enhance precision and reduce waste.

Assembly

After forming, the components are assembled. This stage includes:

- Sub-Assembly: Components are first assembled into smaller units, such as refrigeration units or electronic control panels.

- Main Assembly: The sub-assemblies are integrated to form the complete machine. This involves careful alignment and securing of parts to ensure functionality.

Each assembly step is crucial, as improper assembly can lead to operational failures or safety issues.

Finishing

The final stage is finishing, which involves:

- Surface Treatment: Processes like powder coating or anodizing are applied to protect the machine from corrosion and enhance its aesthetic appeal.

- Quality Checks: Final inspections are conducted to ensure that all components are functioning as intended, and the machine meets safety and regulatory standards.

Quality Assurance in Manufacturing

Quality assurance (QA) is critical in the manufacturing of fish vending machines. It involves systematic monitoring and evaluation of the production process to ensure that products meet predefined quality standards.

International and Industry-Specific Standards

For B2B buyers, awareness of relevant standards is vital. Common standards include:

- ISO 9001: A widely recognized standard for quality management systems, focusing on consistent product quality and continuous improvement.

- CE Marking: Indicates that the machine meets European health, safety, and environmental protection standards.

- API (American Petroleum Institute): While primarily for oil and gas, some principles can be relevant for machinery used in food processing.

These certifications not only ensure compliance with regulations but also enhance the credibility of suppliers.

Quality Control Checkpoints

Quality control (QC) checkpoints are established throughout the manufacturing process, including:

- Incoming Quality Control (IQC): Inspection of raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Ongoing checks during the manufacturing process to identify and rectify issues immediately.

- Final Quality Control (FQC): Comprehensive testing and inspection of the finished product before shipping.

Common Testing Methods

B2B buyers should be familiar with common testing methods, which may include:

- Functional Testing: Ensuring that all features of the machine operate correctly.

- Temperature and Humidity Testing: Verifying that refrigeration systems maintain appropriate conditions for fish storage.

- Safety Testing: Checking electrical components for compliance with safety standards.

Verifying Supplier Quality Control

B2B buyers from regions such as Africa, South America, the Middle East, and Europe should implement strategies to verify supplier quality control:

- Supplier Audits: Conduct regular audits to assess the manufacturing processes and quality management systems of suppliers.

- Request Quality Reports: Ask for documentation of quality checks and test results from the supplier.

- Third-Party Inspections: Engage independent inspection agencies to evaluate the machines before shipment.

Nuances for International B2B Buyers

International buyers should be aware of specific nuances that can affect quality assurance:

- Regulatory Variances: Different countries have varying regulations regarding food safety and equipment standards. Understanding these can prevent compliance issues.

- Cultural Considerations: Communication styles and business practices can differ significantly across regions. Clear expectations regarding quality and timelines should be established upfront.

- Logistics and Shipping: Ensure that quality is maintained throughout transportation. This may involve temperature-controlled shipping methods for sensitive equipment.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing fish vending machines, ensuring they receive products that are reliable, compliant, and tailored to market demands.

Related Video: Most Satisfying Factory Production Processes And Heavy-Duty Factory Machines!

Comprehensive Cost and Pricing Analysis for fish vending machine near me Sourcing

Understanding the cost and pricing structure of fish vending machines is crucial for international B2B buyers. This analysis focuses on the cost components, price influencers, and practical tips for negotiating and optimizing purchasing strategies.

Cost Components

-

Materials: The primary materials for fish vending machines include stainless steel for durability and hygiene, electronic components for payment processing, refrigeration systems, and display units. The choice of materials can significantly affect the overall cost.

-

Labor: Labor costs encompass both direct and indirect labor involved in manufacturing the machines. This includes wages for assembly line workers, engineers for design and testing, and support staff for logistics and sales.

-

Manufacturing Overhead: Overhead costs include utilities, rent, and maintenance of the manufacturing facility. These costs are often allocated on a per-unit basis, affecting the price of each machine.

-

Tooling: Tooling costs refer to the expenses associated with the production tools and molds required for manufacturing the machines. This is a crucial factor for custom designs and can be substantial if specialized equipment is needed.

-

Quality Control (QC): Ensuring that each machine meets quality standards incurs costs related to testing and inspections. Effective QC processes are essential to minimize defects and ensure reliability, which can influence the pricing structure.

-

Logistics: Logistics costs involve transportation, warehousing, and distribution of the machines. These costs vary based on the shipping method, distance, and any tariffs or customs duties applicable to international shipments.

-

Margin: Suppliers typically include a profit margin that varies based on market conditions, competition, and perceived value. Understanding this margin can help buyers gauge whether they are getting a fair price.

Price Influencers

-

Volume/MOQ: The minimum order quantity (MOQ) and the volume of the order can significantly influence pricing. Larger orders often lead to lower per-unit costs due to economies of scale.

-

Specifications/Customization: Custom features or specifications can increase costs. Buyers should clearly define their requirements to avoid unexpected charges.

-

Materials: The choice of materials impacts both cost and durability. High-quality materials may have a higher upfront cost but can lead to lower maintenance expenses over time.

-

Quality/Certifications: Machines that meet international standards or certifications may command higher prices. However, these certifications can also enhance the product’s marketability and reduce liability.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their proven track record, while newer entrants may offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms is essential for international buyers. These terms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can significantly influence total costs.

Buyer Tips

-

Negotiation: Engage suppliers in discussions about pricing, especially if purchasing in bulk. Be prepared to leverage your position as a repeat customer for better terms.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes purchase price, maintenance, operation costs, and potential resale value. A higher initial investment may lead to lower long-term costs.

-

Pricing Nuances: Be aware of regional pricing differences. For example, prices may vary between Europe and Africa due to shipping costs, tariffs, and local market conditions.

-

Research and Compare: Gather quotes from multiple suppliers and compare not just prices but also warranty terms, after-sales support, and delivery times.

Disclaimer

Prices can fluctuate based on market conditions, currency exchange rates, and supplier-specific factors. This analysis provides indicative pricing insights, and buyers are encouraged to conduct thorough market research before making purchasing decisions.

Spotlight on Potential fish vending machine near me Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘fish vending machine near me’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for fish vending machine near me

When considering the procurement of fish vending machines, understanding the essential technical properties and trade terminology is crucial for making informed decisions. Here’s a detailed breakdown of key specifications and terms relevant to international B2B buyers.

Key Technical Properties

-

Material Grade

– Definition: The quality of materials used in the construction of the vending machine, such as stainless steel or food-grade plastics.

– Importance: High-grade materials ensure durability, hygiene, and compliance with health regulations, which are critical for food vending applications. -

Temperature Control Range

– Definition: The range of temperatures that the machine can maintain for preserving fish, typically between -20°C to +4°C.

– Importance: Proper temperature control is vital for food safety and extending the shelf life of fish products. Buyers should verify that the machine meets local food safety standards. -

Power Consumption

– Definition: The amount of electrical energy the machine uses, usually measured in kilowatts (kW).

– Importance: Understanding power requirements helps assess operational costs and compatibility with local electrical infrastructure, which can vary significantly across regions. -

Capacity

– Definition: The volume or weight of fish the machine can store or dispense, often measured in liters or kilograms.

– Importance: Capacity should align with expected sales volume, ensuring that the machine can meet demand without frequent restocking, which is crucial for maintaining freshness. -

User Interface

– Definition: The interface through which customers interact with the machine, such as touchscreen displays or keypad inputs.

– Importance: A user-friendly interface can enhance customer experience and reduce transaction times, which is essential for high-traffic locations. -

Compliance Certifications

– Definition: Certifications that validate the machine meets specific industry standards, such as CE marking in Europe or FDA compliance in the U.S.

– Importance: Compliance certifications are critical for ensuring the machine is safe and legally acceptable for use in various markets, providing peace of mind to buyers.

Common Trade Terms

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Relevance: Understanding OEM relationships can help buyers identify quality suppliers and ensure they are receiving products that meet industry standards. -

MOQ (Minimum Order Quantity)

– Definition: The smallest amount of product a supplier is willing to sell.

– Relevance: Knowing the MOQ helps buyers gauge the feasibility of their orders and negotiate better terms based on their purchasing needs. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers requesting pricing and terms for specific products or services.

– Relevance: Submitting an RFQ is essential for comparing offers from multiple suppliers, ensuring competitive pricing and terms. -

Incoterms (International Commercial Terms)

– Definition: A series of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers.

– Relevance: Familiarity with Incoterms is crucial for understanding shipping costs, risk responsibilities, and delivery terms, particularly in international transactions.

-

Lead Time

– Definition: The amount of time from the placement of an order to its delivery.

– Relevance: Knowing the lead time helps businesses plan their inventory and sales strategies, ensuring they can meet customer demand without delays. -

Warranty

– Definition: A guarantee provided by the manufacturer regarding the repair or replacement of a product within a specified period.

– Relevance: Understanding warranty terms is vital for managing risk and ensuring long-term support for equipment investments.

By grasping these technical properties and trade terms, international B2B buyers can navigate the complexities of purchasing fish vending machines more effectively, ensuring they make decisions that align with their operational needs and market requirements.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the fish vending machine near me Sector

Market Overview & Key Trends

The global market for fish vending machines is witnessing significant growth driven by changing consumer preferences, technological advancements, and a rising demand for convenient food options. Increasing urbanization in regions such as Africa, South America, the Middle East, and Europe has led to a surge in on-the-go dining, propelling the adoption of automated food vending solutions. Notably, countries like Italy and Argentina are experiencing a shift towards fresh, locally sourced seafood, which aligns with the capabilities of modern vending machines to offer high-quality products.

Emerging trends in the B2B sector include the integration of smart technology in vending machines. Features such as cashless payment systems, real-time inventory tracking, and IoT connectivity are becoming standard. These innovations not only enhance user experience but also provide valuable data analytics for businesses to optimize operations and tailor offerings to consumer preferences. Additionally, the implementation of contactless solutions in response to the COVID-19 pandemic has accelerated the adoption of these technologies, particularly in urban environments.

International B2B buyers should consider the regional dynamics affecting supply chains. For instance, Africa’s growing middle class is increasingly demanding seafood products, while South American countries like Argentina are focusing on sustainable fishing practices. Understanding local regulations and consumer behaviors is essential for successful market entry and long-term growth in these regions.

Sustainability & Ethical Sourcing in B2B

Sustainability is a pivotal concern in the fish vending machine sector, as environmental impacts from overfishing and pollution threaten marine ecosystems. B2B buyers must prioritize partnerships with suppliers who adhere to sustainable fishing practices, thereby ensuring that the seafood offered through vending machines is responsibly sourced. Certifications such as Marine Stewardship Council (MSC) and Aquaculture Stewardship Council (ASC) are crucial indicators of ethical sourcing and should be sought after.

The importance of ethical supply chains cannot be overstated, as consumers increasingly demand transparency about the origins of their food. Vending machine operators that can demonstrate a commitment to sustainability will not only attract environmentally conscious customers but also differentiate themselves in a competitive market. Furthermore, utilizing eco-friendly materials for machine construction and packaging can further enhance brand reputation and appeal to a broader audience.

Investing in sustainable practices is not merely a compliance measure; it is a strategic advantage. By aligning business models with sustainability goals, companies can tap into a growing market segment that values ethical consumption, ultimately leading to increased customer loyalty and market share.

Brief Evolution/History

The concept of vending machines has evolved significantly since their inception in the late 19th century, transitioning from simple mechanisms dispensing snacks to sophisticated units offering fresh and perishable goods like seafood. The fish vending machine, in particular, gained traction in the early 2000s, driven by advancements in refrigeration technology and consumer demand for convenience.

Initially popular in Japan and certain European countries, these machines have expanded globally, adapting to local tastes and regulations. Today, they are equipped with smart technology, allowing businesses to offer fresh seafood while ensuring food safety and quality. As the market continues to evolve, the integration of sustainability and ethical sourcing practices will play a critical role in shaping the future of the fish vending machine sector.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of fish vending machine near me

-

What should I consider when vetting suppliers for fish vending machines?

When vetting suppliers, prioritize their experience in manufacturing fish vending machines and check their reputation through reviews and testimonials. Verify certifications and compliance with international standards, especially for food safety and electrical equipment. Request references from previous clients, and assess their production capabilities and technology. It’s also essential to inquire about their customer support and after-sales service to ensure they can address any issues post-purchase. -

Can I customize the fish vending machine to suit my business needs?

Yes, many suppliers offer customization options for fish vending machines. You can request specific features such as size, capacity, payment methods, and branding options. Ensure that the supplier you choose has experience with custom projects and is willing to collaborate closely during the design process. It’s advisable to get a detailed proposal outlining the customization capabilities and any additional costs involved. -

What are the typical minimum order quantities (MOQ) and lead times for fish vending machines?

MOQs can vary widely among suppliers, typically ranging from 1 to 10 units. For international orders, higher MOQs may come into play due to shipping and production costs. Lead times generally depend on the complexity of the machine and the supplier’s current production schedule, usually ranging from 4 to 12 weeks. Always confirm these details upfront to align your purchasing timeline with your business needs. -

What payment methods are commonly accepted for international orders?

Most suppliers accept various payment methods, including bank transfers, letters of credit, and online payment platforms like PayPal. For large international transactions, letters of credit provide a secure option as they protect both buyer and seller. Discuss payment terms early in negotiations, including deposit requirements and payment schedules, to avoid potential misunderstandings later. -

What quality assurance measures should I expect from suppliers?

Reputable suppliers will have established quality assurance (QA) protocols, including inspections during production and before shipping. Ask about their QA certifications, such as ISO 9001, and whether they conduct third-party inspections. Request samples or photographs of previous machines to evaluate their quality. It’s also beneficial to understand their warranty policies and what recourse you have if the machines do not meet agreed specifications. -

How should I handle logistics for importing fish vending machines?

Logistics can be complex for international shipments. Collaborate with your supplier to determine the best shipping method, whether by sea or air, based on your budget and timeline. Ensure that the supplier provides all necessary documentation, including bills of lading and customs declarations. Consider working with a freight forwarder who can assist with customs clearance and ensure compliance with local regulations in your country. -

What should I do if there is a dispute with the supplier?

In case of a dispute, first attempt to resolve the issue directly with the supplier through open communication. Document all correspondence and agreements for clarity. If necessary, refer to the terms of your contract regarding dispute resolution, which may include mediation or arbitration. Familiarize yourself with the legal framework in your country and the supplier’s country regarding international trade disputes, as this can influence your approach. -

Are there certifications I should look for in fish vending machines?

Yes, look for certifications that ensure safety and compliance with food handling regulations. Common certifications include CE marking in Europe, UL listing in the United States, and HACCP (Hazard Analysis Critical Control Points) compliance for food safety. These certifications indicate that the machines have undergone rigorous testing and meet international safety standards, providing assurance of quality and reliability in your investment.

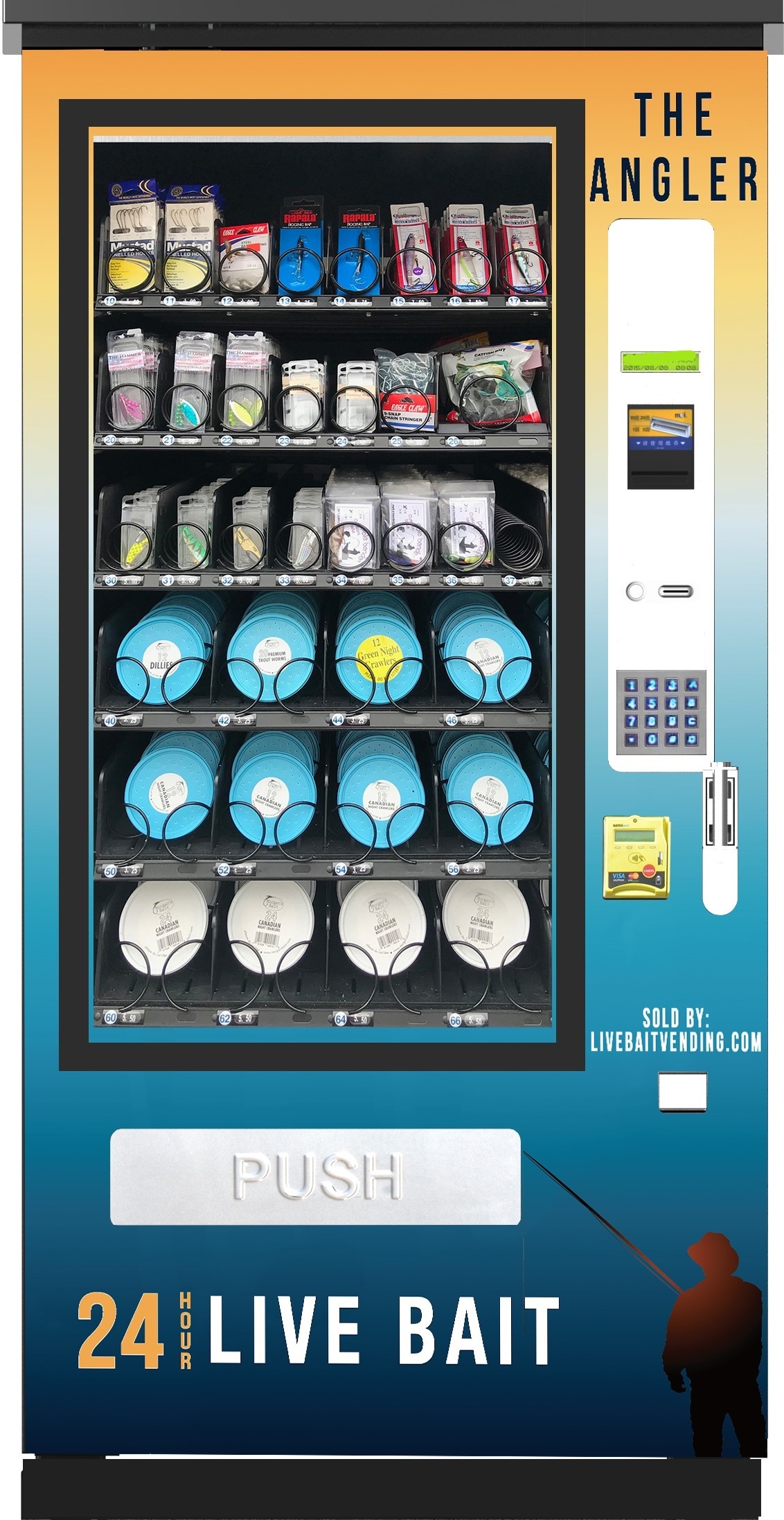

Illustrative Image (Source: Google Search)

Strategic Sourcing Conclusion and Outlook for fish vending machine near me

In conclusion, strategic sourcing for fish vending machines presents a unique opportunity for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. By leveraging local partnerships and understanding regional market demands, businesses can optimize their supply chains, ensuring quality and sustainability in their product offerings. The versatility of fish vending machines allows for tailored solutions that cater to diverse consumer preferences, enhancing customer satisfaction and loyalty.

Key Takeaways:

– Local Insights: Engaging with local suppliers and understanding cultural preferences can significantly enhance market penetration.

– Sustainability Focus: Prioritizing sustainable sourcing practices can differentiate your business and align with global trends.

– Technological Integration: Incorporating advanced technology into vending machines can improve operational efficiency and customer experience.

As the demand for convenient, fresh seafood options continues to rise, now is the time for international buyers to invest strategically in fish vending machines. Embrace this growing market by exploring partnerships that align with your business objectives and values. Take the first step today to secure your competitive advantage in this evolving industry landscape.