Master Sourcing Phone Vending Machines: A Comprehensive B2B

Guide to Phone Vending Machine

- Introduction: Navigating the Global Market for phone vending machine

- Understanding phone vending machine Types and Variations

- Key Industrial Applications of phone vending machine

- Strategic Material Selection Guide for phone vending machine

- In-depth Look: Manufacturing Processes and Quality Assurance for phone vending machine

- Comprehensive Cost and Pricing Analysis for phone vending machine Sourcing

- Spotlight on Potential phone vending machine Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for phone vending machine

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the phone vending machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of phone vending machine

- Strategic Sourcing Conclusion and Outlook for phone vending machine

Introduction: Navigating the Global Market for phone vending machine

The global market for phone vending machines is rapidly evolving, driven by the increasing demand for convenient and accessible mobile technology solutions. For international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, understanding this market is critical for making informed sourcing decisions. Phone vending machines not only provide a streamlined purchasing experience for consumers but also serve as a strategic avenue for businesses looking to enhance their service offerings and capture new revenue streams.

This comprehensive guide delves into various aspects of phone vending machines, including the different types available, materials used in their construction, manufacturing processes, and quality control standards. We will also explore potential suppliers, cost considerations, and market trends that are shaping the industry. By addressing frequently asked questions, this guide aims to empower B2B buyers with the knowledge necessary to navigate the complexities of sourcing phone vending machines effectively.

In an era where technology drives consumer behavior, investing in phone vending machines can position your business at the forefront of innovation. This guide will equip you with actionable insights, enabling you to leverage market opportunities, optimize procurement strategies, and ultimately enhance customer satisfaction in your respective regions. Embrace the future of technology retail with confidence, backed by the information and expertise provided herein.

Understanding phone vending machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Smart Phone Vending Machine | Interactive touchscreen, digital payment options | Retail, airports, corporate offices | Pros: High-tech appeal, varied product offerings. Cons: Higher initial investment and maintenance costs. |

| Basic Phone Vending Machine | Simple design, cash-only transactions | Remote areas, low-cost markets | Pros: Low cost, easy to operate. Cons: Limited functionality, fewer payment options. |

| Customized Phone Vending Machine | Tailored design for specific products | Events, promotions, niche markets | Pros: Unique branding, targeted offerings. Cons: Higher development costs, longer lead times. |

| Kiosk-Style Phone Vending Machine | Enclosed structure, secure environment | Shopping malls, universities | Pros: Security, allows for larger inventory. Cons: Space requirements, higher logistical costs. |

| Mobile Phone Vending Van | Mobile unit, can be relocated easily | Festivals, construction sites | Pros: Flexibility, can reach diverse locations. Cons: Limited inventory, weather-dependent operations. |

Smart Phone Vending Machine

Smart phone vending machines feature interactive touchscreens and support digital payment options, making them highly appealing in urban and tech-savvy environments. They are ideal for retail spaces, airports, and corporate offices where customers expect a modern shopping experience. When considering a purchase, buyers should evaluate the upfront investment and ongoing maintenance costs against the potential for increased sales and customer engagement.

Basic Phone Vending Machine

These machines are characterized by their simple design and cash-only transactions, making them suitable for remote areas and low-cost markets. They require minimal setup and are easy to operate, which can be advantageous for businesses with limited resources. However, buyers should consider the trade-off of limited functionality and fewer payment options, which may deter tech-savvy customers.

Customized Phone Vending Machine

Customized phone vending machines are designed to meet specific business needs, allowing for tailored branding and product offerings. They are particularly effective in niche markets or during events and promotions where unique products are required. While they can enhance brand visibility and cater to specific customer demands, buyers must be prepared for higher development costs and longer lead times for production.

Kiosk-Style Phone Vending Machine

Kiosk-style machines provide a secure environment for phone sales, making them suitable for shopping malls and universities where theft may be a concern. These units allow for a larger inventory and can be designed to accommodate various phone models and accessories. Buyers should consider the space requirements and higher logistical costs associated with installing and maintaining these larger machines.

Mobile Phone Vending Van

Mobile phone vending vans offer flexibility by allowing businesses to reach diverse locations, such as festivals and construction sites. These units can be relocated easily to meet customer demand in various areas. However, buyers should weigh the pros and cons of limited inventory capacity and the potential impact of weather conditions on operations. This type of vending solution can be particularly advantageous for businesses looking to tap into transient markets.

Related Video: Machine Learning in 2024 – Beginner’s Course

Key Industrial Applications of phone vending machine

| Industry/Sector | Specific Application of phone vending machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Automated mobile phone sales and accessories | Increased sales volume, reduced labor costs | Payment integration, inventory management system |

| Hospitality | Guest services and mobile device rentals | Enhanced guest experience, additional revenue stream | Durability, user-friendly interface |

| Education | Providing devices for students and staff | Improved access to technology, cost-effective solutions | Device selection, warranty and support services |

| Transportation | Mobile phone rentals at airports and stations | Convenience for travelers, additional revenue | Location-specific regulations, security features |

| Events and Exhibitions | Onsite phone rentals for attendees | Increased engagement, immediate access to devices | Quick setup, reliable connectivity options |

Retail

In the retail sector, phone vending machines serve as automated sales points for mobile phones and accessories. These machines can be strategically placed in high-traffic areas, allowing businesses to capture impulse purchases. The primary value lies in increased sales volume and reduced labor costs, as they operate autonomously. International buyers should consider payment integration options and inventory management systems to streamline operations and ensure a seamless customer experience.

Hospitality

In the hospitality industry, phone vending machines can offer mobile device rentals or services directly to guests. This application enhances the guest experience by providing immediate access to devices for communication and entertainment. Additionally, it creates an additional revenue stream for hotels and resorts. Buyers in this sector should prioritize durability and a user-friendly interface, as these machines need to withstand high usage and provide a positive impression to guests.

Education

Educational institutions can utilize phone vending machines to provide devices for students and staff, particularly in regions where access to technology is limited. This application addresses the problem of digital divide, ensuring that all students have equal access to educational resources. The key benefits include improved access to technology and a cost-effective solution for device provisioning. Buyers should focus on device selection and warranty support services to ensure reliability and longevity.

Transportation

In the transportation sector, particularly at airports and train stations, phone vending machines can facilitate mobile phone rentals for travelers. This application meets the demand for convenience, allowing travelers to quickly obtain a device without needing to visit a retail store. The additional revenue generated from rentals can significantly benefit transportation hubs. Buyers should be aware of location-specific regulations and security features to ensure compliance and protect users.

Events and Exhibitions

At events and exhibitions, phone vending machines can provide onsite rentals for attendees who may require devices for networking or accessing event information. This application increases engagement and ensures participants have immediate access to necessary technology. The key considerations for international buyers include the ability for quick setup and reliable connectivity options, ensuring that the machines function effectively in diverse environments.

Related Video: How to Start a Vending Machine Business, Cost, Tips, How Much You Make

Strategic Material Selection Guide for phone vending machine

When selecting materials for phone vending machines, it is crucial to consider various factors that affect performance, durability, and cost. The choice of material can significantly impact the machine’s ability to withstand environmental conditions, provide security, and maintain functionality over time. Below, we analyze four common materials used in the construction of phone vending machines, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high strength, and temperature tolerance. It typically has a pressure rating that allows it to withstand significant mechanical stress, making it suitable for outdoor installations.

Pros & Cons:

The primary advantage of stainless steel is its durability and resistance to rust, which is essential for machines exposed to various climates. However, it tends to be more expensive than other materials, which can increase the overall cost of the vending machine. Manufacturing complexity is moderate, as stainless steel requires specialized equipment for cutting and welding.

Impact on Application:

Stainless steel is particularly effective in environments where moisture and humidity are prevalent, ensuring that the machine remains functional over time.

Considerations for International Buyers:

Buyers in regions like the UAE and Saudi Arabia should ensure compliance with local standards for corrosion resistance. Understanding the grade of stainless steel (e.g., 304 vs. 316) is essential, as higher grades offer better resistance to saline environments.

2. Mild Steel

Key Properties:

Mild steel has good mechanical properties and is relatively easy to work with. However, it lacks inherent corrosion resistance, which can be a significant drawback in certain environments.

Pros & Cons:

The main advantage of mild steel is its low cost, making it a budget-friendly option for manufacturers. However, its susceptibility to rust and corrosion can lead to higher maintenance costs over time, especially in humid or coastal areas. Manufacturing processes are straightforward, which can speed up production.

Impact on Application:

Mild steel is suitable for indoor applications where environmental exposure is minimal. Its use in outdoor settings requires protective coatings to prevent rust.

Considerations for International Buyers:

Buyers should consider the need for protective coatings and ensure compliance with local environmental regulations. In Europe, adherence to standards like EN 10025 for structural steel may be necessary.

3. Aluminum

Key Properties:

Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity. It can withstand moderate pressure and temperature variations, making it suitable for various applications.

Pros & Cons:

One of the main advantages of aluminum is its lightweight nature, which simplifies transportation and installation. However, it can be more expensive than mild steel and may not be as strong under heavy loads. Manufacturing complexity is relatively low, but care is needed to prevent galvanic corrosion when in contact with other metals.

Impact on Application:

Aluminum is ideal for environments where weight is a concern, such as mobile vending units. Its corrosion resistance makes it suitable for coastal regions.

Considerations for International Buyers:

Buyers should be aware of the specific aluminum alloys used, as different grades offer varying levels of strength and corrosion resistance. Compliance with standards such as ASTM B221 for aluminum extrusions is essential.

4. Polycarbonate

Key Properties:

Polycarbonate is a high-performance plastic known for its impact resistance and lightweight characteristics. It can withstand a wide range of temperatures and is often used in transparent applications.

Pros & Cons:

The key advantage of polycarbonate is its high impact resistance, making it ideal for protecting sensitive components. However, it may not offer the same level of security as metals and can be prone to scratching. The cost is generally moderate, and manufacturing is relatively simple.

Impact on Application:

Polycarbonate is often used for display panels and protective covers in vending machines, allowing visibility while safeguarding the contents.

Considerations for International Buyers:

Buyers should ensure that the polycarbonate used meets relevant safety standards, such as ISO 9001 for quality management. In regions with extreme temperatures, thermal performance should also be evaluated.

Summary Table

| Material | Typical Use Case for phone vending machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Outdoor vending machines in humid climates | Excellent corrosion resistance | Higher cost compared to alternatives | High |

| Mild Steel | Indoor vending machines | Cost-effective and easy to manufacture | Susceptible to rust without coating | Low |

| Aluminum | Mobile vending units | Lightweight and corrosion-resistant | Less strength under heavy loads | Medium |

| Polycarbonate | Display panels and protective covers | High impact resistance | Prone to scratching and less secure | Medium |

This strategic material selection guide provides a comprehensive overview for international B2B buyers, enabling informed decisions based on specific operational needs and environmental conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for phone vending machine

Manufacturing Processes for Phone Vending Machines

The manufacturing of phone vending machines involves several critical stages that ensure the final product is functional, durable, and meets customer expectations. Understanding these stages is crucial for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, as it helps in making informed purchasing decisions.

Material Preparation

The first stage of manufacturing involves selecting and preparing the materials. Common materials used include:

- Metal: Often used for the chassis and structural components due to its strength and durability.

- Plastic: Utilized for exterior panels and internal components for weight reduction and cost efficiency.

- Electronic components: Includes circuit boards, sensors, and payment systems essential for the machine’s operation.

Material quality is pivotal; thus, suppliers should provide certifications for materials that meet international standards. Buyers should inquire about the sourcing of these materials, especially if they are imported, to ensure compliance with local regulations.

Forming

In this stage, the prepared materials are shaped into the necessary components of the vending machine. Key techniques include:

- Metal stamping: Used for creating precise metal parts.

- Injection molding: Ideal for producing complex plastic components efficiently.

- CNC machining: Offers high precision for custom parts that require specific dimensions.

The choice of forming technique impacts the machine’s overall quality and cost. B2B buyers should assess the supplier’s capabilities in these techniques to ensure they can meet the required specifications.

Assembly

The assembly process is where the machine components are put together. This involves:

- Sub-assembly: Individual components are assembled into functional units, such as the payment system or dispensing mechanism.

- Final assembly: All sub-assemblies are combined into the final product. This stage requires skilled labor and precision to ensure that all components function correctly.

Buyers should look for suppliers that employ lean manufacturing principles to minimize waste and improve efficiency. This can significantly impact lead times and costs.

Finishing

Finishing touches are applied to enhance aesthetics and protect against environmental factors. Techniques include:

- Painting and coating: Provides a protective layer and enhances visual appeal.

- Quality checks: Final inspections are conducted to ensure every machine meets quality standards before packaging.

The finishing process is essential for the machine’s longevity, particularly in regions with challenging climates, such as Africa and the Middle East. Buyers should request information on the finishing processes used and any warranties associated with them.

Quality Assurance in Manufacturing

Quality assurance (QA) is a fundamental aspect of the manufacturing process, ensuring that the final product meets the required standards. For international B2B buyers, understanding the QA process is crucial for mitigating risks associated with product quality.

International Standards

Adhering to international standards is vital for ensuring quality and safety. Key certifications to consider include:

- ISO 9001: Focuses on quality management systems and is essential for any manufacturer aiming to ensure consistent quality.

- CE Marking: Indicates compliance with EU safety, health, and environmental protection standards, crucial for machines sold in Europe.

- API Standards: Relevant in specific markets, particularly where electronic components are involved.

Buyers should verify that suppliers possess these certifications and understand the implications of non-compliance in their respective markets.

Quality Control Checkpoints

Quality control (QC) checkpoints are integrated throughout the manufacturing process to identify defects early. Common checkpoints include:

- Incoming Quality Control (IQC): Inspecting materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Monitoring the assembly process to detect any issues as they arise.

- Final Quality Control (FQC): Conducting comprehensive tests on finished products to ensure they function as intended.

Each of these checkpoints helps maintain a high standard of quality throughout production. Buyers should inquire about the specific QC measures implemented by suppliers.

Common Testing Methods

Various testing methods are employed to ensure the functionality and safety of phone vending machines. Key methods include:

- Functional Testing: Verifies that all operational features work correctly.

- Environmental Testing: Assesses how well the machine performs under various conditions, such as extreme temperatures and humidity.

- Durability Testing: Evaluates the machine’s longevity and resistance to wear and tear.

Buyers should request documentation of testing results to ensure that the machines can withstand local conditions.

Verifying Supplier Quality Control

To build confidence in supplier quality, B2B buyers should engage in thorough verification processes. Strategies include:

- Supplier Audits: Conducting on-site audits to evaluate manufacturing practices and QC processes.

- Requesting Reports: Asking for detailed QC reports that outline inspection results and any corrective actions taken.

- Third-Party Inspections: Engaging independent inspectors to assess the manufacturing process and final product quality.

These steps help ensure that suppliers maintain high standards and can deliver reliable products.

QC Certification Nuances for International Buyers

International buyers, particularly from diverse regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in QC certification. For instance:

- Regional Regulations: Different regions may have unique compliance requirements. Understanding local regulations is critical for avoiding penalties and ensuring smooth market entry.

- Supply Chain Transparency: Buyers should prioritize suppliers who can demonstrate transparency in their supply chains, including sourcing and manufacturing practices.

- Cultural Considerations: Engaging with suppliers in different regions may require sensitivity to cultural differences in business practices and communication styles.

By being informed about these nuances, B2B buyers can make better decisions and foster strong relationships with suppliers, ultimately leading to successful partnerships in the global market.

Related Video: SMART Quality Control for Manufacturing

Comprehensive Cost and Pricing Analysis for phone vending machine Sourcing

When sourcing phone vending machines for international markets, understanding the cost structure and pricing dynamics is essential for maximizing value and ensuring a successful procurement strategy. This analysis delves into the various components that contribute to the overall cost and explores key price influencers that can affect sourcing decisions.

Cost Components

-

Materials: The primary cost driver in the production of phone vending machines is the materials used, which typically include metal, plastic, electronic components, and display screens. The choice of materials impacts not only the cost but also the durability and quality of the machines.

-

Labor: Labor costs vary significantly across regions. Countries with lower labor costs, such as those in parts of Asia, may offer competitive pricing; however, this can affect the quality of workmanship. Understanding the labor market in the supplier’s region is crucial for assessing total costs.

-

Manufacturing Overhead: This includes expenses related to factory operations such as utilities, rent, and administrative costs. A supplier with higher overhead costs may pass these expenses on to buyers, impacting pricing.

-

Tooling: Custom tooling for specific designs or features can be a substantial upfront cost. Buyers should consider whether they need bespoke solutions or if off-the-shelf models suffice, as this can significantly alter the cost landscape.

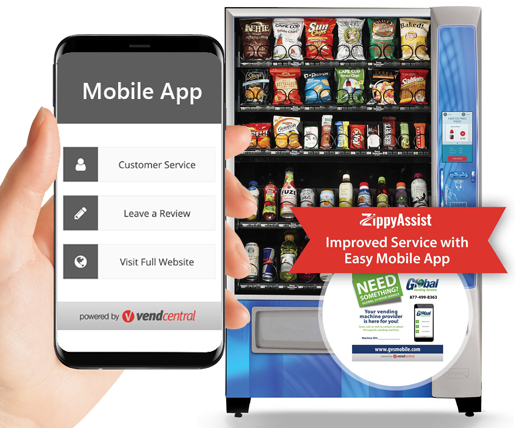

Illustrative Image (Source: Google Search)

-

Quality Control (QC): Implementing rigorous QC processes ensures the machines meet international standards. However, enhanced QC measures can add to the cost. Buyers should weigh the benefits of high-quality assurance against the additional expenses.

-

Logistics: Shipping costs can fluctuate based on distance, shipping method, and current fuel prices. International buyers should factor in customs duties and taxes, which can vary widely by destination.

-

Margin: Suppliers typically add a margin to their costs to ensure profitability. Understanding the industry standard margins can help buyers negotiate better pricing.

Price Influencers

-

Volume/MOQ: Ordering in bulk usually leads to lower per-unit costs. Buyers should evaluate their needs and consider minimum order quantities (MOQ) offered by suppliers to maximize cost-efficiency.

-

Specifications/Customization: Custom features can lead to higher costs. Buyers should clearly define their requirements to avoid unnecessary expenditures while ensuring the machines meet operational needs.

-

Materials and Quality/Certifications: Higher-quality materials and certifications (e.g., CE, ISO) can increase initial costs but may reduce maintenance and replacement expenses over time.

-

Supplier Factors: The supplier’s reputation, location, and production capabilities can influence pricing. Engaging with established suppliers with a track record of reliability may justify a premium price.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is critical for determining who bears the costs and risks at various stages of the shipping process. This knowledge can prevent unexpected expenses.

Buyer Tips

-

Negotiation: Strong negotiation skills can lead to better pricing. Engaging with multiple suppliers and creating competitive tension can also yield favorable terms.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes purchase price, maintenance, and operational costs. This broader perspective helps in making informed decisions that go beyond initial pricing.

-

Pricing Nuances: International buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of regional economic conditions, currency fluctuations, and trade policies that can affect pricing.

Disclaimer

The prices and cost structures mentioned are indicative and may vary based on market conditions, specific supplier agreements, and changing economic factors. It is advisable for buyers to conduct thorough market research and engage in direct discussions with suppliers to obtain accurate pricing tailored to their needs.

Spotlight on Potential phone vending machine Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for phone vending machine.)*

Essential Technical Properties and Trade Terminology for phone vending machine

Key Technical Properties of Phone Vending Machines

Understanding the technical specifications of phone vending machines is crucial for international B2B buyers, as these properties directly impact functionality, durability, and overall operational efficiency. Below are essential technical properties to consider:

-

Material Grade: The construction material significantly influences the machine’s durability and resistance to environmental factors. Common materials include stainless steel for the exterior, which offers corrosion resistance and aesthetic appeal, and high-grade plastics for internal components, ensuring lightweight yet robust functionality. Buyers should seek machines that use high-quality materials to ensure longevity in various climates, particularly in humid or arid regions.

-

Power Supply Specifications: Phone vending machines typically require a stable power supply, often ranging from 110V to 240V. Understanding the power requirements is essential for ensuring compatibility with local infrastructure. Additionally, energy efficiency ratings can offer insights into operational costs, making it critical for buyers to choose machines with lower energy consumption to reduce long-term expenses.

-

Capacity and Size: The capacity of a vending machine refers to how many devices it can hold and dispense. This is crucial for businesses that anticipate high demand. The size of the machine should also be considered, as it must fit the designated space while allowing for ease of access and maintenance. Buyers should evaluate their expected sales volume to select a machine with appropriate capacity.

-

User Interface Technology: Modern phone vending machines often incorporate touch screens or mobile payment systems for user interaction. The quality and responsiveness of these interfaces can significantly affect customer experience. Buyers should assess the technology used for user interfaces, ensuring it is intuitive and compatible with various payment methods, including mobile wallets and credit cards.

-

Security Features: Given the value of the products dispensed, security is paramount. Essential features include surveillance cameras, alarm systems, and robust locking mechanisms. Buyers should prioritize machines with advanced security options to minimize theft and damage, particularly in high-traffic locations.

-

Connectivity Options: Many phone vending machines now offer connectivity features such as Wi-Fi or mobile data capabilities for remote monitoring and management. This allows for real-time inventory tracking, sales reporting, and machine diagnostics. Buyers should consider machines that provide these connectivity options to streamline operations and enhance management efficiency.

Common Trade Terminology

Familiarity with industry jargon is vital for effective communication and negotiation. Here are key terms that B2B buyers should understand:

-

OEM (Original Equipment Manufacturer): This term refers to a company that produces parts and equipment that may be marketed by another manufacturer. In the context of phone vending machines, an OEM may provide components that are integrated into the final product. Buyers should look for reputable OEMs to ensure quality and compatibility.

-

MOQ (Minimum Order Quantity): MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers to ensure they can meet their inventory needs without overcommitting resources. It’s advisable to negotiate MOQ with suppliers to find a balance between cost and inventory management.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers requesting pricing and other relevant details for specific products. For phone vending machines, this is a crucial step in the procurement process, enabling buyers to compare offers and make informed purchasing decisions.

-

Incoterms (International Commercial Terms): These are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is critical for buyers to understand their obligations and risks related to shipping and delivery.

-

Lead Time: This term refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is essential for effective inventory management and planning. Buyers should communicate with suppliers about lead times to ensure timely delivery and avoid disruptions in their operations.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions, ultimately leading to successful procurement of phone vending machines tailored to their specific needs and market conditions.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the phone vending machine Sector

Market Overview & Key Trends

The phone vending machine sector is witnessing a transformative shift driven by several global factors, including increased smartphone penetration, urbanization, and the demand for contactless purchasing solutions. For B2B buyers in Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial. The rise of e-commerce and mobile payments has catalyzed the growth of automated retail solutions, making phone vending machines a viable option for businesses looking to enhance customer engagement and streamline operations.

Key trends to consider include the integration of advanced technologies such as artificial intelligence (AI) and the Internet of Things (IoT) within vending machines. These technologies not only improve inventory management but also offer personalized customer experiences through data analytics. Additionally, the push for convenience has led to an increased focus on multi-functional machines that can dispense accessories alongside phones, catering to consumer needs in one stop.

For international B2B buyers, particularly in regions like the UAE and Saudi Arabia, there is a growing emphasis on localized product offerings. Understanding regional consumer preferences and regulatory requirements is essential for successful market entry. Moreover, partnerships with local distributors can enhance supply chain efficiency and facilitate quicker market penetration.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a non-negotiable aspect of business operations, particularly in the phone vending machine sector. As environmental concerns rise, B2B buyers are increasingly prioritizing vendors that adopt sustainable practices. The environmental impact of electronic waste is significant, making it imperative for businesses to consider the lifecycle of the products they offer.

Ethical sourcing is another critical component, with buyers expected to ensure that their supply chains adhere to responsible labor practices and environmental standards. Companies can enhance their appeal by seeking suppliers with recognized ‘green’ certifications, such as ISO 14001, which focuses on effective environmental management systems. Additionally, the use of recyclable materials in the construction of vending machines can significantly reduce their carbon footprint and resonate with eco-conscious consumers.

By investing in sustainable solutions, businesses can not only improve their brand image but also tap into the growing market segment that values environmental responsibility. Thus, integrating sustainability into sourcing strategies is not just ethical; it is also a smart business decision that can lead to long-term profitability.

Brief Evolution/History

The concept of vending machines has evolved significantly since their inception in the 1880s. Initially serving simple snacks and beverages, the industry began to diversify in the late 20th century with the introduction of electronic and automated machines. The advent of smartphones in the early 2000s marked a pivotal moment, as businesses sought innovative ways to distribute these devices to consumers.

In recent years, the phone vending machine sector has experienced rapid growth, influenced by advancements in technology and changing consumer behaviors. This evolution has been characterized by the integration of payment systems that accept mobile wallets and contactless payments, making transactions seamless. As the sector continues to evolve, B2B buyers must stay informed about technological advancements and market trends to effectively navigate this dynamic landscape.

Related Video: Is global trade transforming? | Counting the Cost

Frequently Asked Questions (FAQs) for B2B Buyers of phone vending machine

-

What should I consider when vetting suppliers for phone vending machines?

When vetting suppliers, focus on their experience in the industry, production capacity, and client testimonials. Ensure they have a solid reputation and check for any certifications that indicate adherence to quality and safety standards. Conduct a factory visit, if possible, to assess their operations firsthand. Additionally, consider suppliers who have experience exporting to your region, as they will be familiar with the specific regulations and logistics involved in international trade. -

Can I customize my phone vending machines?

Yes, many manufacturers offer customization options for phone vending machines. This can include branding, size, color, and features such as payment systems or software integration. When discussing customization, provide detailed specifications to ensure your needs are met. Keep in mind that extensive customization may affect lead times and costs, so it’s crucial to communicate your requirements early in the negotiation process. -

What are the typical minimum order quantities (MOQ) and lead times?

Minimum order quantities can vary significantly by supplier and the complexity of the machine. Common MOQs for phone vending machines range from 10 to 50 units. Lead times can also differ based on the supplier’s production schedule and your location, typically ranging from 4 to 12 weeks. Always confirm these details upfront to avoid delays and ensure they align with your business needs and market launch plans. -

What payment options are available for international orders?

Payment options for international orders may include wire transfers, letters of credit, and payment platforms like PayPal or Alibaba’s Trade Assurance. Each method has its pros and cons concerning security, fees, and processing times. It’s advisable to negotiate payment terms that offer protection against fraud, such as a partial upfront payment followed by the balance upon delivery. Always ensure that the chosen method complies with international trade regulations. -

How can I ensure quality assurance and certifications for the machines?

To ensure quality, request documentation of certifications such as ISO 9001 or CE marking, which indicate compliance with international quality standards. Ask for samples or conduct an inspection before full production to assess the machines’ functionality and build quality. Establish clear quality control processes with the supplier, including agreed-upon testing procedures before shipment to minimize the risk of defects or failures. -

What are the logistics considerations for importing phone vending machines?

Logistics can be complex when importing phone vending machines, particularly regarding customs regulations, shipping methods, and costs. Collaborate with a freight forwarder experienced in handling such equipment to navigate these challenges. Understand the import duties and taxes that will apply in your country and ensure that all necessary documentation, like commercial invoices and packing lists, are in order to prevent delays at customs.

Illustrative Image (Source: Google Search)

-

How should I handle disputes with suppliers?

Disputes can arise over quality, delivery times, or payment terms. To handle them effectively, maintain open communication with the supplier and document all agreements and correspondence. If issues persist, refer to the contract clauses regarding dispute resolution, which may include mediation or arbitration. It’s beneficial to establish a clear escalation process at the beginning of your partnership to address potential conflicts proactively. -

Are there specific regulations I need to be aware of when importing vending machines?

Yes, each region has its regulations regarding electronic devices, including safety standards and environmental considerations. Research the specific requirements in your country, such as certifications needed for electrical appliances or compliance with local data protection laws if the machines collect user data. Engaging a local compliance expert can help ensure that you meet all necessary legal and regulatory requirements to avoid costly fines or delays.

Strategic Sourcing Conclusion and Outlook for phone vending machine

As the global market for phone vending machines evolves, strategic sourcing has emerged as a critical factor for B2B buyers seeking to capitalize on this trend. Understanding the unique demands of various regions—such as the tech-savvy youth in Africa, the growing urbanization in South America, and the robust retail landscapes in the Middle East and Europe—enables companies to make informed purchasing decisions.

Key Takeaways:

– Market Research: Conduct thorough research to identify local consumer behavior and preferences to tailor offerings effectively.

– Supplier Relationships: Build strong partnerships with suppliers who understand regional dynamics, ensuring timely delivery and support.

– Cost Efficiency: Leverage competitive pricing by sourcing from multiple suppliers to reduce costs while maintaining quality.

Looking ahead, the adoption of phone vending machines is expected to accelerate, driven by advances in technology and changing consumer habits. For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, now is the time to engage in strategic sourcing practices that not only enhance operational efficiency but also position your business for sustainable growth. Embrace this opportunity to innovate and stay ahead in the competitive landscape.