Your Ultimate Guide to Sourcing Vending Machine Buisness

Guide to Vending Machine Buisness

- Introduction: Navigating the Global Market for vending machine buisness

- Understanding vending machine buisness Types and Variations

- Key Industrial Applications of vending machine buisness

- Strategic Material Selection Guide for vending machine buisness

- In-depth Look: Manufacturing Processes and Quality Assurance for vending machine buisness

- Comprehensive Cost and Pricing Analysis for vending machine buisness Sourcing

- Spotlight on Potential vending machine buisness Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for vending machine buisness

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the vending machine buisness Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of vending machine buisness

- Strategic Sourcing Conclusion and Outlook for vending machine buisness

Introduction: Navigating the Global Market for vending machine buisness

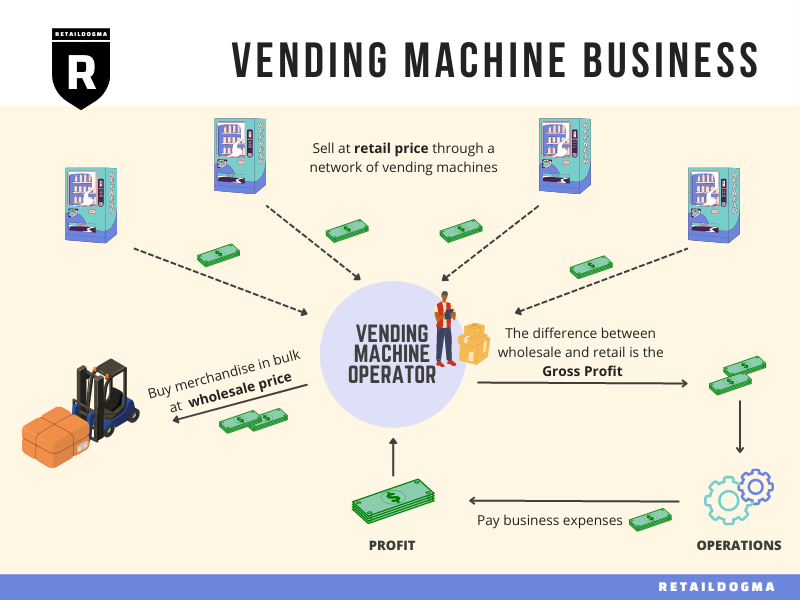

In today’s fast-paced world, the vending machine business stands out as a versatile and lucrative venture, catering to a diverse range of consumer needs across various markets. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the intricacies of this industry is essential for making informed sourcing decisions. The vending machine sector not only offers convenience but also provides a unique opportunity for businesses to reach customers in diverse environments, from bustling urban centers to remote locations.

This comprehensive guide will delve into the various types of vending machines available, the materials and technologies used in their manufacturing, and the critical quality control measures that ensure reliability and customer satisfaction. Additionally, we will explore the landscape of suppliers, enabling you to identify trustworthy partners that align with your business goals. Cost analysis and market trends will provide insights into optimizing your investment in vending solutions.

By equipping international buyers with the knowledge needed to navigate the global vending machine market, this guide empowers you to make strategic decisions that enhance your business’s operational efficiency and profitability. Whether you’re looking to expand your existing offerings or enter this dynamic market for the first time, understanding these key aspects will position you for success in the evolving landscape of vending solutions.

Understanding vending machine buisness Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Snack Machines | Dispense snacks and beverages, typically coin-operated | Offices, schools, and public areas | Pros: Low maintenance; Cons: Limited product variety |

| Healthy Vending Machines | Focus on nutritious snacks and beverages | Gyms, schools, and health-oriented businesses | Pros: Attract health-conscious consumers; Cons: Higher upfront costs |

| Automated Retail Machines | Use advanced technology for a wide range of products | Airports, malls, and convenience stores | Pros: 24/7 operation; Cons: Higher initial investment and complexity |

| Specialty Vending Machines | Offer niche products (e.g., electronics, cosmetics) | Events, trade shows, and urban centers | Pros: Unique offerings can attract specific demographics; Cons: Limited audience |

| Coffee Vending Machines | Provide a variety of coffee drinks on-demand | Offices, hotels, and cafes | Pros: High demand for coffee; Cons: Requires regular maintenance and supply management |

Traditional Snack Machines

Traditional snack machines are the most common type of vending machine, offering a selection of snacks and beverages, typically operated by coins or cards. These machines are ideal for environments like offices, schools, and public areas, where quick access to snacks is desired. When considering a purchase, B2B buyers should evaluate the machine’s capacity, ease of restocking, and durability, as these factors will influence long-term operational efficiency and customer satisfaction.

Healthy Vending Machines

Healthy vending machines cater to the growing demand for nutritious food options, featuring items like granola bars, fruit snacks, and low-calorie drinks. These machines are particularly suitable for gyms, schools, and health-focused businesses. Buyers must consider the higher initial investment, but the potential to attract a health-conscious clientele can lead to increased sales. Moreover, these machines often come with educational marketing materials, which can enhance their appeal.

Automated Retail Machines

Automated retail machines represent the latest innovation in vending technology, allowing for the sale of a wide variety of products, including electronics, apparel, and personal care items. They are ideal for high-traffic areas such as airports and shopping malls. While these machines operate 24/7 and can significantly increase revenue potential, buyers should be aware of the higher upfront costs and the need for robust technical support to ensure seamless operation.

Specialty Vending Machines

Specialty vending machines are designed to offer niche products, such as cosmetics, electronics, or gourmet foods. These machines are perfect for events, trade shows, and urban centers, where unique offerings can draw in specific demographics. B2B buyers should assess the target market and foot traffic in the area before investing, as the success of these machines heavily relies on finding the right location and product selection.

Coffee Vending Machines

Coffee vending machines provide a convenient way to serve a variety of coffee drinks, making them a popular choice for offices, hotels, and cafes. With a strong demand for coffee, these machines can generate substantial revenue. However, buyers need to consider the regular maintenance and supply management required to keep the machines operational and appealing to customers. Additionally, the quality of the coffee and the machine’s capabilities should be evaluated to ensure customer satisfaction.

Related Video: Pros And Cons Of Starting A Vending Machine Business

Key Industrial Applications of vending machine buisness

| Industry/Sector | Specific Application of vending machine business | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Automated medication dispensing | Improved patient compliance, reduced errors | Compliance with health regulations, secure payment options |

| Education | Snack and beverage vending in schools | Enhances student satisfaction, generates additional revenue | Nutritional standards, machine durability |

| Corporate Offices | Office pantry solutions with vending machines | Increases employee morale, reduces downtime | Variety of products offered, machine maintenance services |

| Retail | 24/7 product vending in shopping centers | Maximizes sales opportunities, reduces labor costs | High foot traffic locations, inventory management systems |

| Transportation Hubs | Vending for travel essentials at airports and stations | Convenience for travelers, enhanced customer experience | Secure payment systems, diverse product offerings |

Healthcare Applications

In the healthcare sector, vending machines are increasingly used for automated medication dispensing. These machines facilitate patient compliance by ensuring timely access to prescribed medications, thereby reducing the risk of errors associated with manual dispensing. For international buyers, especially in Africa and the Middle East, it is crucial to source machines that comply with local health regulations and offer secure payment options, ensuring both safety and convenience for users.

Education Applications

Vending machines in educational institutions serve as a reliable source for snacks and beverages, catering to the needs of students and staff. By enhancing the overall satisfaction of students, these machines can also generate additional revenue for schools. Buyers from South America and Europe should consider machines that adhere to nutritional standards and are durable enough to withstand heavy usage, ensuring a good return on investment.

Corporate Office Applications

In corporate environments, vending machines provide a convenient solution for office pantry needs, offering snacks and beverages that can boost employee morale and productivity. The availability of quality food options minimizes downtime and enhances workplace satisfaction. B2B buyers in Europe and Africa should focus on sourcing machines that offer a diverse range of products and have reliable maintenance services to ensure continuous operation.

Retail Applications

Vending machines positioned in retail settings, particularly in high-traffic areas, allow businesses to maximize sales opportunities around the clock. These machines can significantly reduce labor costs by automating the sales process. International buyers, especially from South America and the Middle East, should prioritize locations with high foot traffic and consider integrating inventory management systems to optimize stock levels and product offerings.

Transportation Hubs Applications

Vending machines located in transportation hubs, such as airports and train stations, cater to the needs of travelers seeking quick access to essential items. These machines enhance the customer experience by providing convenience in busy environments. For B2B buyers in Africa and Europe, key sourcing considerations include secure payment systems and a diverse range of product offerings to meet the varying needs of international travelers.

Related Video: How to Start a Vending Machine Business, Cost, Tips, How Much You Make

Strategic Material Selection Guide for vending machine buisness

When selecting materials for vending machines, it is crucial to consider the specific requirements of the application, including durability, cost, and regulatory compliance. Here, we analyze several common materials used in vending machine construction, focusing on their properties, advantages, disadvantages, and implications for international buyers.

Stainless Steel

Key Properties: Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand high temperatures. It can typically handle pressures up to 1500 psi, making it suitable for various environments.

Pros & Cons: The primary advantage of stainless steel is its durability and resistance to rust and staining, which is essential for machines exposed to moisture. However, it is relatively expensive compared to other materials and can be challenging to machine, increasing manufacturing complexity.

Impact on Application: Stainless steel is ideal for vending machines that dispense food and beverages, as it maintains hygiene and prevents contamination. Its compatibility with a wide range of media makes it versatile for different product offerings.

Considerations for International Buyers: Compliance with food safety standards (e.g., FDA in the USA, EFSA in Europe) is critical. Buyers from Africa, South America, the Middle East, and Europe should also consider local regulations regarding material safety and environmental impact.

Aluminum

Key Properties: Aluminum is lightweight, has good corrosion resistance, and can withstand moderate temperatures and pressures. It is often used in applications where weight is a critical factor.

Pros & Cons: The advantages of aluminum include its low weight and ease of fabrication, which can reduce shipping costs and manufacturing time. However, it is less durable than stainless steel and can be prone to scratching and denting.

Impact on Application: Aluminum is well-suited for vending machines designed for outdoor use, as it can resist corrosion from environmental exposure. However, its lower strength may limit its use in high-traffic areas where durability is paramount.

Considerations for International Buyers: Buyers should be aware of the varying grades of aluminum and their respective properties. Compliance with international standards such as ASTM or ISO may also be necessary, particularly in Europe.

Plastic (Polycarbonate and ABS)

Key Properties: Plastics like polycarbonate and ABS are lightweight, impact-resistant, and can handle temperatures ranging from -40°C to 100°C. They are also resistant to many chemicals.

Pros & Cons: The main advantages of using plastics are their low cost and versatility in design. However, they may not be as durable as metals and can degrade over time when exposed to UV light, especially in outdoor applications.

Impact on Application: Plastic components are often used in vending machines for housing and internal parts. They are particularly effective in environments where weight and cost savings are essential, such as in portable vending solutions.

Considerations for International Buyers: It is essential to verify that the plastics used meet safety and environmental regulations, such as REACH in Europe. Buyers should also consider the recyclability of materials to align with sustainability goals.

Glass

Key Properties: Glass is known for its excellent transparency and aesthetic appeal. It can withstand moderate pressure and temperature but is more fragile than other materials.

Pros & Cons: The key advantage of glass is its ability to showcase products effectively, enhancing consumer appeal. However, its fragility and weight can lead to higher shipping costs and potential breakage during use.

Impact on Application: Glass is commonly used in vending machines that require product visibility, such as those dispensing beverages. Its compatibility with various liquids makes it a suitable choice for drink vending machines.

Considerations for International Buyers: Buyers should consider the safety regulations concerning glass in vending machines, especially in public spaces. Compliance with standards such as EN 12150 in Europe for tempered glass may also be necessary.

| Material | Typical Use Case for vending machine buisness | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food and beverage vending machines | Excellent corrosion resistance and durability | High cost and manufacturing complexity | High |

| Aluminum | Outdoor vending machines | Lightweight and easy to fabricate | Less durable and prone to scratching | Medium |

| Plastic (Polycarbonate and ABS) | Housing and internal components | Low cost and versatile design | Less durable and UV degradation | Low |

| Glass | Beverage vending machines | Aesthetic appeal and product visibility | Fragile and heavier than alternatives | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for vending machine buisness

Understanding the Manufacturing Processes for Vending Machines

The manufacturing of vending machines is a complex process that requires precision, quality materials, and adherence to industry standards. For B2B buyers, especially those from Africa, South America, the Middle East, and Europe, understanding the key stages of production and the associated quality assurance measures is crucial for making informed purchasing decisions.

Main Stages of Manufacturing

-

Material Preparation

The first step involves selecting high-quality materials, typically metals, plastics, and electronic components. Suppliers should be evaluated on their sourcing practices, ensuring that materials meet international standards for safety and durability. -

Forming

This stage includes processes like cutting, bending, and welding to shape the materials into the various components of the vending machine. Advanced techniques such as CNC machining and laser cutting are often employed to achieve precision. Buyers should inquire about the technologies used by manufacturers to ensure they can produce parts that meet specific design and functional requirements. -

Assembly

Once the components are formed, they are assembled into a complete vending machine. This process can be manual or automated, depending on the manufacturer’s capabilities. Buyers should consider the level of automation, as higher automation often leads to consistency and reduced labor costs, translating to better pricing. -

Finishing

The final stage includes painting, coating, and adding decals or branding. Finishing not only improves aesthetics but also protects the machine from environmental factors. B2B buyers should check for environmentally friendly practices in finishing processes, which can be a selling point in many markets.

Quality Assurance Measures

Quality assurance (QA) is a critical aspect of the manufacturing process, especially for vending machines that require reliability and safety. B2B buyers must familiarize themselves with both international and industry-specific standards.

Relevant International Standards

- ISO 9001: This standard focuses on quality management systems and is critical for ensuring that manufacturers consistently meet customer requirements and enhance satisfaction.

- CE Marking: Essential for products sold in Europe, CE marking indicates conformity with health, safety, and environmental protection standards.

- API Standards: Particularly relevant for vending machines that dispense food or beverages, these standards ensure that the products are safe for consumption.

Key Quality Control Checkpoints

-

Incoming Quality Control (IQC)

This step involves inspecting raw materials and components upon arrival at the manufacturing facility. It ensures that only materials meeting the required specifications are used. -

In-Process Quality Control (IPQC)

Throughout the manufacturing process, periodic inspections are conducted to catch defects early. This can include checking dimensions, tolerances, and functionality. -

Final Quality Control (FQC)

Before shipping, a thorough inspection of the completed vending machines is conducted to ensure they meet all specifications and standards. This may include functionality tests, safety checks, and aesthetic evaluations.

Illustrative Image (Source: Google Search)

Common Testing Methods

- Functional Testing: Verifying that all electronic components work as intended.

- Stress Testing: Assessing the durability of the machine under various conditions.

- Environmental Testing: Ensuring the machine can withstand different climates and conditions, especially important for markets in Africa and South America.

Verifying Supplier Quality Control

For international B2B buyers, verifying a supplier’s quality control processes is vital. Here are actionable steps to ensure that the manufacturer adheres to high standards:

-

Conduct Audits

Regular audits can help assess the manufacturer’s compliance with quality standards. Buyers can either conduct these audits themselves or hire third-party services for an unbiased evaluation. -

Request Quality Assurance Reports

Suppliers should provide documentation of their QA processes, including test results and compliance with standards. This transparency can help build trust. -

Third-Party Inspections

Engaging third-party inspection agencies can provide an additional layer of assurance. These agencies can perform inspections at various stages of the manufacturing process, ensuring adherence to quality standards before shipment.

Navigating Quality Control Nuances for International Buyers

When purchasing vending machines from international suppliers, B2B buyers must be aware of specific nuances that could affect quality assurance:

-

Cultural Differences: Understanding the manufacturing practices and business cultures of suppliers from different regions (e.g., Europe vs. Africa) can influence negotiation and quality expectations.

-

Regulatory Compliance: Different regions have varied regulations regarding product safety and quality. Buyers should ensure that suppliers are compliant with local regulations in their respective markets.

-

Supply Chain Transparency: In regions like Africa and South America, where supply chains may be less regulated, ensuring transparency in sourcing and manufacturing processes is crucial for maintaining quality.

Conclusion

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding the manufacturing processes and quality assurance measures for vending machines is essential. By focusing on material selection, production techniques, and rigorous quality control, buyers can make informed decisions that lead to successful partnerships and high-quality vending solutions.

Related Video: SMART Quality Control for Manufacturing

Comprehensive Cost and Pricing Analysis for vending machine buisness Sourcing

Understanding the Cost Structure of Vending Machine Sourcing

When sourcing vending machines, international B2B buyers must navigate a complex cost structure. This includes several key components:

-

Materials: The cost of raw materials, such as metal for the body, plastic for components, and electronic parts, can vary significantly based on quality and supplier location. For instance, sourcing from regions with lower material costs may enhance profit margins, but could compromise quality.

-

Labor: Labor costs are influenced by local wages and manufacturing capabilities. Countries in Africa and South America may offer competitive labor rates compared to Europe, but it’s essential to consider the skill level and experience of the workforce.

-

Manufacturing Overhead: This includes utilities, facility maintenance, and general administrative costs. Buyers should evaluate manufacturers’ overhead rates to understand the true cost of production.

-

Tooling: Initial tooling costs for custom designs can be substantial. Buyers should consider whether a standard machine meets their needs to avoid these expenses.

-

Quality Control (QC): Investing in quality control processes ensures that the machines meet international standards. While this may increase upfront costs, it minimizes long-term expenses related to repairs and replacements.

-

Logistics: Shipping and handling costs can significantly impact the final price. Consideration of Incoterms is crucial here, as they define the responsibilities of buyers and sellers in shipping arrangements.

-

Margin: Suppliers will typically include a margin in their pricing to ensure profitability. Understanding the typical margins in the vending machine industry can help buyers negotiate better deals.

Factors Influencing Pricing

Several factors can influence the pricing of vending machines:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit prices. Buyers should assess their market demand to determine optimal order sizes.

-

Specifications/Customization: Customized machines with specific features or branding will generally cost more. Buyers should weigh the benefits of customization against the potential price increase.

-

Materials: The choice of materials affects durability and aesthetics. High-quality materials may incur higher costs but can enhance the machine’s lifespan and reduce maintenance needs.

-

Quality and Certifications: Machines that meet international quality standards or certifications (like ISO) may command higher prices. However, these certifications can also justify higher pricing due to reduced risk and enhanced reliability.

-

Supplier Factors: The reputation and reliability of the supplier can influence costs. Established suppliers may charge a premium but often provide better quality assurance and after-sales support.

Tips for B2B Buyers

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, the following tips can enhance cost-efficiency:

-

Negotiate Smartly: Building a strong relationship with suppliers can lead to better pricing and terms. Consider negotiating based on long-term partnerships rather than one-off transactions.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the long-term costs associated with maintenance, operations, and potential downtime. Machines that are more expensive upfront may save money over time through increased reliability and lower maintenance costs.

-

Understand Pricing Nuances: Be aware of regional pricing differences. For example, suppliers in Europe may have higher costs due to stringent regulations, while those in Africa might offer lower prices but could lack certain certifications.

-

Consider Currency Fluctuations: For buyers in emerging markets, currency exchange rates can affect costs significantly. Locking in prices or payments in stable currencies may mitigate risks associated with currency fluctuations.

Disclaimer on Pricing

Prices for vending machines can vary widely based on the factors discussed. The information provided here is for indicative purposes only and should not be considered as fixed pricing. Buyers are encouraged to conduct thorough market research and obtain multiple quotes to ensure competitive pricing.

Spotlight on Potential vending machine buisness Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for vending machine buisness.)*

Essential Technical Properties and Trade Terminology for vending machine buisness

Critical Technical Properties of Vending Machines

When investing in vending machines, understanding their technical properties is essential for making informed purchasing decisions. Here are some key specifications that international B2B buyers should consider:

-

Material Grade

– Definition: The quality of materials used in the construction of the vending machine, typically categorized by standards such as stainless steel, plastic, or aluminum.

– Importance: High-grade materials enhance durability, resistance to corrosion, and overall longevity, which is crucial for machines operating in diverse environments, from humid tropical climates in Africa to cold winters in Europe. -

Tolerance

– Definition: The allowable deviation in the dimensions of machine components, ensuring proper fit and functionality.

– Importance: Precise tolerances are vital for the seamless operation of mechanical parts. Poor tolerances can lead to malfunctions, which may result in costly downtime and repairs, impacting service delivery. -

Power Consumption

– Definition: The amount of electricity the vending machine uses during operation, typically measured in watts.

– Importance: Understanding power consumption helps buyers assess operational costs and energy efficiency. Machines with lower power usage are more sustainable and can save businesses money in the long run. -

Capacity

– Definition: The total volume or number of products that a vending machine can hold, often determined by the number of shelves and the size of the compartments.

– Importance: Buyers must consider capacity in relation to expected foot traffic and sales volume. A machine with insufficient capacity may lead to stockouts, while an oversized machine could take up unnecessary space. -

User Interface

– Definition: The design and functionality of the machine’s control panel, including payment options (cash, card, mobile).

– Importance: A user-friendly interface can enhance customer experience, increasing sales. International buyers should look for machines that support multiple languages and payment methods suitable for their target markets.

Common Trade Terminology in the Vending Machine Industry

Familiarity with industry jargon is crucial for effective communication with suppliers and partners. Here are some common terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts and equipment that may be marketed by another manufacturer.

– Significance: Understanding OEM relationships can help buyers ensure they are sourcing quality machines and parts, often at competitive prices. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Significance: Recognizing MOQ is essential for budgeting and inventory management. Buyers should negotiate MOQs to align with their market demand while ensuring they don’t overstock. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers asking for a quote on specific products or services.

– Significance: RFQs are critical for comparing prices and terms from multiple suppliers, ensuring that buyers get the best deal for their vending machine investments. -

Incoterms (International Commercial Terms)

– Definition: A series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers.

– Significance: Understanding Incoterms is vital for international shipping and logistics. They dictate who is responsible for shipping, insurance, duties, and other logistics, which can significantly affect total costs. -

Lead Time

– Definition: The amount of time from when an order is placed until it is fulfilled and delivered.

– Significance: Knowing the lead time helps buyers plan their inventory and align with market demand, preventing potential lost sales due to stock shortages.

By familiarizing themselves with these technical properties and trade terms, international B2B buyers can make more informed decisions, negotiate better contracts, and ultimately improve their vending machine business operations.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the vending machine buisness Sector

Market Overview & Key Trends

The global vending machine industry is experiencing a transformative phase, driven by various market dynamics and technological advancements. One of the most significant drivers is the increasing demand for convenience and on-the-go options, particularly in urbanized regions across Africa, South America, the Middle East, and Europe. As consumer behaviors evolve, businesses are adapting by incorporating smart vending solutions that offer cashless payment options, real-time inventory tracking, and personalized marketing through digital interfaces.

Emerging technologies such as IoT (Internet of Things) and AI (Artificial Intelligence) are shaping sourcing trends in the vending machine sector. IoT-enabled machines allow for seamless data collection and analytics, helping businesses optimize their inventory management and reduce operational costs. In regions like Europe and the Middle East, the integration of AI is enhancing user experience through tailored product offerings based on consumer preferences.

International B2B buyers should also be aware of the growing trend towards healthier snack options. This shift is prompting vending machine operators to diversify their product range, catering to health-conscious consumers. Moreover, sustainability is becoming a crucial element in the decision-making process for procurement. Companies that prioritize eco-friendly practices are more likely to succeed in securing contracts and partnerships, as buyers increasingly favor vendors who demonstrate a commitment to environmental responsibility.

Sustainability & Ethical Sourcing in B2B

Sustainability is at the forefront of the vending machine business, as companies strive to minimize their environmental impact. This includes reducing energy consumption through the adoption of energy-efficient machines and utilizing renewable energy sources. International buyers should look for suppliers who invest in technology that lowers emissions and enhances energy efficiency, which can lead to significant cost savings over time.

Ethical sourcing is also gaining traction. Businesses are expected to maintain transparency in their supply chains, ensuring that materials are sourced responsibly and sustainably. This means selecting vendors who adhere to fair labor practices and environmental regulations. Certifications such as Fair Trade, Rainforest Alliance, and ISO 14001 can serve as indicators of a supplier’s commitment to ethical standards.

Incorporating ‘green’ materials into vending machines, such as recyclable plastics and biodegradable packaging, is increasingly important. Buyers should prioritize manufacturers that actively engage in sustainable practices, as these efforts not only enhance brand reputation but also meet the growing consumer demand for environmentally friendly products.

Brief Evolution/History

The vending machine industry has evolved significantly since its inception in the late 19th century. Initially, these machines offered simple products like postcards and candy. However, the advent of technology in the late 20th century led to the introduction of electronic vending machines, which expanded the range of products to include beverages, snacks, and even fresh food.

In recent years, the focus has shifted towards creating a more interactive and personalized experience for consumers. With advancements in payment systems and product variety, vending machines are now considered an integral part of the retail landscape. For international B2B buyers, understanding this evolution is crucial, as it highlights the need for adaptability and innovation in a rapidly changing market.

Related Video: Is global trade transforming? | Counting the Cost

Frequently Asked Questions (FAQs) for B2B Buyers of vending machine buisness

-

How can I effectively vet suppliers for vending machines?

Vetting suppliers is crucial for ensuring quality and reliability. Start by researching potential vendors through trade shows, online directories, and industry associations. Request references and check their reputations on platforms like Trustpilot or local business bureaus. Conduct site visits if possible, or utilize third-party verification services. Additionally, assess their financial stability and production capacity to ensure they can meet your demands. -

What customization options should I consider for vending machines?

Customization is key to attracting customers in diverse markets. Consider options like branding with your logo, color schemes, and product selections tailored to local preferences. Inquire about software capabilities for cashless payments, inventory management, and user-friendly interfaces. Discuss the possibility of smart technology integrations, such as remote monitoring and data analytics, which can enhance operational efficiency and customer satisfaction. -

What are typical minimum order quantities (MOQs) and lead times for vending machines?

MOQs can vary significantly based on supplier capabilities and machine types. Generally, expect MOQs to range from 5 to 50 units. Lead times often depend on customization and production schedules, typically ranging from 4 to 12 weeks. Always confirm these details upfront and negotiate terms that align with your operational needs, especially if you are entering a new market. -

What quality assurance certifications should I look for in suppliers?

Quality assurance certifications ensure that vending machines meet industry standards and regulations. Look for ISO 9001 certification, indicating effective quality management systems. Additionally, check for compliance with local safety regulations, such as CE marking in Europe or UL certification in North America. Request documentation that verifies these certifications to ensure that the machines are safe and reliable for your market. -

How should I handle logistics and shipping for vending machines?

Logistics can be complex due to the size and weight of vending machines. Work with suppliers who have experience in international shipping and can provide guidance on freight forwarding options. Understand the costs involved, including customs duties and taxes, and ensure the supplier can assist with necessary documentation. Consider using a logistics partner who specializes in heavy equipment to streamline the process.

Illustrative Image (Source: Google Search)

-

What steps should I take to resolve disputes with suppliers?

Disputes can arise from various issues, including product quality or delivery delays. Establish clear communication channels from the outset and document all agreements in contracts. If a dispute occurs, attempt to resolve it amicably through direct negotiation. If that fails, refer to the terms outlined in your contract regarding dispute resolution, which may include mediation or arbitration, to protect your interests. -

What payment terms are commonly accepted in international vending machine transactions?

Payment terms can vary widely, but common practices include advance payments, letters of credit, and payment upon delivery. For first-time transactions, it may be safer to negotiate partial upfront payments to mitigate risk. Ensure that payment terms are clearly defined in your contract, including currency and method, to avoid misunderstandings. Utilizing escrow services can also provide security for both parties during high-value transactions. -

How can I keep up with market trends in vending machine technology?

Staying informed about market trends is essential for maintaining competitiveness. Subscribe to industry publications, attend trade shows, and participate in online forums relevant to vending technology. Networking with other B2B buyers and suppliers can provide insights into emerging technologies and consumer preferences. Additionally, consider collaborating with local research institutions or consulting firms to gain tailored market intelligence for your region.

Strategic Sourcing Conclusion and Outlook for vending machine buisness

As the vending machine industry continues to evolve, strategic sourcing emerges as a pivotal component for international B2B buyers. By leveraging global supply chains, companies can reduce costs, enhance product quality, and improve service delivery. Key takeaways for buyers include the importance of developing strong relationships with suppliers, understanding regional market dynamics, and embracing technological advancements to streamline operations.

Strategic sourcing not only helps in optimizing procurement processes but also fosters innovation by enabling access to diverse product offerings. Buyers from Africa, South America, the Middle East, and Europe should prioritize sourcing partners that align with their sustainability goals and local preferences.

Looking ahead, the demand for vending machines that cater to specific consumer needs, such as healthy snacks or cashless payment options, will likely grow. By acting now and investing in strategic sourcing initiatives, international B2B buyers can position themselves to capitalize on emerging trends and secure a competitive advantage in their markets. Engage with suppliers who share a vision for future growth and remain adaptable to the evolving landscape of the vending machine business.