Your Ultimate Guide to Sourcing Gravity Falls Vending

Guide to Gravity Falls Vending Machine Code

- Introduction: Navigating the Global Market for gravity falls vending machine code

- Understanding gravity falls vending machine code Types and Variations

- Key Industrial Applications of gravity falls vending machine code

- Strategic Material Selection Guide for gravity falls vending machine code

- In-depth Look: Manufacturing Processes and Quality Assurance for gravity falls vending machine code

- Comprehensive Cost and Pricing Analysis for gravity falls vending machine code Sourcing

- Spotlight on Potential gravity falls vending machine code Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for gravity falls vending machine code

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the gravity falls vending machine code Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of gravity falls vending machine code

- Strategic Sourcing Conclusion and Outlook for gravity falls vending machine code

Introduction: Navigating the Global Market for gravity falls vending machine code

In an era of rapid globalization, the demand for unique and engaging consumer experiences has propelled the popularity of themed vending machines, particularly those inspired by cultural phenomena like Gravity Falls. The Gravity Falls vending machine code is not just a technical specification; it represents a lucrative opportunity for international businesses aiming to tap into the growing market of entertainment-based products. For B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of this market is crucial to sourcing innovative solutions that resonate with local consumers.

This guide serves as a comprehensive resource for navigating the complexities of acquiring Gravity Falls vending machine code and related products. It covers crucial aspects including various types of codes, essential materials, manufacturing processes, quality control measures, and potential suppliers. Additionally, the guide provides insights into market trends, cost structures, and answers to frequently asked questions.

By leveraging the information within this guide, B2B buyers will be empowered to make informed sourcing decisions that align with their business goals. Whether you are a distributor in Kenya looking to diversify your offerings, or a retailer in Brazil aiming to attract a younger audience, understanding the intricacies of Gravity Falls vending machine code will be instrumental in capturing market share and driving growth. Embrace the opportunity to innovate and engage your customers with this exciting product category.

Understanding gravity falls vending machine code Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Numeric Input Code | Utilizes a sequence of numbers for transactions | Retail, event ticketing | Pros: Easy to implement; Cons: Limited customization options. |

| QR Code Integration | Incorporates QR codes for quick access and transactions | Marketing, customer engagement | Pros: High engagement; Cons: Requires smartphone access. |

| Touchscreen Interface | Interactive display for user selections | Food service, entertainment | Pros: User-friendly; Cons: Higher maintenance costs. |

| Subscription-Based Access | Codes linked to subscription models | Membership services, gyms | Pros: Recurring revenue; Cons: Customer commitment required. |

| Multi-Language Support | Offers codes in various languages | International markets | Pros: Broader market reach; Cons: Increased complexity in design. |

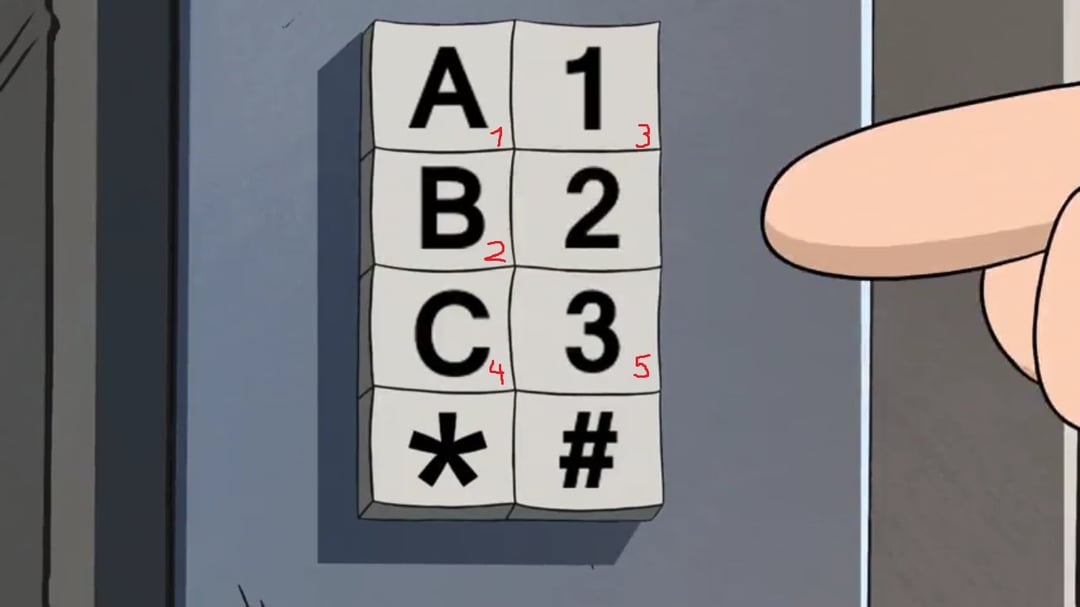

Numeric Input Code

This type of vending machine code relies on a straightforward numeric sequence, allowing users to input specific codes to complete transactions. It is particularly suitable for retail environments and event ticketing, where speed and ease of use are paramount. When considering this option, B2B buyers should evaluate the simplicity of implementation against the limited customization capabilities, which may restrict branding opportunities.

Illustrative Image (Source: Google Search)

QR Code Integration

QR code integration has become increasingly popular due to its ability to facilitate quick transactions through mobile devices. This method is particularly effective in marketing and customer engagement applications, allowing businesses to link promotional offers directly to their vending machines. Buyers should consider the potential for high customer engagement but remain aware of the necessity for customers to have smartphones, which may not be universally accessible in all target markets.

Touchscreen Interface

Vending machines equipped with touchscreen interfaces offer an interactive experience, allowing users to make selections visually. This type is widely utilized in food service and entertainment sectors, enhancing user satisfaction through intuitive navigation. B2B purchasers should weigh the user-friendly design against the higher maintenance costs associated with touchscreen technology, which may require more frequent servicing and updates.

Subscription-Based Access

Subscription-based access codes enable businesses to create a recurring revenue model, linking transactions to membership services such as gyms or exclusive clubs. This approach can foster customer loyalty but requires a commitment from users. Buyers should assess the potential for stable revenue streams against the challenge of retaining customers long-term, as well as the necessity of managing subscription renewals effectively.

Multi-Language Support

With the globalization of markets, multi-language support in vending machine codes is essential for reaching diverse customer bases. This feature allows businesses to cater to international markets, making it particularly relevant for B2B buyers targeting regions with varied linguistic preferences. However, while it broadens market reach, the increased complexity in design and implementation should be carefully considered to ensure a seamless user experience.

Related Video: Machine Learning in 2024 – Beginner’s Course

Key Industrial Applications of gravity falls vending machine code

| Industry/Sector | Specific Application of gravity falls vending machine code | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Automated product dispensing in convenience stores | Increased operational efficiency and reduced labor costs | Integration capabilities with existing POS systems |

| Food & Beverage | Custom snack and beverage vending solutions | Enhanced customer experience through variety | Compliance with health and safety regulations |

| Transportation | Mobile repair parts vending for logistics companies | Reduced downtime with immediate access to parts | Durability of the machine in various environments |

| Education | Educational material vending in schools and universities | Improved accessibility to resources for students | Customization options for diverse educational needs |

| Healthcare | Medication dispensing in clinics and hospitals | Improved patient adherence to medication schedules | Security features to prevent misuse and ensure compliance |

Retail: Automated Product Dispensing in Convenience Stores

In the retail sector, gravity falls vending machine code can automate the dispensing of various products, such as snacks and beverages, in convenience stores. This application addresses the challenge of labor shortages and the need for efficient customer service. By utilizing this technology, retailers can streamline operations and reduce overhead costs. International buyers should consider the integration capabilities with existing point-of-sale systems and the adaptability of the machine to local market preferences.

Food & Beverage: Custom Snack and Beverage Vending Solutions

The food and beverage industry benefits significantly from gravity falls vending machine code by offering customized vending solutions that cater to regional tastes. This application enhances customer experience by providing a diverse product range, allowing businesses to attract a broader audience. Buyers in Africa, South America, the Middle East, and Europe must ensure compliance with local health and safety regulations, which can vary significantly by region, to avoid legal complications.

Transportation: Mobile Repair Parts Vending for Logistics Companies

In the transportation sector, gravity falls vending machine code is utilized for mobile repair parts vending, providing logistics companies with immediate access to essential parts. This application helps minimize downtime, thereby enhancing operational efficiency. International buyers should prioritize the durability of the vending machines, as they may be exposed to various environmental conditions, and assess the vendor’s ability to supply replacement parts consistently.

Education: Educational Material Vending in Schools and Universities

Educational institutions can leverage gravity falls vending machine code to dispense educational materials, such as textbooks and stationery. This application improves accessibility for students, particularly in regions with limited resources. When sourcing these machines, international buyers should look for customization options that cater to diverse educational needs and ensure that the vending solutions align with institutional budgets.

Healthcare: Medication Dispensing in Clinics and Hospitals

In healthcare settings, gravity falls vending machine code can be applied to medication dispensing, ensuring that patients have easy access to their prescribed medications. This application addresses the challenge of medication adherence, as it allows for timely access to necessary treatments. Buyers in the healthcare sector must prioritize security features to prevent misuse and ensure compliance with regulations governing medication distribution, which can vary widely across different countries.

Related Video: Finally!! ALL Gravity Falls Ciphers & Codes EXPLAINED – Season 1

Strategic Material Selection Guide for gravity falls vending machine code

When selecting materials for gravity falls vending machine code, it is essential to consider various factors that impact performance, durability, and compliance with international standards. Below is an analysis of four common materials used in this context, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

1. Stainless Steel (e.g., AISI 304)

Key Properties:

Stainless steel is renowned for its excellent corrosion resistance, high strength, and ability to withstand a wide range of temperatures. It typically operates effectively in environments up to 870°C (1600°F) and offers good mechanical properties under both high and low temperatures.

Pros & Cons:

Stainless steel is durable and has a long lifespan, making it suitable for vending machines exposed to various environmental conditions. However, it is more expensive than other materials, which can impact the overall cost of the vending machine. Manufacturing complexity is moderate, as stainless steel can be welded and formed easily, but it requires specialized tools.

Impact on Application:

Stainless steel is compatible with a variety of media, including food and beverages, making it ideal for vending machine applications. Its non-reactive nature ensures that it does not alter the taste or quality of the products dispensed.

Considerations for International Buyers:

Buyers from regions such as Africa and South America should ensure compliance with local food safety regulations. Common standards like ASTM and DIN are applicable, and there may be a preference for specific grades based on local availability and cost.

2. Aluminum (e.g., 6061-T6)

Key Properties:

Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity. It can typically withstand temperatures up to 150°C (302°F) without significant deformation.

Pros & Cons:

The primary advantage of aluminum is its low weight, which facilitates easier installation and transportation. However, it is less durable than stainless steel and can be prone to dents and scratches. Additionally, while it is cost-effective, the manufacturing process can be more complex due to the need for specialized welding techniques.

Impact on Application:

Aluminum is suitable for dry environments and can be used for components that do not come into direct contact with liquids. Its compatibility with various coatings can enhance its protective qualities.

Considerations for International Buyers:

Buyers should verify that the aluminum used meets local standards, such as JIS in Japan or EN in Europe. Environmental regulations regarding aluminum recycling and disposal may also be pertinent, particularly in regions with strict waste management policies.

3. Polycarbonate

Key Properties:

Polycarbonate is a strong, transparent thermoplastic known for its impact resistance and lightweight nature. It can withstand temperatures ranging from -40°C to 120°C (-40°F to 248°F).

Pros & Cons:

The key advantage of polycarbonate is its high impact resistance, making it ideal for protective covers and components subject to physical stress. However, it can be susceptible to scratching and UV degradation unless treated. The cost is generally moderate, and manufacturing complexity is low, allowing for easy molding and shaping.

Impact on Application:

Polycarbonate is suitable for applications where visibility of the products is essential, such as display panels in vending machines. Its chemical resistance is adequate for various environments, but it may not be suitable for exposure to certain solvents.

Considerations for International Buyers:

Buyers should ensure that the polycarbonate used complies with international safety standards, particularly in regions with stringent consumer protection regulations. Certifications related to food safety may also be necessary for applications involving food products.

4. Carbon Steel (e.g., A36)

Key Properties:

Carbon steel is known for its high tensile strength and durability. It typically operates well in temperatures up to 400°C (752°F) but is prone to corrosion if not properly treated.

Pros & Cons:

Carbon steel is cost-effective and widely available, making it a popular choice for structural components. However, its susceptibility to rust and corrosion requires protective coatings, which can add to manufacturing costs. The complexity of manufacturing is moderate, with standard machining processes applicable.

Impact on Application:

Carbon steel is suitable for structural applications within vending machines but should be avoided in areas exposed to moisture or corrosive environments without adequate protection.

Considerations for International Buyers:

Buyers should be aware of local regulations regarding the use of carbon steel, especially in food-related applications. Compliance with standards such as ASTM is crucial, and buyers should consider the availability of protective coatings in their region.

Summary Table

| Material | Typical Use Case for gravity falls vending machine code | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel (e.g., AISI 304) | Structural and contact components for food and beverages | Excellent corrosion resistance | Higher cost compared to alternatives | High |

| Aluminum (e.g., 6061-T6) | Lightweight structural components and covers | Low weight, good thermal conductivity | Less durable, prone to dents | Medium |

| Polycarbonate | Protective covers and display panels | High impact resistance | Susceptible to scratching and UV | Medium |

| Carbon Steel (e.g., A36) | Structural components in dry environments | Cost-effective, high strength | Prone to corrosion if untreated | Low |

In-depth Look: Manufacturing Processes and Quality Assurance for gravity falls vending machine code

The manufacturing process of gravity falls vending machine code is crucial for ensuring both functionality and reliability, particularly for international B2B buyers looking for quality assurance. This section will delve into the typical stages of manufacturing, the key techniques used, and the quality control (QC) measures that are essential for maintaining high standards throughout the production cycle.

Manufacturing Processes

The manufacturing of gravity falls vending machine code involves several critical stages, each contributing to the final product’s integrity and efficiency.

1. Material Preparation

Material preparation is the foundation of the manufacturing process. It involves sourcing high-quality components and materials that meet industry specifications. Key materials for vending machine components may include:

- Metals (e.g., aluminum, steel): For structural elements and casings.

- Plastics: Used in various components such as buttons and housings.

- Electronic components: Microcontrollers, sensors, and wiring for operational functionality.

Buyers should ensure that suppliers can provide documentation regarding material certifications to verify the quality and source of materials used.

2. Forming

Forming processes shape raw materials into functional components. Common techniques include:

- CNC Machining: Precision cutting of metal parts for reliability.

- Injection Molding: Creating plastic components with high accuracy and repeatability.

- Stamping: For creating metal parts quickly and efficiently.

Each technique has its advantages and should be selected based on the component’s design and functional requirements. Buyers should inquire about the forming methods employed by suppliers to ensure they align with expected quality standards.

3. Assembly

The assembly stage is where individual components come together to form the complete vending machine system. Key considerations include:

- Automated Assembly: Utilization of robotics to enhance precision and reduce human error.

- Manual Assembly: Skilled labor is crucial for complex components that require detailed attention.

B2B buyers should evaluate the assembly process to ensure that it minimizes defects and enhances overall product reliability. A thorough understanding of assembly methods can also inform buyers about potential lead times and efficiency.

4. Finishing

Finishing processes enhance the aesthetic and functional quality of the vending machines. This may involve:

- Painting: To provide a protective layer and improve appearance.

- Coating: Applying protective coatings to prevent corrosion.

- Final Assembly Checks: Ensuring all components function as intended before shipment.

Buyers should ask suppliers for details about finishing processes and any certifications that might guarantee the quality of the final product.

Quality Assurance

Quality assurance is a critical component of the manufacturing process, ensuring that the vending machines meet international standards and buyer expectations.

International Standards

Adhering to established international standards is essential for verifying product quality. Key standards include:

- ISO 9001: This standard focuses on quality management systems and is essential for manufacturers aiming to ensure consistent product quality.

- CE Marking: Indicates compliance with EU safety standards, which is crucial for buyers in Europe.

- API Standards: Relevant for specific technical components that may require adherence to precise industry standards.

Buyers should confirm that suppliers possess the necessary certifications and understand the implications of these standards in their own markets.

Quality Control Checkpoints

Effective quality control involves multiple checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Inspection of materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Ongoing inspections during manufacturing to catch defects early.

- Final Quality Control (FQC): A comprehensive review of the finished product before shipment.

Each checkpoint serves to minimize defects and ensures that only quality products reach the market.

Common Testing Methods

Testing methods vary based on the components but typically include:

- Functional Testing: Verifying that the vending machine operates as intended.

- Durability Testing: Assessing the product’s longevity under typical usage conditions.

- Electrical Safety Testing: Ensuring that all electrical components meet safety standards.

B2B buyers should request detailed reports on testing methods used and the results to verify product reliability.

Verification of Supplier Quality Control

To ensure that suppliers maintain rigorous quality control, buyers should consider the following strategies:

- Audits: Conduct regular audits of supplier facilities to assess compliance with quality standards.

- Reports: Request documentation of quality assurance processes and outcomes, including test results and inspection reports.

- Third-party Inspections: Engage independent inspectors to evaluate manufacturing processes and quality assurance protocols.

QC and Certification Nuances for International Buyers

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of QC and certification is vital:

- Regulatory Compliance: Different regions may have specific regulations that affect product certifications. Buyers should familiarize themselves with local laws to ensure compliance.

- Cultural Considerations: Understanding the cultural context of suppliers can improve communication regarding quality expectations and standards.

- Logistics and Supply Chain: Quality assurance extends beyond manufacturing; logistics can impact product integrity. Buyers should evaluate the entire supply chain for quality assurance practices.

By focusing on these aspects of manufacturing processes and quality assurance, B2B buyers can establish strong, reliable partnerships with suppliers of gravity falls vending machine code, ensuring that they receive products that meet their high standards for quality and performance.

Related Video: SMART Quality Control for Manufacturing

Comprehensive Cost and Pricing Analysis for gravity falls vending machine code Sourcing

Cost Structure for Gravity Falls Vending Machine Code Sourcing

When sourcing gravity falls vending machine code, understanding the comprehensive cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: This includes the software components, coding languages, and any proprietary technology required for operation. High-quality materials often lead to higher costs but can significantly impact performance and user satisfaction.

-

Labor: Skilled labor is necessary for both development and support. The cost of labor can vary widely depending on the region, with less expensive options available in emerging markets like Kenya or Brazil, but may come with trade-offs in expertise.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities, rent, and administrative expenses. Effective management of these costs can lead to better pricing for buyers.

-

Tooling: Initial setup costs for manufacturing or software development tools can be significant. Investing in quality tooling can enhance production efficiency and reduce long-term costs.

-

Quality Control (QC): Ensuring the vending machine code meets international standards requires rigorous quality checks. Depending on the complexity, this can add to the overall cost but is critical for reducing defects and enhancing buyer confidence.

-

Logistics: Transportation and warehousing costs must be factored in, especially for international buyers. Shipping costs can vary based on distance, mode of transport, and current geopolitical conditions.

-

Margin: Suppliers typically include a profit margin that reflects their business model and market conditions. Understanding this margin can help buyers negotiate more effectively.

Price Influencers

Several factors can influence the pricing of gravity falls vending machine code. Key influencers include:

-

Volume/MOQ: Larger orders usually result in lower per-unit costs. Buyers should consider their projected needs to negotiate better terms.

-

Specifications/Customization: Customized solutions can increase costs due to additional design and development work. Buyers should clearly define their requirements to avoid unexpected price increases.

-

Materials: The choice of materials can significantly affect pricing. Higher quality or specialized materials typically command higher prices.

-

Quality and Certifications: Products that meet certain quality standards or certifications may be priced higher but can offer better reliability and performance, making them worth the investment.

-

Supplier Factors: The supplier’s reputation, location, and financial stability can impact pricing. Buyers should conduct due diligence to understand these factors before committing.

-

Incoterms: The terms of delivery can affect total costs. For instance, FOB (Free on Board) may transfer costs differently than CIF (Cost, Insurance, and Freight), impacting overall pricing strategies.

Buyer Tips for Cost Efficiency

International B2B buyers can adopt several strategies to enhance cost efficiency in sourcing gravity falls vending machine code:

-

Negotiate Effectively: Leverage volume discounts and long-term partnerships to negotiate better terms. Don’t hesitate to discuss pricing openly with suppliers.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also operational costs, maintenance, and potential downtime. A slightly higher upfront cost can lead to lower TCO if the product is more reliable.

-

Understand Pricing Nuances: Be aware of price fluctuations based on regional economic conditions. Buyers from Africa, South America, the Middle East, and Europe should factor in local market dynamics and currency exchange rates during negotiations.

-

Engage Local Suppliers: Whenever possible, consider sourcing from local suppliers to reduce logistics costs and lead times. Local suppliers may also have a better understanding of regional preferences and regulations.

-

Stay Informed on Market Trends: Keeping up with market trends can provide insights into potential price changes and innovative solutions that may impact sourcing strategies.

Conclusion

Navigating the cost and pricing landscape for gravity falls vending machine code requires careful consideration of various factors. By understanding the cost structure, price influencers, and employing effective buying strategies, international B2B buyers can make informed decisions that align with their business objectives.

Disclaimer: Prices mentioned in this analysis are indicative and subject to change based on market conditions and supplier negotiations. Always seek updated quotes and conduct thorough market research before finalizing any agreements.

Spotlight on Potential gravity falls vending machine code Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for gravity falls vending machine code.)*

Essential Technical Properties and Trade Terminology for gravity falls vending machine code

Key Technical Properties

Understanding the technical properties of gravity falls vending machine code is crucial for any B2B buyer seeking to invest in or develop vending machine solutions. Here are some essential specifications:

-

Material Grade

This refers to the quality and type of materials used in the construction of vending machines, such as steel or aluminum. The material grade impacts durability, maintenance costs, and overall lifespan. For B2B buyers, selecting machines made from high-grade materials ensures long-term reliability, reducing the frequency of replacements and repairs. -

Tolerance Levels

Tolerance levels indicate the acceptable limits of variation in the dimensions of machine components. These specifications are critical for ensuring that parts fit together correctly, which affects the machine’s operational efficiency. For international buyers, understanding tolerance levels can help in sourcing compatible parts and ensuring that machines meet local standards. -

Power Consumption

This property measures how much electricity the vending machine uses during operation. High power consumption can lead to increased operational costs and may influence the choice of machine based on local energy prices. Buyers should consider energy-efficient models that align with sustainability goals and offer lower long-term operating costs. -

User Interface Design

The user interface (UI) encompasses the controls and displays that customers interact with. A well-designed UI enhances user experience, potentially increasing sales. B2B buyers should evaluate UI accessibility and language options, especially in diverse markets in Africa, South America, and the Middle East, ensuring it meets the needs of local consumers. -

Connectivity Options

This refers to how the vending machine connects to payment systems, inventory management, and user data analytics. Machines with advanced connectivity options, such as Wi-Fi or mobile payment capabilities, can offer better customer engagement and inventory tracking. Buyers should assess connectivity features to maximize operational efficiency and customer satisfaction. -

Safety Standards

Compliance with local and international safety standards is essential for vending machine operation. This includes electrical safety, fire safety, and user safety regulations. Buyers must ensure that the machines they purchase meet these standards to avoid legal issues and ensure consumer trust.

Common Trade Terminology

Familiarity with industry terminology is vital for B2B buyers to navigate procurement processes efficiently. Here are some key terms to know:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of vending machines, sourcing from reputable OEMs can ensure high-quality components and reliable performance. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers to manage inventory costs effectively. It can also influence negotiation strategies when placing orders with manufacturers. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price proposals for specific products or services. B2B buyers should use RFQs to compare pricing, identify potential suppliers, and negotiate better deals. -

Incoterms (International Commercial Terms)

These are a series of pre-defined commercial terms published by the International Chamber of Commerce. They clarify the responsibilities of buyers and sellers, particularly regarding shipping and delivery. Understanding Incoterms can help buyers avoid disputes and ensure smooth logistics. -

Lead Time

Lead time refers to the time taken from placing an order to the delivery of goods. It is crucial for inventory management and planning. Buyers should inquire about lead times to align their procurement strategies with business needs. -

Warranty

A warranty is a guarantee provided by the manufacturer regarding the condition of the product and the support offered. Understanding warranty terms can help buyers assess the risk associated with their investments and ensure they have recourse in case of defects.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, negotiate effectively, and ultimately enhance their procurement strategies in the vending machine market.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the gravity falls vending machine code Sector

Market Overview & Key Trends

The global market for gravity falls vending machine code is witnessing significant growth, driven by the increasing demand for interactive and engaging vending solutions. B2B buyers from regions such as Africa, South America, the Middle East, and Europe are particularly keen on sourcing advanced vending technologies that enhance customer experience and streamline operations. Notably, the integration of IoT technology into vending machines is a prominent trend, allowing for real-time inventory tracking and data analytics, which can lead to optimized supply chain management.

Moreover, the rise of cashless payment systems is transforming the vending landscape. Buyers should consider machines that support mobile payments and contactless transactions, as these features are becoming increasingly essential for attracting tech-savvy consumers. The shift towards personalization—where machines can offer tailored products based on consumer preferences—is also gaining traction. This trend opens up new opportunities for international buyers to differentiate their offerings and cater to local tastes.

Finally, as markets evolve, buyers must remain vigilant about regulatory changes and trade agreements that may impact sourcing strategies. Understanding the geopolitical landscape can help in making informed decisions that align with both market dynamics and consumer expectations.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer optional for B2B buyers in the gravity falls vending machine code sector; it is a critical factor influencing purchasing decisions and brand reputation. The environmental impact of vending operations can be significant, with energy consumption and waste generation being key concerns. Buyers should prioritize sourcing machines that utilize energy-efficient technologies and components made from recyclable materials.

Ethical sourcing practices are equally important, as they not only ensure compliance with international standards but also promote corporate responsibility. Buyers should seek suppliers that demonstrate a commitment to ethical labor practices and transparent supply chains. Certifications such as ISO 14001 (Environmental Management) and Fair Trade can serve as indicators of a supplier’s dedication to sustainability.

Investing in “green” vending machines—those that minimize environmental impact through design and operation—can also enhance brand loyalty among consumers who prioritize sustainability. As international buyers navigate their sourcing strategies, incorporating sustainability and ethical considerations can lead to long-term benefits, including reduced costs and improved market positioning.

Brief Evolution/History

The gravity falls vending machine code sector has evolved significantly since its inception, paralleling advancements in technology and consumer behavior. Initially, vending machines were simple mechanical devices offering limited products. However, the introduction of electronic components in the late 20th century marked a turning point, allowing for more complex operations and user interactions.

In recent years, the convergence of digital technology and vending solutions has transformed the industry. The emergence of smart vending machines equipped with touch screens, internet connectivity, and mobile payment options reflects a broader trend towards automation and personalization. This evolution presents an array of opportunities for B2B buyers looking to invest in innovative solutions that cater to an increasingly discerning consumer base. As the sector continues to grow, understanding its historical context can provide valuable insights for strategic sourcing and market positioning.

Related Video: India-USA Interim Trade Deal | Foxconn asks Chinese staff to leave India | 2025 BRICS Summit

Frequently Asked Questions (FAQs) for B2B Buyers of gravity falls vending machine code

-

How do I vet suppliers for gravity falls vending machine code?

When sourcing gravity falls vending machine code, it is crucial to thoroughly vet suppliers to ensure quality and reliability. Start by checking the supplier’s business credentials, including registration and incorporation status. Request references and case studies from previous clients, especially those in your region. Utilizing platforms like Alibaba or Global Sources can help you access supplier ratings and reviews. Additionally, consider visiting the supplier’s facility if possible or arranging for a third-party audit to assess their manufacturing capabilities and quality control processes. -

Can the gravity falls vending machine code be customized to suit my specific needs?

Yes, many suppliers offer customization options for gravity falls vending machine code. Discuss your requirements in detail with potential suppliers to understand their capabilities. This may include adjustments to functionalities, user interfaces, or compatibility with particular vending machines. Ensure the supplier has a clear process for customization, including timelines and additional costs. Request samples or prototypes to evaluate if the modifications meet your expectations before finalizing any agreements. -

What are the typical minimum order quantities (MOQ) and lead times for gravity falls vending machine code?

Minimum order quantities can vary significantly among suppliers, but it’s common to see MOQs ranging from 50 to 200 units, depending on the complexity of the code and the supplier’s production capacity. Lead times typically range from 4 to 12 weeks, influenced by the customization required and the supplier’s current workload. To optimize your supply chain, negotiate terms that align with your business needs and ensure that the supplier can meet your required timelines without compromising quality. -

What payment methods are available, and what terms should I expect?

When dealing with international suppliers for gravity falls vending machine code, payment methods can include wire transfers, letters of credit, and payment platforms like PayPal. Typically, suppliers may require a deposit (often 30-50%) upfront, with the balance due upon delivery or prior to shipment. It’s essential to clarify payment terms in your contract to avoid disputes later on. Consider using escrow services for larger transactions to protect your investment until the goods meet your expectations. -

What quality assurance measures should I look for in suppliers?

Quality assurance (QA) is critical when sourcing gravity falls vending machine code. Look for suppliers who adhere to international standards such as ISO 9001 or equivalent certifications. Ask about their QA processes, including testing of the code before shipment and post-installation support. Request documentation that outlines their QA procedures and any third-party testing results. Establishing clear quality benchmarks in your contract can help mitigate risks related to product performance. -

How can logistics and shipping impact my sourcing strategy?

Logistics and shipping are vital components of any B2B sourcing strategy, especially for international buyers. Evaluate potential suppliers based on their shipping capabilities, including methods, costs, and delivery times. Consider the total landed cost, which encompasses shipping, customs duties, and taxes. Familiarize yourself with import regulations in your country to avoid delays. Partnering with a logistics provider who understands international trade can streamline the process and reduce potential complications. -

What should I do if there is a dispute with a supplier?

Disputes can arise for various reasons, such as quality issues or delays in delivery. The first step is to communicate directly with the supplier to address your concerns. Maintain a professional demeanor and document all correspondence. If the issue remains unresolved, refer to your contract for dispute resolution procedures, which may include mediation or arbitration. Engaging a legal advisor familiar with international trade laws can provide guidance on your rights and options for resolution. -

Are there specific certifications I should request from suppliers?

Yes, when sourcing gravity falls vending machine code, certain certifications can provide assurance of quality and compliance. Request certifications such as ISO, CE marking for European markets, or other relevant industry standards. These documents demonstrate that the supplier adheres to recognized quality management systems and regulatory requirements. Additionally, inquire about software security certifications to ensure that the vending machine code is safe from breaches, which is essential for protecting consumer data and maintaining trust.

Strategic Sourcing Conclusion and Outlook for gravity falls vending machine code

In conclusion, the strategic sourcing of gravity falls vending machine codes offers international B2B buyers a unique opportunity to enhance their operational efficiency and profitability. By leveraging these codes, businesses can streamline their inventory management, optimize product selection, and elevate customer engagement through targeted marketing strategies.

Illustrative Image (Source: Google Search)

Key Takeaways:

– Cost Efficiency: Implementing strategic sourcing can significantly reduce overhead costs, allowing for better pricing models.

– Market Adaptability: Understanding local consumer preferences in regions like Africa, South America, the Middle East, and Europe can lead to more tailored offerings and improved sales.

– Technology Integration: Embracing technology in sourcing processes facilitates real-time data analysis, enhancing decision-making and operational agility.

As we move forward, businesses are encouraged to adopt a proactive approach to sourcing by collaborating with trusted suppliers and investing in data-driven strategies. The evolving landscape of vending solutions presents an exciting horizon for growth. International B2B buyers should seize this moment to explore partnerships and innovations that position them ahead of the competition. Embrace the future of vending—unlock the potential today!