Unlock Profits with Hot Wheels Vending Machine: A Strategic

Guide to Hot Wheels Vending Machine

- Introduction: Navigating the Global Market for hot wheels vending machine

- Understanding hot wheels vending machine Types and Variations

- Key Industrial Applications of hot wheels vending machine

- Strategic Material Selection Guide for hot wheels vending machine

- In-depth Look: Manufacturing Processes and Quality Assurance for hot wheels vending machine

- Comprehensive Cost and Pricing Analysis for hot wheels vending machine Sourcing

- Spotlight on Potential hot wheels vending machine Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for hot wheels vending machine

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the hot wheels vending machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of hot wheels vending machine

- Strategic Sourcing Conclusion and Outlook for hot wheels vending machine

Introduction: Navigating the Global Market for hot wheels vending machine

In an increasingly competitive landscape, the Hot Wheels vending machine stands out as a unique opportunity for international B2B buyers seeking to tap into the lucrative toy and collectibles market. These innovative machines not only provide a novel retail experience but also cater to the growing demand for instant gratification among consumers, particularly children and collectors. As markets in Africa, South America, the Middle East, and Europe evolve, the integration of such vending solutions can significantly enhance revenue streams for businesses looking to diversify their offerings.

This comprehensive guide will delve into the critical aspects of sourcing Hot Wheels vending machines, covering various types available, the materials used in their construction, and the manufacturing and quality control processes that ensure product reliability. It will also highlight reputable suppliers from different regions, providing insights into cost structures and market trends that can influence purchasing decisions.

Additionally, we will address common FAQs to equip buyers with the knowledge needed to make informed choices. By leveraging this guide, B2B buyers from regions like Nigeria and Germany will be empowered to navigate the global market with confidence, ensuring they select the right vending machines that align with their business goals. This strategic approach not only mitigates risks but also positions buyers to capitalize on emerging opportunities in the dynamic world of vending retail.

Understanding hot wheels vending machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Hot Wheels Vending | Mechanical dispensing mechanism, variety of cars | Retail stores, events | Pros: Simple to operate; Cons: Limited customization options. |

| Digital Hot Wheels Vending | Touchscreen interface, digital payment options | Amusement parks, malls | Pros: Engaging user experience; Cons: Higher upfront costs. |

| Customizable Hot Wheels Vending | Modular design, customizable car selection | Promotional events, businesses | Pros: Tailored branding; Cons: Longer lead times for setup. |

| Collectible Hot Wheels Vending | Focus on rare and limited edition cars | Specialty shops, collectors | Pros: Attracts enthusiasts; Cons: Higher inventory costs. |

| Hybrid Hot Wheels Vending | Combines physical and digital elements | Trade shows, exhibitions | Pros: Versatile marketing tool; Cons: Complexity in management. |

Classic Hot Wheels Vending

The Classic Hot Wheels Vending machine features a straightforward mechanical dispensing system, offering a set variety of cars. This type is primarily used in retail environments and events where simplicity and ease of use are paramount. B2B buyers should consider the low operational costs and minimal maintenance requirements, although the lack of customization options may limit branding opportunities.

Digital Hot Wheels Vending

Incorporating a touchscreen interface and digital payment options, Digital Hot Wheels Vending machines provide an interactive experience that attracts a tech-savvy audience. These machines are ideal for amusement parks and malls where user engagement is crucial. While they offer a modern appeal, buyers should weigh the higher initial investment against the potential for increased sales through enhanced customer interaction.

Customizable Hot Wheels Vending

The Customizable Hot Wheels Vending machine allows businesses to select the types of cars offered, catering to specific target audiences or promotional events. This modular design is particularly beneficial for companies looking to strengthen their brand identity through tailored experiences. However, buyers need to consider longer lead times for customization and potential complexities in inventory management.

Collectible Hot Wheels Vending

Focusing on rare and limited edition cars, the Collectible Hot Wheels Vending machine serves specialty shops and collectors. This type appeals to enthusiasts who are willing to pay a premium for unique items. While it can generate higher margins, B2B buyers should be aware of the increased inventory costs and the need for effective marketing strategies to attract the right audience.

Hybrid Hot Wheels Vending

Combining physical and digital elements, the Hybrid Hot Wheels Vending machine is a versatile tool for trade shows and exhibitions. It provides a unique marketing opportunity by merging traditional vending with digital engagement strategies. However, the complexity in management and higher operational demands can pose challenges for buyers looking to implement this solution effectively.

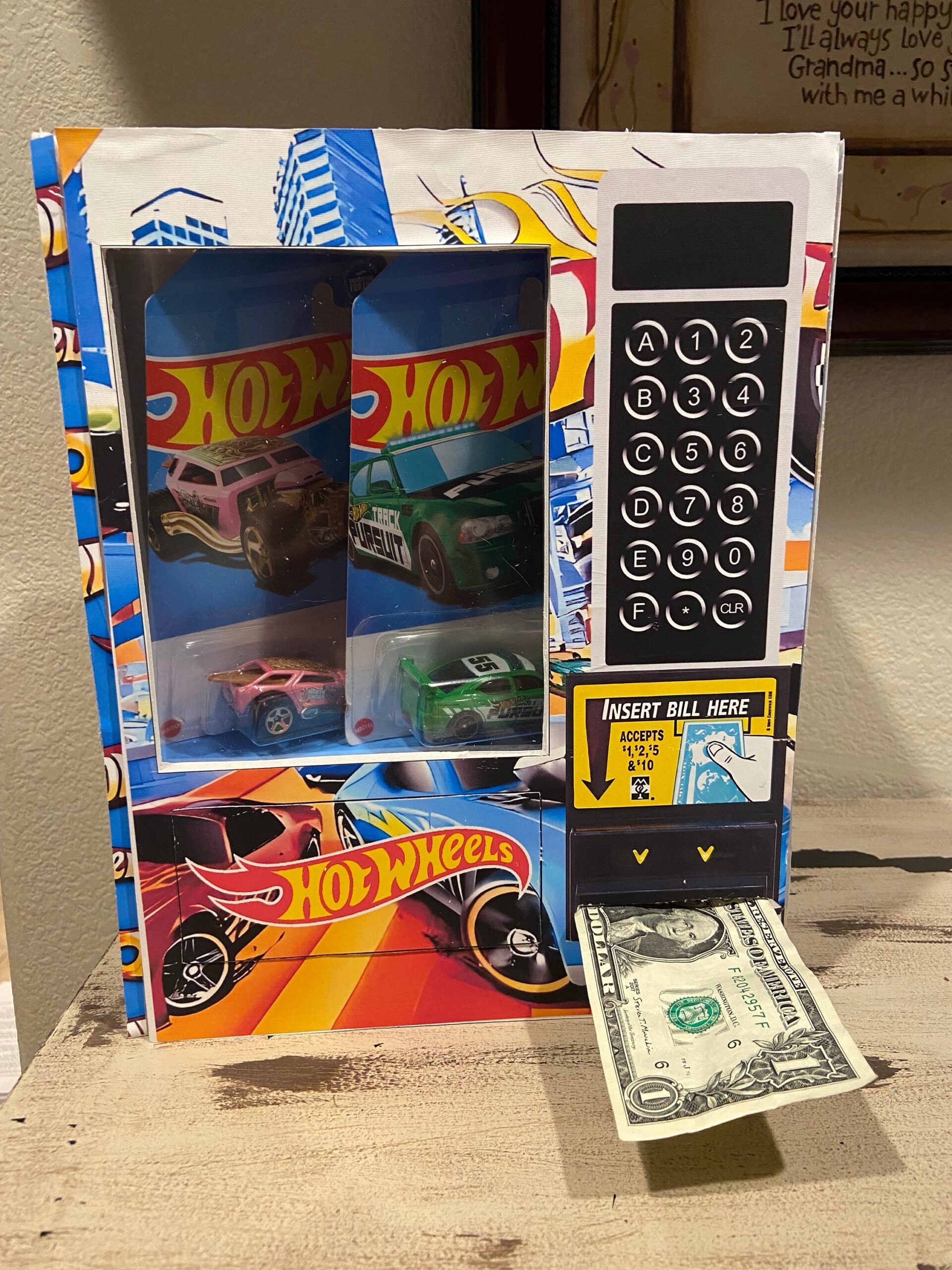

Related Video: How To Make Hot Wheels Car Vending Machine THAT REQUIRES MONEY!

Key Industrial Applications of hot wheels vending machine

| Industry/Sector | Specific Application of hot wheels vending machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Point-of-sale merchandise vending | Increases impulse purchases, enhances customer experience | Machine size and placement, inventory management system |

| Entertainment Venues | Event merchandise sales | Generates additional revenue streams during events | Custom branding options, payment processing compatibility |

| Educational Institutions | Fundraising and school events | Engages students, supports fundraising initiatives | Durability, ease of use, and maintenance support |

| Transportation Hubs | Travel-themed collectibles vending | Captures tourist interest, increases foot traffic | Location analysis, security features, and product variety |

| Corporate Offices | Employee engagement and corporate gifts | Boosts morale, enhances company culture | Customization options, machine maintenance, and support |

Retail Sector

In retail environments, hot wheels vending machines serve as effective point-of-sale merchandise options. They provide a unique and engaging way for customers to purchase collectible items, often leading to increased impulse buying. This application is particularly valuable for businesses looking to enhance customer experiences and maximize sales. International buyers should consider machine size, placement in high-traffic areas, and the integration of an inventory management system to optimize stock levels and ensure product availability.

Entertainment Venues

Hot wheels vending machines are increasingly popular in entertainment venues, such as theme parks and concert halls, where they offer event-specific merchandise. This application not only generates additional revenue streams but also enhances the overall visitor experience. For B2B buyers, it’s crucial to evaluate custom branding options and ensure compatibility with various payment processing systems to cater to diverse customer preferences.

Educational Institutions

In educational settings, hot wheels vending machines can play a significant role in fundraising and event engagement. Schools and universities can utilize these machines during events to promote school spirit and raise funds. The machines must be durable and easy to use, ensuring that they withstand frequent use by students. Buyers in this sector should also prioritize maintenance support to keep the machines operational and effective throughout the academic year.

Transportation Hubs

Transportation hubs, such as airports and train stations, can leverage hot wheels vending machines to offer travel-themed collectibles to tourists. This application captures the interest of travelers and can significantly increase foot traffic in the area. When sourcing these machines, it’s essential to conduct a location analysis to identify high-traffic areas and to incorporate security features that protect the merchandise while ensuring ease of access for customers.

Corporate Offices

Corporate offices can utilize hot wheels vending machines as a means of employee engagement and as a source for corporate gifts. By offering collectible items, companies can boost employee morale and foster a positive workplace culture. When sourcing these machines, businesses should look for customization options that reflect their brand, as well as reliable maintenance and support services to ensure consistent operation and employee satisfaction.

Strategic Material Selection Guide for hot wheels vending machine

Material Analysis for Hot Wheels Vending Machines

When selecting materials for hot wheels vending machines, international B2B buyers must consider various factors that affect the machine’s performance, durability, and compliance with regional standards. Below is an analysis of four common materials used in the construction of these vending machines, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

1. Stainless Steel (e.g., AISI 304)

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand varying temperatures. It typically has a temperature rating of up to 870°C (1600°F) and can handle pressures up to 2000 psi, depending on thickness.

Pros & Cons:

Stainless steel is highly durable and resistant to rust, making it suitable for outdoor and high-humidity environments. However, it tends to be more expensive than other materials, which can impact the overall cost of the vending machine. Manufacturing complexity is moderate, as stainless steel requires specific welding techniques.

Impact on Application:

This material is compatible with various media, including water and food products, making it ideal for vending machines that may dispense snacks or beverages alongside toys.

Considerations for International Buyers:

Buyers should ensure compliance with local standards such as ASTM and DIN for food safety and corrosion resistance. In regions like Germany, stringent regulations may apply, necessitating certifications that verify the material’s quality.

2. Mild Steel (e.g., A36)

Key Properties:

Mild steel offers good weldability and machinability, with a temperature rating of around 400°C (752°F). It has lower corrosion resistance compared to stainless steel.

Pros & Cons:

This material is cost-effective and provides good strength for structural applications. However, it is susceptible to rust and may require additional coatings or treatments, increasing long-term maintenance costs.

Impact on Application:

Mild steel is suitable for internal components of vending machines where exposure to moisture is minimal. It is less ideal for external surfaces without protective coatings.

Considerations for International Buyers:

Buyers in regions with high humidity, such as parts of Africa and South America, should consider the additional costs of protective coatings. Compliance with local manufacturing standards is also essential to ensure product safety and durability.

3. Aluminum (e.g., 6061-T6)

Key Properties:

Aluminum is lightweight, has excellent corrosion resistance, and can handle temperatures up to 200°C (392°F). It is also known for its good strength-to-weight ratio.

Pros & Cons:

The lightweight nature of aluminum makes it easy to transport and install. However, it is not as strong as stainless steel or mild steel, which may limit its use in high-stress applications. The manufacturing process can be more complex due to the need for specialized techniques like anodizing.

Impact on Application:

Aluminum is suitable for components that require frequent movement or adjustment, such as sliding doors or internal mechanisms in vending machines.

Considerations for International Buyers:

In Europe, buyers should look for materials that comply with EN standards for aluminum alloys. In regions like the Middle East, where temperatures can be extreme, ensuring adequate thermal protection is crucial.

4. Plastic (e.g., Polycarbonate)

Key Properties:

Polycarbonate is a thermoplastic known for its high impact resistance and transparency. It can withstand temperatures from -40°C to 120°C (-40°F to 248°F) and is lightweight.

Pros & Cons:

Plastic is cost-effective and offers design flexibility, allowing for creative shapes and colors. However, it may not be suitable for high-stress applications and can degrade under UV exposure unless treated.

Impact on Application:

Ideal for external panels or components that require visibility, such as viewing windows for the toys dispensed. Its lightweight nature also aids in reducing the overall weight of the vending machine.

Considerations for International Buyers:

Buyers should ensure that the plastic complies with local environmental regulations, especially in Europe, where there are strict guidelines regarding the use of certain plastics.

Summary Table

| Material | Typical Use Case for hot wheels vending machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel (e.g., AISI 304) | External structure and components for durability | Excellent corrosion resistance | Higher cost, moderate manufacturing complexity | High |

| Mild Steel (e.g., A36) | Internal structural components | Cost-effective, good strength | Susceptible to rust, requires coatings | Low |

| Aluminum (e.g., 6061-T6) | Sliding doors and internal mechanisms | Lightweight, good corrosion resistance | Lower strength compared to steel | Medium |

| Plastic (e.g., Polycarbonate) | External panels and visibility features | Cost-effective, design flexibility | May degrade under UV, not for high-stress | Low |

In-depth Look: Manufacturing Processes and Quality Assurance for hot wheels vending machine

Manufacturing Processes for Hot Wheels Vending Machines

Understanding the manufacturing processes behind hot wheels vending machines is crucial for international B2B buyers looking to ensure product quality and reliability. The production typically involves several key stages, each employing specific techniques to achieve the desired outcome.

1. Material Preparation

The first step in the manufacturing process involves sourcing and preparing high-quality materials. Common materials for hot wheels vending machines include:

- Metal Components: Steel or aluminum for structural integrity and durability.

- Plastic Parts: High-density polyethylene (HDPE) or polycarbonate for transparency and impact resistance.

- Electronic Components: Circuit boards, sensors, and payment systems.

Suppliers should ensure that materials comply with international standards, such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals). This is particularly important for buyers from regions like Europe, where regulatory compliance is stringent.

2. Forming

The forming stage involves shaping the prepared materials into usable components. Key techniques include:

- Injection Molding: Used for creating plastic parts, this method allows for high-volume production with consistent quality.

- Metal Stamping: Ideal for crafting metal components, this technique ensures precision and repeatability.

- CNC Machining: Employed for custom or complex parts, CNC (Computer Numerical Control) machining provides high accuracy.

B2B buyers should inquire about the technology and machinery used by suppliers, as modern equipment often indicates a commitment to quality and efficiency.

3. Assembly

Once the individual components are formed, the assembly stage begins. This process may involve:

- Manual Assembly: Skilled workers put together components, ensuring attention to detail.

- Automated Assembly: Robotics may be utilized for repetitive tasks, increasing speed and reducing human error.

It’s essential for buyers to understand the assembly process, as it directly impacts the final product’s quality. Suppliers should provide information on their assembly line layout, workforce training, and safety protocols.

4. Finishing

The finishing stage enhances the aesthetic and functional qualities of the vending machines. Techniques include:

- Painting and Coating: Protective coatings and paint enhance appearance and durability.

- Quality Control Markings: Labels and certifications are applied to signify compliance with industry standards.

Buyers should request details on the finishing processes to ensure that the final products meet their branding and quality expectations.

Quality Assurance in Manufacturing

Quality assurance (QA) is a critical aspect of the manufacturing process for hot wheels vending machines. A robust QA system ensures that products meet both international and industry-specific standards.

Relevant International Standards

For B2B buyers, understanding the certifications that suppliers adhere to is vital. Key standards include:

- ISO 9001: This quality management standard ensures consistent quality in products and services.

- CE Marking: Indicates compliance with European safety, health, and environmental protection standards.

- API (American Petroleum Institute): Relevant for machines that may dispense products associated with the oil and gas industry.

These certifications provide assurance of a supplier’s commitment to quality and safety.

Quality Control Checkpoints

Effective quality control typically involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Inspecting raw materials upon arrival to ensure compliance with specifications.

- In-Process Quality Control (IPQC): Monitoring production processes to catch defects early.

- Final Quality Control (FQC): A thorough inspection of the finished product before shipping.

Buyers should insist on transparency regarding these QC checkpoints, as they are crucial for maintaining product integrity.

Common Testing Methods

Various testing methods are employed to ensure quality, including:

- Functional Testing: Verifying that the vending machine operates as intended.

- Durability Testing: Assessing the machine’s ability to withstand wear and tear.

- Safety Testing: Ensuring compliance with electrical and mechanical safety standards.

Buyers should request documentation of testing procedures and results to validate the quality of the machines.

Verifying Supplier Quality Control

For international B2B buyers, verifying a supplier’s quality control processes is essential to mitigate risks. Here are some actionable steps:

- Supplier Audits: Conduct on-site or remote audits to assess the manufacturing and QA processes. This helps in understanding the supplier’s capabilities and commitment to quality.

- Quality Reports: Request detailed reports on past quality control measures, including defect rates and corrective actions taken.

- Third-Party Inspections: Engage independent inspection agencies to conduct assessments at various production stages, ensuring impartiality in evaluations.

QC Certification Nuances for International Buyers

Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of the nuances in QC certifications. For instance, while CE marking is crucial for European markets, other regions may prioritize different certifications based on local regulations. Understanding these differences can help buyers make informed decisions when selecting suppliers.

Conclusion

For B2B buyers, a comprehensive understanding of the manufacturing processes and quality assurance measures for hot wheels vending machines is essential for ensuring product quality and compliance. By focusing on material preparation, forming, assembly, and finishing, along with robust quality control practices, buyers can mitigate risks and ensure they receive high-quality products that meet international standards. Engaging in thorough supplier evaluations and maintaining a proactive approach to quality assurance will enhance the procurement process and build long-term partnerships.

Related Video: SMART Quality Control for Manufacturing

Comprehensive Cost and Pricing Analysis for hot wheels vending machine Sourcing

When sourcing hot wheels vending machines, understanding the cost structure and pricing dynamics is crucial for international B2B buyers. This analysis outlines key cost components, price influencers, and actionable buyer tips to help businesses make informed decisions.

Cost Components

-

Materials: The primary materials include high-quality plastics, electronic components, and mechanical parts. The choice of materials impacts both the durability and aesthetic appeal of the vending machines. Sustainable materials may also be preferred, particularly in regions where eco-friendliness is a significant concern.

-

Labor: Labor costs vary significantly by region. Countries in Southeast Asia often have lower labor costs compared to Europe or North America. However, it’s essential to consider the skill level required for assembly and quality assurance, as skilled labor may command higher wages.

-

Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and administrative expenses. Efficient manufacturing processes can reduce overhead costs, making it imperative to evaluate the supplier’s operational efficiency.

-

Tooling: Initial tooling costs can be substantial, especially for custom designs or modifications. Buyers should inquire about tooling costs upfront, as these can significantly affect the overall price, especially for low-volume orders.

-

Quality Control (QC): Implementing rigorous QC processes ensures that machines meet safety and performance standards. The cost of QC can vary based on the complexity of the machines and the certifications required for different markets.

-

Logistics: Shipping costs depend on the origin of the products and the destination. Import duties and taxes should also be factored into the logistics budget. For buyers in Africa and South America, understanding local customs regulations is essential to avoid unexpected costs.

-

Margin: Suppliers typically include a profit margin that can vary based on market competition, brand reputation, and product uniqueness. It’s advisable to compare multiple suppliers to gauge reasonable margins.

Price Influencers

-

Volume/MOQ (Minimum Order Quantity): Purchasing in larger quantities often leads to lower per-unit costs. Buyers should assess their capacity for inventory storage and sales forecasts to negotiate favorable terms.

-

Specifications/Customization: Custom features can increase costs. Buyers should clearly define their specifications to avoid unexpected expenses during production.

-

Materials: The choice between standard and premium materials can influence pricing. Buyers should balance cost with the desired quality and longevity of the machines.

-

Quality/Certifications: Machines that comply with international safety and quality standards (e.g., CE marking in Europe) may carry a premium. However, these certifications can enhance marketability and reduce liability risks.

-

Supplier Factors: The supplier’s location, reputation, and production capabilities can affect pricing. Engaging with reputable suppliers who have a track record in international trade can mitigate risks.

-

Incoterms: Understanding Incoterms is vital for determining responsibility for shipping costs and risks. Different terms (e.g., FOB, CIF) can impact the total landed cost of the vending machines.

Buyer Tips

-

Negotiation: Leverage relationships with suppliers to negotiate better pricing, especially if you can commit to repeat orders. Establishing long-term partnerships can lead to more favorable terms.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO) rather than just the upfront price. This includes maintenance, warranty, and operational costs over the machine’s lifespan.

-

Pricing Nuances: Be aware of regional pricing differences, as economic factors can influence costs. For instance, buyers from Europe may face different pricing structures compared to those in Africa or South America due to local demand and supply conditions.

-

Market Research: Conduct thorough market research to understand competitive pricing and features offered by various suppliers. This will empower buyers to make informed decisions and negotiate effectively.

-

Risk Assessment: Evaluate the potential risks associated with sourcing, including political, economic, and logistical factors in the supplier’s region. A comprehensive risk assessment can help mitigate potential disruptions in supply chains.

Disclaimer: Prices are subject to fluctuations based on market conditions, supplier negotiations, and changes in material costs. It is advisable to conduct regular market assessments to ensure accurate budgeting.

Spotlight on Potential hot wheels vending machine Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for hot wheels vending machine.)*

Essential Technical Properties and Trade Terminology for hot wheels vending machine

Key Technical Properties of Hot Wheels Vending Machines

When considering the procurement of hot wheels vending machines, it’s crucial to understand several technical properties that can significantly impact their performance, durability, and overall value. Below are some essential specifications:

-

Material Grade

The material grade of a vending machine typically refers to the quality and type of materials used in its construction, such as steel, aluminum, or high-grade plastic. Higher-grade materials enhance durability and resistance to wear and tear, which is particularly important in high-traffic locations. For B2B buyers, investing in machines made from superior materials can lead to lower maintenance costs and extended service life. -

Tolerance Levels

Tolerance levels indicate the acceptable range of deviation from specified dimensions in the machine’s components. This is crucial for ensuring that parts fit together correctly, which affects the machine’s reliability and functionality. For buyers, understanding tolerance levels can help in assessing the quality of manufacturing processes and in forecasting potential maintenance issues. -

Power Requirements

The power requirements specify the voltage and wattage needed for the vending machine to operate efficiently. This information is essential for ensuring compatibility with local electrical systems, especially for international buyers who may encounter different electrical standards. Knowledge of power requirements can prevent operational disruptions and additional costs related to electrical adaptations. -

Capacity and Dispensing Mechanism

The capacity refers to how many items the vending machine can hold and dispense at one time. Understanding the capacity is vital for businesses looking to maximize sales in high-demand areas. Additionally, the type of dispensing mechanism—whether it is gravity-fed, spiral, or electronic—affects both the speed of service and the types of products that can be offered. -

Software Integration

Many modern vending machines come equipped with software that allows for inventory management, sales tracking, and remote monitoring. For B2B buyers, the ability to integrate this software with existing business systems can streamline operations and improve decision-making processes. Compatibility with various payment systems, including cashless options, is also a key consideration.

Common Trade Terminology

Understanding industry-specific terminology is crucial for navigating the purchasing process effectively. Here are some key terms relevant to hot wheels vending machines:

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of vending machines, an OEM may provide the machine itself or specific components. For buyers, working with reputable OEMs ensures quality and consistency in the products supplied. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. This term is significant for B2B buyers as it impacts inventory management and cash flow. Understanding MOQs can help businesses plan their purchases more effectively, ensuring they meet demand without overcommitting financially. -

RFQ (Request for Quotation)

An RFQ is a formal request sent to suppliers asking for prices and terms for specific products or services. For international buyers, issuing an RFQ can facilitate competitive pricing and help in evaluating multiple suppliers based on cost and quality. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers. These terms dictate who is responsible for shipping, insurance, and tariffs. For B2B buyers, understanding Incoterms is essential for minimizing risks and ensuring compliance with international shipping regulations. -

Lead Time

Lead time refers to the amount of time between placing an order and receiving the goods. For buyers, knowing the lead time helps in planning inventory and operational schedules. It is particularly important in international transactions, where shipping and customs can introduce significant delays.

Illustrative Image (Source: Google Search)

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions, ensuring that they select the right hot wheels vending machines that meet their operational needs and market demands.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the hot wheels vending machine Sector

Market Overview & Key Trends

The hot wheels vending machine sector is experiencing significant growth driven by several global factors. The increasing demand for innovative and interactive consumer experiences, particularly among younger demographics, is reshaping the retail landscape. B2B buyers from regions like Africa, South America, the Middle East, and Europe are witnessing a rise in foot traffic at locations such as shopping malls, airports, and entertainment venues, making vending machines an attractive investment.

Emerging technologies play a crucial role in the evolution of hot wheels vending machines. Contactless payment systems and smart inventory management are becoming standard features, enhancing user convenience and operational efficiency. For international buyers, especially in diverse markets like Nigeria and Germany, understanding local payment preferences and technological adoption is essential for successful implementation.

Additionally, there is a growing trend towards customization and themed collections within the hot wheels product offerings. This allows businesses to cater to specific market segments, creating a more personalized shopping experience that can drive sales. B2B buyers should consider sourcing machines that support these features to remain competitive.

The competitive landscape is also shifting, with a focus on local manufacturing to reduce lead times and shipping costs. Buyers should explore partnerships with regional manufacturers who can offer tailored solutions while adhering to local regulations and consumer preferences.

Sustainability & Ethical Sourcing in B2B

As sustainability becomes a critical concern globally, the hot wheels vending machine sector is not exempt. The environmental impact of production, operation, and disposal of vending machines calls for a strategic approach to sourcing. International buyers must prioritize suppliers that demonstrate a commitment to sustainable practices, such as using recyclable materials and energy-efficient technologies.

Ethical sourcing is increasingly important, with consumers more aware of the origins of the products they purchase. B2B buyers should seek vendors who can provide transparency in their supply chains, ensuring that all components of the vending machines are sourced responsibly. Certifications such as ISO 14001 for environmental management and FSC for sustainable wood sourcing can serve as indicators of a supplier’s commitment to sustainability.

Furthermore, integrating green technologies into the vending machines, such as solar panels for energy generation, can enhance the sustainability profile of a business. This not only aligns with global sustainability goals but can also appeal to eco-conscious consumers, providing a competitive edge in the marketplace.

Brief Evolution/History

The hot wheels vending machine concept has evolved significantly since its inception. Initially, vending machines primarily dispensed snacks and beverages; however, the introduction of collectible toys, particularly in markets with a strong toy culture, has transformed the landscape. The rise of digital payment methods and the integration of smart technology have further modernized these machines, allowing for real-time inventory tracking and enhanced consumer interaction.

As the market continues to evolve, the focus on customization and sustainability will likely dictate future trends. B2B buyers who stay ahead of these changes will be well-positioned to capitalize on emerging opportunities in this vibrant sector.

Related Video: Is global trade transforming? | Counting the Cost

Frequently Asked Questions (FAQs) for B2B Buyers of hot wheels vending machine

-

How can I effectively vet suppliers of hot wheels vending machines?

When vetting suppliers, start by conducting thorough online research to assess their reputation and customer feedback. Request references from previous clients, particularly those in your region. Verify certifications and compliance with international standards, such as ISO or CE, which indicate quality assurance. Additionally, consider visiting the supplier’s manufacturing facility if feasible, or engage third-party inspectors to evaluate their production capabilities and quality control processes. -

Can I customize my hot wheels vending machine order?

Most suppliers offer customization options, allowing you to tailor the machine’s design, branding, and functionality to meet your business needs. Discuss specific features such as size, color, and product selection with potential suppliers. Ensure you receive detailed specifications and mock-ups before placing an order. Be aware that extensive customization may affect lead times and costs, so clarify these aspects during negotiations. -

What are the typical minimum order quantities (MOQ) and lead times for hot wheels vending machines?

MOQs can vary significantly by supplier and order complexity, ranging from a few units to several dozen. It is essential to confirm these details early in your discussions. Lead times typically depend on customization and production capacity, often ranging from 4 to 12 weeks. For urgent needs, inquire about expedited services or stock availability to avoid delays in your business operations. -

What payment options are available for purchasing hot wheels vending machines?

Payment terms vary by supplier and may include options such as letters of credit, bank transfers, or payment via secure online platforms. Establish clear payment terms upfront, including deposit requirements and any milestones tied to production progress. For international transactions, consider using escrow services to mitigate risks. Always ensure that payment methods comply with your local regulations and financial practices. -

How can I ensure quality assurance for my hot wheels vending machines?

To guarantee quality, request detailed information about the supplier’s quality assurance processes, including inspections and testing protocols. Ask for certifications that demonstrate compliance with international safety and manufacturing standards. It is also wise to negotiate a quality assurance agreement that specifies acceptable defect rates and outlines remedies for any non-conformance, including returns or replacements.

Illustrative Image (Source: Google Search)

-

What logistics considerations should I be aware of when importing hot wheels vending machines?

Importing vending machines involves several logistics considerations, including shipping methods, customs regulations, and duties. Engage a reliable freight forwarder who understands the specifics of transporting machinery internationally. Ensure all documentation, such as commercial invoices and packing lists, is accurate to avoid delays. Familiarize yourself with the customs procedures of your country to ensure compliance and minimize potential penalties. -

How do I handle disputes with suppliers?

To effectively manage disputes, establish clear contractual terms that outline responsibilities, quality expectations, and resolution processes. Maintain open lines of communication with your supplier to address issues promptly. If disputes arise, consider mediation or arbitration as potential resolution methods, as they are often less costly and quicker than legal action. Document all communications and agreements to support your position if formal dispute resolution becomes necessary. -

Are there specific certifications I should look for in hot wheels vending machines?

Yes, look for certifications that ensure safety and quality, such as ISO 9001 for quality management systems and CE marking for compliance with European safety standards. If you are operating in specific markets, additional certifications may be required. These certifications not only enhance the credibility of the supplier but also ensure that the products meet your local regulatory requirements, reducing the risk of legal issues down the line.

Strategic Sourcing Conclusion and Outlook for hot wheels vending machine

The strategic sourcing of hot wheels vending machines presents a significant opportunity for international buyers aiming to enhance their business offerings. By leveraging key insights into market trends and supplier capabilities, businesses can secure competitive advantages in diverse regions such as Africa, South America, the Middle East, and Europe.

Key Takeaways:

– Market Demand: The popularity of collectible items, particularly among younger demographics, indicates a growing market for hot wheels vending machines.

– Supplier Relationships: Establishing strong partnerships with manufacturers can lead to better pricing, product availability, and support services.

– Customization Opportunities: Tailoring vending machines to local preferences can significantly improve customer engagement and sales.

The value of strategic sourcing cannot be overstated; it enables businesses to optimize costs while ensuring quality and innovation. As international markets continue to evolve, proactive sourcing strategies will be essential for maintaining competitiveness.

Looking ahead, it is crucial for B2B buyers to stay informed about emerging trends and technologies in the vending industry. By doing so, businesses can position themselves for success and capitalize on the lucrative opportunities that lie ahead. Engage with suppliers today to explore the potential of hot wheels vending machines in your market and drive your business forward.