Master Sourcing Can Vending Machines: Essential Insights

Guide to Can Vending Machine

- Introduction: Navigating the Global Market for can vending machine

- Understanding can vending machine Types and Variations

- Key Industrial Applications of can vending machine

- Strategic Material Selection Guide for can vending machine

- In-depth Look: Manufacturing Processes and Quality Assurance for can vending machine

- Comprehensive Cost and Pricing Analysis for can vending machine Sourcing

- Spotlight on Potential can vending machine Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for can vending machine

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the can vending machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of can vending machine

- Strategic Sourcing Conclusion and Outlook for can vending machine

Introduction: Navigating the Global Market for can vending machine

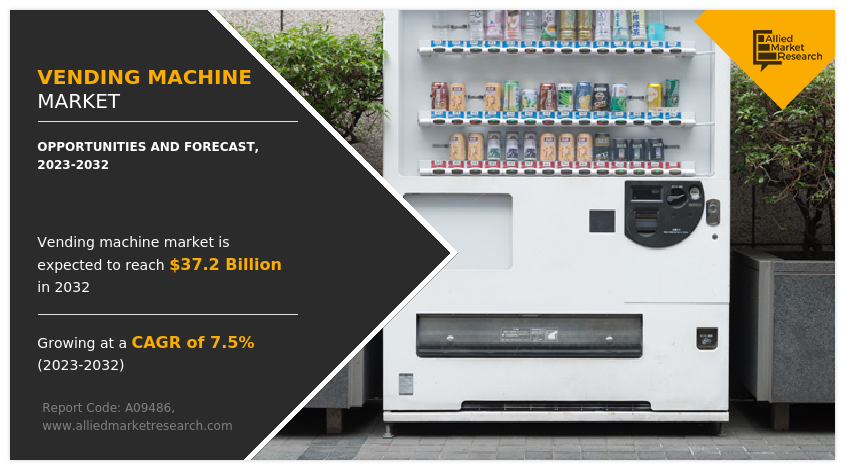

In the evolving landscape of global commerce, can vending machines have emerged as a crucial asset for businesses aiming to enhance customer engagement and streamline operations. These machines not only cater to the growing demand for convenience but also offer a cost-effective solution for retailers and service providers across various sectors. As B2B buyers from diverse regions, including Africa, South America, the Middle East, and Europe, seek innovative ways to optimize their offerings, understanding the intricacies of can vending machines becomes essential.

Illustrative Image (Source: Google Search)

This guide serves as a comprehensive resource, meticulously designed to empower international buyers with the knowledge needed to make informed sourcing decisions. It delves into the various types of can vending machines available in the market, their construction materials, and the manufacturing processes that ensure quality and reliability. Additionally, it provides insights into reputable suppliers, pricing structures, and market dynamics that influence purchasing strategies.

By exploring frequently asked questions and addressing common concerns, this guide aims to equip buyers with actionable insights that transcend geographical barriers. Whether you are operating in Colombia or Turkey, the information contained herein will help you navigate the complexities of sourcing can vending machines, enabling you to enhance your business operations while meeting the evolving needs of your customers. Embrace the potential of this versatile solution and unlock new avenues for growth in your market.

Understanding can vending machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Can Vending | Mechanical design, accepts standard can sizes | Offices, schools, public spaces | Pros: Low maintenance, cost-effective; Cons: Limited to specific can sizes. |

| Smart Can Vending | Digital interface, cashless payment capabilities | Retail, events, high-traffic areas | Pros: Enhanced user experience, real-time inventory tracking; Cons: Higher initial investment. |

| Refrigerated Can Vending | Temperature control for cold beverages | Convenience stores, gyms, cafes | Pros: Attracts customers seeking cold drinks; Cons: Higher energy costs and maintenance. |

| Multi-Product Can Vending | Allows for various products beyond cans | Airports, malls, vending hubs | Pros: Increased revenue potential; Cons: More complex inventory management. |

| Customizable Can Vending | Tailored design and product selection options | Corporate branding, specialized markets | Pros: Unique market positioning; Cons: Longer lead times and higher costs. |

Traditional Can Vending

Traditional can vending machines are characterized by their mechanical design, which typically accepts standard can sizes. They are widely used in environments like offices, schools, and public spaces due to their simplicity and reliability. When considering purchasing, B2B buyers should evaluate the operational costs and maintenance needs, as these machines are generally low-maintenance but limited in product variety.

Smart Can Vending

Smart can vending machines integrate digital interfaces and cashless payment systems, catering to modern consumer preferences. They are ideal for retail environments, events, and high-traffic areas where user experience and convenience are paramount. Buyers should consider the higher initial investment against the potential for increased sales and enhanced customer engagement through features like real-time inventory tracking.

Refrigerated Can Vending

Refrigerated can vending machines are designed to maintain the temperature of beverages, making them particularly suitable for convenience stores, gyms, and cafes. The ability to offer cold drinks can significantly boost sales, especially in warmer climates. However, buyers must account for higher energy costs and maintenance requirements, which can impact long-term profitability.

Multi-Product Can Vending

These machines allow for a variety of products beyond just canned beverages, making them versatile for locations such as airports, malls, and vending hubs. Their ability to offer multiple product types can increase revenue potential. However, B2B buyers should be aware that this complexity requires more sophisticated inventory management systems to ensure product availability and minimize waste.

Customizable Can Vending

Customizable can vending machines offer tailored designs and product selections, making them suitable for corporate branding and specialized markets. This flexibility allows businesses to differentiate themselves in competitive environments. However, potential buyers should consider longer lead times and higher costs associated with customization, as well as the need for ongoing market analysis to ensure product relevance.

Related Video: Machine Learning in 2024 – Beginner’s Course

Key Industrial Applications of can vending machine

| Industry/Sector | Specific Application of can vending machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Automated beverage sales | Increased sales volume, reduced labor costs | Machine capacity, payment options, and product variety |

| Hospitality | On-demand refreshments in hotels | Enhanced guest experience, improved service speed | Durability, energy efficiency, and aesthetic design |

| Corporate Offices | Breakroom beverage dispensing | Employee satisfaction, reduced waste | Size, user interface, and maintenance requirements |

| Public Spaces | Beverage access in parks and transit areas | Increased accessibility, convenience for users | Weather resistance, security features, and refill frequency |

| Educational Institutions | Campus beverage sales | Student convenience, revenue generation | Payment integration, machine size, and product selection |

Retail

In the retail sector, can vending machines are revolutionizing the way beverages are sold. These machines can be strategically placed in high-traffic areas to maximize visibility and sales. By automating beverage sales, retailers can significantly reduce labor costs while increasing sales volume. International B2B buyers should consider machine capacity and the variety of products offered, as well as payment options that cater to diverse customer preferences, particularly in regions with varying technological adoption.

Hospitality

In hotels and resorts, can vending machines offer guests the convenience of on-demand refreshments without the need for staff intervention. This not only enhances the guest experience but also speeds up service delivery, allowing staff to focus on more personalized services. When sourcing these machines, buyers in the hospitality industry should prioritize durability and energy efficiency to ensure they withstand heavy usage and align with sustainability goals, while also considering aesthetic design to match the hotel’s overall ambiance.

Corporate Offices

Corporate environments are increasingly adopting can vending machines in breakrooms to provide employees with quick access to beverages. This not only boosts employee satisfaction by offering convenience but also helps reduce waste by promoting the use of recyclable cans. For B2B buyers in corporate settings, important considerations include the machine’s size to fit available space, user-friendly interfaces for ease of use, and low maintenance requirements to ensure consistent operation.

Public Spaces

Can vending machines are vital in public spaces such as parks and transit areas, providing easy access to beverages for users on the go. They enhance the convenience of public amenities, encouraging hydration and refreshment in outdoor settings. Buyers in this sector should focus on sourcing machines that are weather-resistant and equipped with secure features to prevent vandalism, as well as those that can handle high traffic with sufficient refill frequency.

Educational Institutions

In educational settings, can vending machines serve as a valuable resource for students, offering quick access to beverages between classes. This not only adds to campus convenience but can also generate additional revenue for the institution. When sourcing machines for schools and universities, B2B buyers should consider payment integration options that accommodate various payment methods, the size of the machines to fit designated spaces, and a diverse product selection to cater to student preferences and dietary requirements.

Related Video: How to Start a Vending Machine Business, Cost, Tips, How Much You Make

Strategic Material Selection Guide for can vending machine

When selecting materials for can vending machines, it is crucial to consider various factors such as durability, cost, and compatibility with the intended application. Below is an analysis of four common materials used in the construction of can vending machines, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand a wide range of temperatures. It typically has a temperature rating of up to 800°F (427°C) and can handle moderate pressure levels, making it suitable for environments where hygiene and durability are paramount.

Pros & Cons:

The main advantage of stainless steel is its longevity and low maintenance requirements, which can lead to reduced lifecycle costs. However, it is generally more expensive than other materials, and its manufacturing can be complex due to the need for specialized welding techniques.

Impact on Application:

Stainless steel is compatible with various media, including beverages and cleaning agents, making it ideal for vending machines. Its non-reactive nature ensures that it does not alter the taste or quality of the products dispensed.

Considerations for International Buyers:

Compliance with food safety standards like FDA or EU regulations is essential. Buyers should also ensure that the stainless steel grade meets local standards, such as ASTM in the U.S. or EN in Europe.

Aluminum

Key Properties:

Aluminum is lightweight, offers good corrosion resistance, and has a temperature rating up to 600°F (316°C). It is also known for its excellent thermal conductivity, which can be beneficial in temperature-sensitive applications.

Pros & Cons:

The primary advantage of aluminum is its low weight, which can reduce shipping costs and ease installation. However, it is less durable than stainless steel and can be prone to scratching and denting, which may affect aesthetics and functionality over time.

Impact on Application:

Aluminum is suitable for non-corrosive environments and is often used in vending machines for snacks and beverages. However, it may not be ideal for high-pressure applications.

Considerations for International Buyers:

Buyers should be aware of the varying standards for aluminum alloys in different regions. Compliance with local regulations, such as those set by ASTM or ISO, is also necessary.

Carbon Steel

Key Properties:

Carbon steel is known for its high strength and durability, with a temperature rating of around 500°F (260°C) depending on the grade. However, it has limited corrosion resistance unless treated or coated.

Pros & Cons:

Carbon steel is often more cost-effective than stainless steel and aluminum, making it a popular choice for budget-conscious projects. However, its susceptibility to rust and corrosion can lead to higher maintenance costs over time.

Impact on Application:

Carbon steel is suitable for structural components of vending machines but may not be ideal for parts that come into direct contact with beverages, unless adequately coated.

Considerations for International Buyers:

Buyers should ensure that the carbon steel used complies with local standards like DIN or JIS. Additionally, protective coatings may be required to meet corrosion resistance standards.

Plastic Composites

Key Properties:

Plastic composites are lightweight, resistant to corrosion, and can be molded into various shapes. They typically have a temperature rating of up to 200°F (93°C), making them suitable for low-temperature applications.

Pros & Cons:

The main advantage of plastic composites is their versatility and lower cost compared to metals. However, they may not offer the same level of strength and durability, especially in high-stress applications.

Impact on Application:

Plastic composites are often used in non-structural components of vending machines, such as panels and dispensers. They are particularly effective in environments where moisture is a concern.

Considerations for International Buyers:

Buyers should verify that the plastic materials meet relevant safety and environmental regulations in their region, such as REACH in Europe or similar standards elsewhere.

Summary Table

| Material | Typical Use Case for can vending machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural components and exterior panels | Excellent durability and corrosion resistance | Higher cost and complex manufacturing | High |

| Aluminum | Lightweight frames and internal components | Low weight and good thermal conductivity | Less durable, prone to scratches | Medium |

| Carbon Steel | Structural components, base frames | Cost-effective and strong | Susceptible to corrosion | Low |

| Plastic Composites | Non-structural panels and dispensers | Versatile and low cost | Lower strength and durability | Low |

This guide provides a strategic overview of material selection for can vending machines, enabling international B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for can vending machine

Understanding the Manufacturing Processes of Can Vending Machines

The manufacturing of can vending machines is a complex and multi-stage process, involving various techniques and technologies. For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding this process is crucial for making informed purchasing decisions. Below, we outline the main stages of manufacturing, key techniques used, and the importance of quality assurance.

Main Stages of Manufacturing

-

Material Preparation

– Sourcing Raw Materials: The process begins with sourcing high-quality materials such as steel, aluminum, and plastic. Buyers should ensure that suppliers are using materials compliant with international standards to ensure durability and safety.

– Material Treatment: This may include processes like cutting, bending, and coating to prepare materials for forming. Proper treatment is essential to enhance resistance to corrosion and wear. -

Forming

– Metal Forming Techniques: Techniques such as stamping, welding, and laser cutting are commonly used. Stamping is often used to create the structural components of the vending machine, while welding ensures the parts are securely joined.

– Plastic Injection Molding: For components such as buttons and coin mechanisms, injection molding is typically employed. This technique allows for precision and consistency in component manufacturing. -

Assembly

– Component Assembly: After forming, the various components are assembled. This stage may involve mechanical assembly as well as the integration of electronic systems for payment processing and inventory management.

– Testing During Assembly: Quality checkpoints during assembly (In-Process Quality Control, or IPQC) help catch defects early. This can prevent costly rework and ensure that the final product meets specifications. -

Finishing

– Surface Treatments: Finishing processes such as painting, powder coating, or anodizing are applied to enhance aesthetics and protect against environmental factors.

– Final Assembly and Inspection: The last step involves a comprehensive inspection of the fully assembled machine to ensure all parts function correctly and meet quality standards.

Quality Assurance in Manufacturing

Quality assurance (QA) is critical in the manufacturing of can vending machines. It ensures that the machines are reliable, safe, and meet customer expectations.

Relevant International Standards

- ISO 9001: This standard outlines the requirements for a quality management system (QMS) and is essential for manufacturers aiming to ensure consistent quality.

- CE Marking: In Europe, CE marking indicates that a product meets EU safety, health, and environmental protection requirements.

- API Standards: For certain components, especially those related to the payment system, adherence to American Petroleum Institute (API) standards may be necessary.

Quality Control Checkpoints

-

Incoming Quality Control (IQC):

– This initial stage involves inspecting raw materials and components upon delivery to ensure they meet specified standards. -

In-Process Quality Control (IPQC):

– Continuous monitoring during the manufacturing process to catch defects early. This may include functional checks and measurements at various assembly stages. -

Final Quality Control (FQC):

– A thorough inspection of the final product before shipment, ensuring that all specifications and functions are met. This may involve testing the vending machine’s operational efficiency, security features, and user interface.

Common Testing Methods

- Functional Testing: Ensures all components work as intended, including coin mechanisms, dispensing systems, and electronic interfaces.

- Durability Testing: Simulates real-world usage to assess the machine’s resilience against wear and tear.

- Safety Testing: Confirms compliance with electrical safety standards and assesses any potential hazards.

Verifying Supplier Quality Control

For B2B buyers, especially those from diverse regions, verifying the supplier’s quality control processes is paramount. Here are actionable steps:

-

Conduct Audits:

– Regular audits of suppliers can reveal their adherence to quality standards and help identify any potential risks in the manufacturing process. -

Request Quality Reports:

– Suppliers should provide documentation demonstrating their quality control processes and results from recent inspections. This transparency is crucial for building trust. -

Engage Third-party Inspectors:

– Hiring third-party inspection services can provide an unbiased assessment of the manufacturing processes and product quality. This is particularly beneficial for buyers in regions where they may not have direct access to suppliers.

Quality Control and Certification Nuances for International Buyers

When sourcing can vending machines from international suppliers, understanding the nuances of quality control and certification is vital:

-

Regional Standards Compliance: Different regions may have specific certifications or requirements. For example, African and Middle Eastern markets may prioritize different safety standards compared to European markets. Always verify that the supplier is compliant with the relevant standards for your specific market.

-

Language and Communication: Ensure all quality documentation is available in a language you understand. Miscommunication can lead to misunderstandings about quality expectations.

-

Cultural Considerations: Be aware of cultural differences in business practices that may affect quality assurance processes. Building a strong relationship with suppliers can facilitate better communication regarding quality expectations.

By understanding the manufacturing processes and quality assurance practices of can vending machines, B2B buyers can make informed decisions, ensuring they invest in reliable, high-quality products that meet their specific needs.

Related Video: SMART Quality Control for Manufacturing

Comprehensive Cost and Pricing Analysis for can vending machine Sourcing

When considering the sourcing of can vending machines, understanding the comprehensive cost structure and pricing dynamics is essential for international B2B buyers. This section delves into the critical cost components involved in the manufacturing and procurement process, price influencers that can affect the overall expenditure, and practical tips for negotiation and cost efficiency.

Cost Components

-

Materials: The primary materials used in can vending machines include steel, plastics, and electronic components. Prices for these materials can fluctuate based on global supply and demand, impacting the overall cost. Buyers should consider sourcing materials locally where possible to mitigate transport costs.

-

Labor: Labor costs vary significantly across regions. For buyers in Africa and South America, labor may be less expensive compared to Europe or the Middle East. Understanding local labor laws and wage standards can influence sourcing decisions, especially if considering assembly or manufacturing in different regions.

-

Manufacturing Overhead: This encompasses utilities, rent, and indirect labor costs associated with the production process. Efficient manufacturing practices can help reduce these overheads, which is critical for maintaining competitive pricing.

-

Tooling: Initial tooling costs can be substantial, particularly for custom designs. Buyers should evaluate whether standard models meet their needs to avoid excessive tooling charges.

-

Quality Control (QC): Implementing rigorous QC processes is essential to ensure the reliability of the machines. While this adds to upfront costs, it can significantly reduce long-term maintenance expenses and enhance customer satisfaction.

Illustrative Image (Source: Google Search)

-

Logistics: Transportation costs, including shipping and customs duties, play a crucial role in the total cost. Buyers should consider proximity to suppliers and shipping routes to optimize logistics expenses.

-

Margin: Supplier margins can vary widely. Understanding the expected profit margins of suppliers can aid in negotiations and help buyers identify the best value for their investment.

Price Influencers

Several factors can influence the final price of can vending machines:

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly affect pricing. Bulk orders often lead to discounts, so buyers should assess their demand forecast to negotiate better terms.

-

Specifications/Customization: Custom features or specifications can increase costs. Buyers should balance the need for customization with the benefits of standard models to find a price point that fits their budget.

-

Materials: The choice of materials directly impacts both the quality and price. Higher-quality materials may cost more initially but can lead to lower maintenance and replacement expenses over time.

-

Quality and Certifications: Compliance with international standards can add to costs. However, machines that meet higher quality standards often yield better reliability and customer satisfaction.

-

Supplier Factors: Supplier reputation, reliability, and geographic location can affect pricing. Building relationships with reputable suppliers can lead to better pricing structures and flexibility.

-

Incoterms: Understanding shipping terms (Incoterms) is vital for cost calculations. They define the responsibilities of buyers and sellers in international trade, impacting total landed costs.

Buyer Tips

-

Negotiation: Buyers should engage in thorough negotiations, leveraging volume commitments or long-term contracts to secure favorable pricing.

-

Cost-Efficiency: Evaluating the Total Cost of Ownership (TCO) is crucial. This includes not only the purchase price but also operational costs, maintenance, and depreciation.

-

Pricing Nuances: International buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of currency fluctuations and their impact on pricing. It is advisable to negotiate in stable currencies or consider hedging options to minimize risk.

-

Local Regulations: Understanding local import duties and taxes can help buyers anticipate additional costs that may not be reflected in the initial price.

Disclaimer

Prices and cost structures can vary widely based on numerous factors, including market conditions and supplier negotiations. It is advisable for buyers to conduct their own research and obtain multiple quotes to ensure they are making informed purchasing decisions.

Spotlight on Potential can vending machine Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for can vending machine.)*

Essential Technical Properties and Trade Terminology for can vending machine

Key Technical Properties of Can Vending Machines

When evaluating can vending machines, several technical properties are critical in making informed purchasing decisions. Understanding these specifications can help buyers ensure that the machines meet operational needs and compliance standards.

-

Material Grade

The material grade refers to the quality of materials used in the construction of the vending machine, such as stainless steel or high-grade plastics. This specification is essential for durability, corrosion resistance, and overall reliability. Machines made from higher-grade materials often have longer lifespans, reducing long-term operational costs. -

Capacity

Capacity indicates how many cans a vending machine can hold at one time. This specification is vital for businesses with high customer traffic, as a larger capacity can lead to increased revenues and reduced downtime for restocking. Buyers should assess their expected sales volume to choose a machine that balances capacity and space requirements. -

Power Consumption

This property outlines the energy efficiency of the vending machine, typically measured in watts. For international buyers, especially in regions with varying electricity costs, understanding power consumption can significantly impact operational expenses. Energy-efficient machines not only save money but may also qualify for government rebates or incentives in some countries. -

Dimensions and Weight

The physical dimensions and weight of the vending machine are crucial for space planning and transport logistics. Buyers must ensure that the machine fits within designated areas and that local regulations regarding installation and weight limits are met. Compact designs may be preferable in urban settings where space is limited. -

Temperature Range

This specification refers to the operational temperature range the machine can maintain for beverages. Understanding the temperature range is important, particularly in warmer climates where beverage cooling is essential for consumer satisfaction. Machines with advanced cooling technology may offer better temperature control and energy efficiency.

Common Trade Terminology

Familiarity with industry terminology is crucial for effective communication and negotiation with suppliers. Below are some common terms that B2B buyers should know.

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of can vending machines, buyers may work directly with OEMs for customized solutions or replacement parts, ensuring compatibility and quality. -

MOQ (Minimum Order Quantity)

MOQ defines the smallest number of units a supplier is willing to sell. Understanding MOQ can help buyers manage inventory costs and negotiate better deals. Smaller businesses should consider their cash flow and storage capabilities when evaluating MOQs. -

RFQ (Request for Quotation)

An RFQ is a formalized process where buyers request pricing and terms from suppliers for specific products or services. This process is essential for ensuring competitive pricing and understanding the full scope of costs involved, including shipping and handling. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities and risks of buyers and sellers in international transactions. Familiarity with these terms can help buyers understand who is responsible for shipping costs, insurance, and customs duties, thereby avoiding unexpected expenses. -

Lead Time

Lead time refers to the amount of time from placing an order to receiving the goods. Understanding lead times is important for inventory management and planning, especially for businesses in regions with longer shipping durations. Buyers should factor in lead times when planning for product launches or seasonal demand spikes.

By grasping these essential technical properties and trade terminologies, international B2B buyers can make more informed decisions when sourcing can vending machines, ensuring they meet both operational requirements and financial constraints.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the can vending machine Sector

Market Overview & Key Trends

The global can vending machine market is experiencing a notable transformation driven by technological advancements, changing consumer behaviors, and the ongoing shift towards automation. As urbanization continues to rise, particularly in regions such as Africa and South America, the demand for convenient and accessible beverage options is surging. This trend is fostering the growth of innovative vending solutions that offer not only traditional products but also healthier and locally sourced alternatives.

Emerging technologies are reshaping the vending machine landscape. Contactless payment systems, integrated mobile apps, and IoT connectivity are becoming standard features, enhancing user experience and operational efficiency. For international B2B buyers, particularly in regions like Turkey and Colombia, investing in machines equipped with these technologies can provide a competitive edge in capturing the evolving consumer market.

Moreover, sustainability is becoming a crucial factor in purchasing decisions. Buyers are increasingly looking for vending machines that minimize waste and support eco-friendly practices. This includes options for recycling, energy-efficient models, and machines that utilize sustainable materials. Keeping abreast of these trends will not only aid in aligning products with consumer expectations but also in establishing a responsible brand image.

Sustainability & Ethical Sourcing in B2B

In the context of can vending machines, sustainability is more than a trend; it’s an imperative. The environmental impact of traditional vending operations often includes excessive energy consumption and waste generation. Buyers should prioritize machines that incorporate energy-efficient technologies and renewable energy sources. This not only reduces carbon footprints but can also lead to significant operational cost savings.

Ethical sourcing is equally vital. B2B buyers should ensure their suppliers adhere to ethical practices throughout the supply chain. This includes the use of certified green materials, such as recycled plastics or sustainably sourced metals, which can enhance a company’s sustainability profile. Certification from recognized bodies can serve as a reliable benchmark for assessing suppliers’ commitments to responsible sourcing.

Investing in sustainable vending solutions can also create new marketing opportunities. Brands that emphasize their commitment to sustainability can differentiate themselves in competitive markets, appealing especially to environmentally conscious consumers in regions like Europe and the Middle East.

Brief Evolution/History

The can vending machine industry has evolved significantly since its inception in the late 19th century. Initially designed for basic snack and beverage dispensing, these machines have now transformed into sophisticated retail platforms equipped with advanced technologies. The introduction of electronic payment systems in the late 20th century marked a turning point, enhancing user convenience and expanding market reach.

In recent years, the focus has shifted towards integrating technology with sustainability, responding to increasing consumer demand for ethical and eco-friendly options. This evolution signifies a dynamic market that is continuously adapting to meet the needs of both consumers and operators, providing a fertile ground for B2B buyers seeking innovative solutions in the vending sector.

Related Video: Is global trade transforming? | Counting the Cost

Frequently Asked Questions (FAQs) for B2B Buyers of can vending machine

-

What criteria should I use to vet suppliers of can vending machines?

When vetting suppliers, prioritize their experience in the vending machine industry, particularly with can vending machines. Request references from previous clients and assess their track record for reliability and service quality. Check for certifications that ensure compliance with international safety and quality standards. It’s also beneficial to evaluate their financial stability and production capacity to meet your demand, as well as their ability to provide ongoing support and maintenance after purchase. -

Can can vending machines be customized to fit my brand?

Yes, many suppliers offer customization options for can vending machines. You can request features such as branding elements like logos and color schemes, as well as functionality tailored to your specific market needs. Customization may include adjusting the machine’s size, payment acceptance methods, or additional features like cashless payment options. Discuss your requirements during the initial negotiations to understand the extent of customization available and any associated costs. -

What is the typical minimum order quantity (MOQ) for can vending machines?

The MOQ for can vending machines can vary significantly by supplier and region. Generally, it ranges from 5 to 50 units, depending on the manufacturer’s production capabilities and your specific customization requests. Be clear about your purchasing needs upfront, and negotiate the MOQ if necessary. Suppliers may offer lower MOQs for first-time buyers or bulk discounts for larger orders, so it’s essential to communicate your intentions and explore options. -

What are the lead times for delivery after placing an order?

Lead times can vary based on several factors, including the supplier’s location, production schedules, and any customization requirements. Typically, standard lead times for can vending machines range from 4 to 12 weeks. To ensure timely delivery, confirm the estimated lead time before finalizing your order. It’s advisable to build in extra time for potential delays, especially if international shipping is involved, and to confirm logistics plans well in advance. -

What quality assurance measures should I expect from suppliers?

Reputable suppliers should provide comprehensive quality assurance (QA) measures, including inspections at various production stages and final product testing. Request documentation of their QA processes, including certifications such as ISO 9001, which indicates adherence to quality management standards. Additionally, inquire about warranties and after-sales support, as these can be indicators of the supplier’s commitment to product quality and customer satisfaction. -

What certifications should I look for when sourcing can vending machines?

When sourcing can vending machines, look for certifications relevant to your market, such as CE marking in Europe or UL certification in North America. These certifications indicate compliance with safety and performance standards. For international purchases, check if the supplier adheres to local regulations in your country or region, especially in terms of electrical safety and environmental impact. Confirm that the machines are tested for reliability and durability to minimize operational risks. -

How should I handle logistics and shipping for international orders?

Logistics and shipping are critical considerations for international orders. Ensure that you have a reliable freight forwarder who understands the complexities of shipping can vending machines, including customs regulations and import duties. Discuss logistics with your supplier, as they may offer shipping solutions or recommendations. Always factor in the total landed cost, including shipping fees, customs duties, and insurance, to avoid unexpected expenses upon delivery. -

What steps can I take to resolve disputes with suppliers?

To mitigate disputes, establish clear terms in your purchase agreement, covering payment terms, delivery timelines, and quality expectations. In case of a disagreement, communicate directly and professionally with the supplier to seek a resolution. If the issue persists, refer to any dispute resolution clauses in your contract, which may include mediation or arbitration. Keeping thorough documentation of all transactions and communications can also support your case if escalation becomes necessary.

Strategic Sourcing Conclusion and Outlook for can vending machine

In the rapidly evolving landscape of can vending machines, strategic sourcing has emerged as a crucial element for international B2B buyers. By prioritizing quality suppliers and leveraging data analytics, companies can ensure a robust supply chain that meets local demands while remaining cost-effective. Key takeaways include the importance of assessing supplier reliability, understanding regional market dynamics, and fostering partnerships that can adapt to changing consumer preferences.

For buyers in Africa, South America, the Middle East, and Europe, recognizing regional trends is vital. For instance, the growing demand for healthier beverage options can influence the types of products offered in vending machines, necessitating collaboration with innovative suppliers. Moreover, sustainability is increasingly becoming a priority; thus, sourcing from eco-friendly manufacturers can enhance brand reputation and appeal to environmentally conscious consumers.

Looking ahead, the market for can vending machines promises significant opportunities for growth. By embracing a strategic sourcing approach, international B2B buyers can position themselves for success in this competitive environment. Now is the time to explore partnerships that can unlock value and drive innovation. Engage with your suppliers today to stay ahead of the curve and capitalize on emerging trends in the vending machine sector.