Master Sourcing Old Snack Vending Machines for Competitive

Guide to Old Snack Vending Machine

- Introduction: Navigating the Global Market for old snack vending machine

- Understanding old snack vending machine Types and Variations

- Key Industrial Applications of old snack vending machine

- Strategic Material Selection Guide for old snack vending machine

- In-depth Look: Manufacturing Processes and Quality Assurance for old snack vending machine

- Comprehensive Cost and Pricing Analysis for old snack vending machine Sourcing

- Spotlight on Potential old snack vending machine Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for old snack vending machine

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the old snack vending machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of old snack vending machine

- Strategic Sourcing Conclusion and Outlook for old snack vending machine

Introduction: Navigating the Global Market for old snack vending machine

In the evolving landscape of the global market, old snack vending machines present a unique opportunity for B2B buyers looking to diversify their product offerings and enhance customer satisfaction. These machines not only serve as a nostalgic reminder of simpler times but also tap into a growing trend where convenience meets affordability. As consumer behavior shifts towards quick, accessible snacks, investing in refurbished or vintage vending machines can provide a competitive edge in various markets, particularly in regions like Africa, South America, the Middle East, and Europe.

This comprehensive guide aims to equip international buyers with the essential insights needed to navigate the complexities of sourcing old snack vending machines. We will explore a variety of types available on the market, the materials used in their construction, and the manufacturing and quality control processes that ensure reliability. Additionally, we will provide a detailed overview of potential suppliers, cost considerations, and market trends that can influence purchasing decisions.

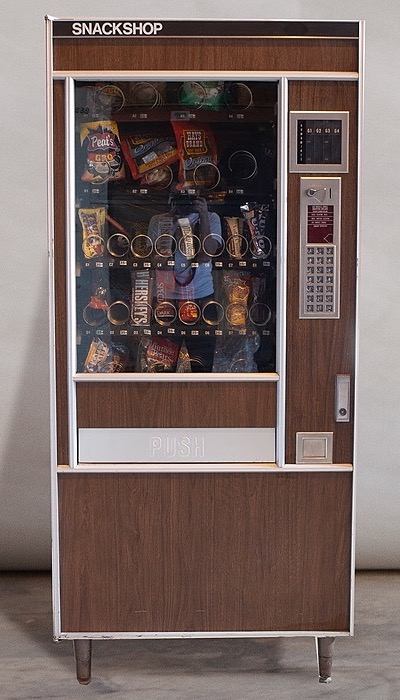

Illustrative Image (Source: Google Search)

By delving into frequently asked questions and addressing common concerns, this guide empowers B2B buyers to make informed sourcing decisions. Understanding these elements will not only enhance procurement strategies but also foster relationships with suppliers that align with business goals. As the demand for innovative snack solutions continues to rise, the insights provided here will be invaluable for leveraging the potential of old snack vending machines in a competitive marketplace.

Understanding old snack vending machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Spiral Vending Machines | Coiled racks that allow products to spiral down | Office buildings, schools, and hospitals | Pros: Easy to restock; Cons: Limited to small items only |

| Tray Vending Machines | Flat trays that hold various snack products | Airports, malls, and convenience stores | Pros: Versatile product selection; Cons: More complex to maintain |

| Glass Front Vending Machines | Transparent glass fronts for product visibility | Retail environments and service stations | Pros: Attracts customers; Cons: Higher initial cost |

| Snack and Beverage Combo | Integrated units offering snacks and drinks | Cafeterias, break rooms, and hotels | Pros: Maximizes space; Cons: Can be prone to mechanical issues |

| Automated Micro Markets | Self-service kiosks with a wide range of products | Corporate offices and residential complexes | Pros: High-tech appeal; Cons: Requires regular tech support |

Spiral Vending Machines

Spiral vending machines are characterized by their coiled racks that allow snacks to spiral down for easy dispensing. These machines are particularly suitable for environments like office buildings and schools where quick, grab-and-go options are essential. When purchasing, buyers should consider the ease of restocking and the range of products that can be accommodated. However, they may be limited to smaller items, which could restrict sales potential.

Tray Vending Machines

Tray vending machines utilize flat trays to hold a variety of snack products. They are commonly found in high-traffic areas such as airports and malls, where diverse product offerings can cater to a broad audience. Buyers should assess the machine’s capacity for different snack sizes and types. While they offer versatility, maintenance can be more complex due to the need for regular cleaning and restocking.

Glass Front Vending Machines

These machines feature transparent glass fronts that enhance product visibility, making them an attractive option for retail environments and service stations. Their design encourages impulse buying, as customers can easily see what’s available. When considering a purchase, buyers should weigh the higher initial costs against potential increased sales from enhanced visibility. However, they may require more maintenance to keep the glass clean and appealing.

Snack and Beverage Combo

Snack and beverage combo machines combine snacks and drinks in a single unit, making them ideal for cafeterias, break rooms, and hotels. They maximize space and provide convenience for users looking for a quick meal or snack. Buyers should consider the mechanical complexity and potential for issues, as the integration of both snacks and beverages can lead to increased maintenance needs. The ability to offer a wider range of products can offset these concerns.

Automated Micro Markets

Automated micro markets are self-service kiosks that provide a wide range of snacks and beverages, often with a high-tech appeal. These markets are suitable for corporate offices and residential complexes, allowing users to browse and purchase items without the need for staff. Buyers should evaluate the technology required for operation and the ongoing support needed. While they offer a modern solution to vending, the complexity of maintenance and technology can be a drawback for some businesses.

Related Video: Snack Vending Machine at Employee Break Room

Key Industrial Applications of old snack vending machine

| Industry/Sector | Specific Application of old snack vending machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Education | Campus snack distribution | Provides convenient access to snacks for students | Assess machine durability and ease of maintenance |

| Healthcare | Staff and visitor refreshments | Enhances employee satisfaction and patient experience | Ensure compliance with health regulations and food safety standards |

| Manufacturing & Warehousing | Break room snack services | Boosts employee morale and productivity | Evaluate capacity and energy efficiency |

| Hospitality | Guest amenities in hotels | Increases guest satisfaction and additional revenue | Consider product selection and payment options |

| Corporate Offices | Employee break areas | Improves workplace environment and reduces downtime | Look for machines with customizable product offerings |

Education

In educational institutions, old snack vending machines serve as a convenient solution for providing snacks to students and staff. These machines can be strategically placed in high-traffic areas, such as libraries and cafeterias, ensuring easy access during breaks. They solve the problem of limited on-campus food options, promoting healthy snacking habits. For international buyers, especially in regions like Africa and South America, it is crucial to consider the machine’s durability and ability to withstand heavy usage in bustling environments.

Healthcare

In healthcare settings, old snack vending machines can play a vital role in enhancing the experience of both staff and visitors. By offering a selection of healthy snacks and beverages, these machines help maintain energy levels and improve satisfaction during long shifts or visits. Buyers from the Middle East and Europe should prioritize compliance with health regulations and food safety standards, ensuring that the machines are suitable for use in sensitive environments.

Manufacturing & Warehousing

In manufacturing and warehousing sectors, old snack vending machines can be used in break rooms to provide quick access to refreshments for employees. This convenience can significantly boost morale and productivity, as workers can easily refuel during breaks. For B2B buyers, particularly in Africa and Europe, evaluating the machine’s capacity to accommodate high traffic and its energy efficiency is essential to ensure it meets the demands of a busy workplace.

Hospitality

In the hospitality industry, old snack vending machines can enhance guest amenities in hotels and resorts. By offering a variety of snacks and beverages, hotels can improve guest satisfaction and create additional revenue streams. Buyers should consider the product selection available in the machines and the payment options, ensuring that they align with guest preferences and payment trends in their specific markets, especially in regions like South America and the Middle East.

Corporate Offices

Corporate offices can benefit from the inclusion of old snack vending machines in employee break areas. These machines help create a positive workplace environment by providing easy access to snacks, which can reduce downtime and encourage social interactions among employees. For international B2B buyers, especially in Europe, looking for machines with customizable product offerings will allow them to cater to diverse employee preferences and dietary needs, enhancing overall workplace satisfaction.

Related Video: How to Make A Chocolate Vending Machine From Cardboard

Strategic Material Selection Guide for old snack vending machine

When selecting materials for old snack vending machines, it’s essential to consider their performance characteristics, cost implications, and suitability for specific environments. The following analysis covers four common materials used in the construction of these machines, focusing on their properties, advantages, disadvantages, and considerations for international buyers.

1. Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand a range of temperatures. It typically has a temperature rating of up to 800°F (427°C) and exhibits good resistance to oxidation and staining.

Pros & Cons:

The durability of stainless steel makes it a preferred choice for vending machines, as it can withstand heavy use and exposure to various environmental factors. However, it is generally more expensive than other materials, which can impact the overall cost of the vending machine. Manufacturing complexity is moderate, as stainless steel requires specialized welding techniques.

Impact on Application:

Stainless steel is compatible with a wide range of snack products, including those that may be oily or acidic. Its non-reactive nature ensures that the quality of the snacks is maintained.

Considerations for International Buyers:

Buyers should ensure that the stainless steel used complies with international standards such as ASTM A240. In regions like Africa and South America, where humidity can be high, opting for higher-grade stainless steel (e.g., 316) may be advisable.

2. Mild Steel

Key Properties:

Mild steel is characterized by its ductility and good weldability, with a typical tensile strength of around 370 MPa. It offers moderate corrosion resistance but is less effective than stainless steel.

Pros & Cons:

Mild steel is cost-effective and easy to manufacture, making it a popular choice for budget-conscious buyers. However, its susceptibility to rust and corrosion can be a significant drawback, especially in humid environments. Regular maintenance is required to prolong its lifespan.

Impact on Application:

Mild steel is suitable for internal components of vending machines but may require protective coatings for external surfaces to prevent corrosion.

Considerations for International Buyers:

Buyers should be aware of the need for protective coatings, particularly in regions with high moisture levels. Compliance with local standards (e.g., DIN or JIS) is also essential.

3. Polycarbonate

Key Properties:

Polycarbonate is a high-performance plastic known for its impact resistance and transparency. It can withstand temperatures up to 270°F (132°C) and offers good resistance to UV light.

Pros & Cons:

The lightweight nature of polycarbonate makes it easy to handle and install, while its transparency allows for easy visibility of products. However, it is less durable than metal options and can be prone to scratching and yellowing over time.

Impact on Application:

Polycarbonate is ideal for display windows in vending machines, allowing consumers to see the products inside. Its chemical resistance makes it suitable for various snack types.

Considerations for International Buyers:

Buyers should check for compliance with food safety standards, especially in Europe, where regulations are stringent. The material’s performance can vary based on the grade, so selecting a high-quality variant is crucial.

4. Aluminum

Key Properties:

Aluminum is lightweight, with a density approximately one-third that of steel. It has good corrosion resistance and can withstand temperatures up to 1,200°F (649°C).

Pros & Cons:

Aluminum’s lightweight nature facilitates easy transport and installation. It is also relatively cost-effective compared to stainless steel. However, it is softer than steel, which can lead to dents and damage under heavy use.

Impact on Application:

Aluminum is suitable for various components in vending machines, including frames and panels. Its corrosion resistance makes it a viable option for outdoor installations.

Considerations for International Buyers:

Buyers should consider the local availability of aluminum and its compliance with international standards. In regions like the Middle East, where temperatures can soar, aluminum’s heat resistance is an advantage.

Summary Table

| Material | Typical Use Case for old snack vending machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | External panels, internal components | Excellent corrosion resistance | Higher cost, moderate manufacturing complexity | High |

| Mild Steel | Internal structural components | Cost-effective, easy to manufacture | Susceptible to corrosion, requires maintenance | Low |

| Polycarbonate | Display windows | Impact-resistant, lightweight | Less durable, prone to scratching | Medium |

| Aluminum | Frames and panels | Lightweight, good corrosion resistance | Softer than steel, can dent easily | Medium |

This guide provides a comprehensive overview of material options for old snack vending machines, enabling international B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for old snack vending machine

Manufacturing Processes for Old Snack Vending Machines

The manufacturing of old snack vending machines involves several key stages, each critical to ensuring the functionality and durability of the final product. Understanding these processes allows international B2B buyers to assess potential suppliers effectively.

1. Material Preparation

The first stage in the manufacturing process is the selection and preparation of materials. Common materials for snack vending machines include:

- Metal Alloys: Steel and aluminum are frequently used for structural components due to their strength and resistance to corrosion.

- Plastics: High-density polyethylene (HDPE) and polycarbonate are often used for components like windows and internal compartments, offering transparency and durability.

- Electrical Components: Wiring, sensors, and control systems are critical for machine functionality.

Buyers should inquire about the source and quality of these materials, as they can significantly impact the longevity and reliability of the vending machines.

2. Forming

In this stage, the prepared materials undergo various forming techniques to create the machine’s structure. Key techniques include:

- Sheet Metal Fabrication: Processes like laser cutting, bending, and stamping are used to create the chassis and outer casing.

- Injection Molding: This technique is commonly applied for producing plastic components, ensuring precision and uniformity.

- Welding: Used to join metal parts, welding ensures structural integrity and strength.

Understanding the forming techniques used can help buyers assess the durability and quality of the vending machines.

3. Assembly

Once the components are formed, the assembly process begins. This stage includes:

- Component Integration: Various parts, such as the coin mechanism, display panel, and refrigeration units, are assembled into the machine.

- Wiring and Electrical Setup: Ensuring all electrical components are correctly installed and tested is crucial for functionality.

It is beneficial for buyers to understand the assembly process, as it impacts both the performance and maintenance of the machines.

4. Finishing

The final stage involves applying finishes to enhance both aesthetics and protection. Common practices include:

- Painting and Coating: Protective coatings are applied to metal surfaces to prevent rust and wear. Powder coating is a popular choice for its durability and variety of colors.

- Quality Checks: Final inspections are conducted to ensure the machine meets all specifications and standards.

Buyers should ask suppliers about the types of finishes applied and their expected lifespan to ensure that machines will endure environmental conditions.

Quality Assurance in Manufacturing

Quality assurance (QA) is critical in the manufacturing of old snack vending machines. Implementing rigorous QA processes helps ensure that the machines function reliably over time and comply with international standards.

Relevant International Standards

To ensure quality, manufacturers often adhere to various international standards:

- ISO 9001: This standard focuses on quality management systems, ensuring that manufacturing processes are consistently monitored and improved.

- CE Marking: Required for products sold in the European Economic Area, this marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: While more common in the oil and gas industry, some vending machine components may fall under these standards, particularly in terms of electronic safety and performance.

B2B buyers should ensure that their suppliers comply with these standards, as they provide a framework for quality assurance.

Quality Control Checkpoints

Quality control (QC) is typically divided into several checkpoints during the manufacturing process:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing checks during the manufacturing process help identify any defects or deviations from standards.

- Final Quality Control (FQC): A thorough inspection of the finished product ensures it meets all design specifications and quality standards.

Understanding these checkpoints allows buyers to assess the thoroughness of a supplier’s QC processes.

Common Testing Methods

Testing methods play a crucial role in the quality assurance of vending machines. Common tests include:

- Functional Testing: Ensuring all mechanical and electrical components operate correctly.

- Stress Testing: Simulating extreme conditions to evaluate the machine’s durability and performance under stress.

- Safety Testing: Checking electrical components for compliance with safety regulations.

Buyers can request detailed testing reports to verify that these methods have been implemented.

Verifying Supplier Quality Control

For international B2B buyers, verifying a supplier’s quality control processes is vital. Here are actionable steps to ensure supplier reliability:

- Conduct Audits: Periodic audits of suppliers’ manufacturing facilities can provide insights into their QA processes and adherence to standards.

- Request Documentation: Buyers should ask for quality assurance reports, including IQC, IPQC, and FQC results, to evaluate compliance with standards.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s manufacturing and quality control processes.

Quality Control Nuances for International Buyers

When dealing with suppliers from different regions, it’s essential to understand specific quality control nuances:

- Cultural Differences: Variations in manufacturing practices and quality expectations can occur based on local industry standards and cultural norms. For instance, suppliers in Europe may have more stringent quality controls than those in certain African or South American regions.

- Regulatory Compliance: Buyers should be aware of the specific regulations governing vending machines in their region and ensure that suppliers meet these requirements.

- Language Barriers: Communication can sometimes hinder clarity regarding quality expectations. Ensuring that documentation is available in a common language can mitigate misunderstandings.

By focusing on these aspects, international B2B buyers can make informed decisions when sourcing old snack vending machines, ensuring they receive high-quality products that meet their specific needs.

Related Video: Parle-G Biscuits Manufacturing process – Food Factory Tour- Modern Food factory, Mega Factory II

Comprehensive Cost and Pricing Analysis for old snack vending machine Sourcing

When sourcing old snack vending machines, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers. This analysis covers the key components influencing costs and pricing, as well as actionable insights for negotiating favorable terms.

Cost Components

-

Materials: The primary materials involved in old snack vending machines include metal, plastic, and electronic components. The condition and quality of these materials significantly affect the overall cost. When sourcing, it’s beneficial to inquire about the materials used and their durability, as this can impact maintenance costs over time.

-

Labor: Labor costs can vary widely depending on the region where the machines are refurbished or maintained. Skilled labor in regions like Europe may incur higher costs compared to South America or Africa. Understanding local wage standards and labor practices is essential for accurate cost estimation.

-

Manufacturing Overhead: This includes expenses related to utilities, rent, and administrative costs incurred during the refurbishment process. Buyers should consider the efficiency of the supplier’s operations, as more streamlined processes can lead to lower overhead costs.

-

Tooling: Tooling costs refer to the equipment and machinery needed to refurbish the vending machines. These costs can be significant, especially if custom modifications are required. Buyers should assess whether the supplier has the necessary tooling capabilities to meet their specifications.

-

Quality Control (QC): Implementing a robust QC process ensures that the machines meet safety and operational standards. This can add to the cost but is essential for minimizing future maintenance and operational disruptions. Inquire about the QC procedures employed by potential suppliers.

-

Logistics: Transportation costs can vary based on the distance from the supplier to the buyer’s location. Factors such as shipping mode, packaging, and customs duties can significantly affect total logistics expenses. It’s advisable to evaluate multiple shipping options to find the most cost-effective solution.

-

Margin: Supplier profit margins can vary based on their market position, operational efficiency, and the demand for refurbished machines. Understanding the typical margins in the region can help buyers gauge whether a quoted price is reasonable.

Price Influencers

-

Volume/MOQ: Minimum order quantities (MOQ) can heavily influence pricing. Suppliers may offer discounts for larger orders, so buyers should evaluate their needs carefully and consider consolidating purchases to benefit from lower per-unit costs.

-

Specifications/Customization: Custom features may increase costs significantly. Buyers should clearly define their requirements upfront to avoid unexpected price hikes later in the process.

-

Materials and Quality Certifications: Machines that meet international quality standards or come with certifications may command higher prices. However, investing in quality can reduce long-term operational costs and increase customer satisfaction.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Well-established suppliers may charge more due to their experience and quality assurances, while less-known suppliers might offer lower prices but at higher risk.

-

Incoterms: The chosen Incoterms can significantly influence the final price. Buyers should clearly understand the responsibilities for shipping, insurance, and duties to avoid hidden costs.

Buyer Tips

-

Negotiation: Always be prepared to negotiate. Understanding the cost structure allows buyers to identify areas where they can push for better pricing without compromising on quality.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes acquisition, maintenance, and operational costs. A lower initial price may not always translate to lower overall costs.

-

Pricing Nuances for International Buyers: Be aware of regional pricing variances. Factors such as local demand, economic conditions, and currency fluctuations can impact the pricing landscape. Conduct thorough market research to benchmark prices effectively.

-

Disclaimer for Indicative Prices: Pricing for old snack vending machines can fluctuate based on market conditions and supplier pricing strategies. It is advisable to request detailed quotes and confirm all costs before finalizing any agreements.

By carefully evaluating these cost components and pricing influencers, international B2B buyers can make informed decisions and secure the best possible deals for old snack vending machines.

Spotlight on Potential old snack vending machine Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for old snack vending machine.)*

Essential Technical Properties and Trade Terminology for old snack vending machine

Key Technical Properties of Old Snack Vending Machines

Understanding the essential technical properties of old snack vending machines is crucial for international B2B buyers seeking reliable equipment. Here are some critical specifications to consider:

-

Material Grade: The material used in the construction of vending machines directly impacts durability and maintenance costs. Common materials include stainless steel and high-grade plastics. Stainless steel is favored for its resistance to corrosion, making it ideal for environments with high humidity or varying temperatures. Buyers should ensure that the material grade meets industry standards to guarantee longevity.

-

Capacity: This refers to the number of snacks and beverages a vending machine can hold. Capacity is vital for buyers to match machine selection with expected foot traffic and sales volume. Machines with larger capacities reduce the frequency of restocking, which can be a significant operational cost.

-

Power Consumption: Energy efficiency is increasingly important in a sustainability-conscious market. Buyers should look for machines with energy-efficient compressors and lighting systems to minimize electricity costs. Understanding the power consumption specifications can also assist in compliance with local regulations regarding energy use.

-

Temperature Control Range: For machines that dispense perishable items, maintaining the correct temperature is essential. The specified temperature control range ensures that snacks remain fresh and safe for consumption. Buyers need to verify that the machine can maintain the required temperatures across varying environmental conditions.

-

User Interface: The user interface should be intuitive, featuring clear displays and easy-to-use selection mechanisms. Machines with advanced interfaces, such as touch screens or mobile payment options, can enhance customer experience and increase sales. For B2B buyers, ensuring that the interface aligns with local consumer preferences is critical.

Common Trade Terminology in the Vending Machine Industry

Familiarity with industry terminology can streamline negotiations and purchasing processes for international B2B buyers. Here are some common terms:

-

OEM (Original Equipment Manufacturer): This term refers to a company that produces parts and equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify quality standards and potential customization options for vending machines.

-

MOQ (Minimum Order Quantity): MOQ defines the smallest number of units a supplier is willing to sell. This is particularly important for B2B buyers as it can affect inventory management and cash flow. Buyers should negotiate MOQs that align with their operational needs to avoid overstocking or stockouts.

-

RFQ (Request for Quotation): An RFQ is a document issued by buyers to solicit price quotes from suppliers. It’s a crucial step in procurement, allowing buyers to compare pricing, terms, and conditions from different vendors. An effective RFQ should include detailed specifications to ensure accurate and comparable quotes.

-

Incoterms: Short for International Commercial Terms, Incoterms define the responsibilities of buyers and sellers in international trade. Understanding these terms is vital for negotiating shipping costs and risk management during transportation. Familiarity with Incoterms can help buyers avoid unexpected expenses and clarify liability.

-

Lead Time: This term refers to the period between placing an order and receiving the product. Understanding lead times is essential for inventory planning and ensuring that machines are available when needed. Buyers should communicate clearly with suppliers about expected lead times to align with their business schedules.

By grasping these essential technical properties and industry terms, international B2B buyers can make informed decisions when purchasing old snack vending machines, ensuring they select equipment that meets their specific operational needs and market conditions.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the old snack vending machine Sector

Market Overview & Key Trends

The old snack vending machine sector is experiencing notable transformations driven by various global factors. As urbanization accelerates in regions like Africa and South America, there is an increased demand for convenient food options. This trend is further amplified by the growing middle class in these regions, which has led to a shift in consumer preferences towards quality and variety in snack offerings. International B2B buyers must stay attuned to these changing dynamics to capitalize on emerging markets.

Technological advancements are reshaping the vending machine landscape. Features such as cashless payment systems, remote monitoring, and smart inventory management are becoming standard. These innovations not only enhance user experience but also optimize operational efficiency. For buyers, investing in machines equipped with these technologies can lead to improved sales tracking and inventory management, ultimately driving profitability.

Sourcing trends are also evolving, with a heightened focus on localized supply chains. This shift is particularly relevant for businesses in the Middle East and Europe, where sourcing from regional suppliers can reduce lead times and transportation costs. Furthermore, buyers should be aware of the increasing competition from new entrants who are leveraging e-commerce platforms to reach consumers directly. This can challenge traditional vending machine operators to innovate and differentiate their offerings.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical consideration in the old snack vending machine sector. The environmental impact of production and waste management is under scrutiny, compelling buyers to seek solutions that minimize their carbon footprint. This includes selecting vending machines made from recyclable materials and implementing efficient waste disposal strategies.

Ethical sourcing is equally important. Buyers should prioritize suppliers who adhere to fair labor practices and sustainable agricultural methods. Certifications such as Fair Trade and Rainforest Alliance can guide B2B buyers in identifying responsible suppliers. Additionally, integrating ‘green’ materials into vending machine designs—such as biodegradable plastics or energy-efficient components—can enhance brand reputation and appeal to environmentally-conscious consumers.

By focusing on sustainability and ethical sourcing, international buyers can not only meet regulatory requirements but also align their businesses with the values of a growing segment of consumers who prioritize corporate responsibility.

Brief Evolution/History

The evolution of the old snack vending machine sector reflects broader changes in consumer behavior and technology. Initially characterized by simplistic designs that dispensed snacks in exchange for coins, these machines have transformed into sophisticated units that offer a variety of products, including healthy options. The introduction of digital payment systems and touch-screen interfaces has further modernized the sector, catering to tech-savvy consumers.

As the market continues to evolve, international B2B buyers must recognize the importance of adapting to these changes, leveraging both technology and sustainable practices to remain competitive in an increasingly complex landscape.

Related Video: Is global trade transforming? | Counting the Cost

Frequently Asked Questions (FAQs) for B2B Buyers of old snack vending machine

-

What factors should I consider when vetting suppliers of old snack vending machines?

When vetting suppliers, prioritize their reputation in the market and seek out reviews or testimonials from previous clients. Investigate their experience in exporting to your region and their compliance with local regulations. Additionally, request references and inspect their product quality through samples. Engaging in direct communication can also help gauge their responsiveness and willingness to accommodate your specific needs. -

Can I customize old snack vending machines to fit my branding needs?

Yes, many suppliers offer customization options for old snack vending machines. This can include modifications to the exterior design, color schemes, and branding elements such as logos. Discuss your requirements during the initial negotiations, and ensure that the supplier has the capability to deliver your desired specifications. Keep in mind that customizations may affect lead times and costs. -

What are the typical minimum order quantities (MOQs) for old snack vending machines?

MOQs can vary significantly between suppliers, often influenced by the machine’s condition and customization requests. Generally, for old snack vending machines, MOQs may range from 5 to 20 units. It’s essential to clarify these terms upfront and explore if the supplier can accommodate smaller orders, especially if you’re entering the market or testing demand. -

What are the lead times for receiving old snack vending machines?

Lead times for old snack vending machines can depend on factors such as the supplier’s location, availability of inventory, and any customization requests. Typically, you can expect lead times to range from 4 to 12 weeks. Always confirm these timelines with the supplier and consider potential delays due to international shipping, customs, and local regulations.

Illustrative Image (Source: Google Search)

-

What quality assurance measures should I look for in old snack vending machines?

Ensure that suppliers provide clear documentation regarding the quality assurance processes they employ. Look for certifications that indicate adherence to international standards, such as ISO or CE marks. Additionally, request detailed inspections reports or guarantees for the machines, which can safeguard your investment and ensure functionality upon delivery. -

How should I handle logistics when importing old snack vending machines?

Logistics is a critical aspect of importing old snack vending machines. Collaborate with a freight forwarder who understands the complexities of international shipping, including customs documentation, tariffs, and local regulations. Ensure that you have a comprehensive shipping plan that includes insurance and tracking to mitigate risks during transit. -

What steps can I take to resolve disputes with suppliers?

To effectively handle disputes, establish clear terms of agreement in your contract, including payment terms, delivery schedules, and quality expectations. If issues arise, maintain open communication with the supplier to seek resolution amicably. If necessary, consider engaging a third-party mediator or arbitration service that specializes in international trade disputes to help facilitate a resolution. -

What payment methods are recommended for international purchases of old snack vending machines?

For international transactions, consider secure payment methods such as letters of credit, PayPal, or escrow services. These options provide a level of security for both parties, ensuring that funds are only released once agreed-upon conditions are met. Always discuss payment terms upfront with your supplier and ensure you understand any potential fees associated with the chosen payment method.

Strategic Sourcing Conclusion and Outlook for old snack vending machine

In conclusion, the strategic sourcing of old snack vending machines presents a unique opportunity for international B2B buyers to capitalize on cost efficiencies and market demands. By focusing on sustainable procurement practices, businesses can not only reduce operational costs but also align with the growing consumer preference for eco-friendly options. Understanding regional preferences, particularly in Africa, South America, the Middle East, and Europe, allows buyers to tailor their offerings, ensuring that the products resonate with local tastes and purchasing habits.

Furthermore, leveraging data analytics and market insights will enable businesses to make informed decisions regarding inventory management and machine placement. The rise of technology integration in vending solutions, such as cashless payment systems and remote monitoring, also represents a critical aspect for future sourcing strategies.

As the market evolves, it is essential for buyers to remain adaptable and open to innovation. Engaging with suppliers who share a commitment to quality and sustainability will ultimately position businesses for long-term success. Now is the time to reassess your sourcing strategies and explore how old snack vending machines can be integrated into your offerings to drive growth and customer satisfaction in emerging markets.